Double disc type rotating cropper cradling feeding mode and device

A double-disc type, lawn mower technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of affecting the quality of alfalfa, the decline in the quality of conditioning and large limitations, and achieve the improvement of flattening and conditioning The effect of preventing material blockage and increasing the quality of harvest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structure of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

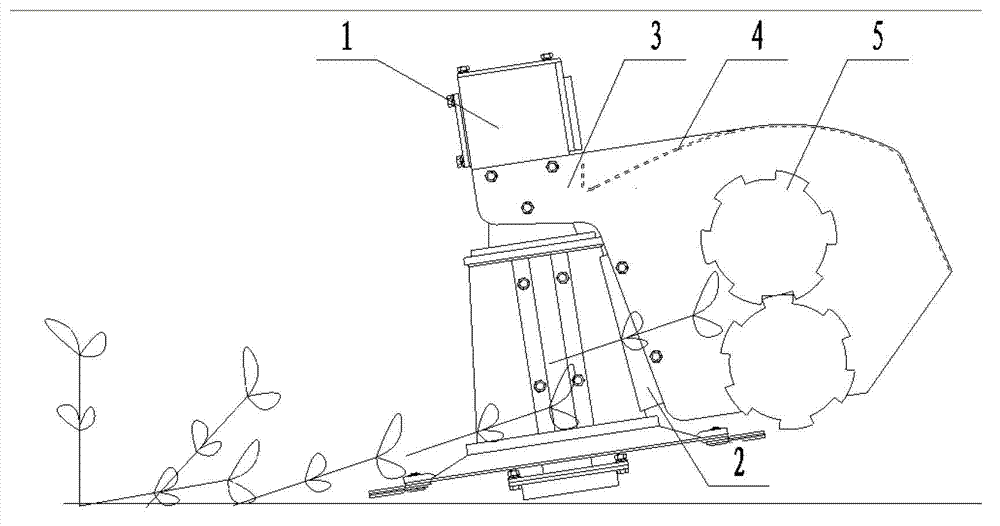

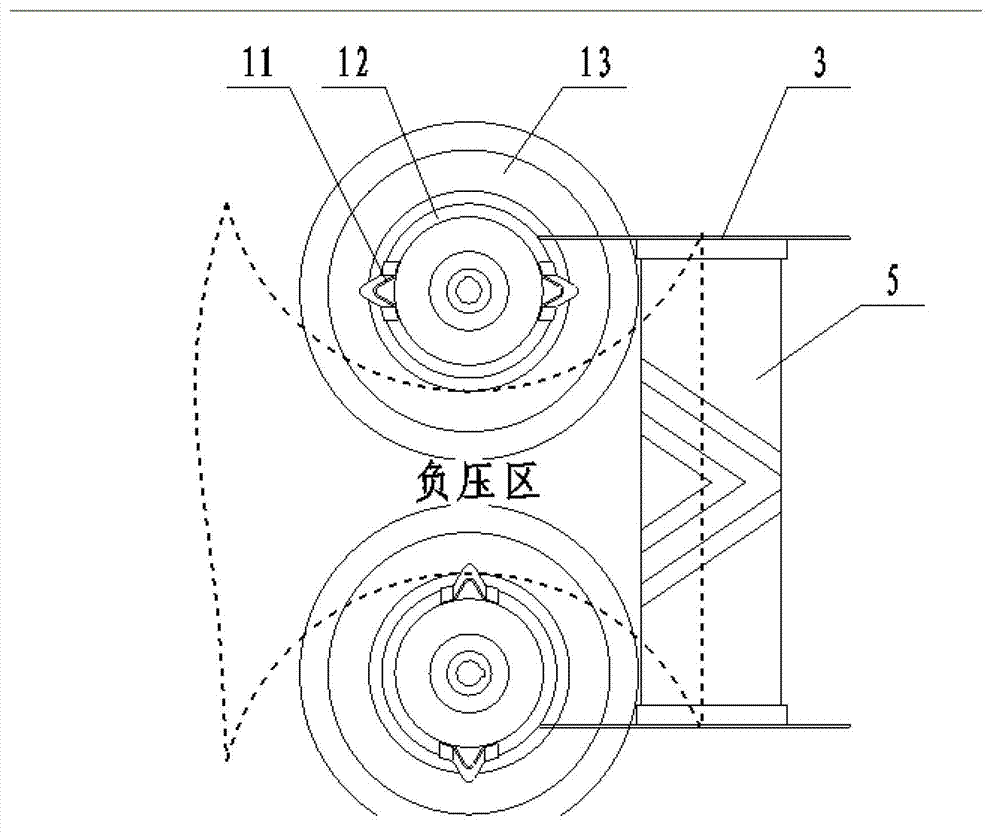

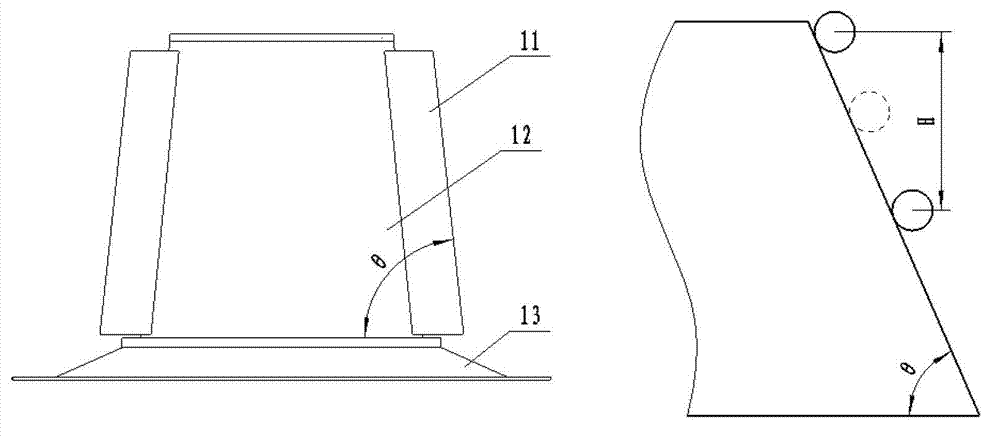

[0024] 1 is a double-disc rotary cutter, 2 is a sealing device, 3 is a side plate device, 4 is a top cover device, 5 is a flattening roller device, 11 is an airflow guide device, 12 is a drum, and 13 is a cutter head. The double-disc rotary cutter (1) is connected with the side plate device (3) by bolts; the flattening roller device (5) is built between the side plate devices (3), and the top cover device (4) is installed on it; the sealing The device (2) is connected to the side plate device (3) by bolts. The airflow grass guiding device (11) is connected to the drum (12) by bolts, and two airflow grass guiding devices (11) are evenly distributed on each drum (12), and are alternately arranged on the two drums (12). The roller (12) is installed on the cutter head (13), the center distance is 600mm, the middle diameter of the roller is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com