Method for weaving inclusive ring of gas compressor of engine

A containment ring and compressor technology, which is applied in the direction of machines/engines, liquid fuel engines, textiles and papermaking, etc., can solve the problems of low impact resistance of the containment ring and the weight of the containment ring, so as to increase the interlayer shear strength and improve Impact resistance, simple and easy manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

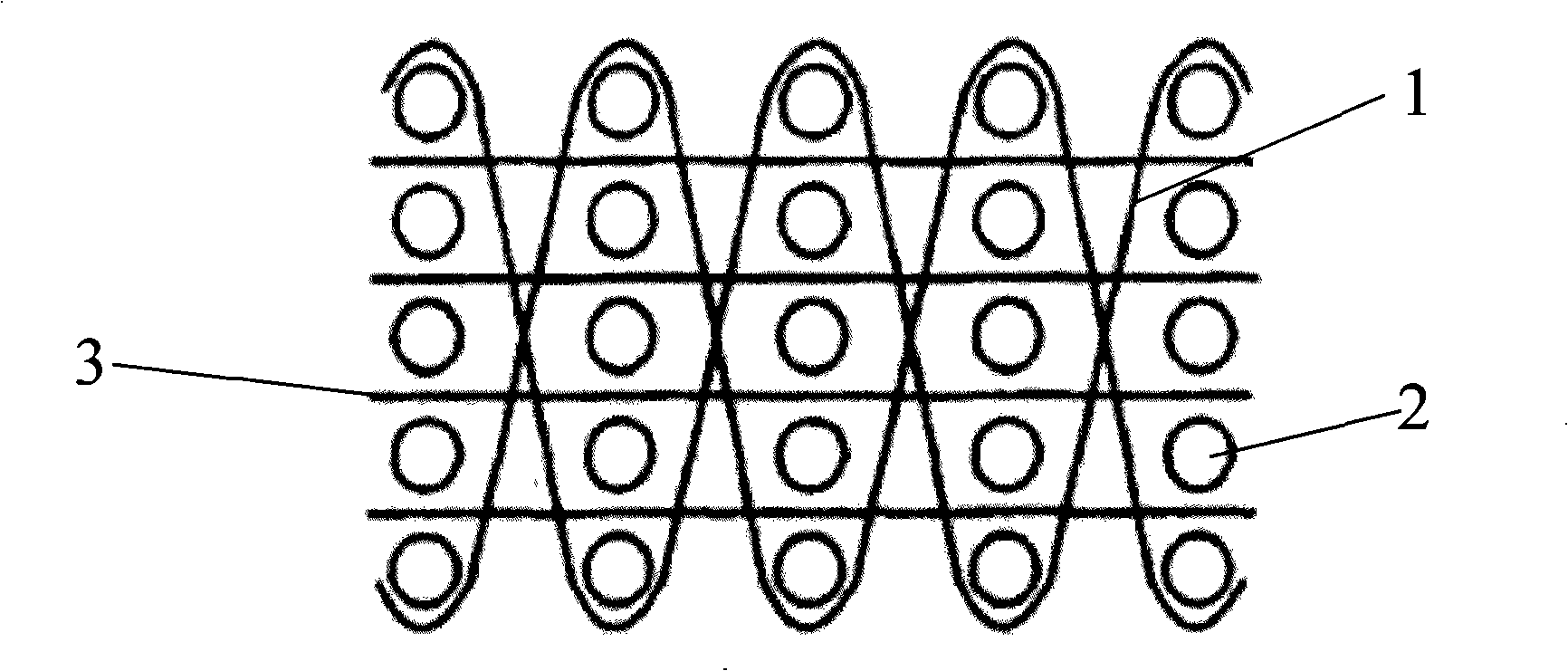

[0018] Aramid fiber is selected as the fiber of the three-dimensional orthogonal fabric, and the three-dimensional orthogonal fabric is woven on the three-dimensional loom according to the measurement size of the containment ring, as shown in figure 1 As shown, it is a schematic structural diagram of a three-dimensional orthogonal fabric. The three-dimensional orthogonal fabric includes warp yarns 3 and weft yarns 2 , and the warp yarns 3 and weft yarns 2 are connected by binding yarns 1 . During the weaving process, the size and spacing of the holes on the fabric to be woven are determined according to the size and spacing of the component interfaces on the engine casing.

