Sugarcane combine-harvester with novel conveying manner

A technology of combine harvesters and conveying methods, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of reducing the quality and efficiency of sugarcane harvesting operations, blockage of conveying channels, and damage to sugarcane stems, etc., and achieve high efficiency in mechanized operations , prevent breakage and damage, and achieve good harvesting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

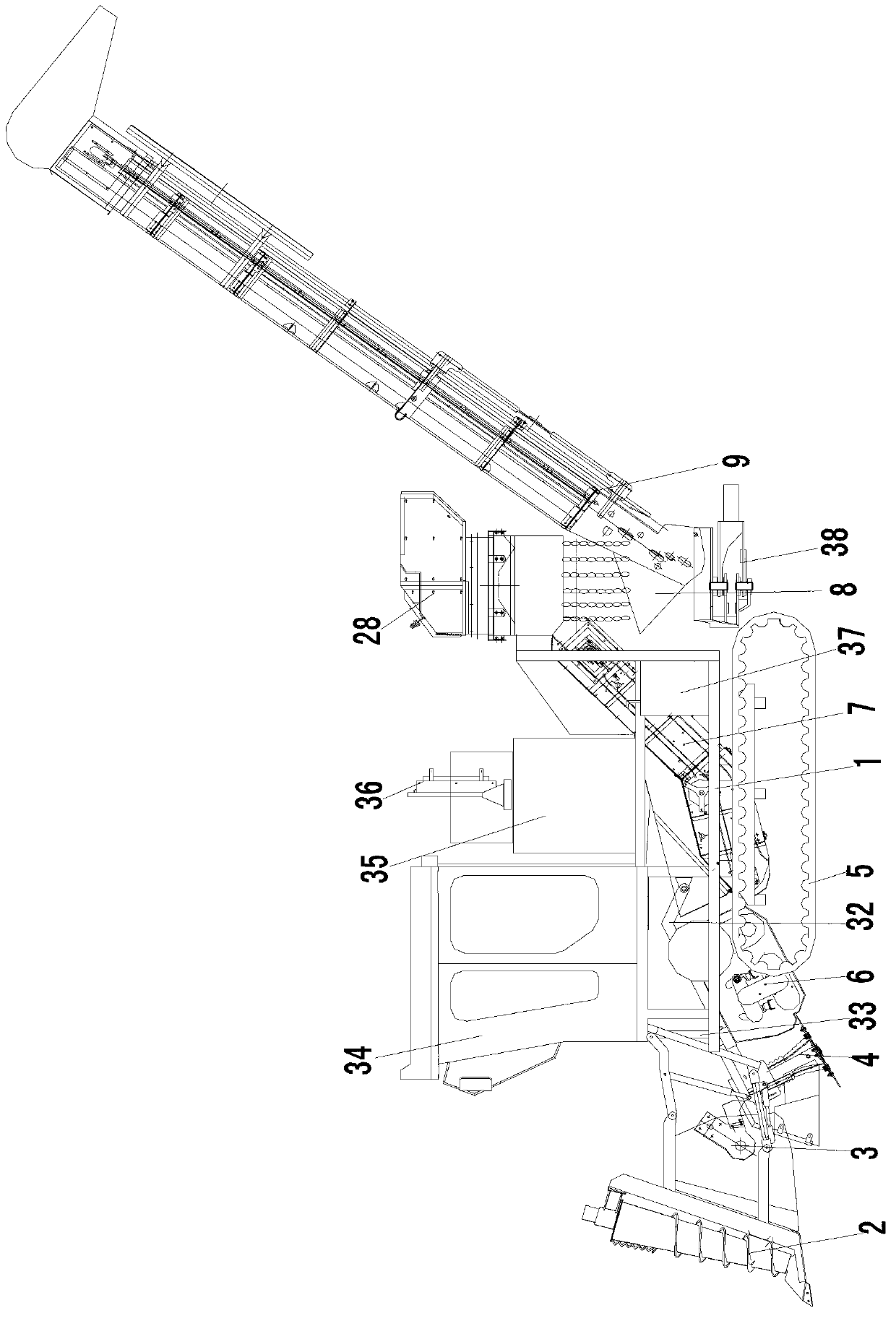

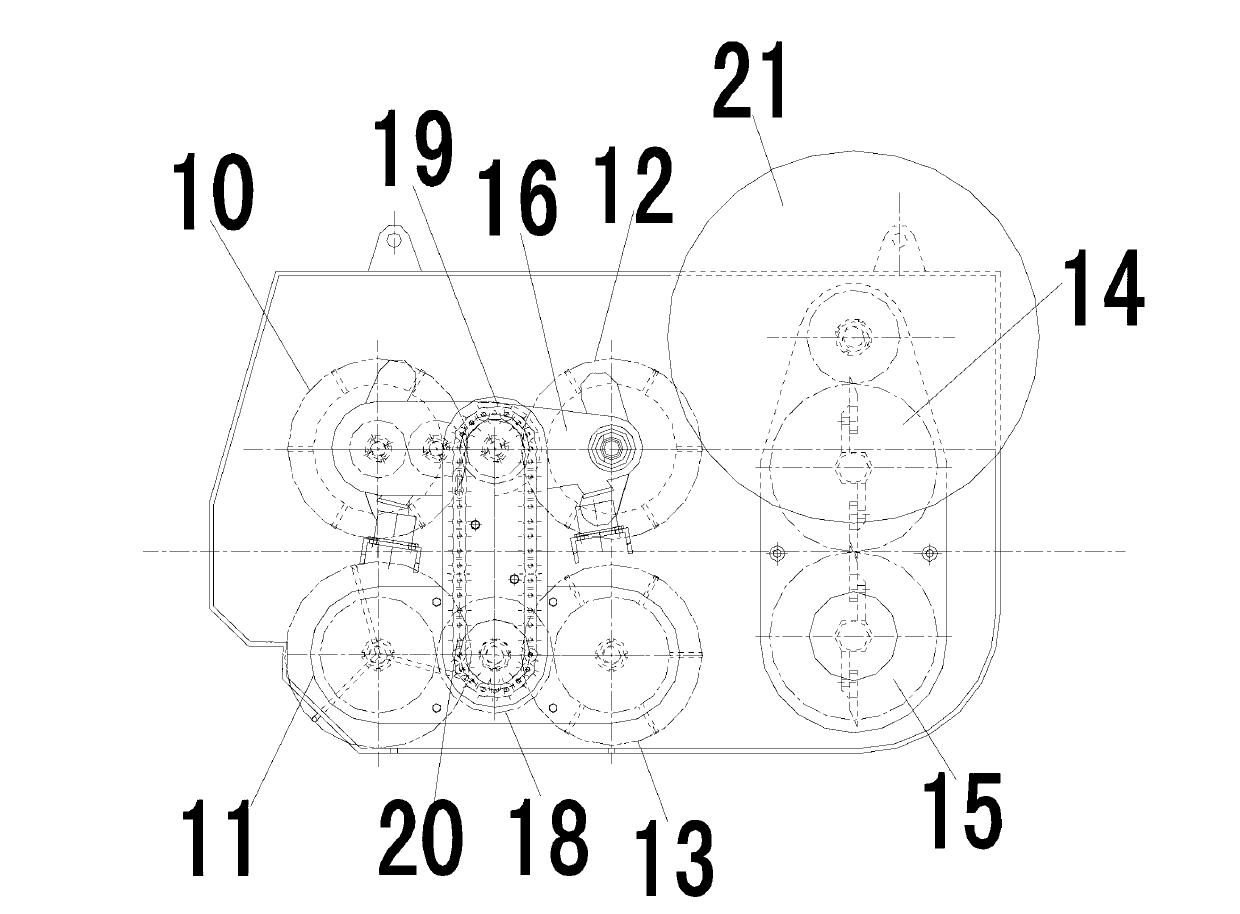

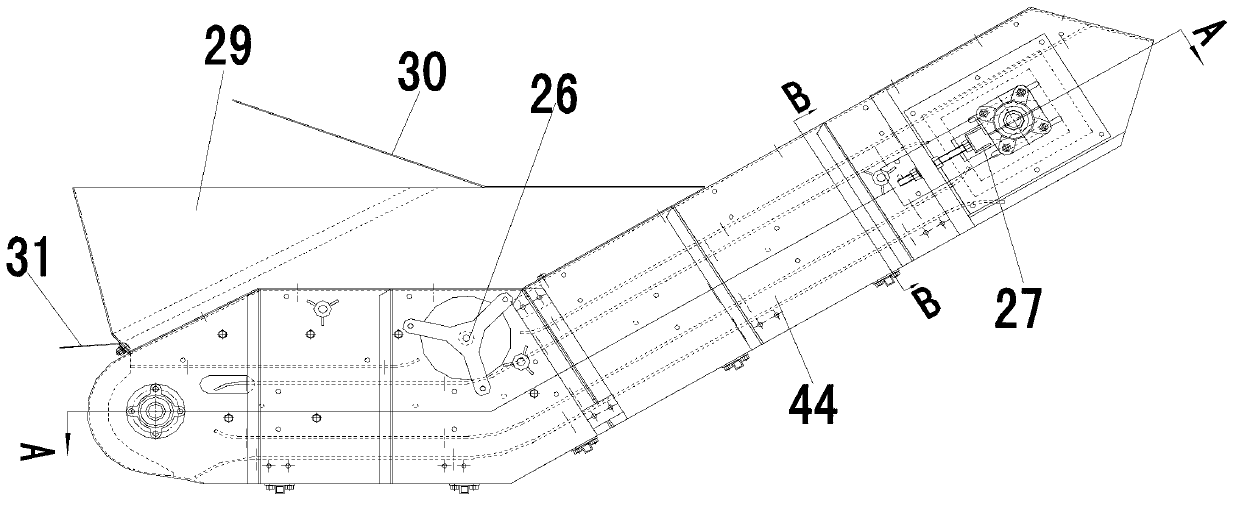

[0032] Such as Figure 1~8 As shown, a sugarcane combine harvester with a new type of logistics transportation, including a spiral divider 2, a knockdown roller 3, a header 4, a primary roller conveying and section cutting device 6, and a secondary screen type conveyor chain for lifting and conveying Device 7, winnowing and miscellaneous removal device 28, delivery arm 9, frame 1, running gear 5, power system, driver's cab 34 and fuel tank 37. Each device is installed on the frame 1 respectively, and gives required power distribution, and power system is made up of engine 35, gear box and hydraulic pump, and engine 35 drives hydraulic pump by gear box, and engine 35 is equipped with cooler 36, cuts Behind the platform 4, there is a primary conveying and section cutting device 6; behind the primary roller conveying and section cutting device 6, there is a secondary screen conveyor chain lifting conveyor 7 for lifting and conveying and removing soil; the secondary screen Above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com