Automatic intelligent deepening controlling system of peanut combine harvester and using method of automatic intelligent deepening controlling system

A technology of intelligent control system and automatic control system, which is applied in the direction of excavator harvester, harvester, application, etc., can solve the problems of uneven depth, unevenness, affecting the effect of peanut harvesting, etc., so as to improve the quality of harvesting and ensure the deep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, various exemplary embodiments will be described in more detail with reference to the accompanying drawings, in which some exemplary embodiments are shown. However, inventive concepts may be embodied in many different forms and should not be construed as limited to the example embodiments set forth herein. Rather, the described aspects are intended to embrace all such alternatives, modifications, and changes that fall within the scope and novel concepts of the present disclosure.

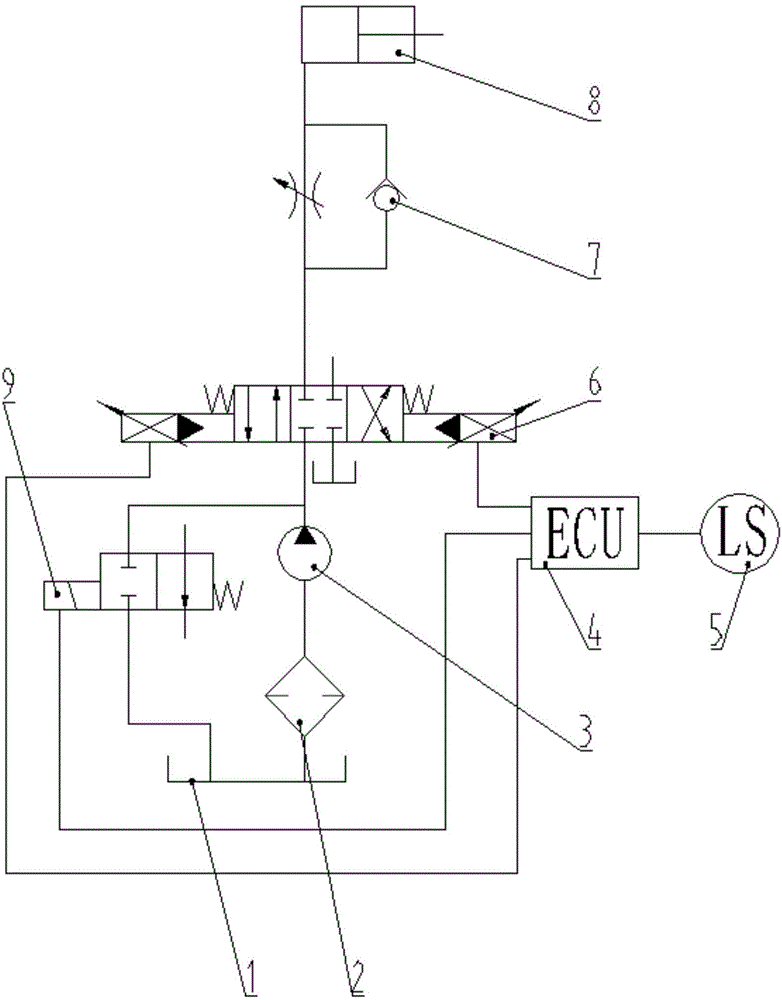

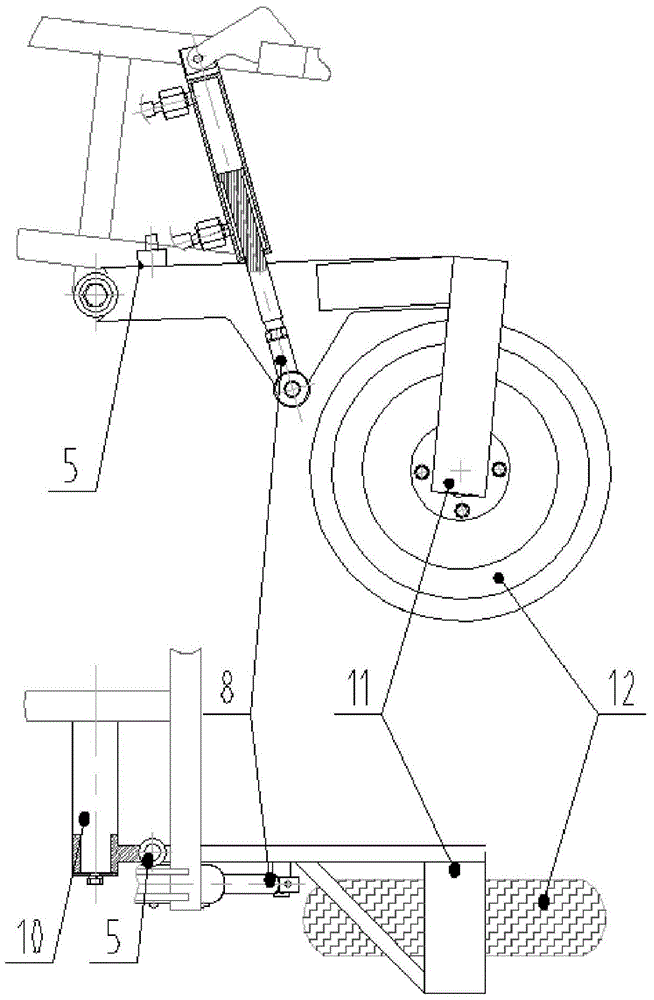

[0026] In the first preferred embodiment of the present invention, a kind of peanut combine harvester is provided with automatic deep-dive intelligent control system, and it comprises:

[0027] Cantilever 10, sinking wheel support 11, sinking wheel 12;

[0028] The sinking wheel 12 is installed on the sinking wheel bracket 11;

[0029] The deep wheel bracket 11 is set on the cantilever 10;

[0030] A control panel, which is used to set the predetermined depth value of the depth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com