Material for heat insulating nano-material, mixing method of material, heat insulating nano-material and preparation method of heat insulating nano-material

A technology of nano-insulation materials and mixtures, which is applied in the field of nano-insulation materials and their preparation, materials for nano-insulation materials and their mixing, and can solve the problem of poor dispersion of dry low-viscosity fibers, weakened reinforcement effect, and surface area Large and other problems, to achieve the effect of promoting mixing and dispersion, low density, low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

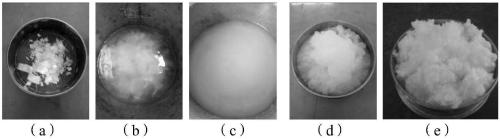

Embodiment 1

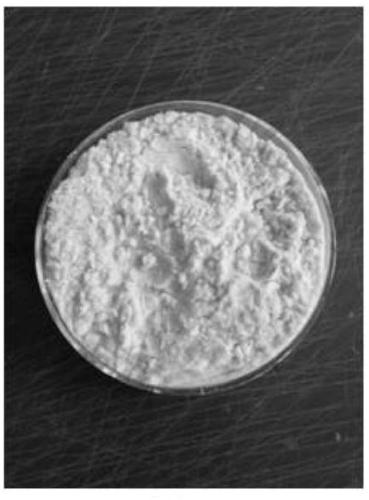

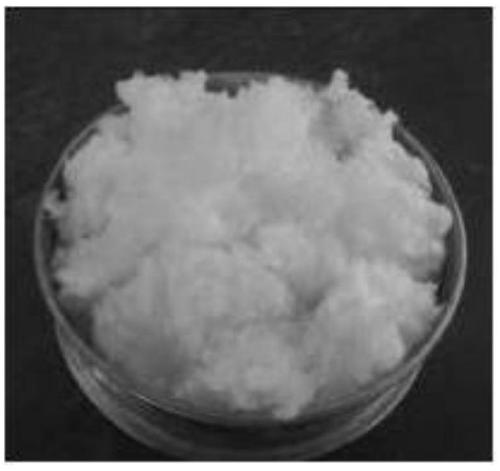

[0063] ① Disperse the quartz fiber evenly with water to obtain a slurry, in which the mass ratio of the quartz fiber to water is 0.5:100; then filter the dispersant from the uniformly dispersed slurry in the tooling, form the quartz fiber and dry it to obtain the pre- Dispersed quartz fibers.

[0064] ② Prepare a mixture according to the ratio of silica nanopowder: pre-dispersed quartz fiber: methyl cellulose = 500:100:6 (mass ratio), and set it aside.

[0065] ③ Put the mixture into the mechanical fusion equipment, the speed of mechanical fusion is 1200r / min, and the time of mechanical fusion is 60min.

[0066] ④Take out the uniformly mixed material to obtain the material for nano heat insulation material, numbered, and set aside.

[0067] ⑤ Prepare the mixture according to the ratio of materials for nano-insulation materials: silicon carbide = 900:90 (mass ratio), and use mechanical fusion equipment to mix evenly to obtain a mixture. The speed of mechanical fusion is 1200r / ...

Embodiment 2

[0071] ①Uniformly disperse the alumina fibers with water to obtain a slurry, in which the mass ratio of alumina fibers to water is 0.5:100; then filter the dispersant from the uniformly dispersed slurry in the tooling, form alumina fibers and dry them , to obtain pre-dispersed alumina fibers.

[0072] ② Prepare a mixture according to the ratio of silica nanopowder: pre-dispersed alumina fiber: methyl cellulose = 500:120:12 (mass ratio), and set it aside.

[0073] ③ Put the mixture into the mechanical fusion equipment, the speed of mechanical fusion is 1000r / min, and the time of mechanical fusion is 60min.

[0074] ④Take out the uniformly mixed material to obtain the material for nano heat insulation material, numbered, and set aside.

[0075] ⑤ Prepare the mixture according to the ratio of materials for nano-insulation materials: silicon carbide = 900:90 (mass ratio), and use mechanical fusion equipment to mix evenly to obtain a mixture. The speed of mechanical fusion is 1200...

Embodiment 3

[0079] ① Disperse the quartz fiber evenly with water to obtain a slurry, in which the mass ratio of the quartz fiber to water is 0.5:100; then filter the dispersant from the uniformly dispersed slurry in the tooling, form the quartz fiber and dry it to obtain the pre- Dispersed quartz fibers.

[0080] ② Prepare a mixture according to the ratio of alumina nanopowder: pre-dispersed quartz fiber: methyl cellulose = 500:100:6 (mass ratio), and set it aside.

[0081] ③ Put the mixture into the mechanical fusion equipment, the speed of mechanical fusion is 1200r / min, and the time of mechanical fusion is 60min.

[0082] ④Take out the uniformly mixed material to obtain the material for nano heat insulation material, numbered, and set aside.

[0083] ⑤ Prepare the mixture according to the ratio of materials for nano-insulation materials: silicon carbide = 900:90 (mass ratio), and use mechanical fusion equipment to mix evenly to obtain a mixture. The speed of mechanical fusion is 1200r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com