Patents

Literature

75results about How to "Does not affect the cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass cleaner and application thereof

InactiveCN102181326AEfficient removalImprove decontamination abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEngineeringCleansing Agents

The invention provides a glass cleaner. The cleaner comprises a nonionic surfactant, an anionic surfactant, a corrosion inhibitor, an antifreezing film-forming agent, a lubricant and a solvent. The invention also provides application of the glass cleaner to the cleaning of front windshields of trains, in particular application of the glass cleaner to the cleaning of front windshields of motor trains. The cleaner has extremely strong decontamination capacity, and can quickly and effectively remove pollutants which appear on windshields of trains running at a high speed; the cleaner has higher ambient temperature adaptability, and can be used at the temperature of between minus 40 and 60 DEG C; the pH value is 6.8 to 7.2, and the cleaner has lower corrosivity; the cleaner has high lubricity and can prevent the windshields from being bruised; an antifreezing film-forming component is added and can achieve the effects of anti-icing and demisting; and the cleaner does not contain components which are toxic or irritant to human bodies such as methanol, ammonia water and the like.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

Cleaning agent for molybdenum aluminum molybdenum coated glass

ActiveCN102586035AEfficient removalImprove decontamination abilityNon-ionic surface-active compoundsDetergent compounding agentsActive agentCleansing Agents

The invention discloses a cleaning agent for molybdenum aluminum molybdenum coated glass, which comprises the following components by weight: 3-8% of anionic surfactants, 10-30% of nonionic surfactants, 0.2-3% of corrosion inhibitors, 10-30.25% of cosolvents, 5-15% of organic solvent, 0.2-0.5% of chelants and 37.35-64.1% of deionized water. The cleaning agent for the molybdenum aluminum molybdenum coated glass is strong in dirt-removing capacity, wide in environmental suitability, good in stability, low in foam, easy to rinse, good in wettability, free of damage to glass surface, elements such as phosphorus and silicium, peculiar smell, toxicity, corrosivity and pollution to environment, safe, reliable, incombustible, low in cost, convenient to transport and store and low in cleaning cost. In addition, the cleaning agent for the molybdenum aluminum molybdenum coated glass does not explode.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

