Profiling system of cutting table and control method of system

A technology of a profiling system and control method, applied in the direction of cutters, harvesters, agricultural machinery and implements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

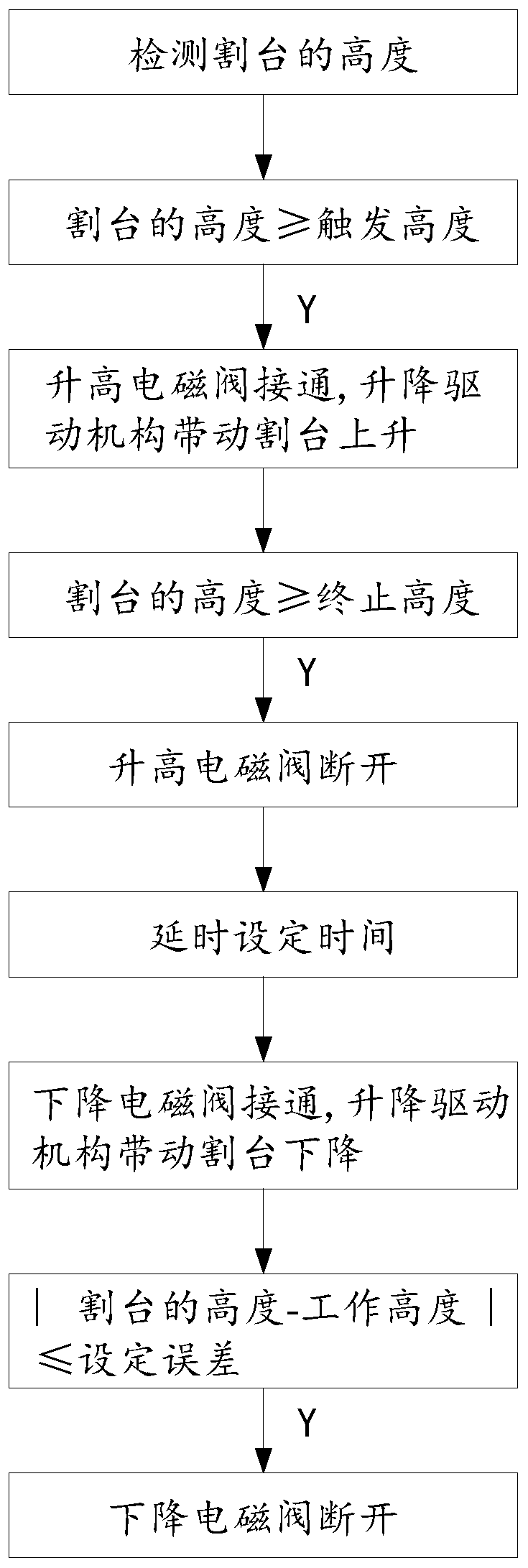

[0049] Please refer to figure 1 , the present embodiment provides a method for controlling a header profiling system, including:

[0050] Start the automatic control unit;

[0051] During the movement of the header, the header floats up and down under the action of the hydraulic accumulator;

[0052] Detect header height;

[0053] When the height of the header rises to the trigger height, the lifting drive mechanism starts, and the lifting drive mechanism drives the header to rise to the termination height;

[0054] After the delay setting time T1, the lifting drive mechanism drives the header down to the working height;

[0055] The working height is less than the trigger height.

[0056] The header profiling system and its control method are applied to the combine harvester. During use, the header is at the working height, and the header moves with the movement of the combine harvester. Under the action of the hydraulic accumulator, it automatically moves upwards to avo...

