Full-automatic fruit peeling machine

A kind of peeling machine, fully automatic technology, applied in the direction of peeling appliances, household appliances, applications, etc., can solve problems such as trouble, knife tip leakage, pulp waste, etc., to solve the problem of low safety performance, troublesome operation, The effect of improving the profiling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

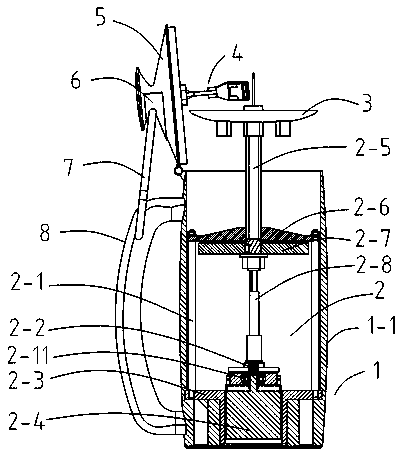

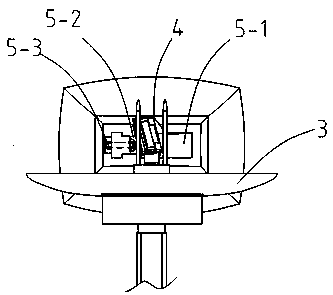

[0028] Such as Figures 1 to 5 As shown, this embodiment provides a fully automatic fruit peeling machine, including a casing mechanism 1, a transmission mechanism 2 and a cutter mechanism 4, the casing machine 1 includes a cylinder 1-1, and the upper edge of the cylinder 1-1 is hingedly arranged There is a cover 5, the inner side of the cover 5 is equipped with a cutter mechanism 4, the transmission mechanism 2 is arranged in the cylindrical body 1-1, and the transmission mechanism 2 is provided with a fruit plate 3 used in conjunction with the cutter mechanism 4.

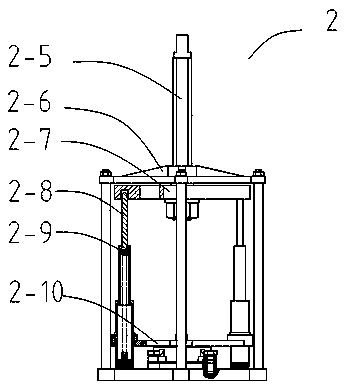

[0029] The transmission mechanism 2 includes a motor fixing plate 2-3 arranged at the bottom of the cylinder body 1-1, a motor 2-4 is arranged in the motor fixing plate 2-3, and the motor 2-4 is connected with a transmission through a thrust ball bearing 2-12. End shaft 2-2, transmission end shaft 2-2 is provided with telescoping rod support plate 2-10, is evenly distributed with two three-stage telescopic rods 2-...

Embodiment 2

[0036] Such as Figures 1 to 5 As shown, this implementation is optimized as follows on the basis of any of the above embodiments. Specifically, the cylinder body 1-1 is connected to the cover 5 through screws and nuts, so that the cover 5 can rotate around the screw. The setting structure of this structure is simple, and the processing cost is low.

[0037] The cylinder 1-1 is provided with a support handle 8, the hinge point of the support handle 8 and the cover 5 is on the same side, the cover 5 is provided with a cover positioning clip 6, and the support handle 8 and the cover positioning clip 6 are connected There is a cover positioning rod 7.

[0038] In this embodiment, the two ends of the cover positioning rod 7 are respectively buckled into the hole on the support handle 8 of the cylinder and the hole of the cover positioning clamp 6 stuck on the cover 5, forming a stable triangle with the screw at the handover point, improving Ensure the stability of the cover duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com