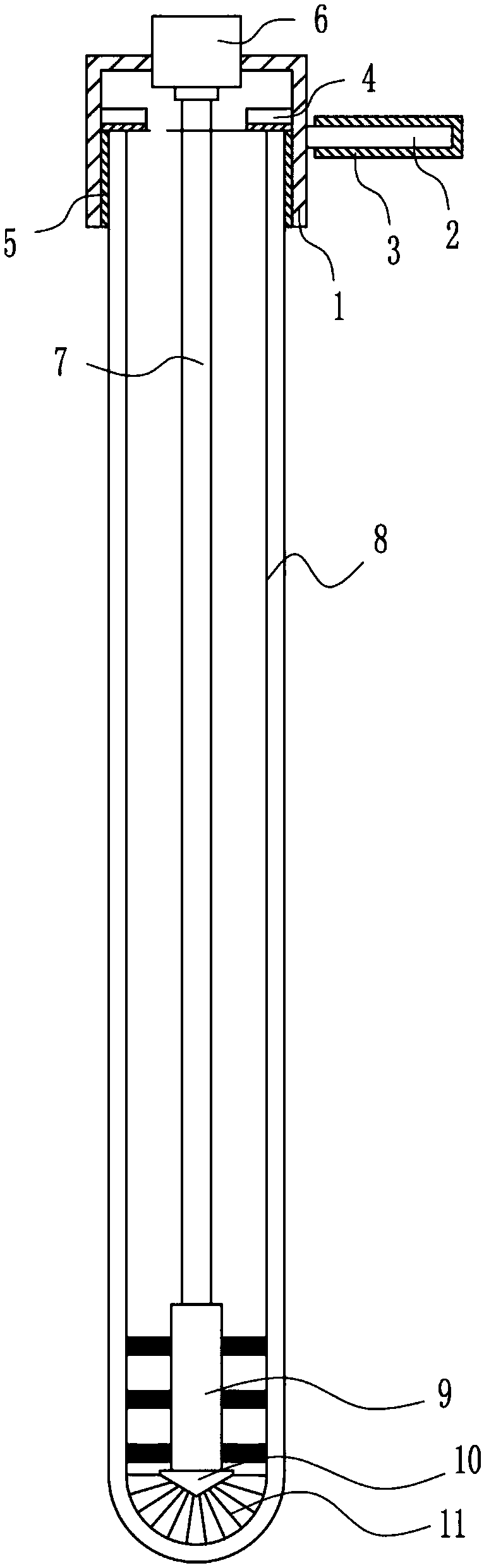

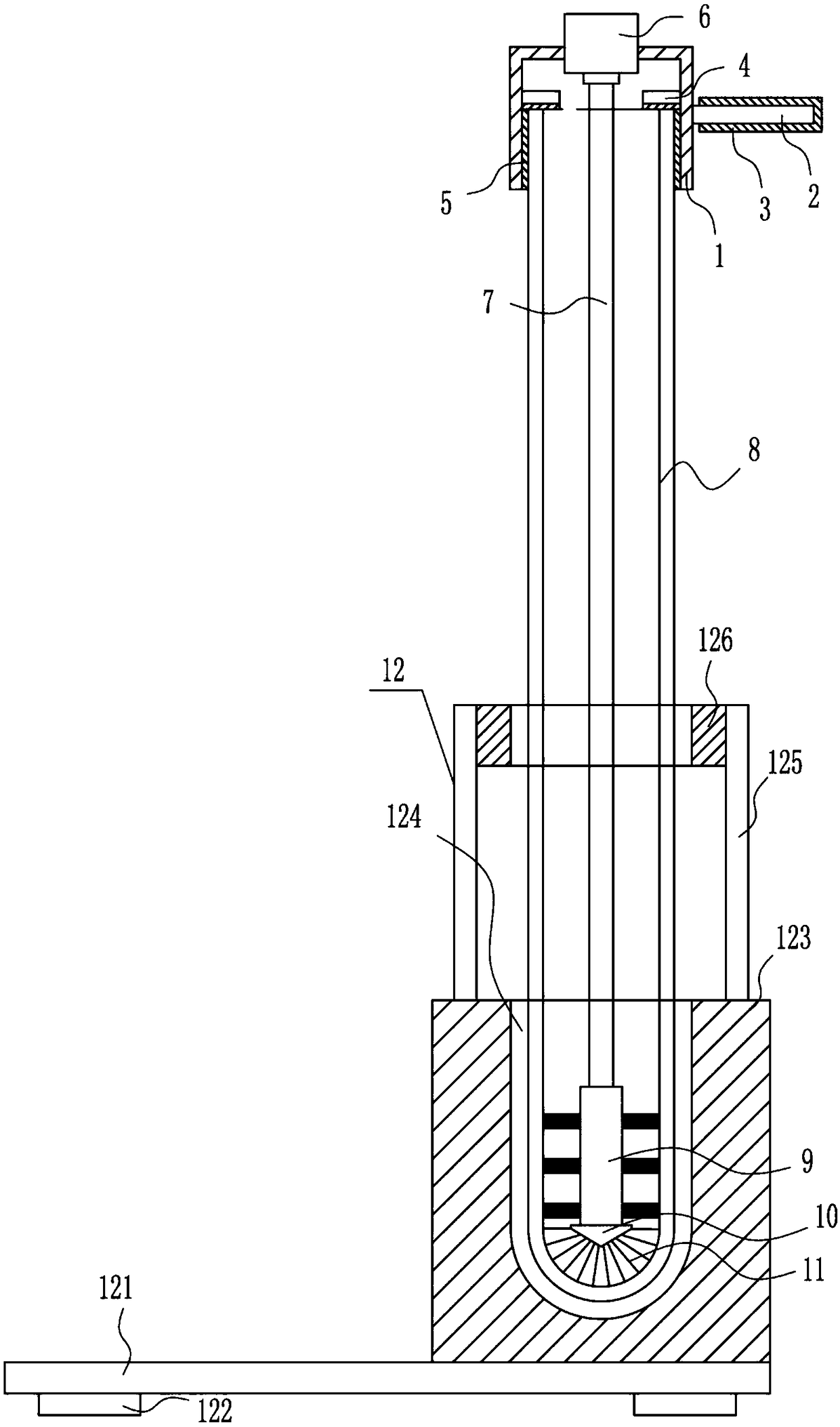

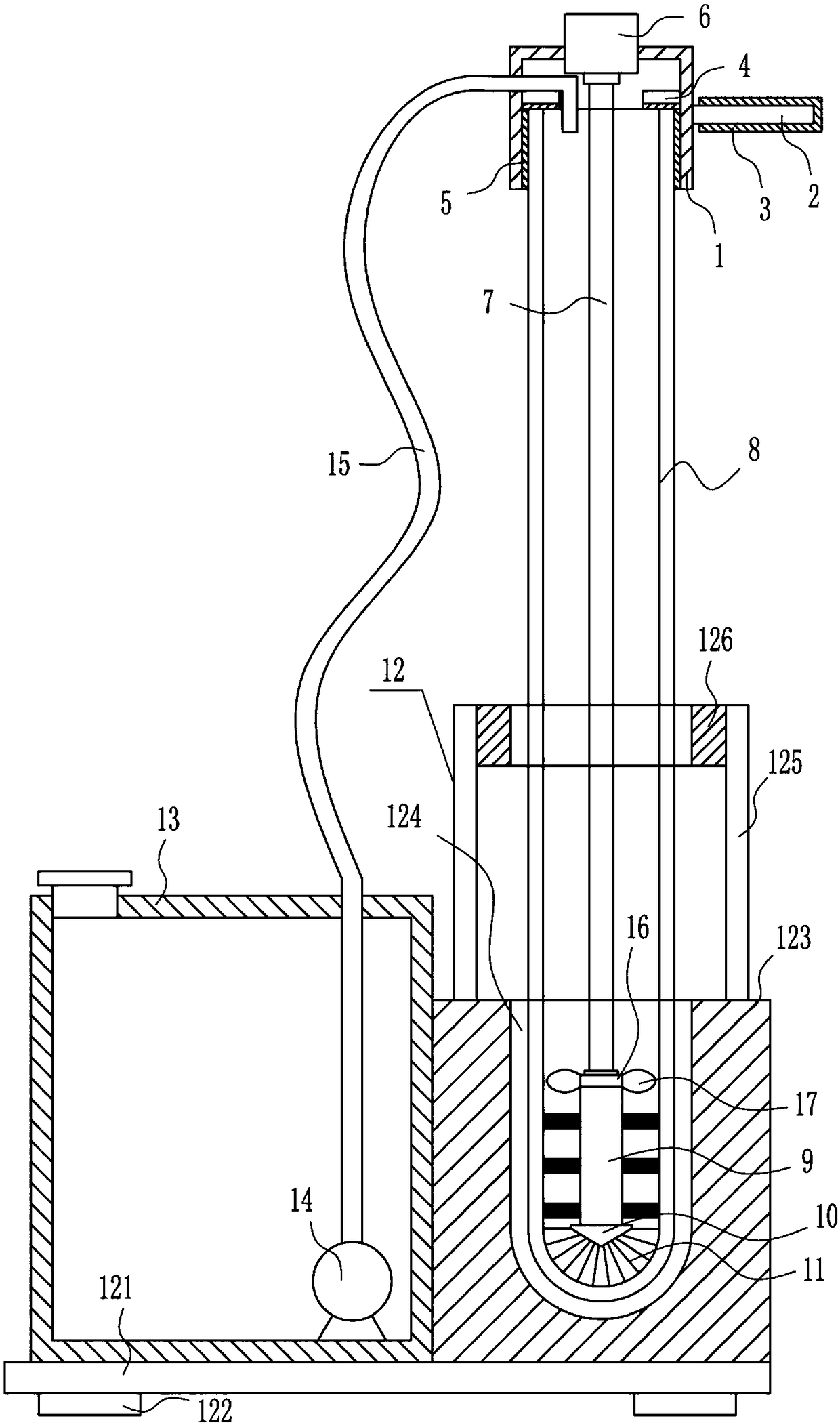

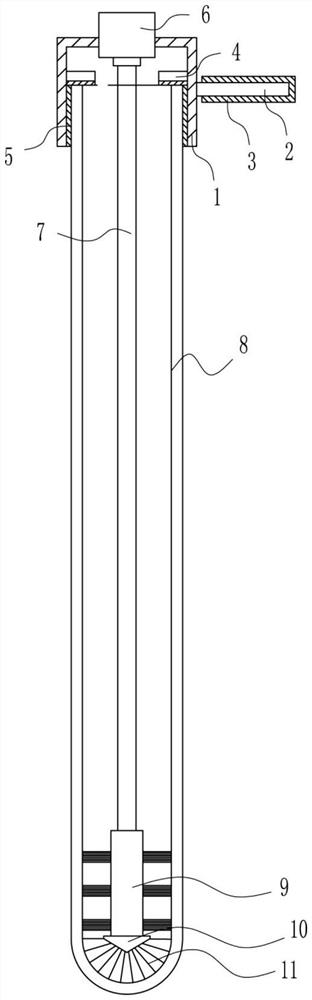

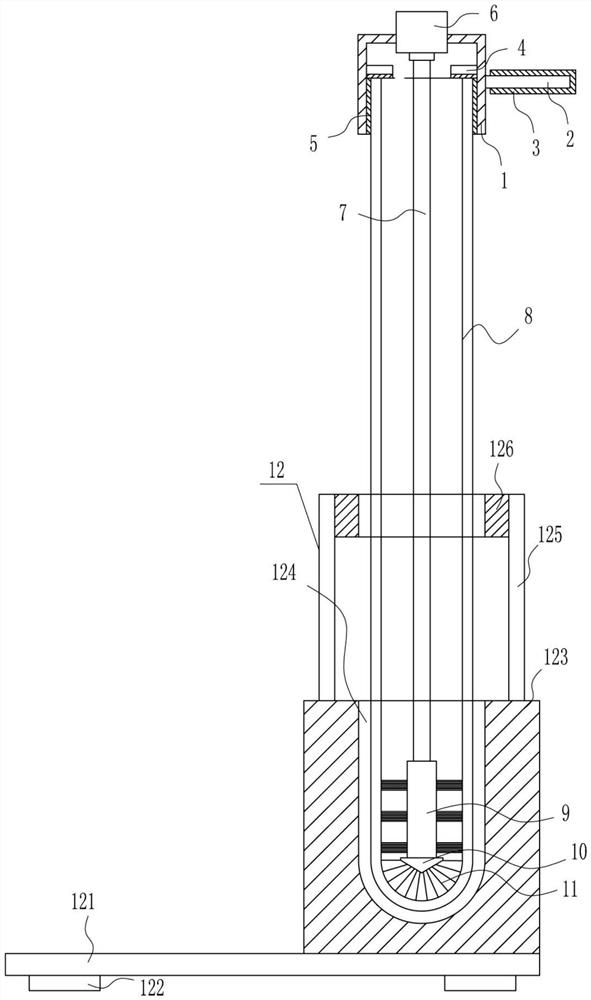

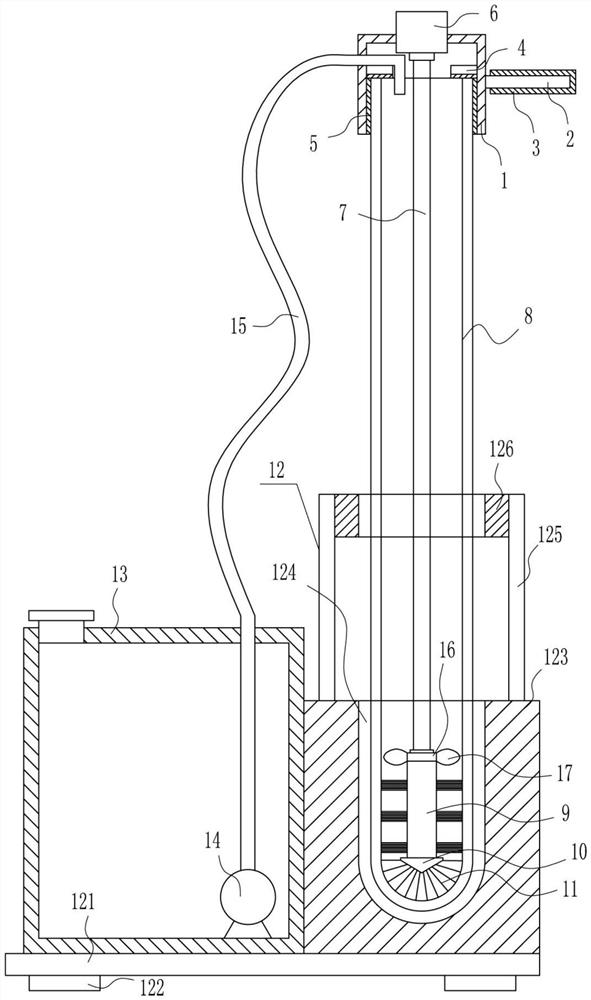

Cleaning device inside solar energy heat collection pipe

The invention relates to a cleaning derive, in particular to a cleaning device inside a solar energy heat collection pipe. The cleaning device inside the solar energy heat collection pipe is comprehensive in cleaning, can place the heat collection pipe well without affecting cleaning. According to the technical scheme, the cleaning device inside the solar energy heat collection pipe comprises a frame body, a handle, a rubber sleeve, limiting blocks, rubber plates, a motor, a rubber rotating rod and the like. The handle is installed on the middle part of the right side face outside the frame body, the rubber sleeve is arranged on the handle, the limiting blocks are installed on the upper portions of the left and right side faces in the frame body, and the rubber plates are installed on thebottom portions of the limiting blocks and the left and right side faces in the frame body. According to the cleaning device inside the solar energy heat collection pipe, the heat collection pipe canbe placed steadily through a support device without affecting cleaning; water is not needed to be continuously poured into the heat collection pipe for cleaning by people through a water injection device, convenience and swiftness are achieved, comprehensive cleaning is achieved, the heat collection pipe can be placed well, and the effect of cleaning is not affected.

