Multilayer composite coating of zirconium alloy cladding surface, and preparation method thereof

A multi-layer composite and composite coating technology, applied in metal material coating process, coating, ion implantation plating, etc. Good property, high adhesion to film base, and the effect of enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

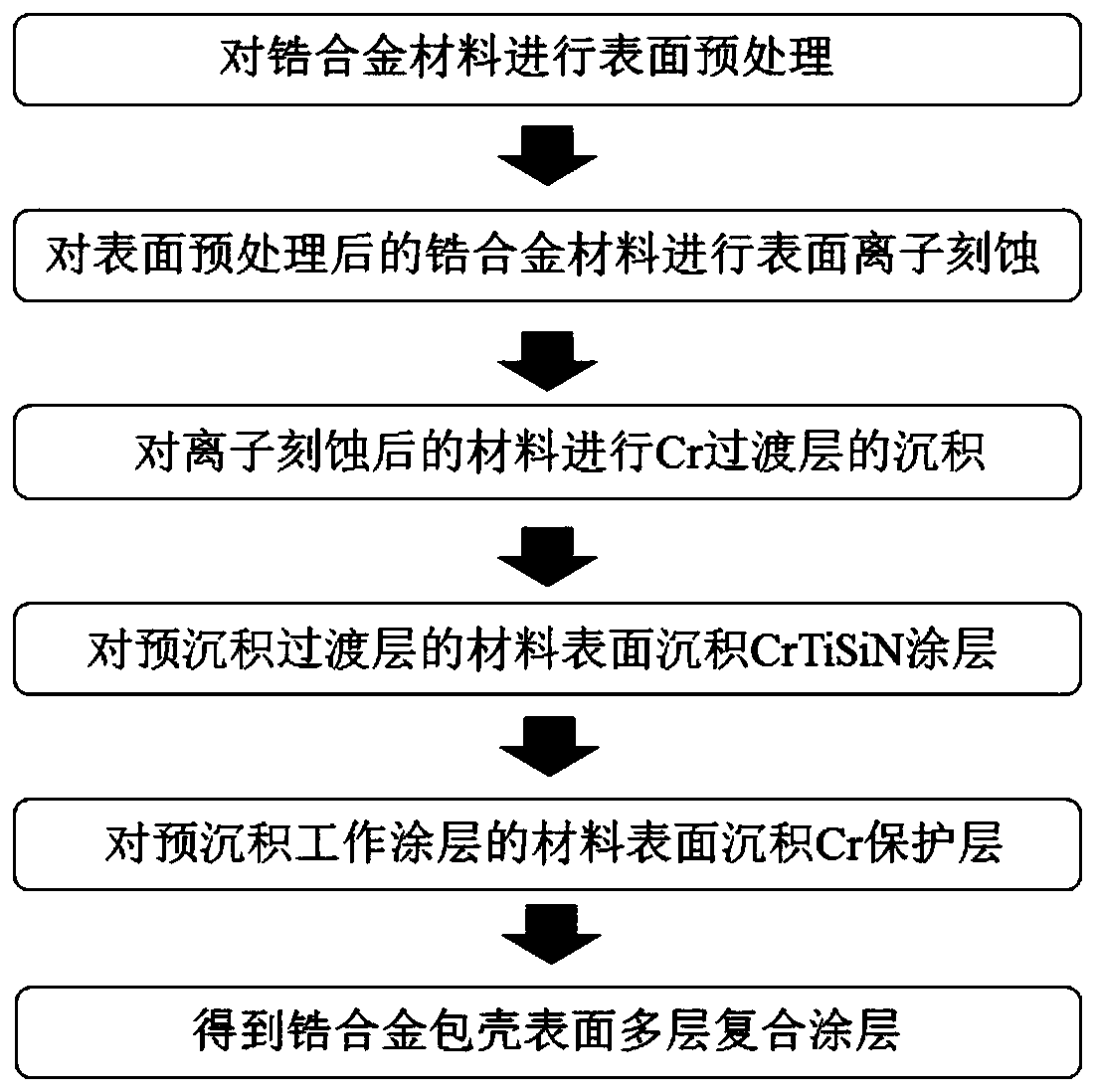

[0041] Utilize multi-arc ion plating technology to deposit metal Cr / CrTiSiN / Cr multilayer composite coating on ZIRLO alloy material surface, the Ar gas that adopts in the embodiment and N 2 The purity of the gas is 99.999vol.%, such as figure 1 As shown, the specific preparation process includes the following steps:

[0042] (1) Surface pretreatment of zirconium alloy materials

[0043] Select the zirconium alloy sample, first use 400#, 800#, 1000#, 2000# and 3000# sandpaper to polish the surface of the workpiece sample, and then polish it with alumina polishing solution with a particle size of 1 μm and silicon dioxide with a particle size of 0.06 μm After polishing, wipe with alcohol and dry to confirm that there are no defects such as cracks, rust, burrs and scratches on the surface of the material. After grinding and polishing, the sample is cleaned. The cleaning solution is a weak alkaline solution prepared by sodium silicate, metal surfactant and industrial deionized wa...

specific Embodiment 1

[0056] The specific process parameters in the step (3) of this embodiment are, the deposition temperature is 400° C., the deposition time is 20 min, the current is 100 A, and the argon gas pressure is 0.3 Pa. The specific process parameters in the step (4) are, the deposition temperature is 400°C, the deposition time is 180min, the current is 100A, the nitrogen gas pressure is 1.5Pa, the specific process parameters in step (5) are, the deposition temperature is 400°C, the deposition time is 20min, the current is 100A, and the argon gas pressure is 0.3Pa , depositing the outer surface of the zirconium alloy substrate to obtain a Cr / CrTiSiN / Cr multilayer composite coating.