no. 2 example

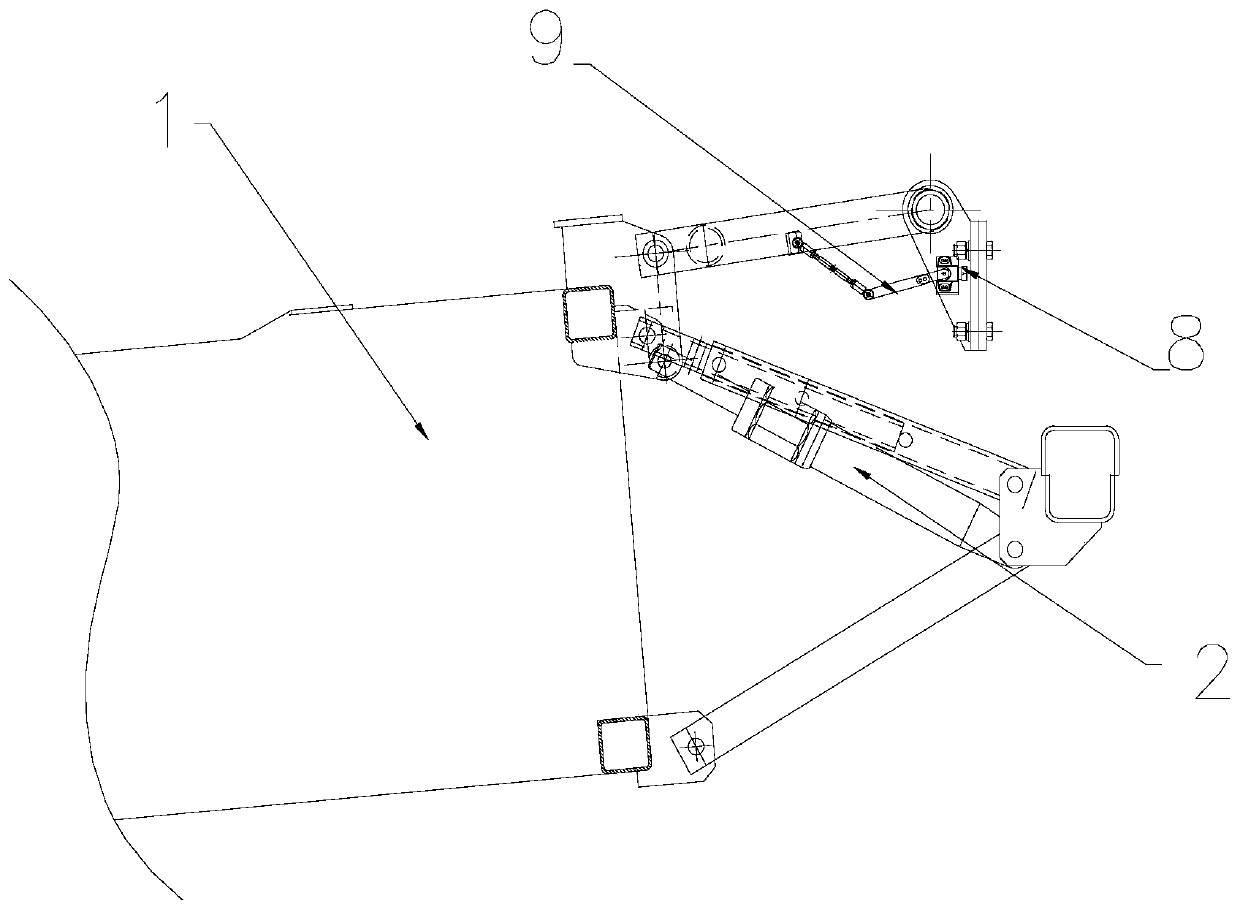

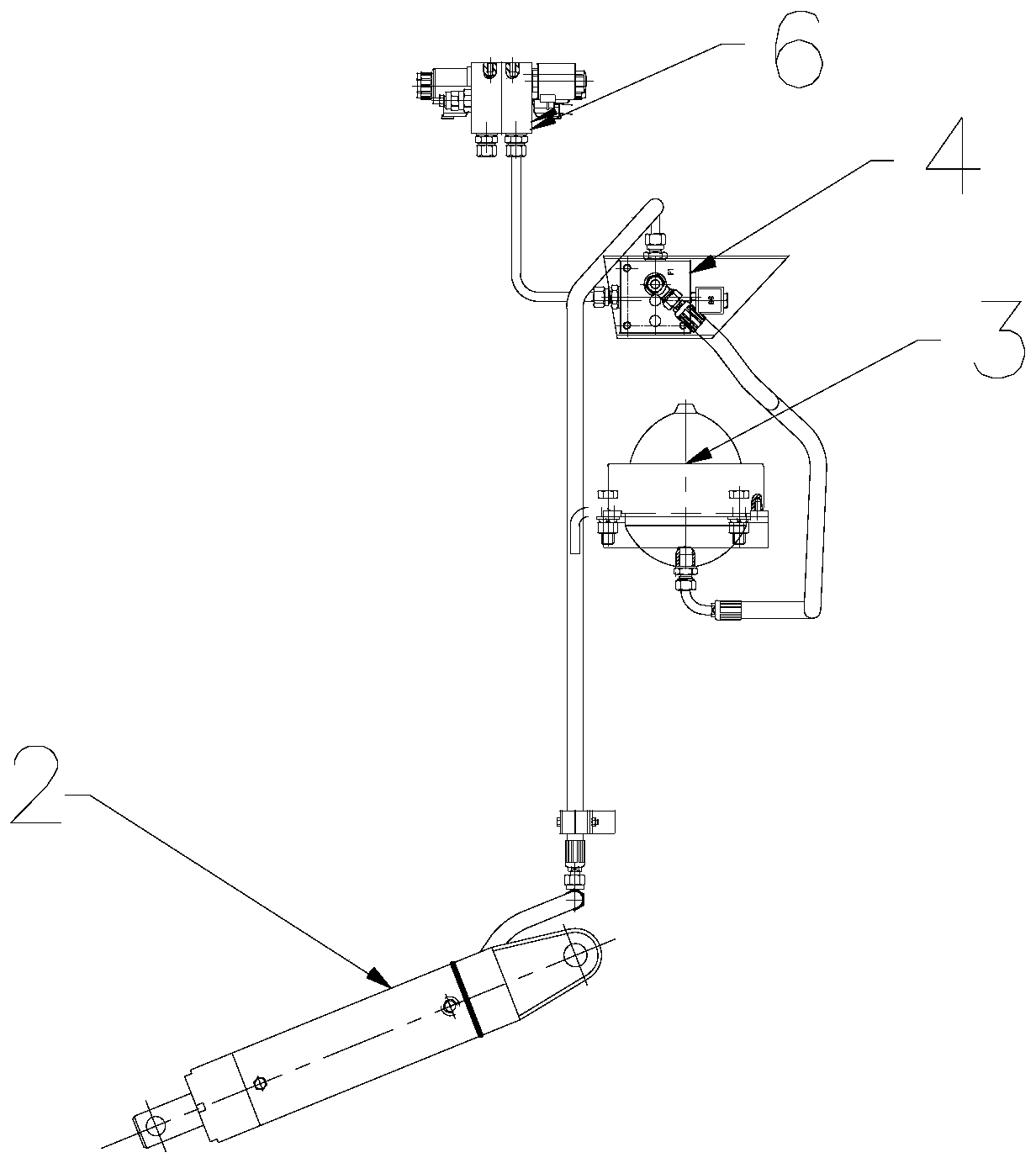

[0087] Such as figure 2 - Figure 6As shown, this embodiment provides a header 1 profiling system, which applies the control method of the header 1 profiling system provided by the first embodiment above. The header 1 profiling system includes the header 1 and an automatic control unit. The automatic control unit includes a lifting drive mechanism, a hydraulic accumulator 3, an automatic control mechanism, and a sensing mechanism. The header 1 is connected to the lifting drive mechanism, and the lifting drive mechanism is connected to The hydraulic accumulator 3 is connected, and the sensing mechanism is used to detect the height of the header 1; the automatic control mechanism is respectively connected with the lifting drive mechanism and the sensing mechanism, and the automatic control mechanism is used for the effect of the hydraulic accumulator 3 on the header 1. When ascending to the trigger height, the header 1 is moved up to the termination height through the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com