Owner:杭州全要素科技服务有限公司

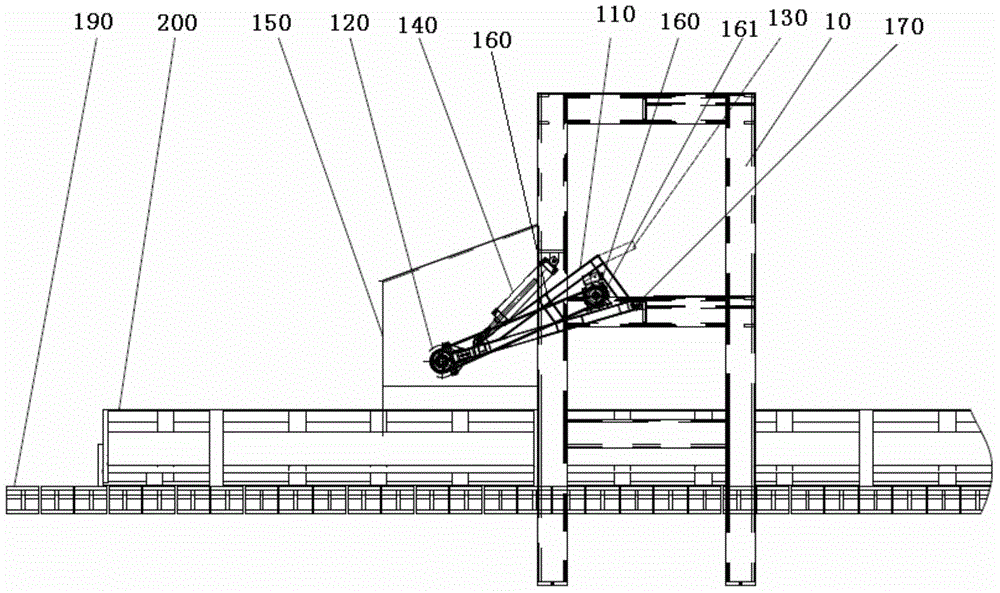

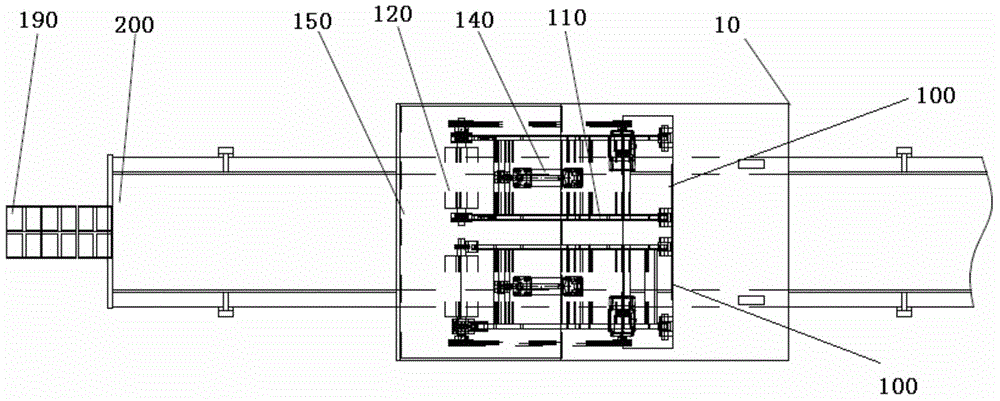

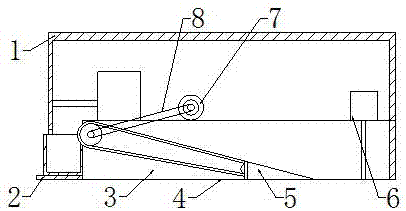

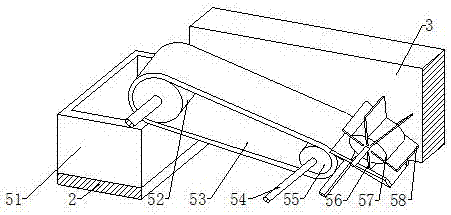

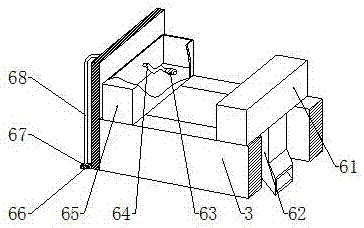

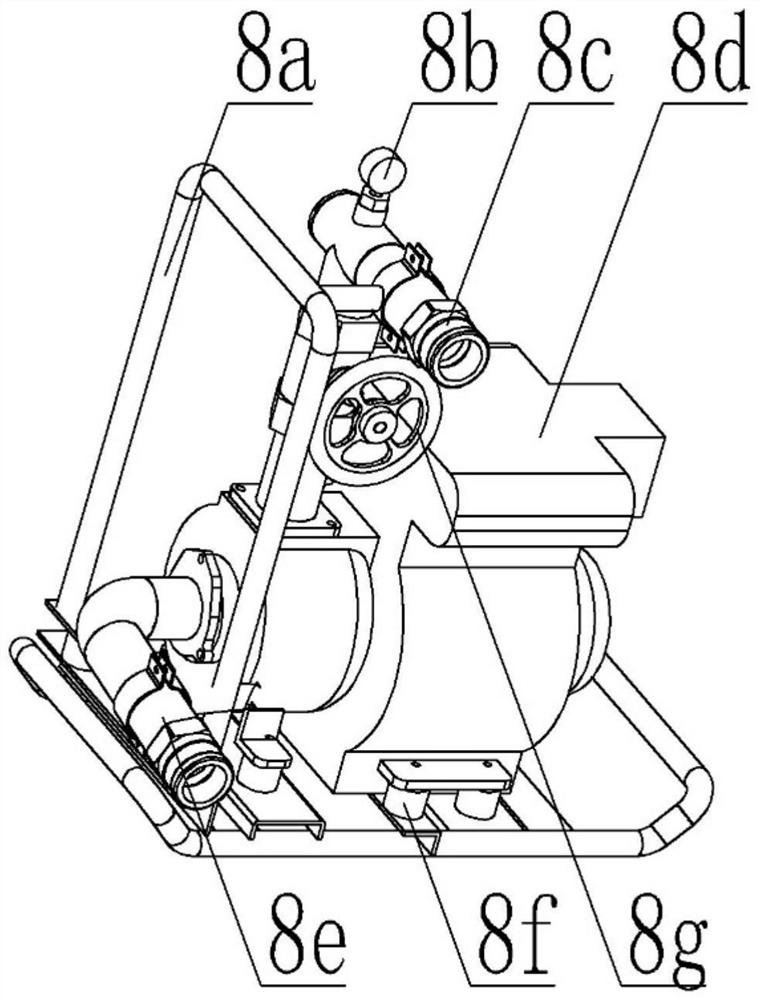

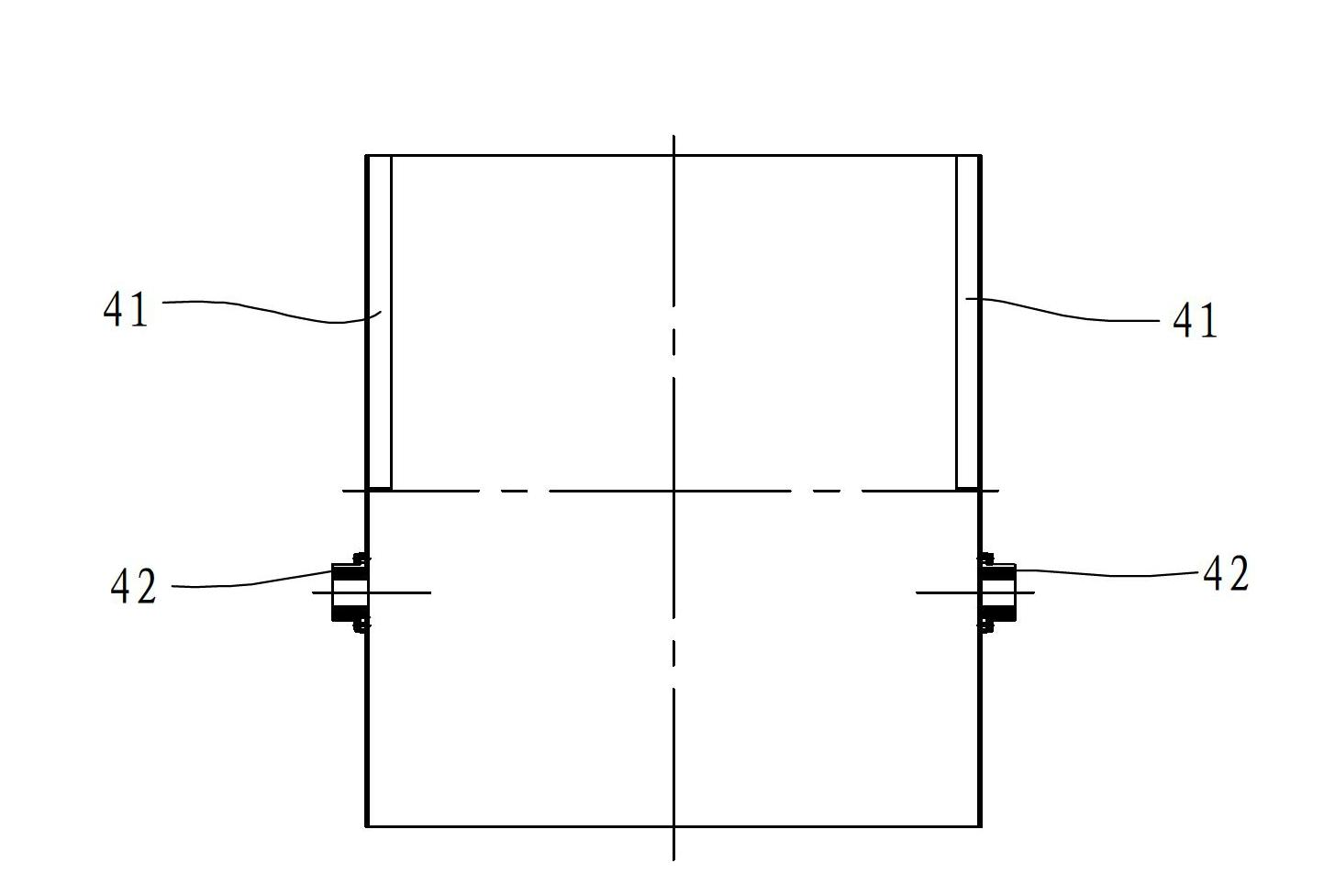

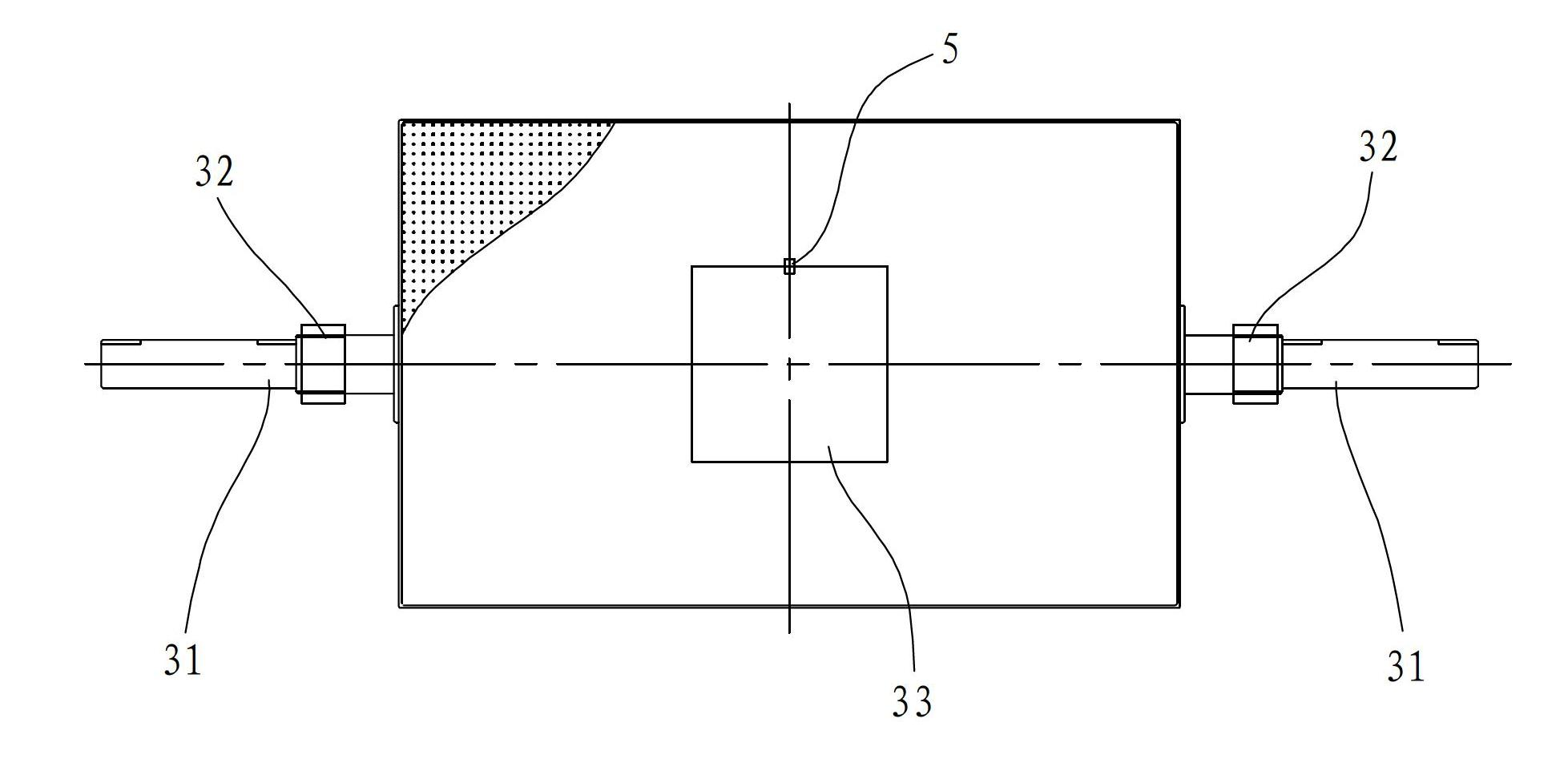

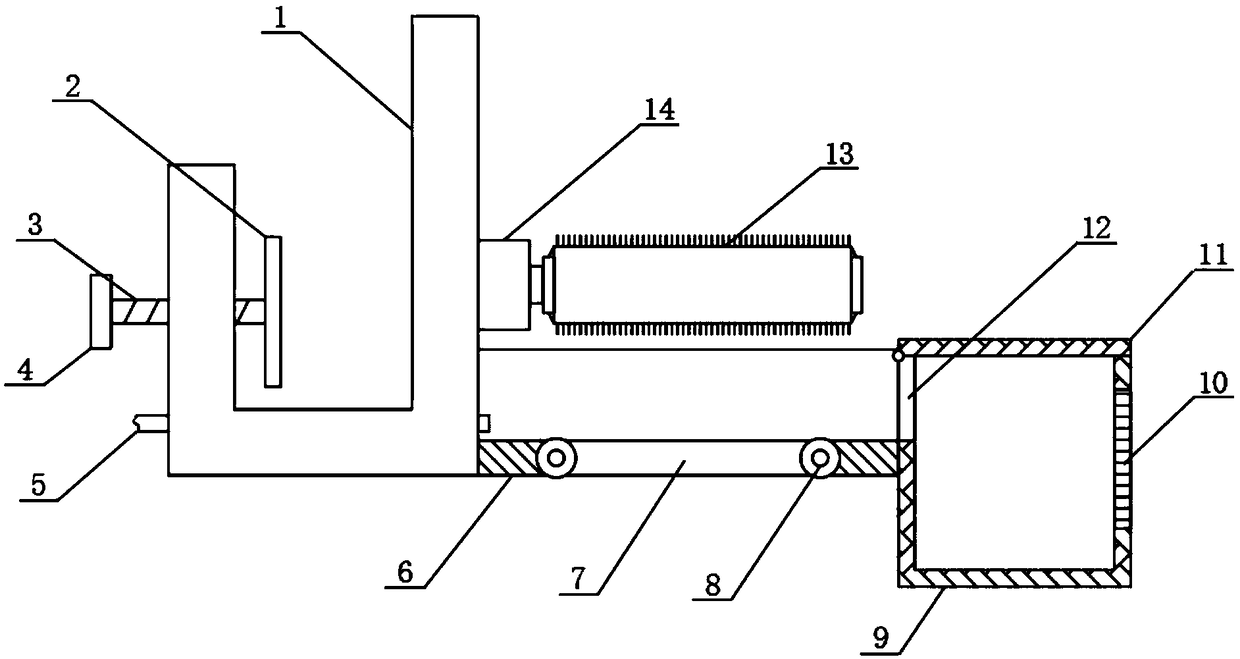

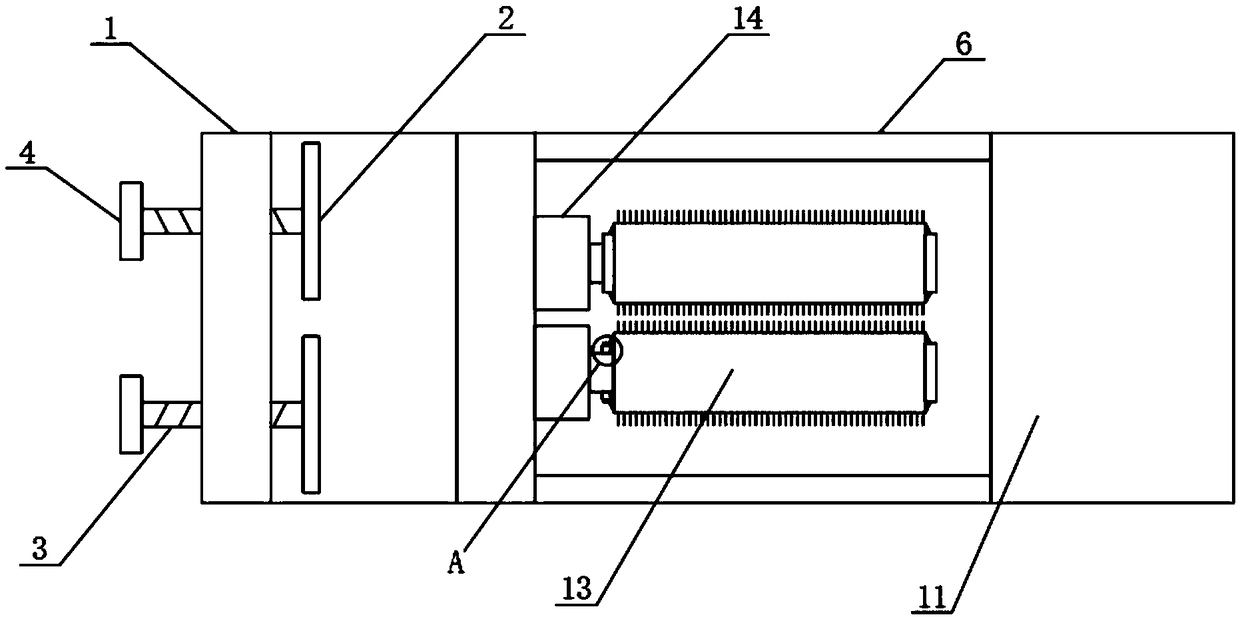

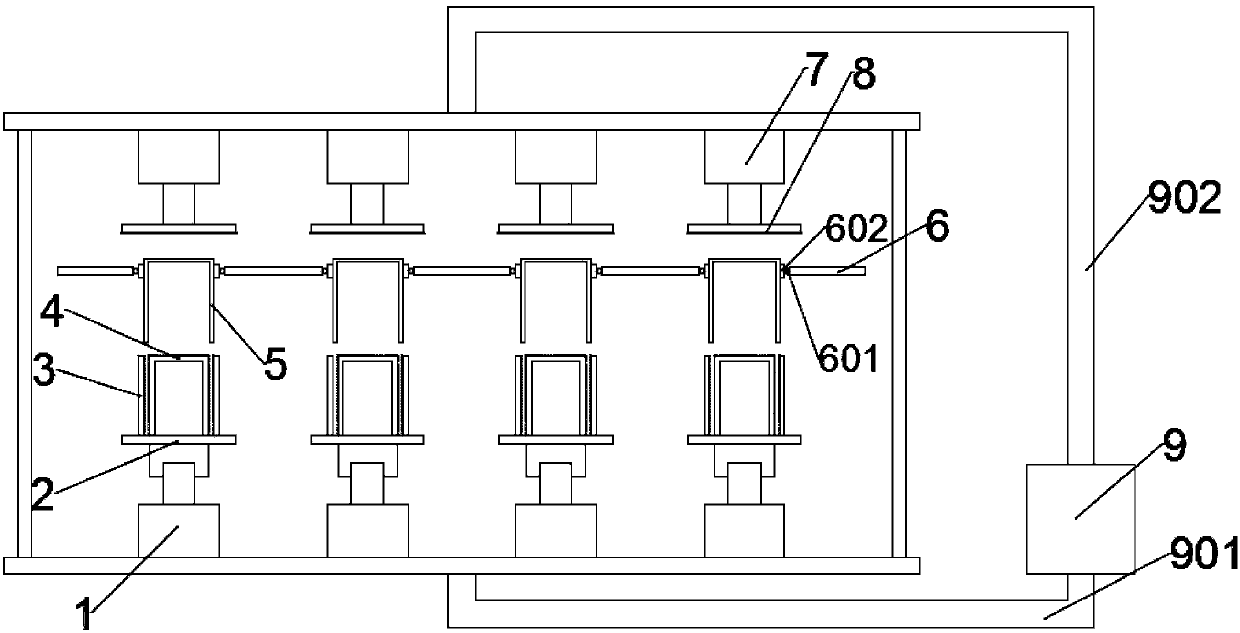

Automatic cleaning machine for steel dies

InactiveCN103551326ADoes not affect the cleaning effectEasy to cleanCleaning using toolsControl systemProgrammable logic controller

The invention discloses an automatic cleaning machine for steel dies. The automatic cleaning machine comprises a cleaning machine frame, a PLC (Programmable Logic Controller) control system and two cleaning devices, wherein the PLC control system is used for controlling the cleaning machine to operate; the two cleaning devices are symmetrically installed on the cleaning machine frame; each cleaning device comprises a lifting frame, a steel wire brush, a balance weight, a cylinder, a dust collecting cover, a driving motor and a belt, wherein the lifting frame can be rotatably installed on the cleaning machine frame, the steel wire brush is installed on the front end of the lifting frame, the balance weight is installed on the back end of the lifting frame, the cylinder, the dust collecting cover and the driving motor are installed on the lifting frame, and the belt is used for driving the steel wire brush to