Cleaning device inside solar energy heat collection pipe

A technology for solar collector tubes and cleaning equipment, which is applied to the field of cleaning equipment inside the solar collector tubes, and can solve the problems of easy movement of the collector tubes and incomplete cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

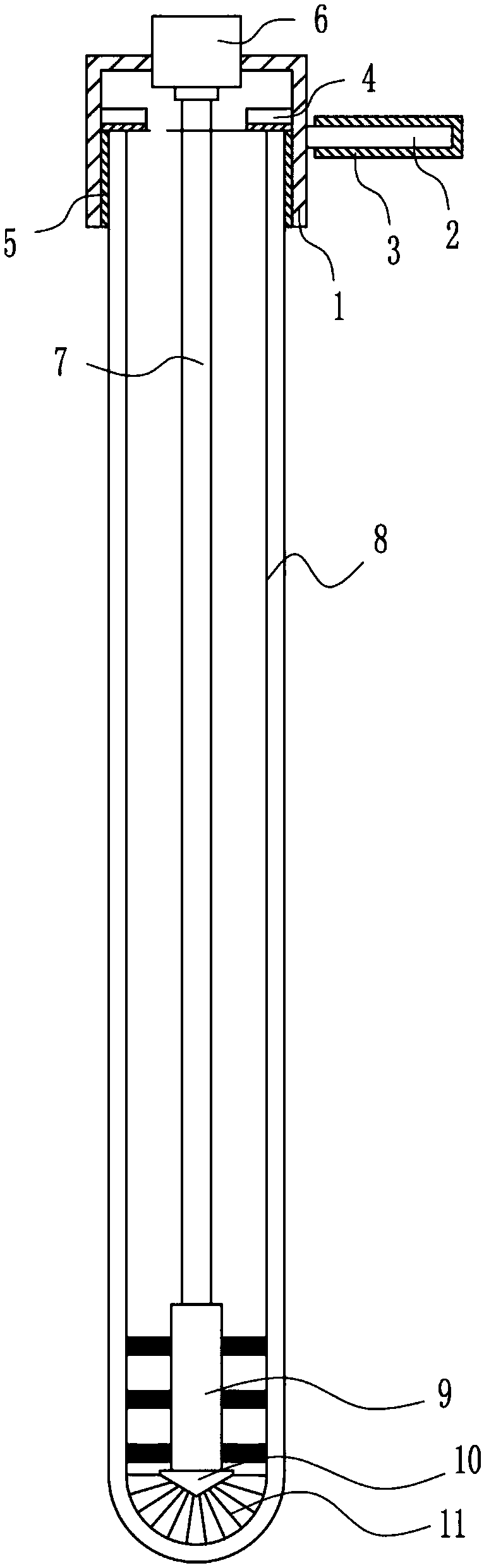

Embodiment 1

[0020] A kind of internal cleaning equipment of solar heat collecting tube, such as Figure 1-3 As shown, it includes a frame body 1, a handle 2, a rubber sleeve 3, a limit block 4, a rubber plate 5, a motor 6, a rubber rotating rod 7, a roller brush 9, a tapered block 10 and a brush 11. A handle 2 is installed in the middle part of the right side, and a rubber sleeve 3 is arranged on the handle 2. Limiting blocks 4 are installed on the upper left side and the upper right side of the frame body 1. The lower part of the side is equipped with a rubber plate 5, and a motor 6 is embedded in the middle of the top of the frame body 1. The output shaft of the motor 6 is connected to a rubber rotating rod 7 through a coupling. The rubber rotating rod 7 is located under the frame body 1, and the rubber rotating rod 7 A roller brush 9 is installed at the bottom of the rod 7, and a tapered block 10 is installed at the bottom of the roller brush 9, and a hairbrush 11 is installed on the o...

