Shield tunnel portal sealing device and shield tunnel portal sealing method

A technology of shield tunnel and sealing device, which is applied to tunnels, tunnel lining, shaft equipment, etc., can solve problems such as inconvenience in construction, and achieve the effects of preventing water seepage, preventing water and soil gushing, and having strong shape plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

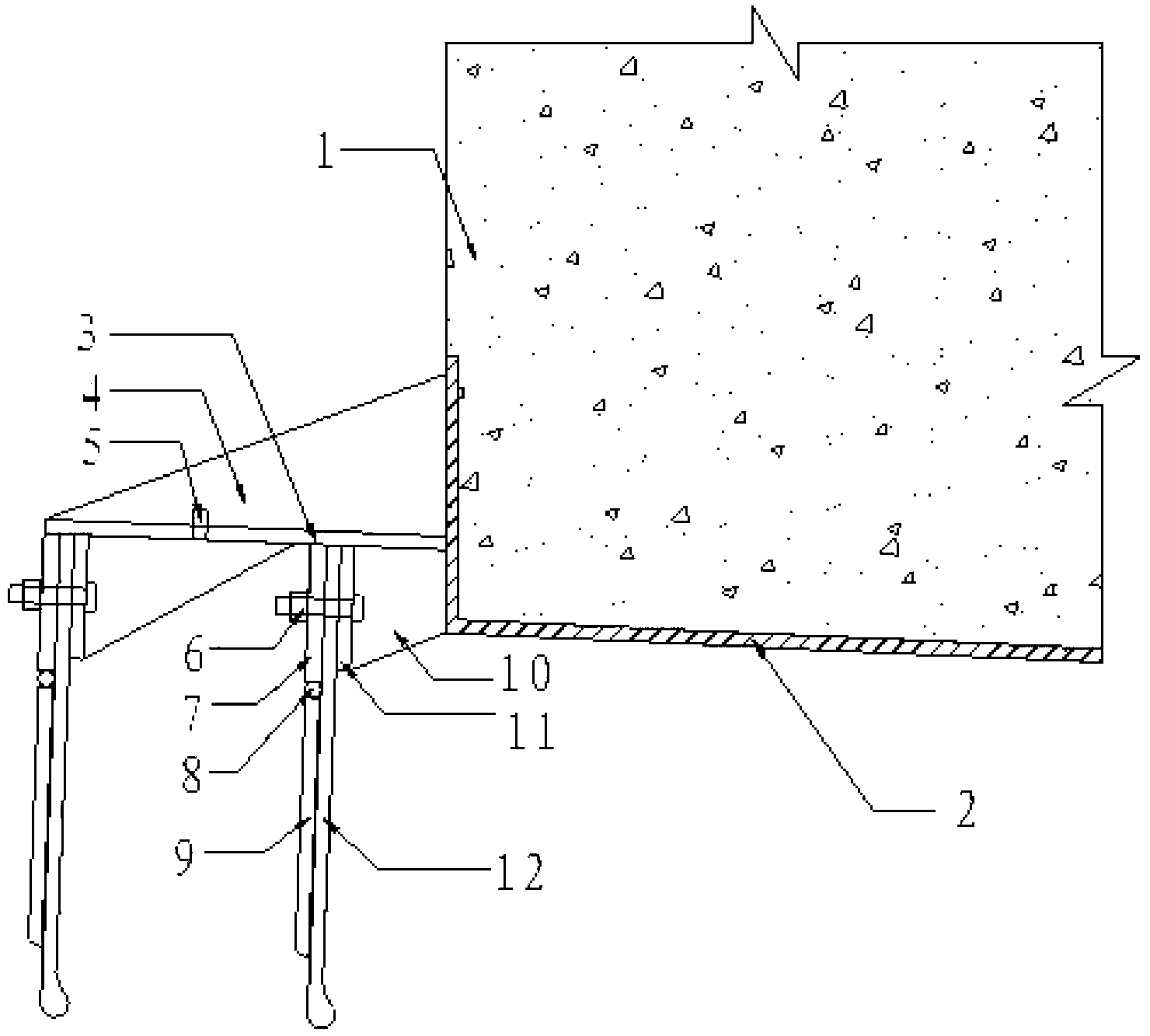

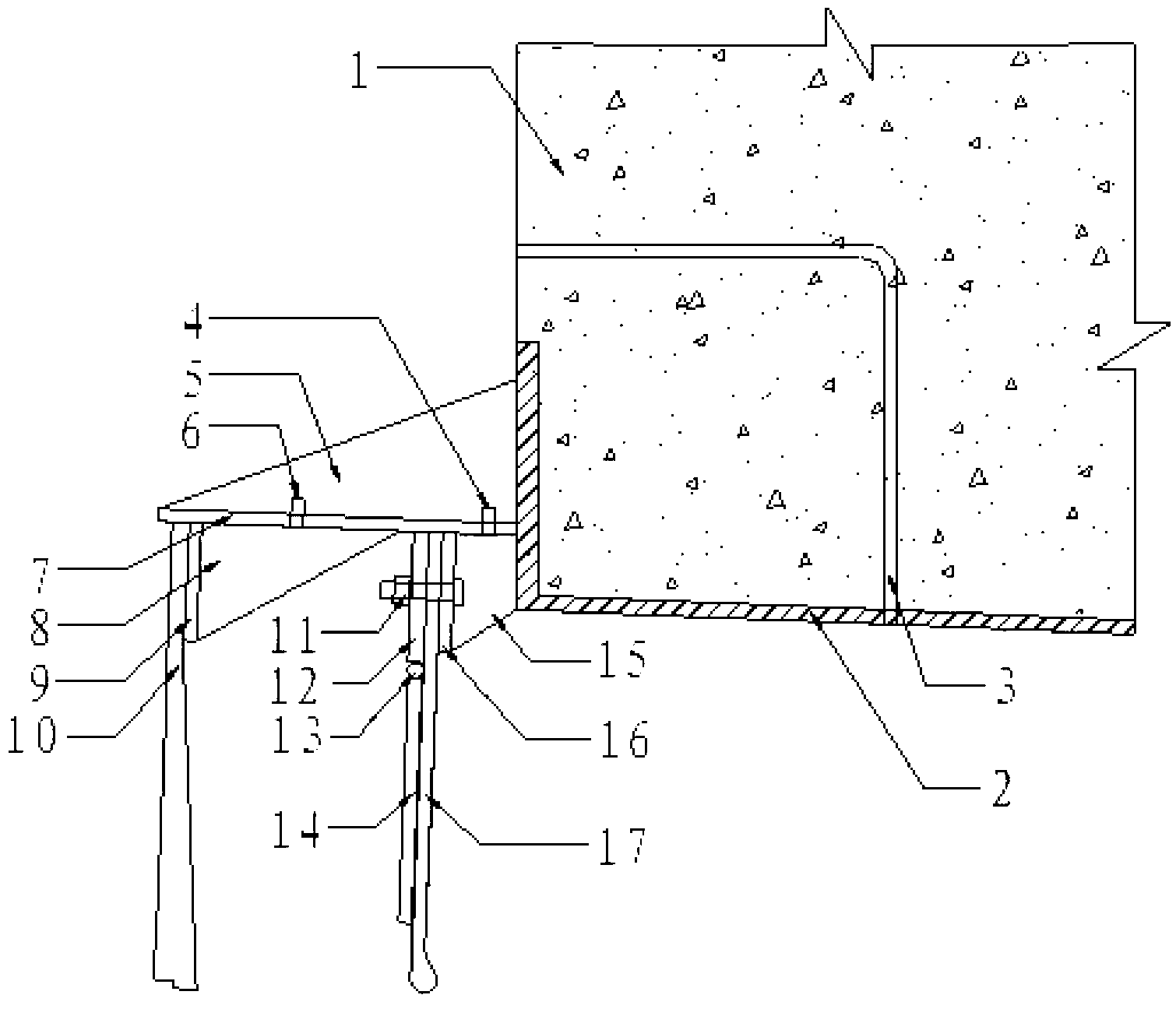

[0022] Such as figure 2 As shown, the present invention comprises an inner lining wall 1, and the inner lining wall 1 is provided with a pre-embedded steel ring 2, and the pre-embedded steel ring 2 is provided with a sealing box, and the sealing box includes a sealing steel ring 7, and the sealing steel ring 7 The front end face is sealed and welded with the pre-embedded steel ring 2, and the sealed steel ring 7 is provided with two waterproof structures at intervals along the axial direction, and the two waterproof structures are arranged radially along the sealed steel ring. The two waterproof structures are wire brushes 10 and cord rubber plates 17 respectively. On the sealing steel ring 7, a number of grease injection holes 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com