operate. The automatic cleaning machine has the advantages of simple structure, convenience in use, high operating efficiency and high degree of automation, and the whole operation of the machine is controlled by the PLC system; additionally, the two cleaning devices which are independently operated are adopted, and the automatic cleaning machine has good cleaning effects on the steel dies at large inclined angles and the steel dies which move up and down during operation.

Owner:SHANGHAI ZHONGJI PILE IND

Easily-rinsed shower cream for moistening the skin

Disclosed is an easily-rinsed shower cream for moistening the skin, which comprises the components (by weight ratio) of fatty acid, anion surface active agent, alkali, C22-36 wax, EGDS, polyacrylic acid, perfume compound, methyl hydroxybenzoate, mixture of imethylol dimethyl hydantoins 3-iodo-2-propynyl butyl carbamate, and deionized water. The cream has a pH=8.2-8.5. it has fine flushing property and skin moistening effect.

Owner:克劳丽化妆品股份有限公司

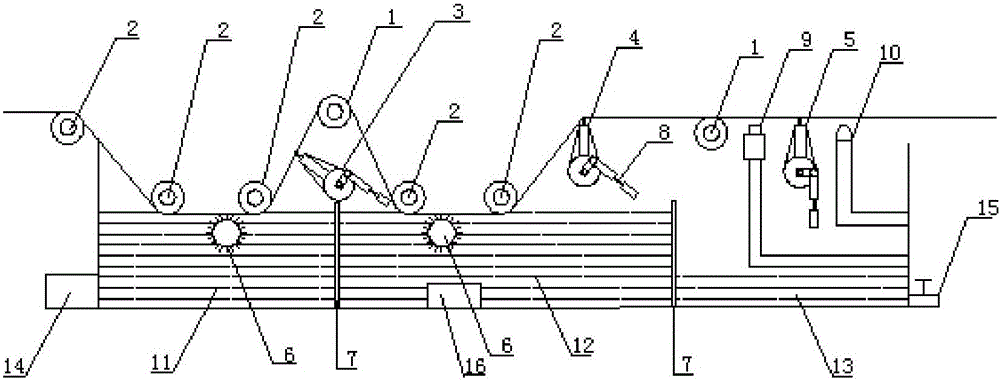

Conduction belt cleaning device of flat screen printing machine

InactiveCN106004039ASimple device structureEasy to usePrinting press partsEngineeringPower consumption

The invention provides a cleaning device for a guide belt of a flat screen printing machine. The third cleaning tank containing the cleaning residue. The guide belt cleaning device of the flat screen printing machine of the present invention uses a scraper and a cleaning tank to recover most of the slurry on the guide belt, and realizes the recovery of most of the slurry; On the premise of not affecting the cleaning effect of the guide belt, the water consumption in the cleaning process is reduced and the power consumption is reduced.