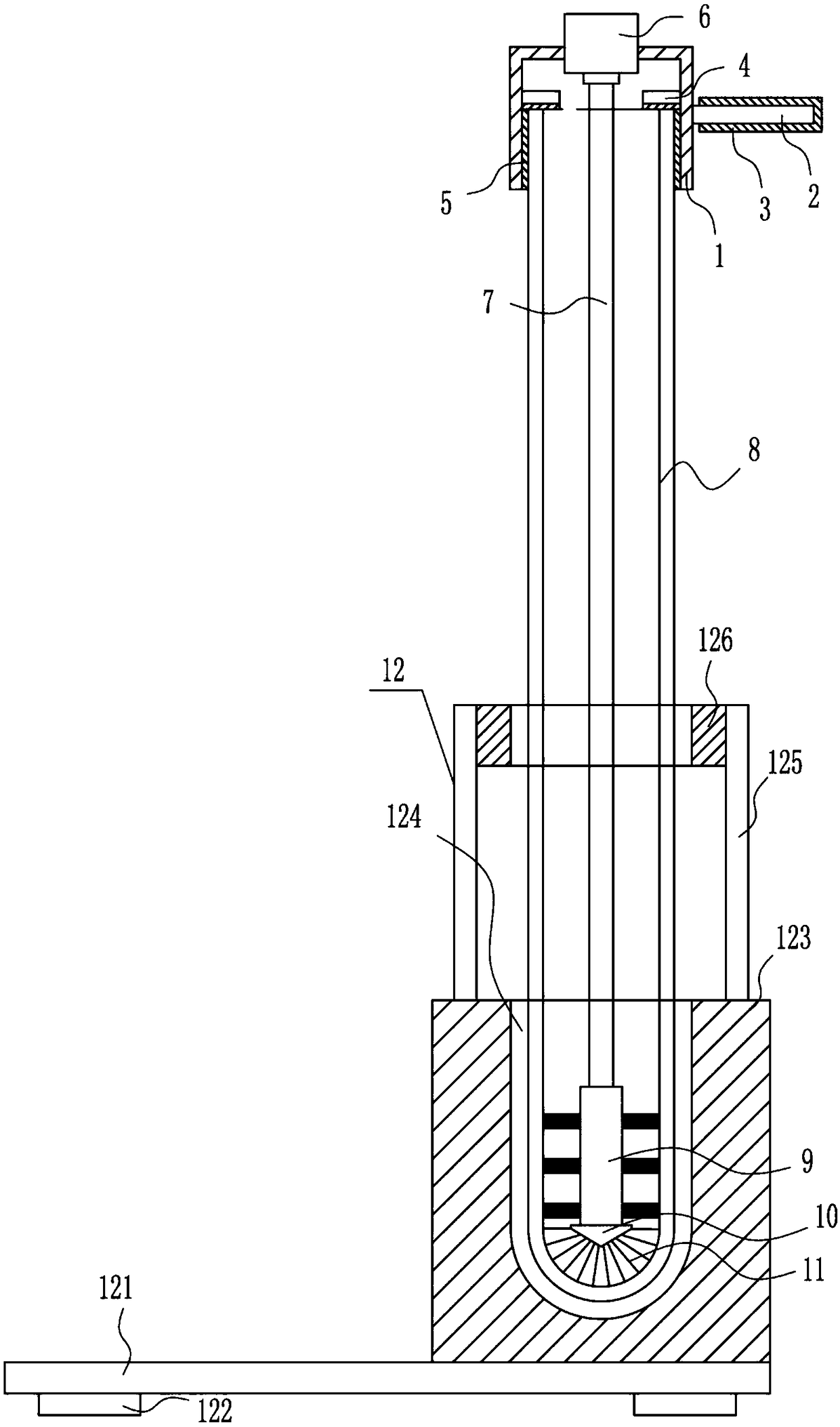

Embodiment 2

[0022] A kind of internal cleaning equipment of solar heat collecting tube, such as Figure 1-3 As shown, it includes a frame body 1, a handle 2, a rubber sleeve 3, a limit block 4, a rubber plate 5, a motor 6, a rubber rotating rod 7, a roller brush 9, a tapered block 10 and a brush 11. A handle 2 is installed in the middle part of the right side, and a rubber sleeve 3 is arranged on the handle 2. Limiting blocks 4 are installed on the upper left side and the upper right side of the frame body 1. The lower part of the side is equipped with a rubber plate 5, and a motor 6 is embedded in the middle of the top of the frame body 1. The output shaft of the motor 6 is connected to a rubber rotating rod 7 through a coupling. The rubber rotating rod 7 is located under the frame body 1, and the rubber rotating rod 7 A roller brush 9 is installed at the bottom of the rod 7, and a tapered block 10 is installed at the bottom of the roller brush 9, and a hairbrush 11 is installed on the o...

