Picking head used in tomato harvester

A technology of harvester and picking head, which is applied in the field of picking head, can solve the problems of low production efficiency and unsuitability for crops with vines, etc., and achieve the effect of high work efficiency, reasonable structure and less failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

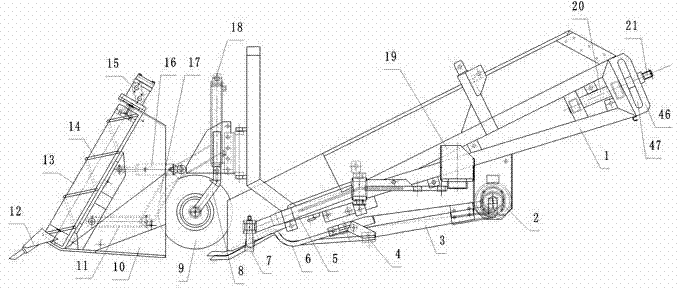

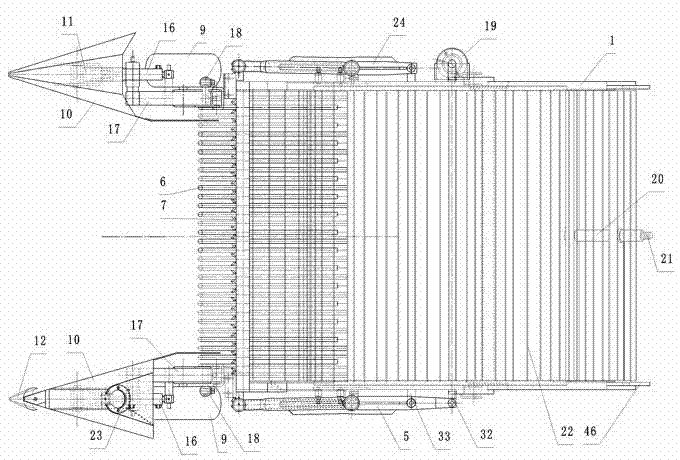

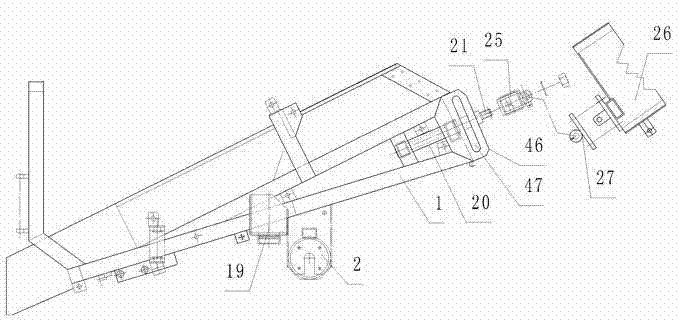

[0038] Example 1: Reference figure 1 — Figure 17 , The embodiment of the present invention is a picking head used on a tomato harvester, which includes a frame 1, a seedling divider 10, a profile wheel 9, a conveying device, a knife mechanism, and a shift fork mechanism. The frame steering mechanism includes a rotating sleeve 20 and a rotating shaft 21 installed at the rear of the frame 1. The two ends of the frame 1 are respectively provided with arc-shaped connecting plates 46. The frame 1 is connected to a bracket 25 through a rotating sleeve 20 and a rotating shaft 21. The middle of the bracket 25 is hinged with the main frame 26 of the locomotive, and both ends of the frame 25 are hinged with the arc-shaped connecting plates 46 of the frame 1, respectively. In addition, the two ends of the frame 25 are respectively connected with the main frame 26 of the locomotive through a fixed seat 27.

[0039] The rotating shaft 21 in the frame rotating mechanism is provided with thr...

Embodiment 2

[0053] Example 2: Referring to the drawings, compared with Embodiment 1, the difference is that the foremost end of the seedling divider is also provided with a guide head 12, the guide head 12 can be made of a metal shaft with a cone-shaped sector, the guide head 12 Use can facilitate the separation of fruit seedlings.

Embodiment 3

[0054] Example 3: With reference to the drawings, compared with Embodiment 1, the difference lies in that the crop separator tube 13 and the rotating motor 15 are not provided on the seedling divider 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com