Efficient automatic rotary hydraulic casting machining device

A processing device and hydraulic technology, used in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problem of not being able to change the distance of the fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

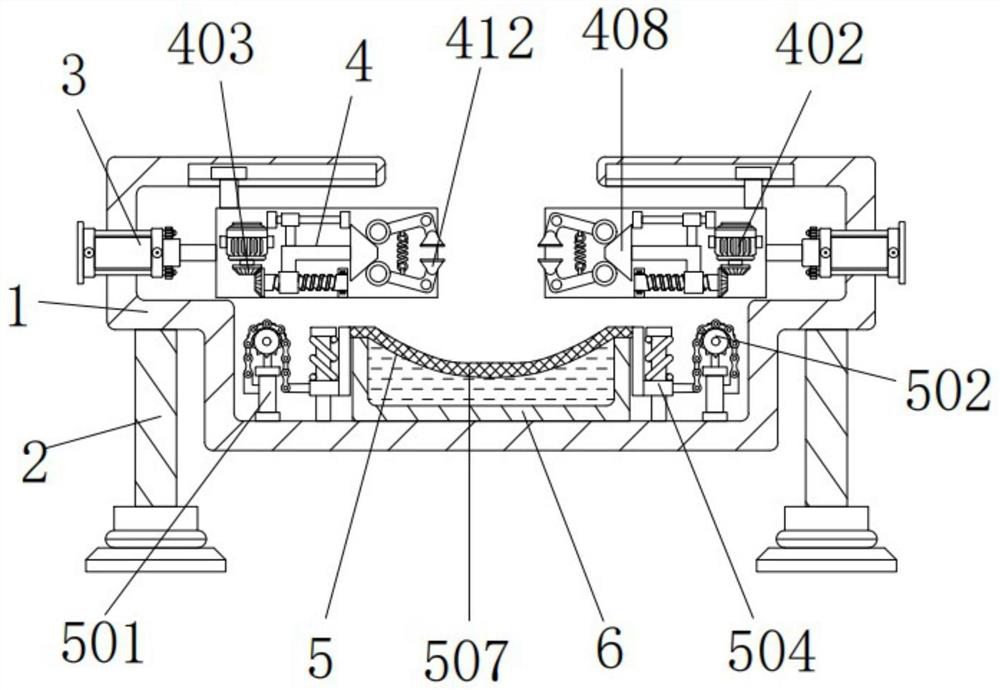

[0030] A high-efficiency automatic rotary hydraulic casting processing device, including a shell 1, a pillar 2 and a rotary hydraulic cylinder 3, two pillars 2 are arranged under the shell 1, and the tops of the two pillars 2 are connected to the left and right sides of the bottom of the shell 1 Fixedly connected, the left and right sides of the housing 1 are provided with rotary hydraulic cylinders 3 , and the outer walls of the two rotary hydraulic cylinders 3 are fixedly connected with the inner walls of the left and right sides of the housing 1 .

