Forage grass harvesting machinery profile modeling method and device

A technology of harvesting machinery and profiling device, which is applied to agricultural machinery and implements, harvesters, cutters, etc., can solve the problems of particularly high profiling capability of harvesting machinery, poor profiling effect, easy damage, etc. Shape effect, avoid accidental damage, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

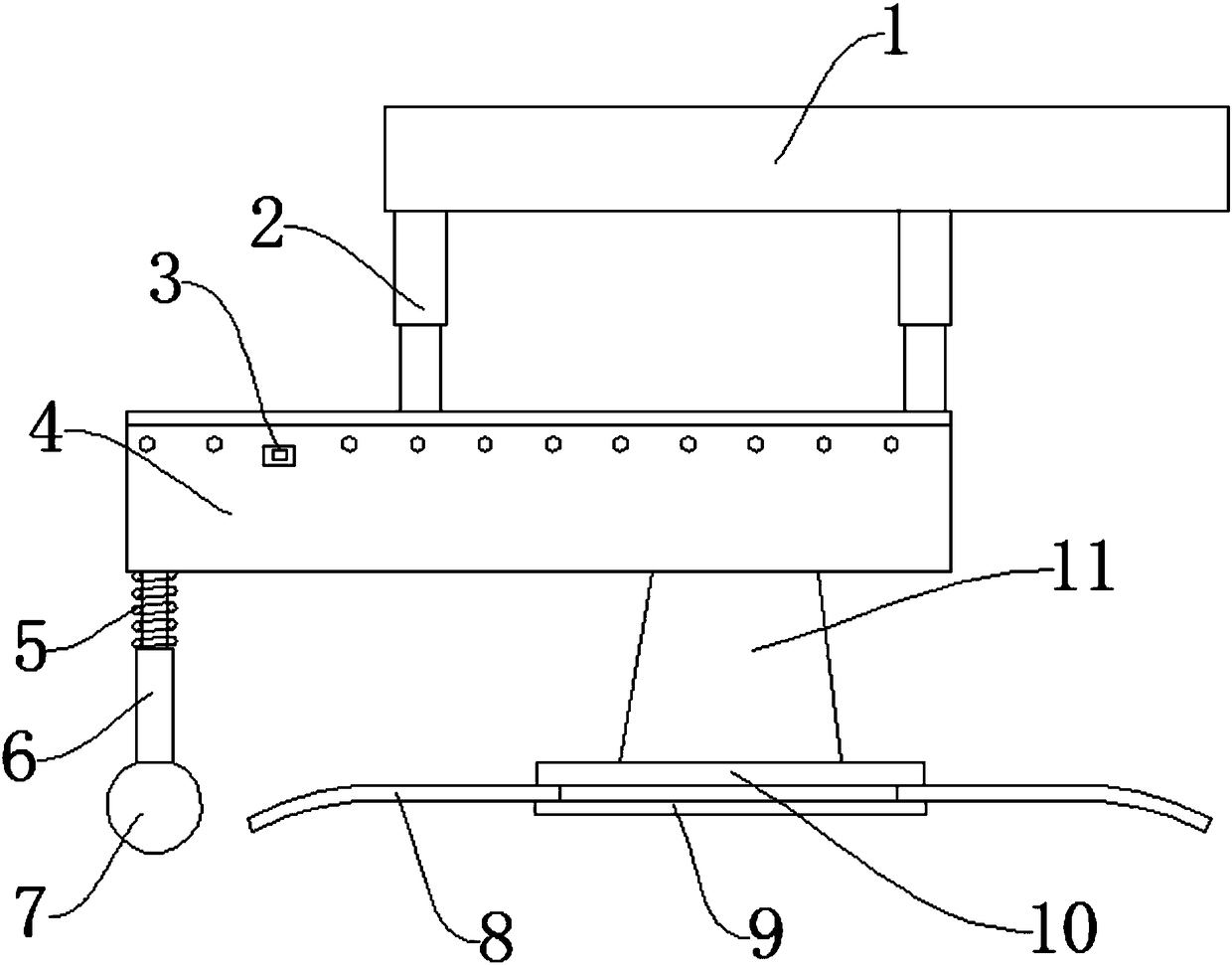

