Antibacterial and breathable philodendron-containing modified fiber and preparation method thereof

A modified fiber and air permeability technology, applied in the field of modified fiber and its preparation, can solve problems such as the decline of antibacterial properties, and achieve the effects of enhancing stability, speeding up the process of sterilization, and improving air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The molar ratio of zinc ions, copper ions and iron ions in this embodiment is 3:2:1.

[0040] The preparation method of philodendron fiber is as follows: select P.bipinnatifidum, put the stems and leaves of philodendron philodendron in a sodium hydroxide solution with a concentration of 2%, and boil for 100min at a temperature of 90°C. , after the temperature of the solution drops to 70°C, add 4wt.% hydrogen peroxide, continue heating at 7°C for 30 minutes, then filter, wash the filter residue with distilled water until it is neutral, and dry it.

[0041] (1) Pretreatment of fiber body:

[0042]a. Weigh and mix each fiber component according to the required ratio, put the mixed fiber into a pulverizer for pulverization, and pass through a 250 mesh sieve to obtain a mixed fiber powder for subsequent use; wherein, the mass percentage of each fiber component It is 45% milk protein fiber, 30% bamboo fiber, 15% jute fiber and 10% philodendron fiber.

[0043] b. Immerse the...

Embodiment 2

[0052] The molar ratio of zinc ions, copper ions and iron ions in this embodiment is 4:2:1.

[0053] The preparation method of philodendron fiber is as follows: select P.bipinnatifidum, put the stems and leaves of philodendron philodendron in a sodium hydroxide solution with a concentration of 4%, and boil for 120min at a temperature of 100°C. , after the temperature of the solution drops to 80°C, add 5wt.% hydrogen peroxide, continue heating at 80°C for 40min, then filter, wash the filter residue with distilled water until it is neutral, and dry it.

[0054] (1) Pretreatment of fiber body:

[0055] a. Weigh and mix each fiber component according to the required ratio, put the mixed fiber into a pulverizer for pulverization, and pass through a 250 mesh sieve to obtain a mixed fiber powder for subsequent use; wherein, the mass percentage of each fiber component It is 40% milk protein fiber, 45% bamboo fiber, 10% jute fiber and 5% philodendron fiber.

[0056] b. Immerse the mi...

Embodiment 3

[0065] The molar ratio of zinc ions, copper ions and iron ions in this embodiment is 5:2:1.

[0066] The preparation method of philodendron fiber is as follows: select P.bipinnatifidum, put the stems and leaves of philodendron philodendron in a 3% sodium hydroxide solution, and boil for 110min at a temperature of 90°C. , after the temperature of the solution drops to 70°C, add 4wt.% hydrogen peroxide, continue heating at 70°C for 40 minutes, then filter, wash the filter residue with distilled water until it is neutral, and dry it.

[0067] (1) Pretreatment of fiber body:

[0068] a. Weigh and mix each fiber component according to the required ratio, put the mixed fiber into a pulverizer for pulverization, and pass through a 300-mesh sieve to obtain a mixed fiber powder for subsequent use; wherein, the mass percentage of each fiber component It is 40% milk protein fiber, 40% bamboo fiber, 15% jute fiber and 5% philodendron fiber.

[0069] b. Immerse the mixed fiber powder obt...

PUM

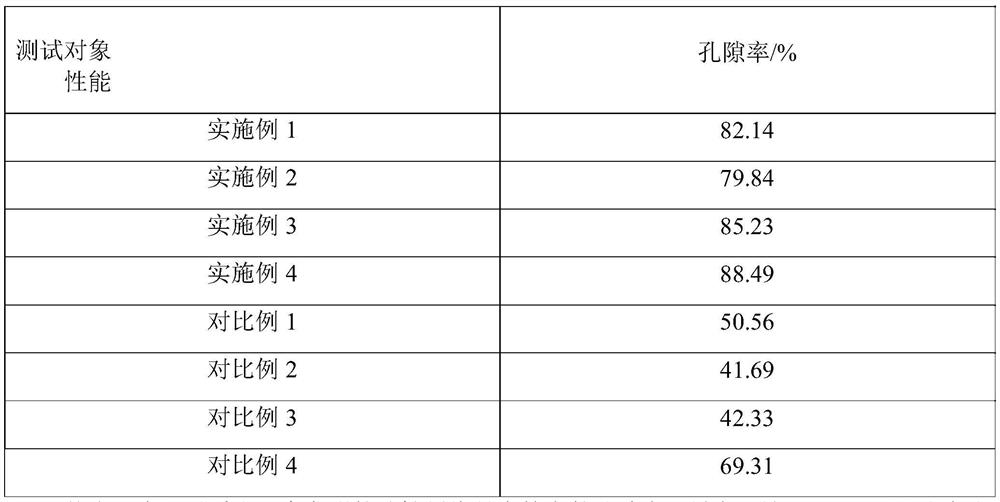

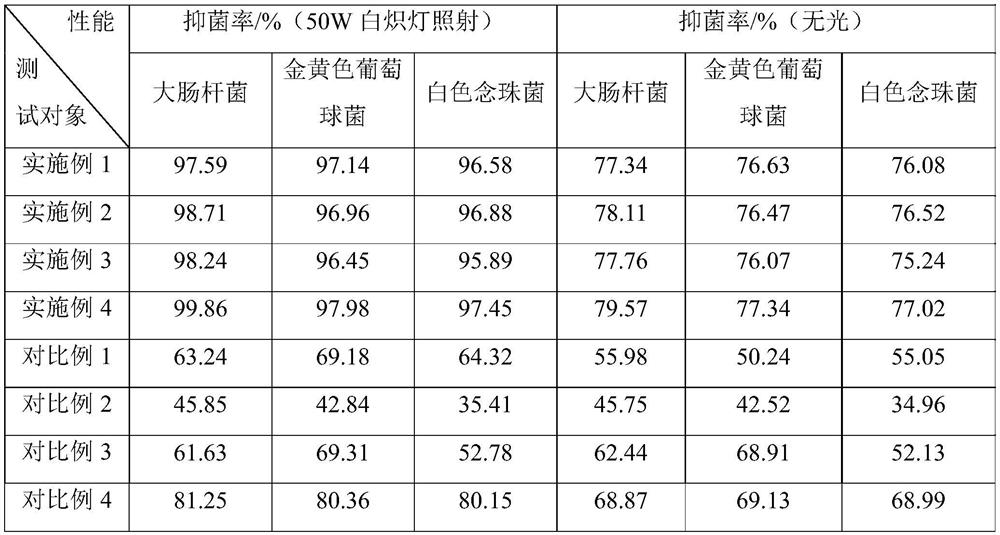

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com