Duprene rubber foamed sheet and preparation method thereof

A chloroprene rubber and foam sheet technology, applied in the field of polymer processing, can solve the problems of discontinuous production process, and achieve the effects of strong continuity, good flame retardancy and simple process

Active Publication Date: 2010-08-18

常州美利晟高分子科技有限公司

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to solve the problems of discontinuous production process existing in the prior art, the present invention proposes a new neoprene foamed sheet and its preparation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

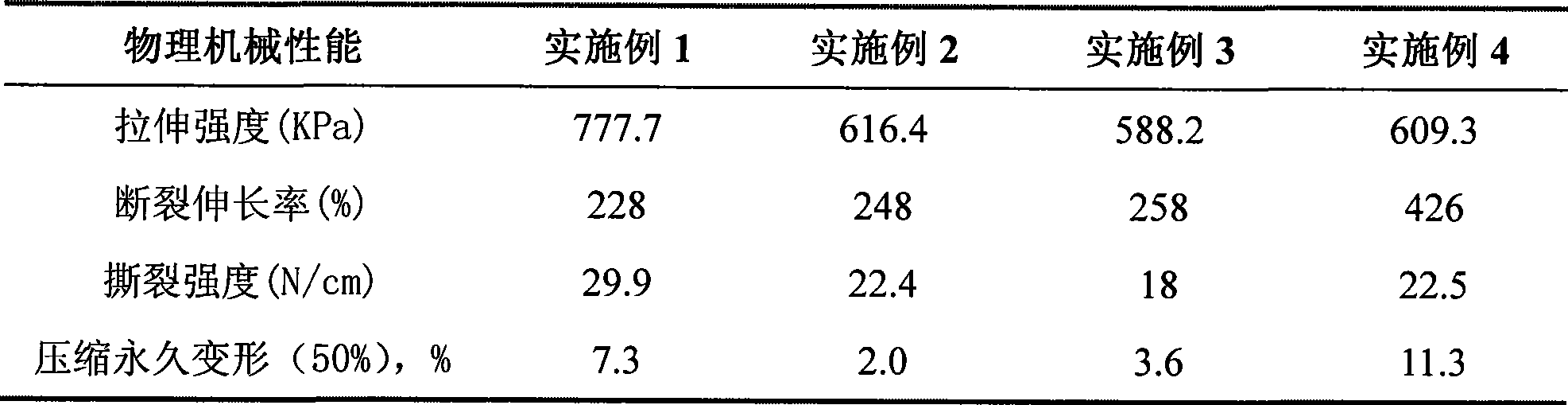

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant,5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Description

technical field The invention relates to a neoprene foamed board and a preparation method thereof, belonging to the field of polymer processing. Background technique Neoprene has excellent mechanical strength, high ozone resistance and weather resistance, good aging resistance, low flammability, good chemical resistance, moderate oil resistance and flame resistance, etc. It is used under harsh and harsh environmental conditions, and the product has a long life and no chemical hazards. Chinese patent CN1982042A discloses a method for manufacturing a composite rubber runway, including neoprene, natural rubber, and EPDM rubber, adding waste tire rubber powder, white carbon black, pottery clay, zinc oxide, stearic acid, and naphthene Oils, flame retardants, UV absorbers, accelerated vulcanization systems, etc. Processing method Weigh the above-mentioned raw rubber and auxiliary materials according to the weight ratio, mix them in a closed rubber mixer, add vulcanization in an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L11/00C08K13/02C08J9/10B29C69/00B29B7/00B29B7/28B29B7/72B29C47/12B29C44/60C08K3/34C08K3/26C08K3/04C08K3/22C08K5/405B29C48/30

Inventor 吴海宙

Owner 常州美利晟高分子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com