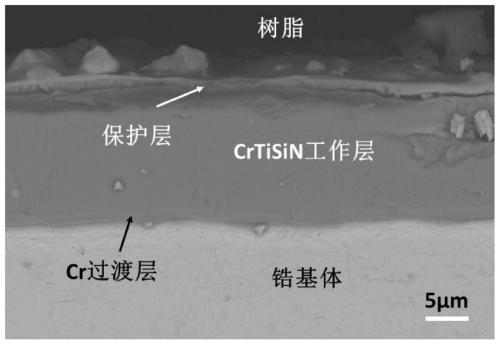

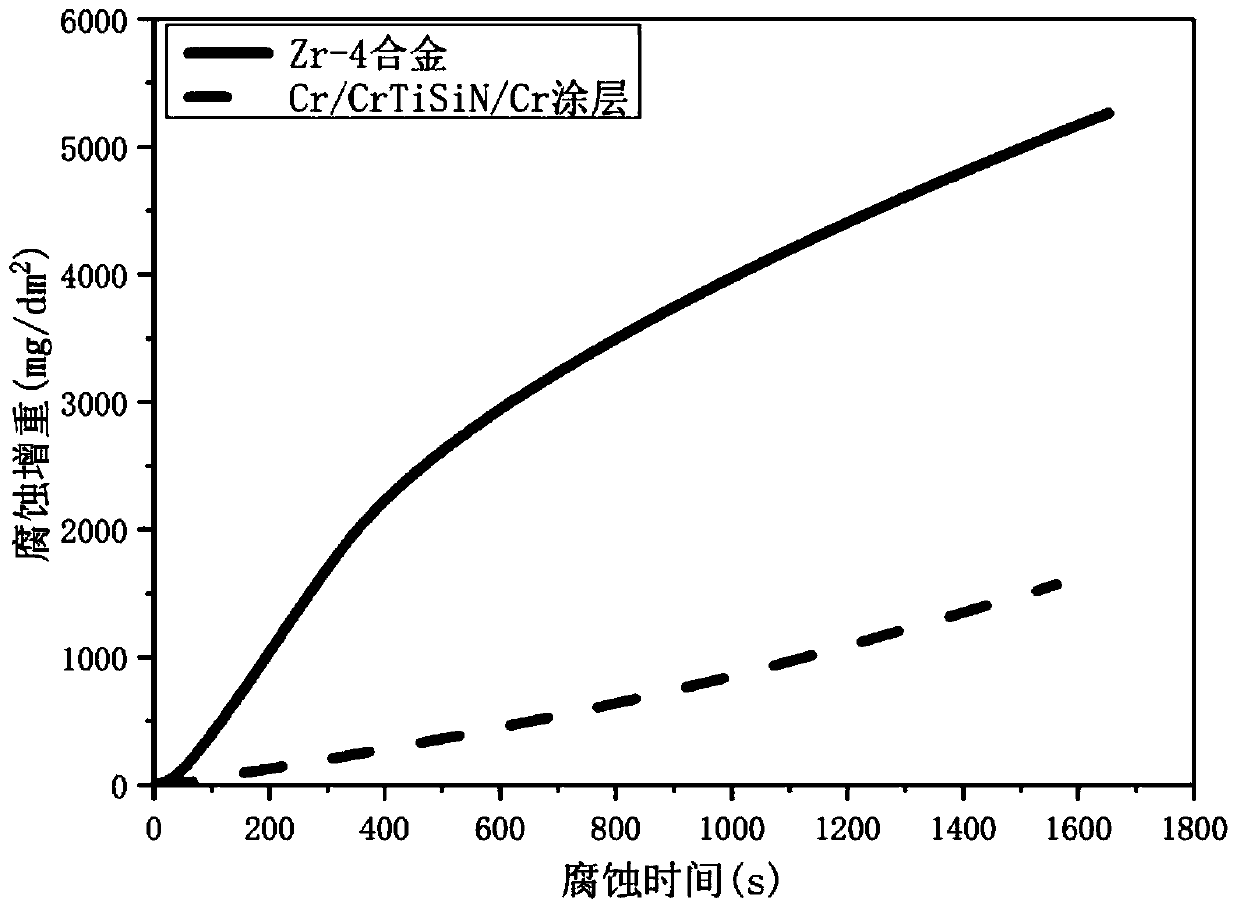

[0057] After testing, the atomic fractions of each element in the CrTiSiN working coating are: Cr42.08%, Ti27.06%, Si3.50%, N27.36%, from figure 2It can be seen from the cross-sectional SEM topography that the coating has a compact structure and no holes. The thicknesses of the Cr transition layer, CrTiSiN ...

specific Embodiment 2

[0059] The specific process parameters in step (3) of this embodiment are, the deposition temperature is 390°C, the deposition time is 18min, the current is 92A, and the argon gas pressure is 0.3Pa. The specific process parameters in step (4) are, the deposition temperature is 400°C, the deposition time is 185min, the current is 100A, the nitrogen gas pressure is 1.8Pa, the specific process parameters in step (5) are, the deposition temperature is 390°C, the deposition time is 18min, the current is 92A, and the argon gas pressure is 0.3Pa , depositing the outer surface of the zirconium alloy substrate to obtain a Cr / CrTiSiN / Cr multilayer composite coating.

[0060] After testing, the atomic fractions of each element in the CrTiSiN working coating are: Cr41.73%, Ti27.68%, Si3.47%, N27.12%, the coating structure is dense, no holes appear, and the Cr transition layer in the coating The thicknesses of the CrTiSiN working coating and the Cr protective layer are 0.86 μm, 13.58 μm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com