Embodiment 2

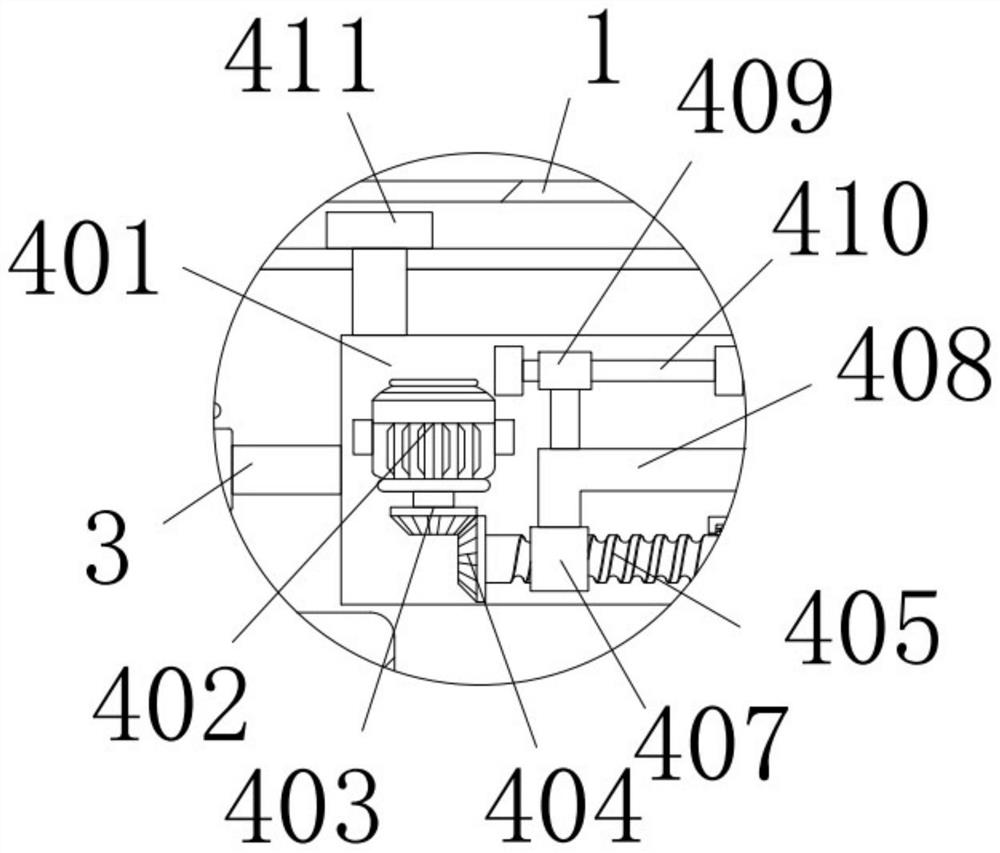

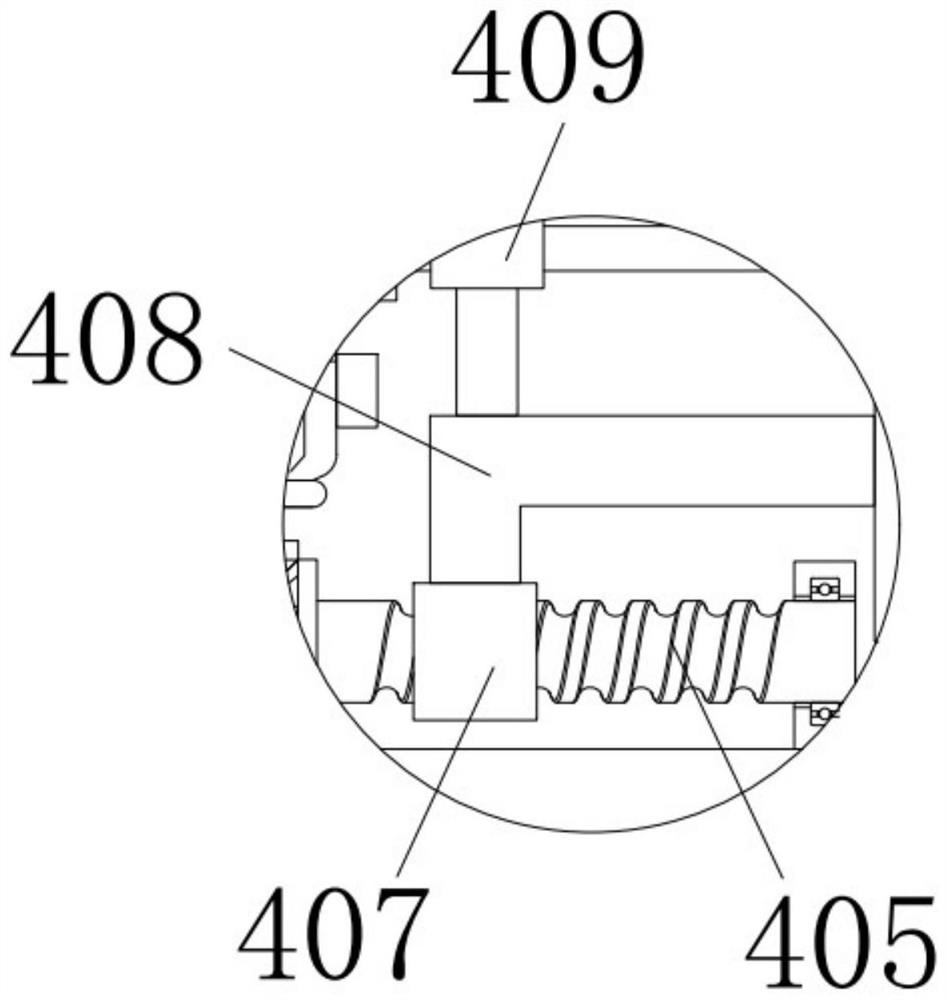

[0032] As an option, see Figure 1-4, high-efficiency automatic rotary hydraulic casting processing device, the interior of the housing 1 is provided with two fixing devices 4, the fixing device 4 includes a square plate 401, a motor 402, a first bevel gear 403, a second bevel gear 404, a screw 405, First spring 406, sleeve 407, straight rod 408, first sliding sleeve 409, first slide bar 410, slide block 411 and curved plate 412, the left side of square plate 401 and the right side of the rotary hydraulic oil cylinder 3 of left side are fixed connection, a slider 411 is provided above the square plate 401, the bottom of the slider 411 is fixedly connected to the top left side of the square plate 401, the outer wall of the slider 411 is slidably engaged with the groove on the left side of the inner wall top of the housing 1, and the sliding The block 411 can move in the groove on the left side of the inner wall top of the housing 1, the front of the square plate 401 is provided...

Embodiment 3

[0035] As an option, see figure 1 , 5 And 6, high-efficiency automatic rotary hydraulic casting processing device, the bottom of the inner wall of the housing 1 is provided with two filter devices 5, and the filter device 5 includes an electric push rod 501, a gear 502, a chain 503, a second sliding sleeve 504, and a second sliding rod 505, the second spring 506 and the filter screen 507, the bottom of the electric push rod 501 is fixedly connected with the bottom of the inner wall of the housing 1, the model of the electric push rod 501 is TG-700, and the top of the electric push rod 501 is connected through the rotation of the pin shaft. The gear 502 is meshed with a chain 503 above the gear 502, the left side of the chain 503 is fixedly connected with the left side of the electric push rod 501, the right side of the chain 503 is fixedly connected with a second sliding sleeve 504, and the inner wall of the second sliding sleeve 504 A second sliding rod 505 is slidingly clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com