Two-dimensional ultrasonic vibration polishing device and method

A two-dimensional ultrasonic vibration and processing device technology, which can solve the problems of uncertain polishing removal, unstable polishing force, and limited processing surface shape, and achieve high-quality polishing, strong profiling ability, and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

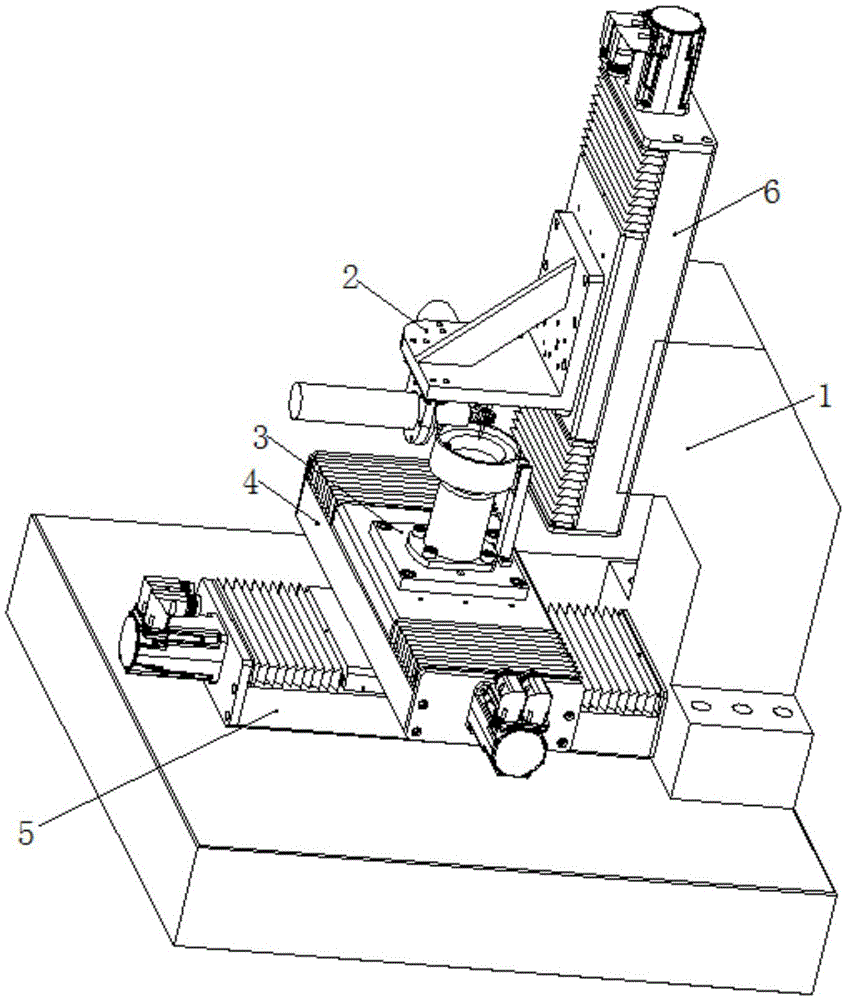

[0038] The two-dimensional ultrasonic vibration polishing tool 2 is fastened to the machine tool z axis 6 by screws, and the workpiece fixture 3 is fixed to the machine tool x axis 4 by screws. The machine tool x axis, the machine tool y axis 5, the machine tool z axis 6 and the machine body 1 are debugged Rear fixed connection;