Owner:XINCHANG BENSHANG REFRIGERATING TECH CO LTD

Environment-friendly industrial cleaning agent

ActiveCN105331995AEliminate Nutritional ProblemsImprove cleaning efficiencySodium silicatePolypropylene

The invention discloses an environment-friendly industrial cleaning agent which comprises, by weight, 4-7 parts of fatty alcohol-polyoxyethylene ether A, 10-13 parts of fatty alcohol-polyoxyethylene ether B, 5-7 parts of polyoxyethylene-polypropylene oxide block polymer, 6-9 parts of coconut oil fatty acid diethanol amide, 5-7 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 3-5 parts of triethanolamine oleic soap, 12-15 parts of sodium gluconate, 11-14 parts of sodium silicate, 5-7 parts of sodium borate, 7-9 parts of sodium molybdate and 17-19 parts of water. The fatty alcohol-polyoxyethylene ether A is a polymer obtained by mixing and addition of fatty alcohol, fatty amine and ethylene oxide, wherein the mass of fatty alcohol is larger than that of fatty amine. The fatty alcohol-polyoxyethylene ether A is fatty alcohol and ethylene oxide. The cleaning agent has the beneficial effects of being low in use concentration, high in cleaning efficiency, long in solution service life and the like and is particularly suitable for cleaning before electroplating of steel, aluminum, aluminum alloy, copper, copper alloy and other base material parts or cleaning between machining processes.

