Workpiece surface processing method for self-propagating reaction synthetic process

A synthesis process and workpiece surface technology, applied in the field of self-propagating reaction synthesis process, can solve problems such as inability to melt, unreliable fixation of coating, fast response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

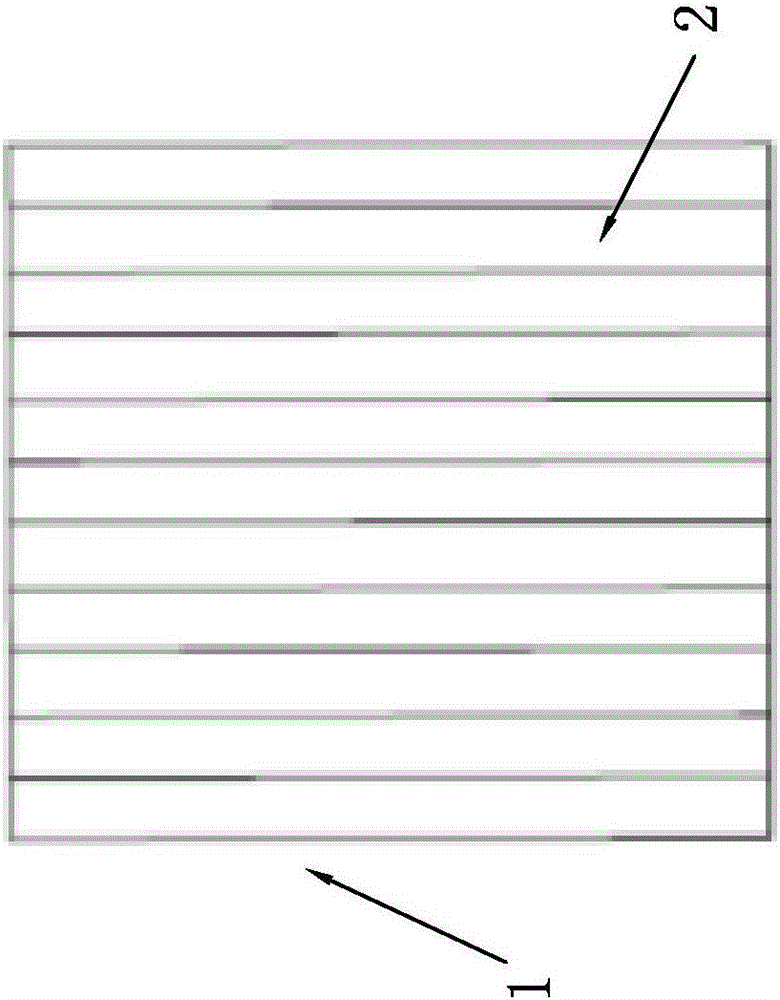

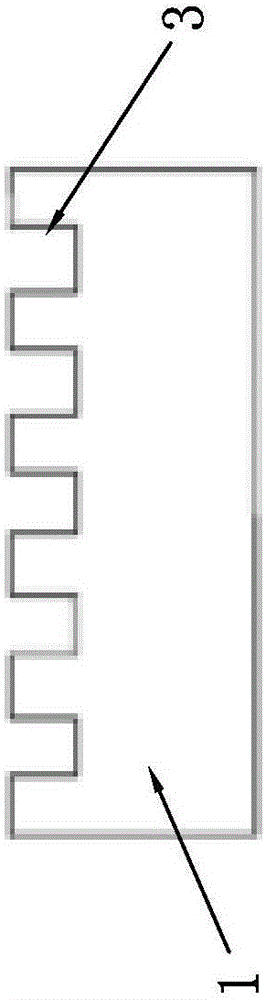

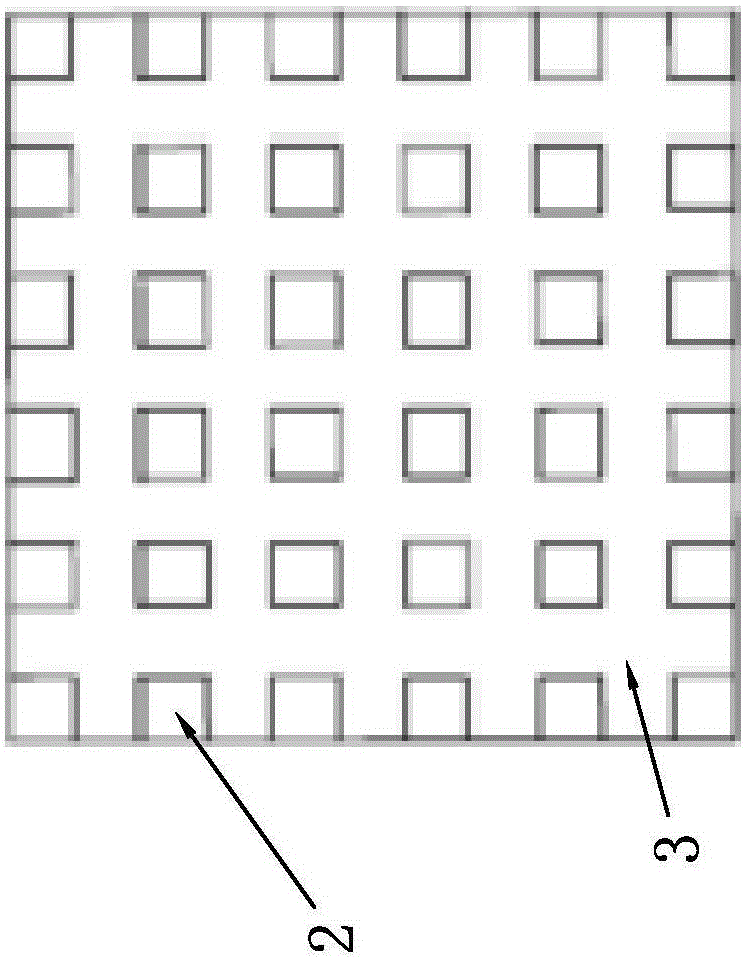

[0028] Such as Figure 1 to Figure 5 shown, see figure 1 with figure 2 , the workpiece surface treatment method of self-propagating reaction synthesis technique of the present invention comprises the steps:

[0029] A. Engraving the surface 2 to be processed of the open-shaped object 1, wherein the engraving method of the surface 2 to be processed is: processing the surface to be processed with at least two grooves 3, preferably a plurality of grooves 3. Groove 3 is straight or curved. Multiple grooves 3 are parallel to each other, or refer to image 3 , Figure 4 with Figure 5 , a plurality of grooves 3 are perpendicular to each other and pass through to form a grid-like groove 3 . The cross-sectional shape of the groove 3 is rectangular, U-shaped, trapezoidal, V-shaped, reverse T-shaped, trapezoidal or dovetail-shaped.

[0030] The workpiece surface treatment method of the self-propagating reaction synthesis process of the present invention can increase the contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com