Grass harvesting machine profiling method and device

A technology for harvesting machinery and profiling devices, applied in agricultural machinery and implements, harvesters, applications, etc., can solve problems such as single profiling methods, affecting operation efficiency, profiling failure, etc., to ensure the quality of operations and improve machine work Efficiency, profiling function and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

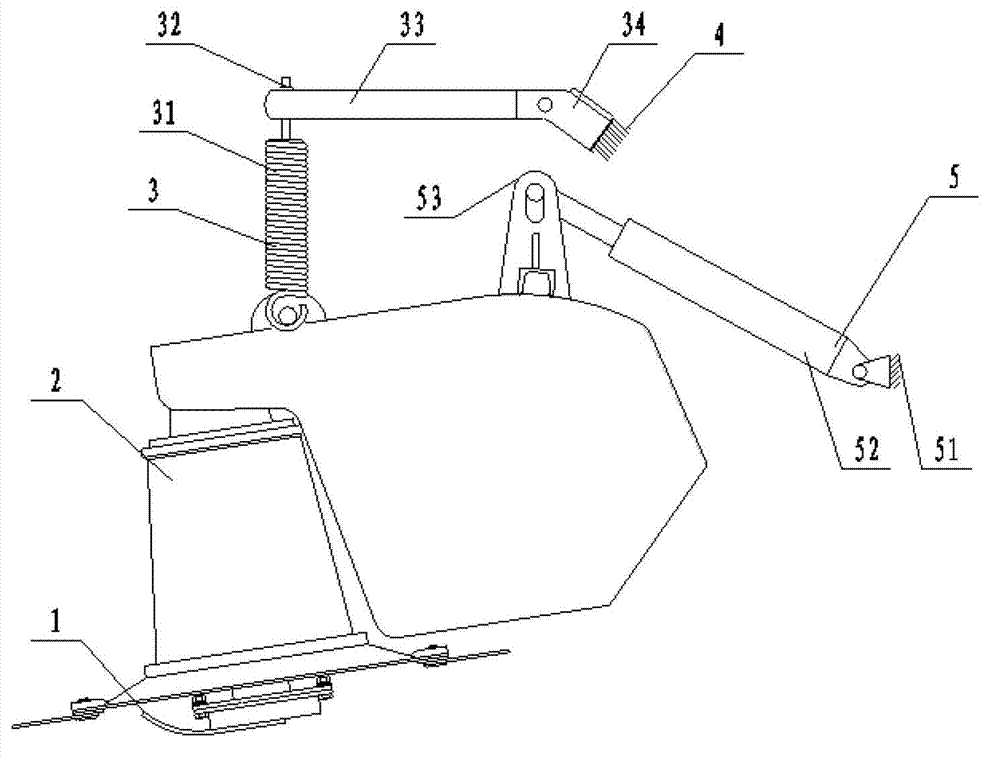

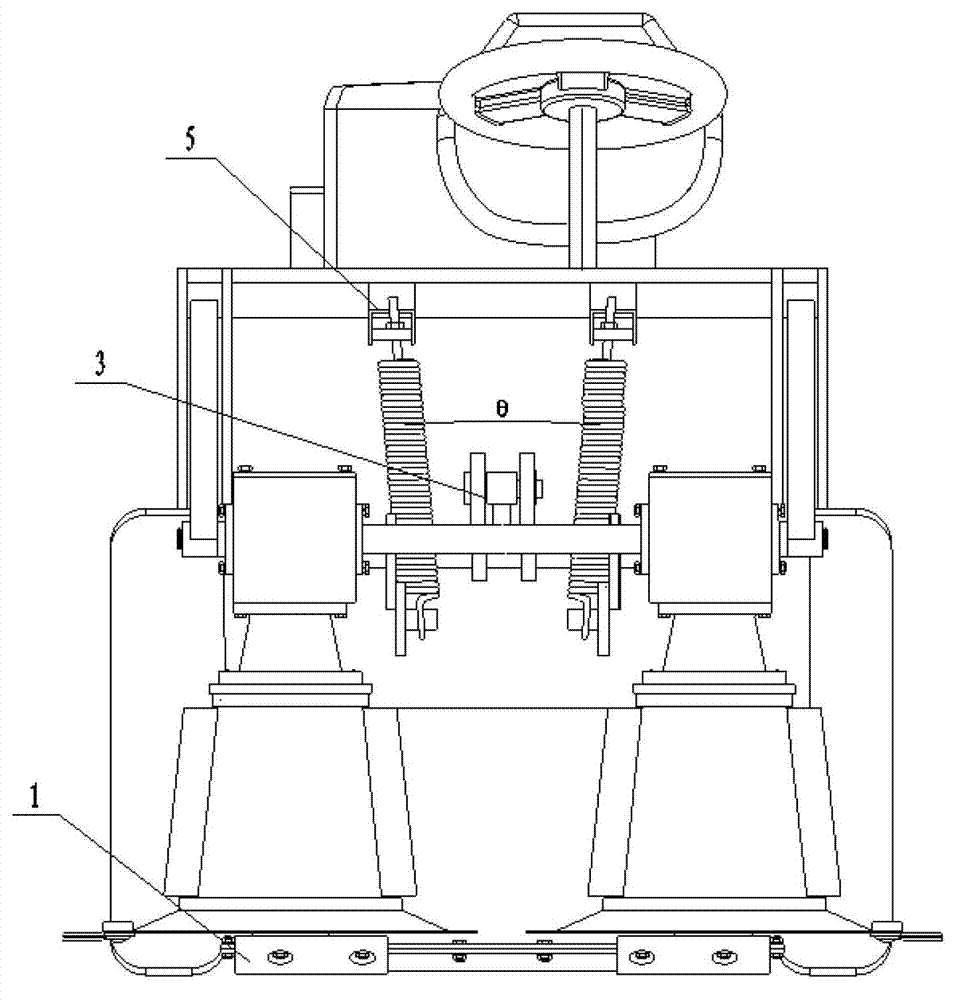

[0016] figure 1 and figure 2 Among them, 1 is the sliding palm device, 2 is the working device, 3 is the floating device, 31 is the floating spring, 32 is the adjustment rod, 33 is the support arm 1, 34 is the support arm 2, 4 is the frame, 5 is the lifting device, 51 is a support seat 1, and 52 is a lifting oil cylinder, and 53 is a support seat 2. The sliding palm device (1) is welded to the bottom of the working device (2), and has two sections in total, and holes are opened at the mounting screw positions for easy installation and disassembly. The floating device (3) includes a floating spring (31), an adjustment rod (32), a support arm 1 (33) and a support arm 2 (34), wherein the support arm 1 (33) and the support arm 2 (34) are hung on the pin Then, the supporting arm 2 (34) is welded on the frame (4); when the working device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com