Owner:江南工业集团有限公司

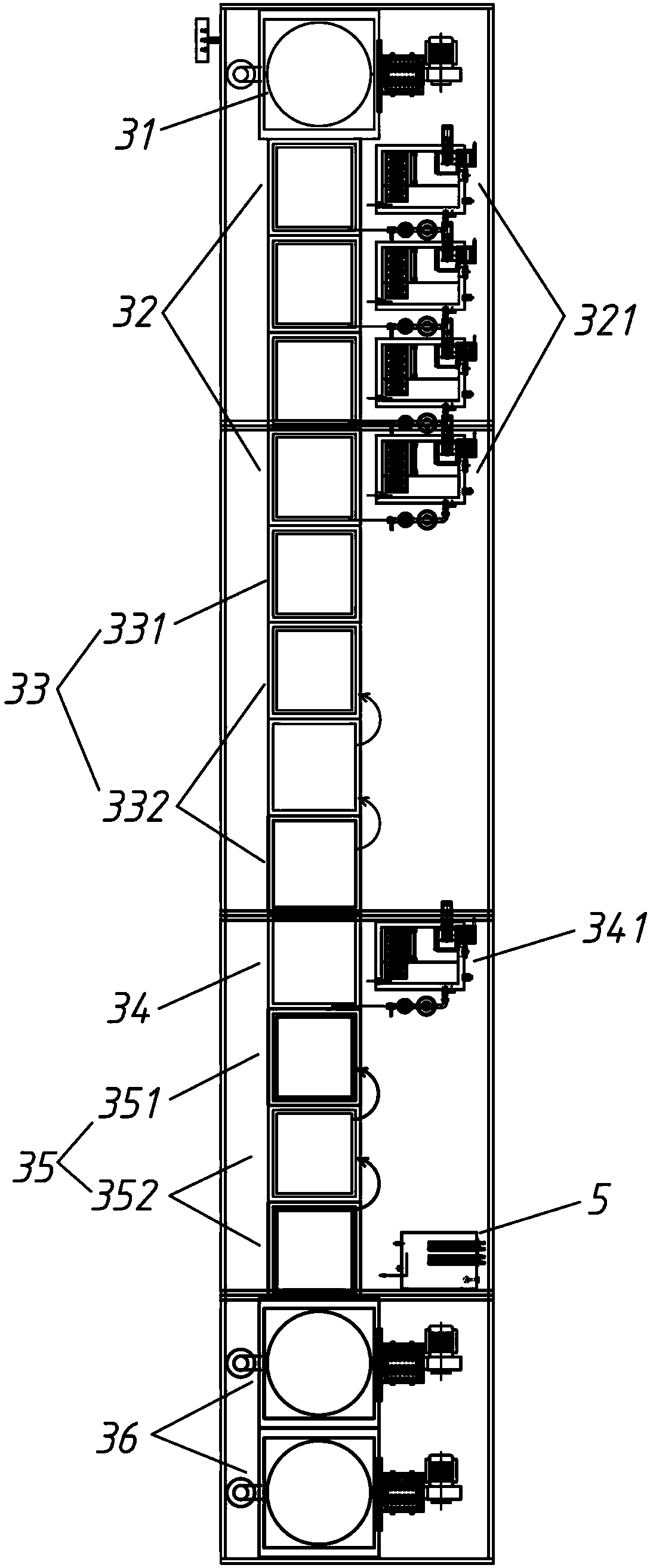

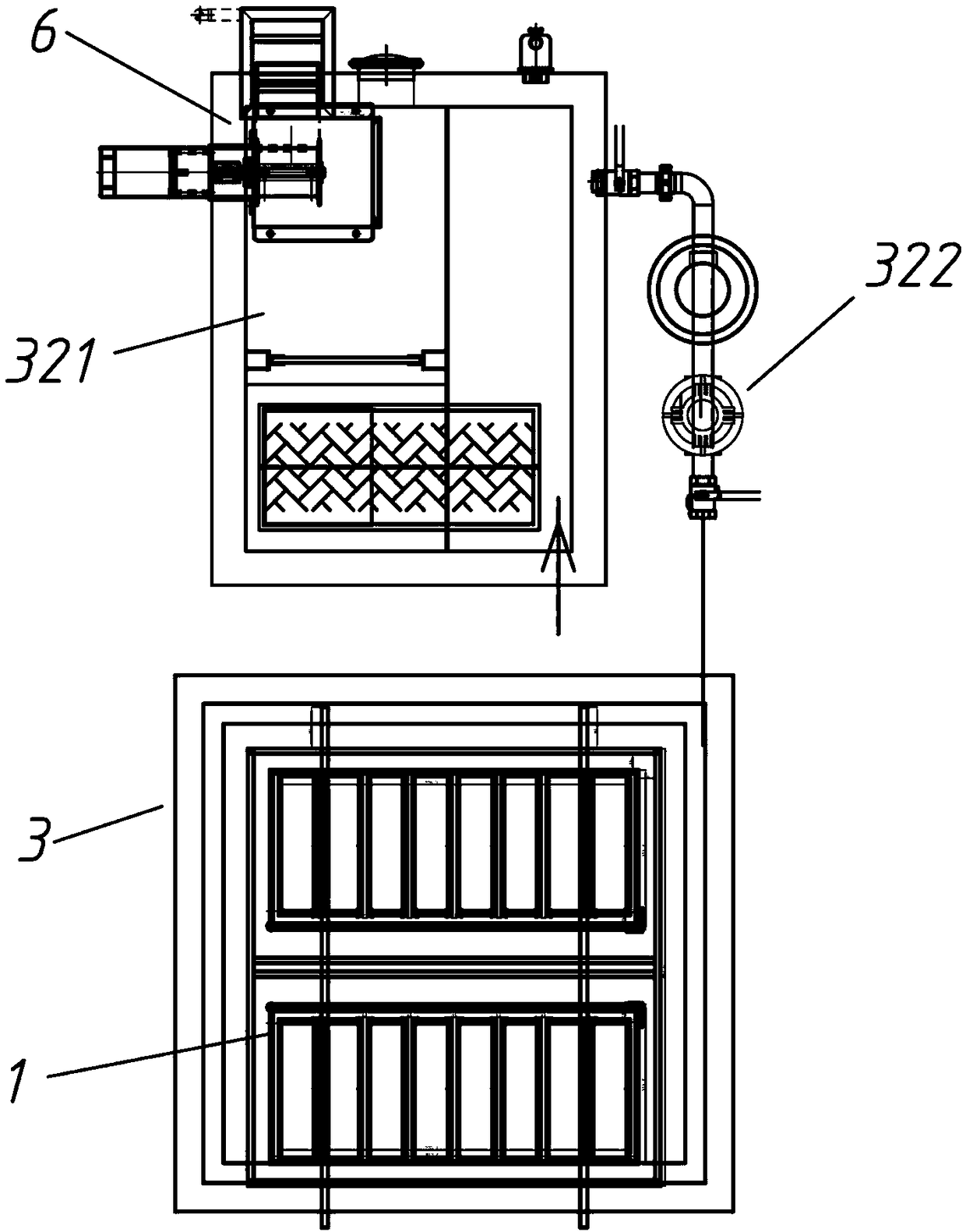

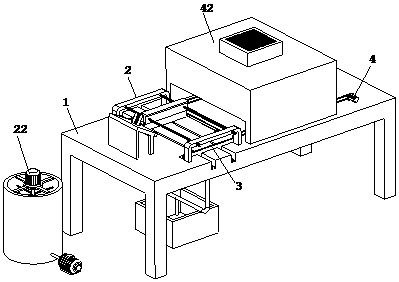

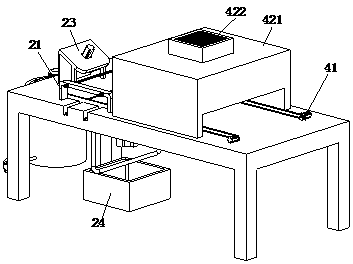

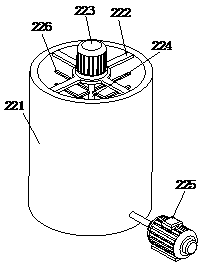

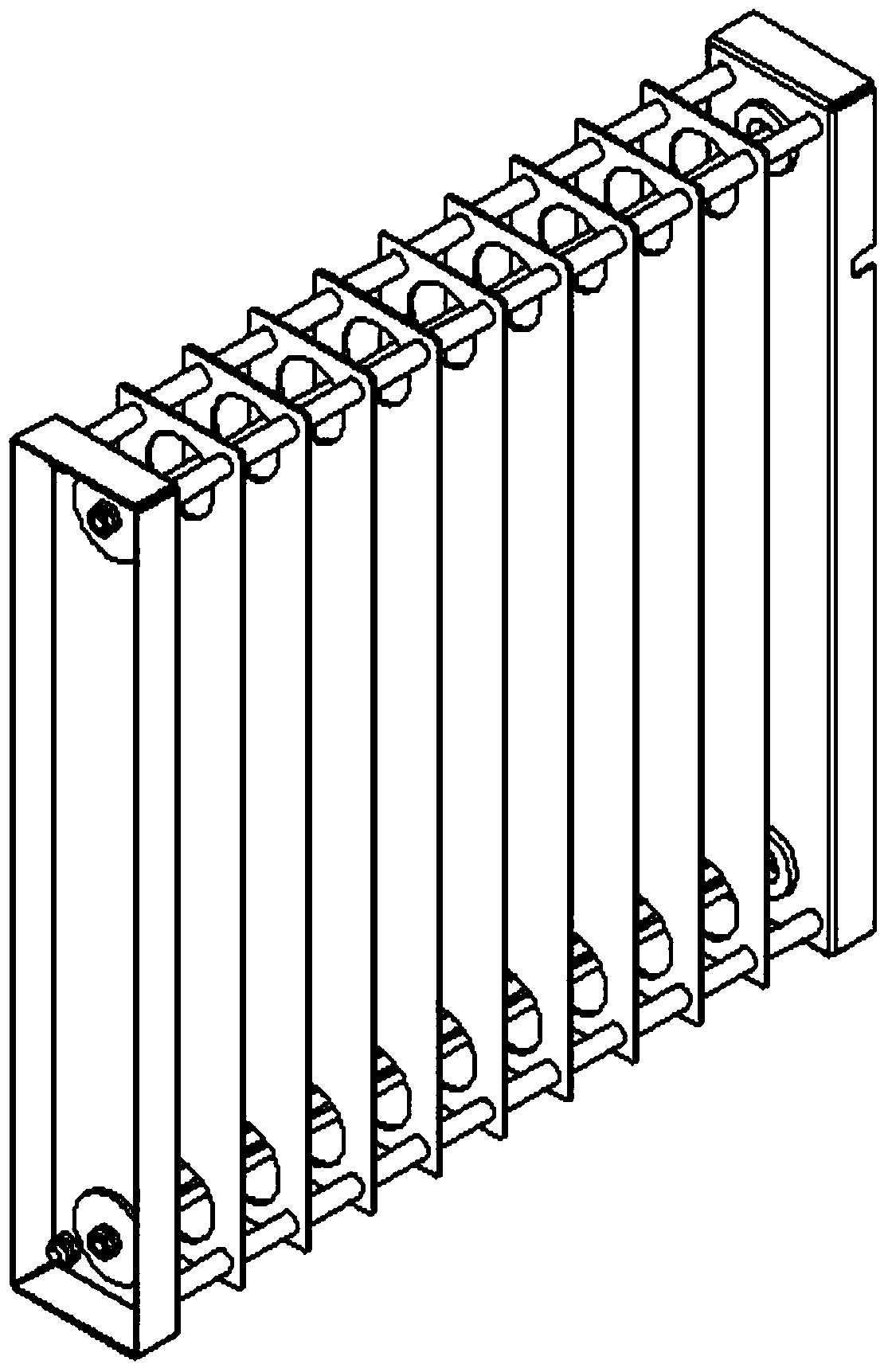

Full-automatic battery aluminum shell ultrasonic cleaning equipment

PendingCN108435696AEasy dischargeLighten the subsequent cleaning loadDrying gas arrangementsDrying machines with progressive movementsMegasonic cleaningAutomation

The invention provides full-automatic battery aluminum shell ultrasonic cleaning equipment. The full-automatic battery aluminum shell ultrasonic cleaning equipment comprises a drying stove, a cleaningbasket loading battery shells, a mechanical arm conveying the cleaning basket and a plurality of cleaning grooves which are arranged in sequence, each cleaning groove comprises a deoiling groove, rough cleaning grooves, front rinsing grooves, a black removing groove, rear rinsing grooves and dewatering grooves, throwing moving mechanisms are arranged from the rough cleaning grooves to the corresponding rear rinsing grooves, all the rough cleaning grooves are internally provided with supersonic vibration devices, the rough cleaning grooves are correspondingly provided with rough cleaning subsidiary grooves and filter pump devices, all the grooves of the front rinsing grooves are associated grooves, the black removing grooves are correspondingly provided with black removing subsidiary grooves and the filter pump devices, and all the grooves of the rear rinsing grooves are the associated grooves. According to the full-automatic battery aluminum shell ultrasonic cleaning equipment, the whole cleaning process is set to be reasonable, cleaning is performed thoroughly and the degree of automation is high.

Owner:江西族光能源科技有限公司

Bridge gap residue removing device with water spraying device

The invention provides a bridge gap residue removal device with a water spray device, which includes a large roller, a rotating shaft, a small roller, a conveyor belt, a guide plate, a roller, a cleaning brush, a water tank, a water pump, a water pipe, an elbow, a high-pressure nozzle and a cleaning brush. The large roller is connected with the small roller through the conveyor belt, the guide plate is fixed on the front end of the small roller, the roller is installed on the top of the guide plate, and the cleaning brush is fixed on the outer surface of the roller. Difficult cleaning of debris. The water pump is installed inside the water tank. The elbow is connected to the water pump through the