Shield tunneling machine and method for controlling same

A technology of shield machine and control valve, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., which can solve problems such as inability to discharge slag, difficulty in discharging slag liquid in excavation bins, and affecting construction efficiency, and achieve the effect of preventing gushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

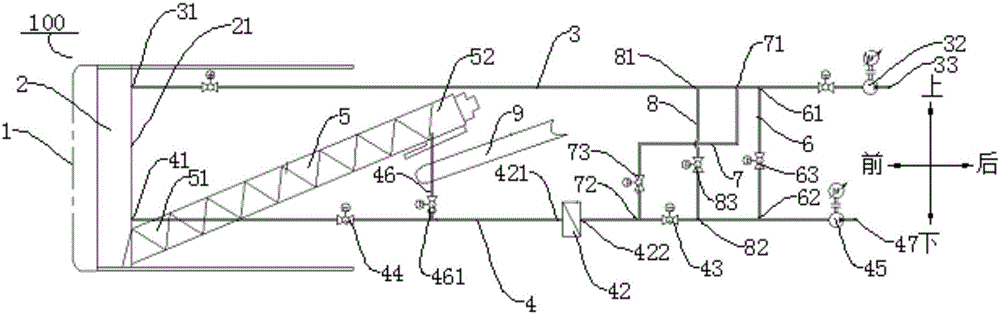

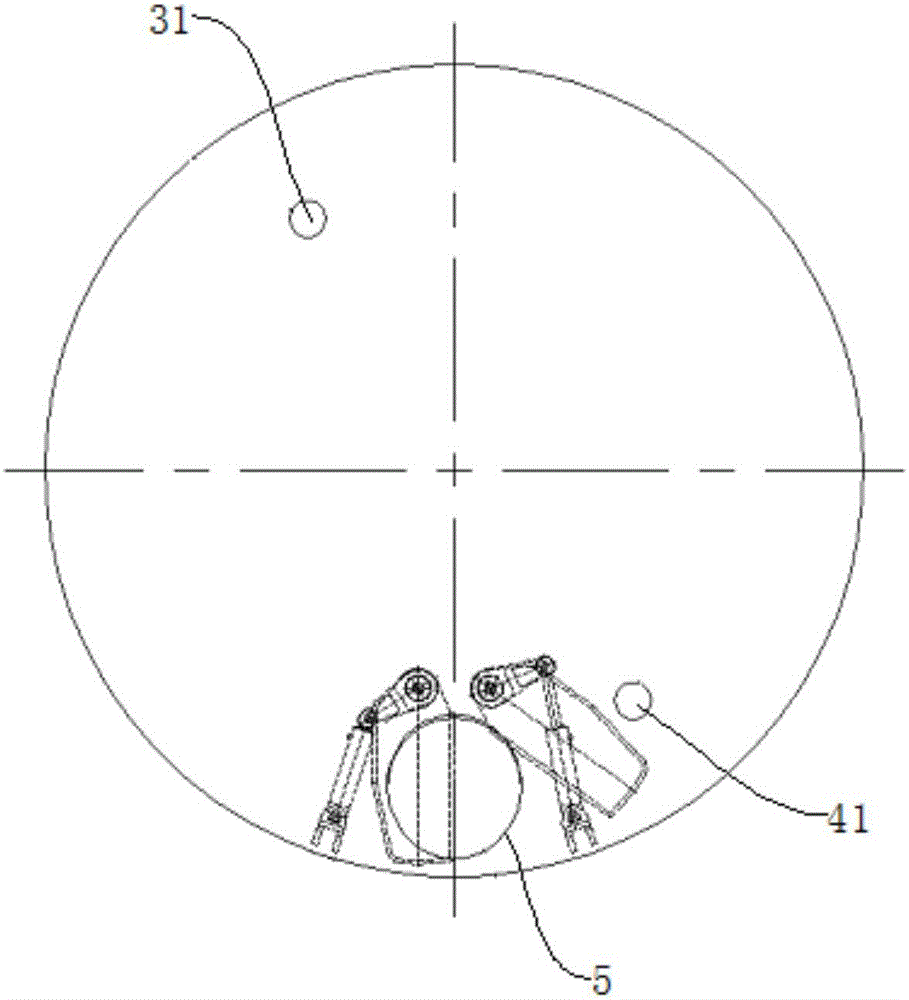

[0041] Refer below figure 1 and figure 2 A shield machine 100 according to an embodiment of the present invention is described.

[0042] Such as figure 1 and figure 2As shown, the shield machine 100 according to the embodiment of the present invention includes a cutter head 1 , a soil bin 2 , a slurry inlet pipe 3 , a slurry discharge pipe 4 , a screw conveyor 5 , a slurry discharge branch pipe 46 and a belt conveyor 9 .

[0043] Specifically, soil bin 2 is located at the rear side of cutter head 1 (as figure 1 shown rear side), the slurry inlet outlet 31 of the slurry inlet pipe 3 communicates with the soil bin 2 and is positioned at the top of the soil b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com