Manufacturing process of ceramic accessory tile and ceramic accessory tile manufactured by the process

A manufacturing process and ceramic tile technology, which is applied in the field of building ceramic tile production, can solve problems such as inconsistent materials and difficulties in matching organization, and achieve the effects of improving the bonding of coatings, saving electroplating materials, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

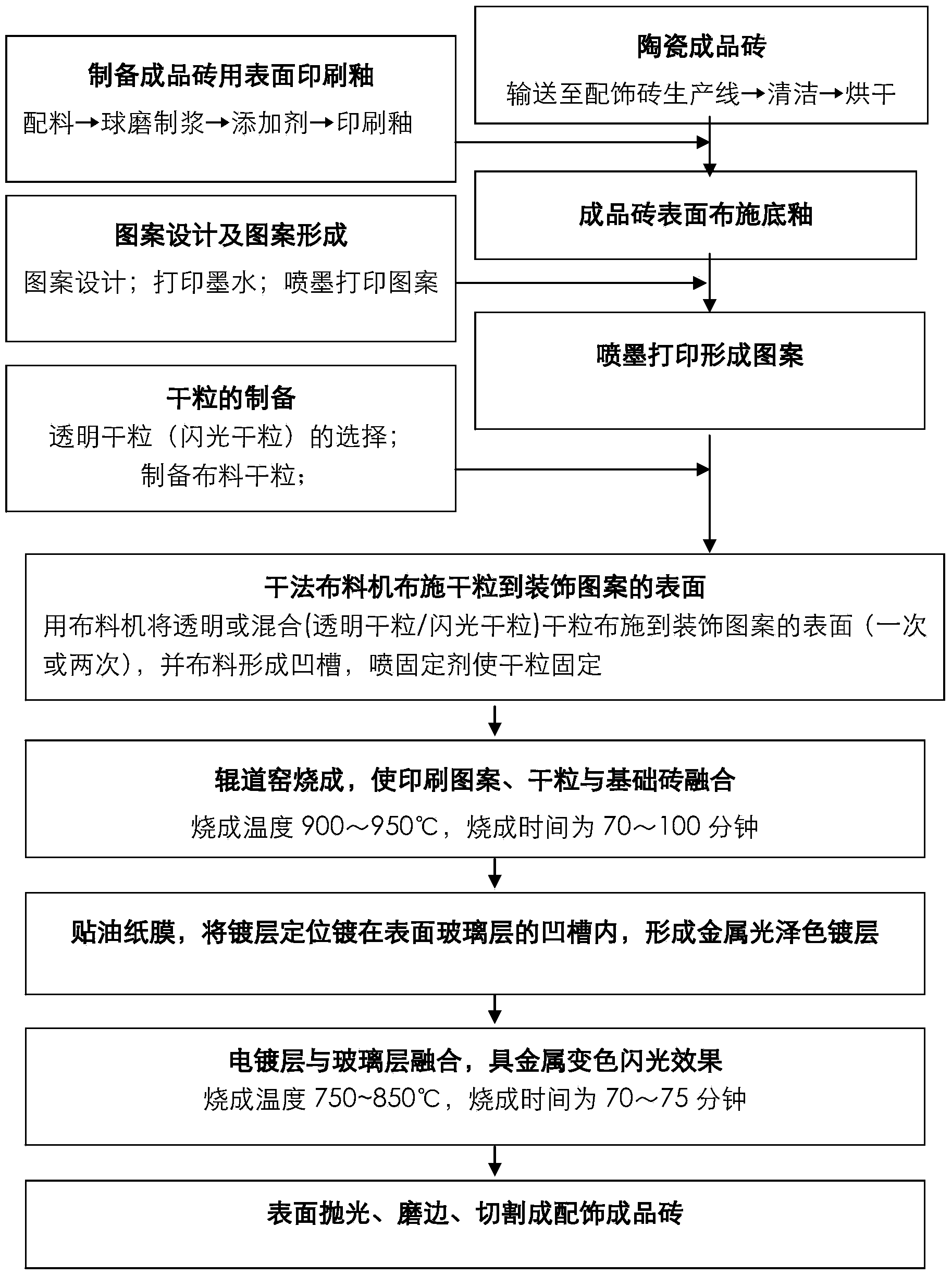

[0043] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0044] see figure 1Shown, the manufacturing process of this ceramic accessory brick, comprises the steps:

[0045] ⑴Print the bottom glaze on the glass layer on the surface of the fired ceramic tile; where:

[0046] The bottom glaze described in step (1) is made up of following components by weight percentage:

[0047] SiO 2 60%~70%Al 2 o 3 5%~8% B 2 o 3 3%~7%

[0048] CaO 3%~9% BaO 2%~8% KNaO 3%~12%.

[0049] ⑵ Patterns are formed on the printing underglaze layer by inkjet printing;

[0050] (3) Distribute transparent dry particles twice on the surface of the pattern layer and burn them;

[0051] The parameters of the step (3) of distributing dry particles of cloth are:

[0052] The first time: 40-mesh fully transparent net is used, the particle size is 60-100 mesh, and the thickness of the dry particle layer is 0.8-1 mm;

[0053] The se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com