water pipe. The lower end of the elbow is equipped with a high-pressure nozzle, and the cleaning brush is installed at the lower part of the elbow. This design can further clean bridge gaps and solve the problem of the original technology. For the problems of difficult cleaning of stains in bridge gaps and solidified soil, the invention is easy to use, easy to operate, wide in scope of application and strong in cleaning power.

Owner:夏新河

Cleaning agent for coated glass

InactiveCN109749878AStrong decontamination abilityBroad environmental adaptabilityNon-ionic surface-active compoundsOrganic detergent compounding agentsSolventChemistry

The invention discloses a cleaning agent for coated glass. The cleaning agent comprises, by weight, 2-5% of anionic surfactants, 5-10% of nonionic surfactants, 15-30% of cosolvents, 5-15% of organic solvents and the balance of deionized water. The cleaning agent for the coated glass has the advantages of strong decontamination ability, high environmental adaptability, high stability, low foaming,easiness in rinsing, high wettability, no environment pollution, low cost, convenience in transportation and storage, and low cleaning cost.

Owner:彭伶俐

Solar cell processing and cleaning equipment

ActiveCN110491810AAffect cleaning operationsRealize automatic fixationFinal product manufactureSemiconductor/solid-state device manufacturingCell processingCells panel

The invention discloses solar cell processing and cleaning equipment, and belongs to the technical field of cell processing. The equipment comprises a workbench, a cleaning assembly, a fixing assemblyand a drying assembly. The cleaning assembly comprises a sweeping part, a mixing part, a cleaning part and a collecting part. The sweeping part is arranged at the top of the fixing assembly, the mixing part is arranged beside the workbench, the cleaning part is arranged at the top of the workbench, the collecting part is arranged below the workbench, the drying assembly comprises a moving part and a drying part, the drying part is arranged at the top of the workbench, and the moving part is arranged at the top of the workbench. The two rotating motors work to drive the two rotating lead screws to rotate on the two fixing frames; the two rotating lead screws rotate to drive the moving plate to move, the moving plate moves to drive the sweeping plate to move, the sweeping plate moves to drive the sweeping brush to sweep residues on the cell panel, after sweeping is conducted, the residues on the cell panel can be cleaned easily, and it is guaranteed that the cell panel is cleaned cleanly.