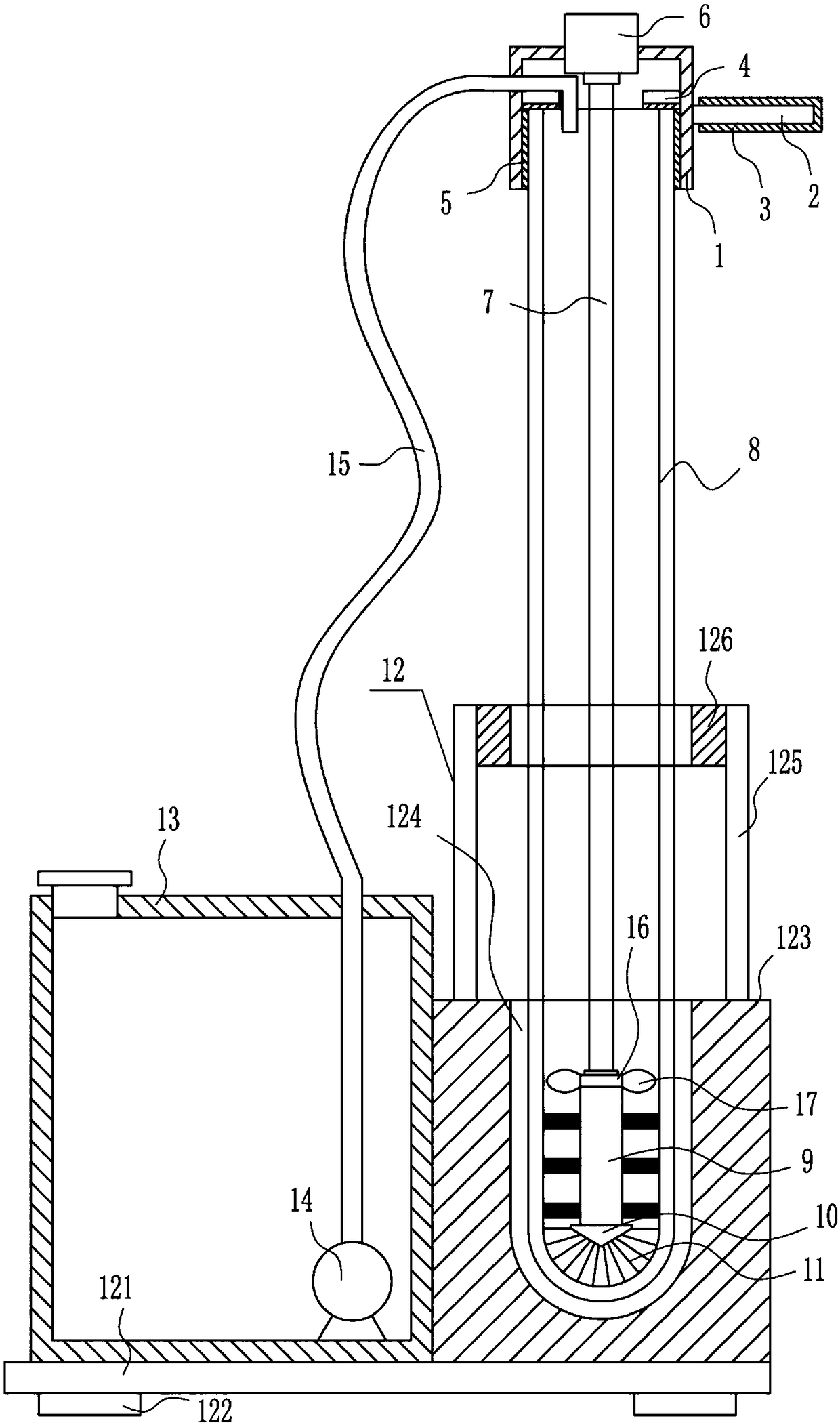

Embodiment 3

[0025] A kind of internal cleaning equipment of solar heat collecting tube, such as Figure 1-3 As shown, it includes a frame body 1, a handle 2, a rubber sleeve 3, a limit block 4, a rubber plate 5, a motor 6, a rubber rotating rod 7, a roller brush 9, a tapered block 10 and a brush 11. A handle 2 is installed in the middle of the right side, and a rubber sleeve 3 is arranged on the handle 2. Limiting blocks 4 are installed on the upper left side and the upper right side of the frame 1, and the bottom of the limiting block 4 is connected to the left and right sides of the frame 1. The lower part of the side is equipped with a rubber plate 5, and a motor 6 is embedded in the middle of the top of the frame body 1. The output shaft of the motor 6 is connected to a rubber rotating rod 7 through a coupling. The rubber rotating rod 7 is located under the frame body 1, and the rubber rotating rod 7 A roller brush 9 is installed at the bottom of the rod 7, and a tapered block 10 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com