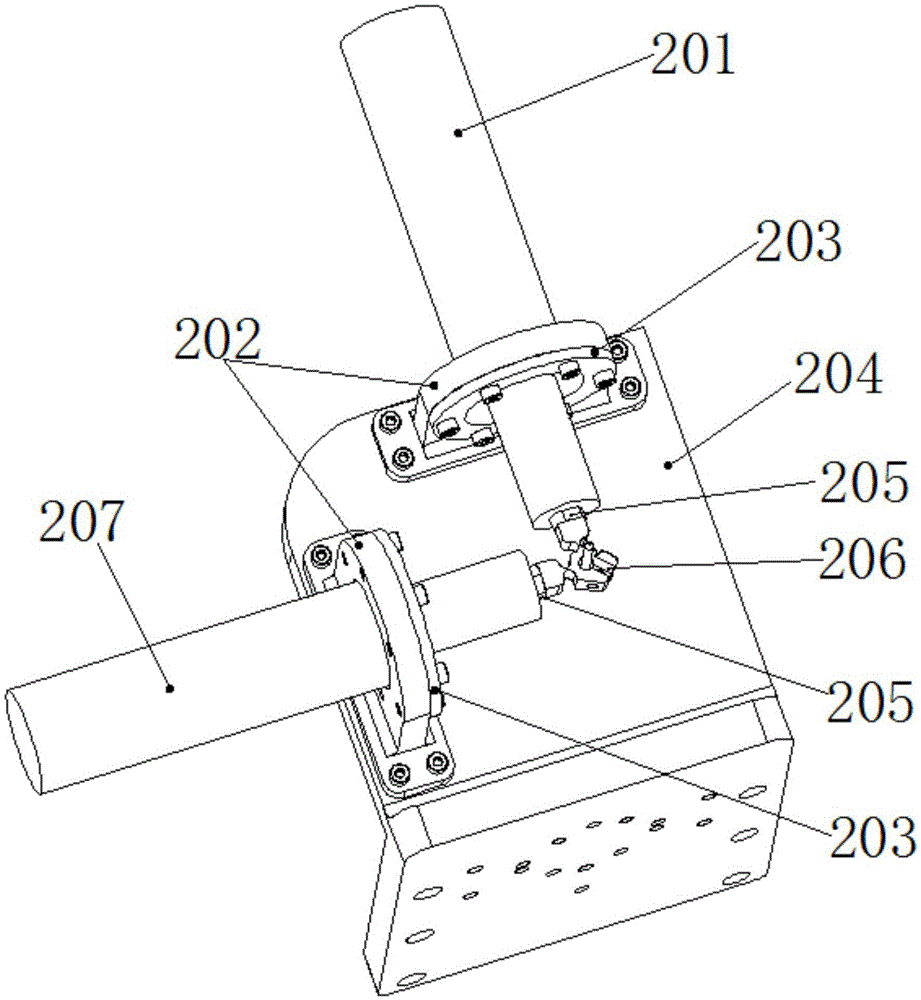

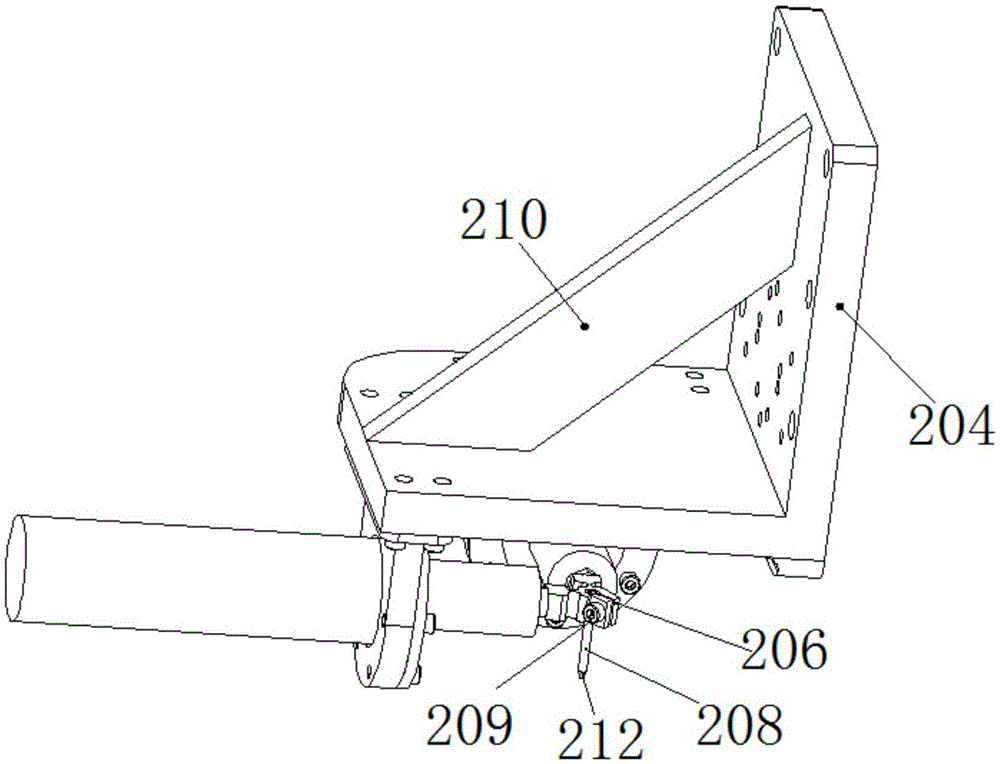

[0039] The structure of the two-dimensional ultrasonic vibration polishing tool 2 of the present invention is: 201, x-direction ultrasonic vibrator, 202, vibrator fixed flange seat, 203, vibrator fixed flange cover, 204, tool system support seat, 205, double head Stud, 206, hinge joint, 207, y-direction ultrasonic vibrator, 208, tool rod, 209, tool holding screw, 210, stiffener, 212, polishing head, two vibrator fixing flange seat 202 and vibrator fixing method The flange cover 203 is respectively connected with the x-direction ultrasonic vibrator 201 and the y-direction ultrasonic vibrator 207 through threads. The two vibrator fixing flange seats 202 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com