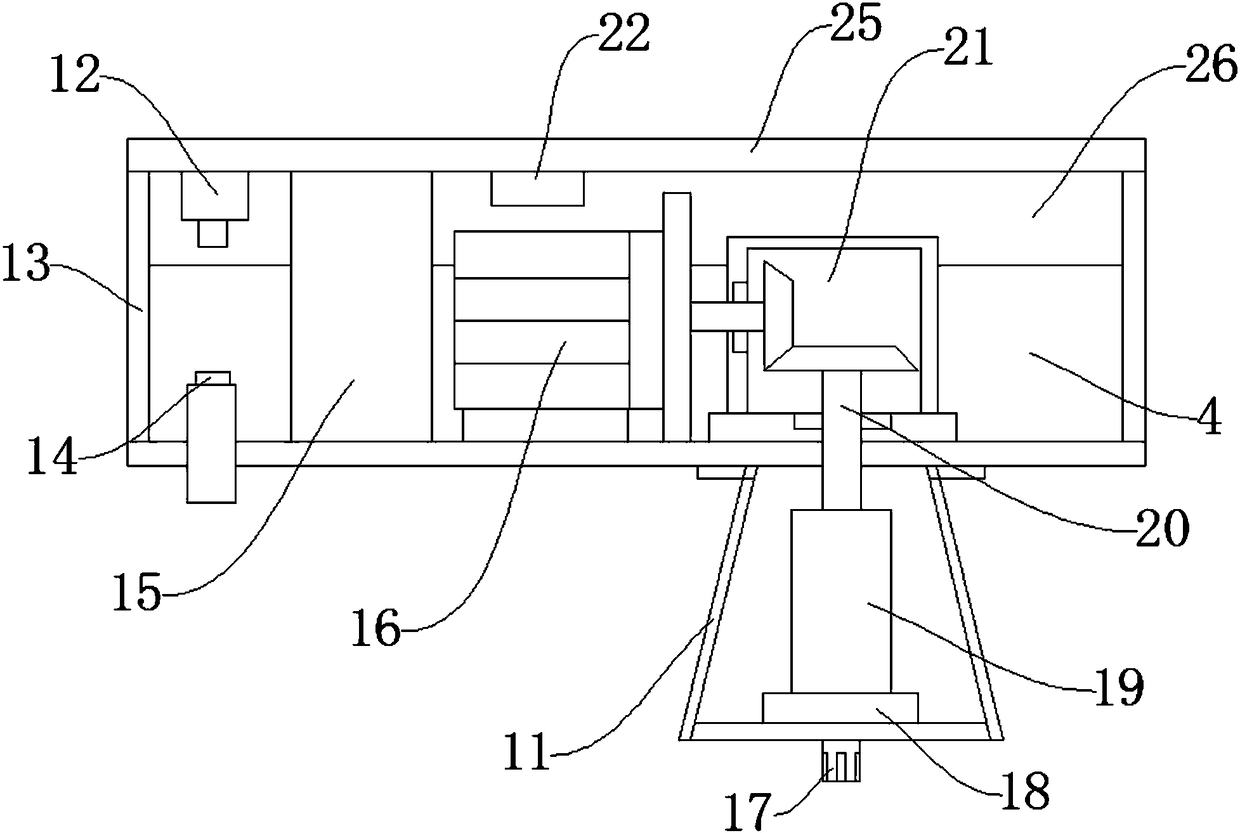

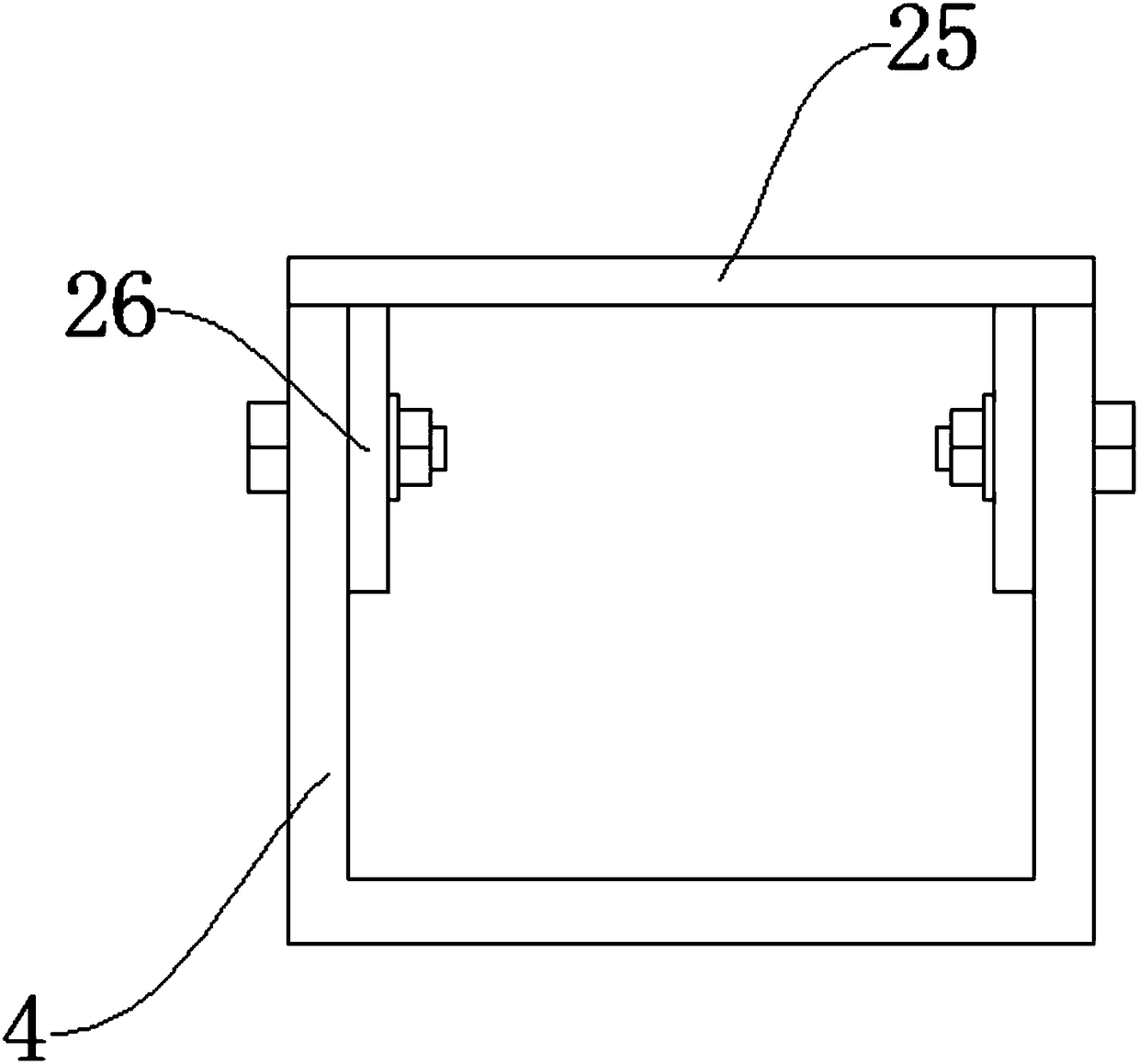

[0023] Such as Figure 1-Figure 4 As shown, a mechanical profiling device for pasture harvesting comprises a frame 1 and a gathering net 8, a hydraulic rod 2 is arranged below the frame 1, a fixed beam 4 is arranged below the hydraulic rod 2, and a fixed beam 4 is arranged below the hydraulic rod 2. An upper cover 25 is arranged above, a connecting plate 26 is arranged on the lower surface of the upper cover 25, side sealing plates 13 are arranged at both ends of the fixed beam 4, and a charging jack 3 is arranged on the side wall of the fixed beam 4 A connection seat 11 is provided under one end of the fixed beam 4, a reduction gear box 19 is provided in the connection seat 11, a power output shaft 17 is provided below the reduction gear box 19, and a power output shaft 17 is provided below the power output shaft 17. Rotating disk 10, the center of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com