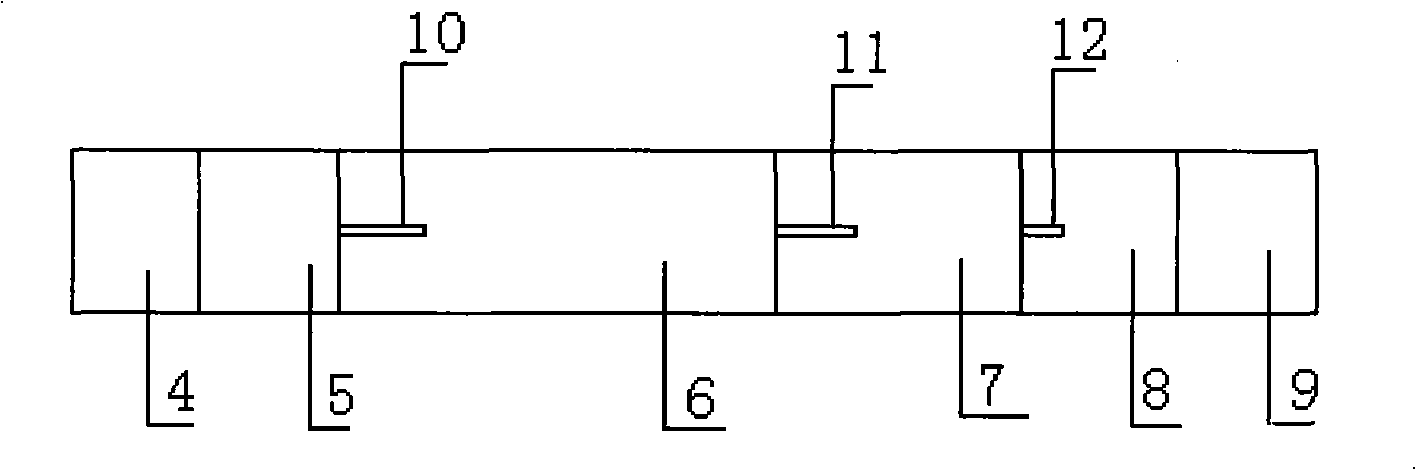

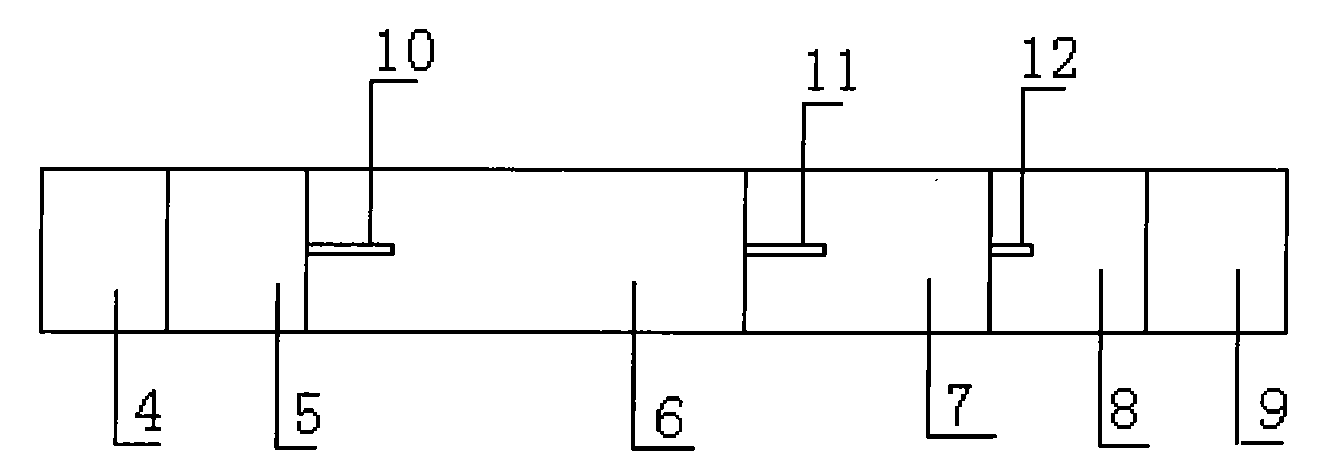

[0019] Such as figure 2 As shown, it is a schematic diagram of the containment ring structure, and the containment ring is composed of the first fabric segment 4, the second fabric segment 5, the third fabric segment 6, the fourth fabric segment 7, the fifth fabric segment 8 and the sixth fabric segment 9...

Embodiment 2

[0023] Similar to Example 1, the difference is that poly-p-phenylenebenzobisoxazole (PBO) fibers are selected as the fibers of the three-dimensional orthogonal fabric.

[0024] As shown in the following table, the impact performance of the containment ring of the present invention has been greatly improved compared with the prior art:

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com