Owner:江苏悦阳光伏科技有限公司

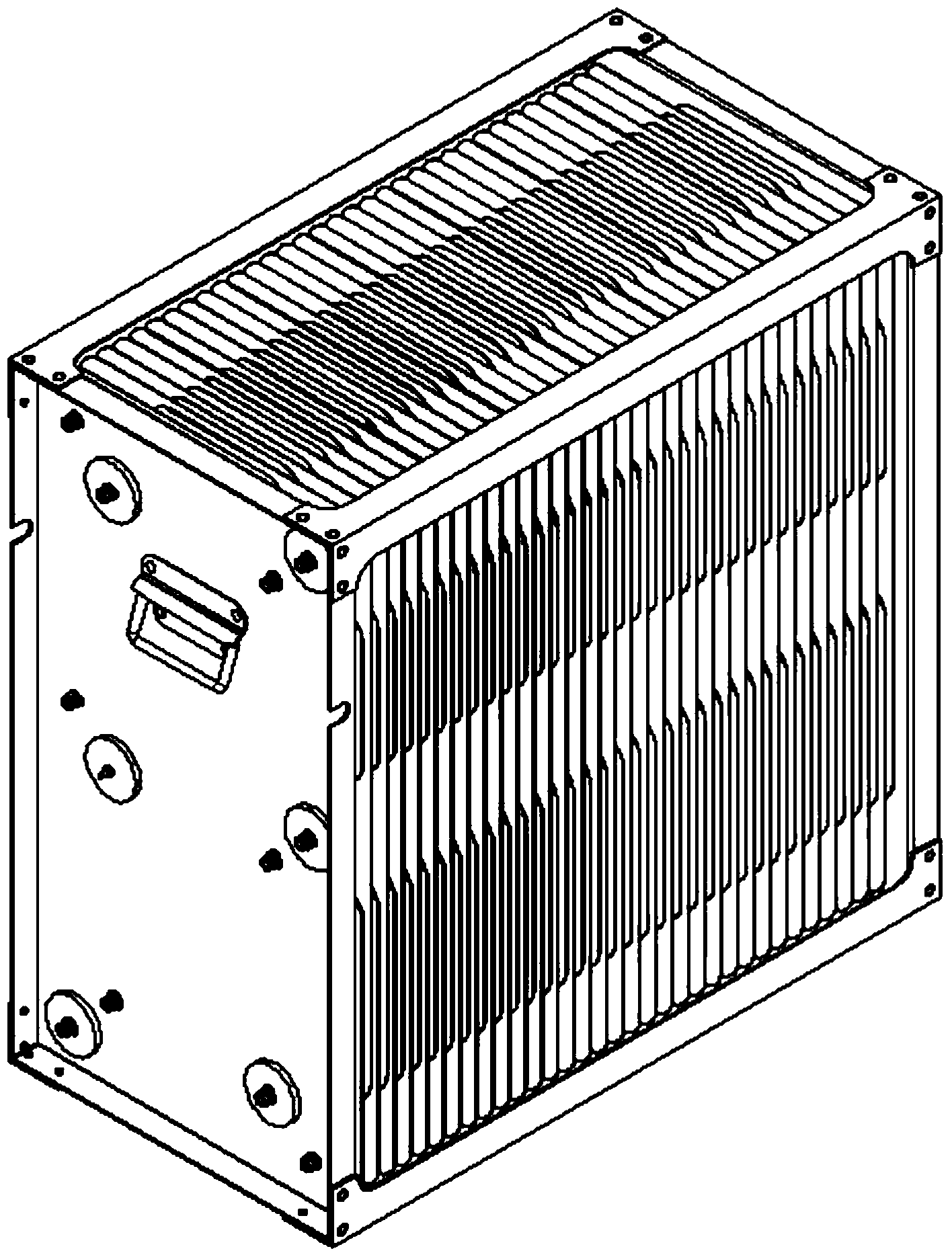

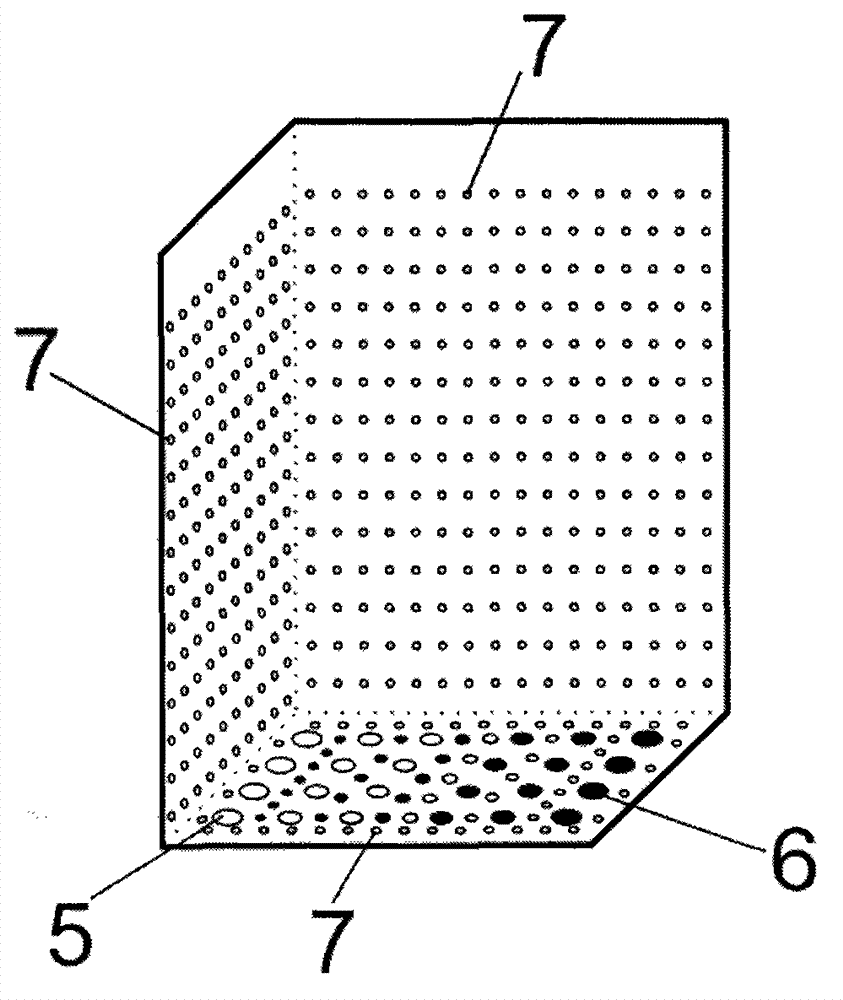

Easily-washed oil mist purifier core body and manufacturing method thereof

InactiveCN104001625ALong cycleDoes not affect the cleaning effectElectrode constructionsBiochemical engineeringCleansing Agents

The invention discloses an easily-washed oil mist purifier core body and a manufacturing method thereof. According to the easily-washed oil mist purifier core body, a coating is arranged on the surface of a core body so that the period of washing and maintaining is greatly prolonged; in a washing process, the oil mist purifier core body only needs to be washed by pressurizing clean water or by using a conventional washing agent; the aim of conveniently washing is realized without affecting the washing effect.

Owner:MEGAUNITY ENVIRONMENTAL SOLUTIONS CO LTD

A kind of internal cleaning equipment of solar heat collecting tube

The invention relates to a cleaning device, in particular to a cleaning device inside a solar heat collecting tube. Therefore, the technical problem of the present invention is to provide a cleaning device that is comprehensive and can place the heat collecting tube well without affecting the cleaning inside the solar heat collecting tube. Technical solution: A cleaning device for the interior of a solar heat collecting tube, including a frame, a handle, a rubber sleeve, a limit block, a rubber plate, a motor, a rubber rotating rod, etc.; Rubber cover, limit block is installed on the top of the left side and the top of the right side in the frame, rubber plates are installed on the bottom of the limit block and the bottom of the left and right sides in the frame. The invention can place the heat collecting tube stably through the supporting device without affecting the cleaning. Through the water spray device, it is not necessary to continuously pour water into the heat collecting tube for cleaning, which is convenient and quick, and achieves comprehensive cleaning. It is well placed without affecting the cleaning effect.

Owner:杭州全要素科技服务有限公司

Corrosion inhibitor of industrial cooling circulating water system

InactiveCN1754838AShort duration of actionGood effectTreatment using complexing/solubilising chemicalsChemical industryMercaptobenzothiazole

The present pertains to the field of chemical industry, wherein an antisludging agent for industrial circulating water systems is disclosed, which comprises thiocarbamide, benzotrizaole, mercaptobenzothiazole, sodium silicate and water. The antisludging agent has good inhibiting effects to various acids and metals.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

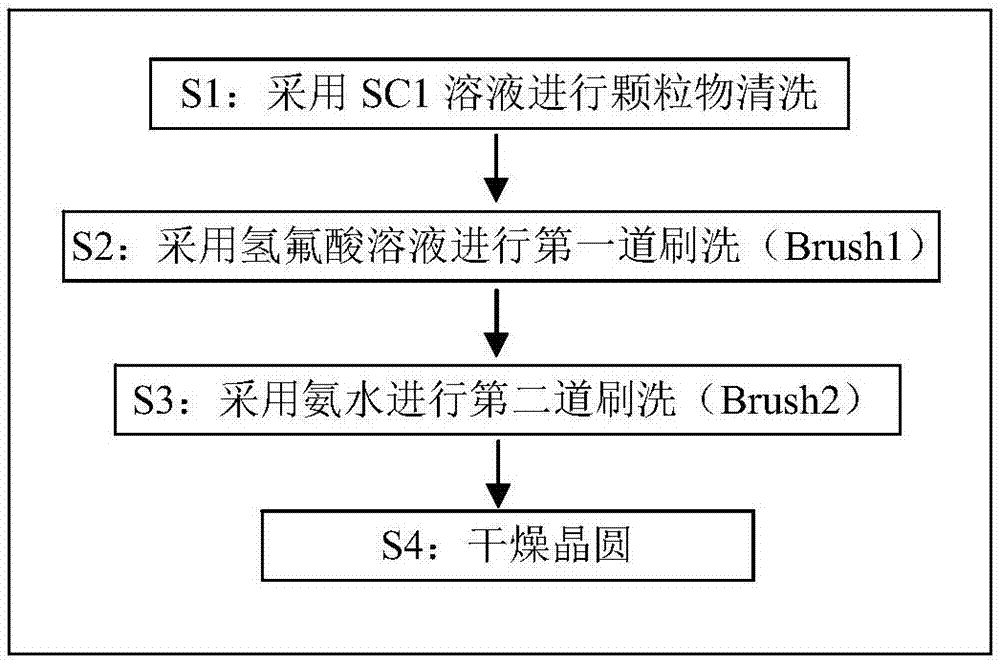

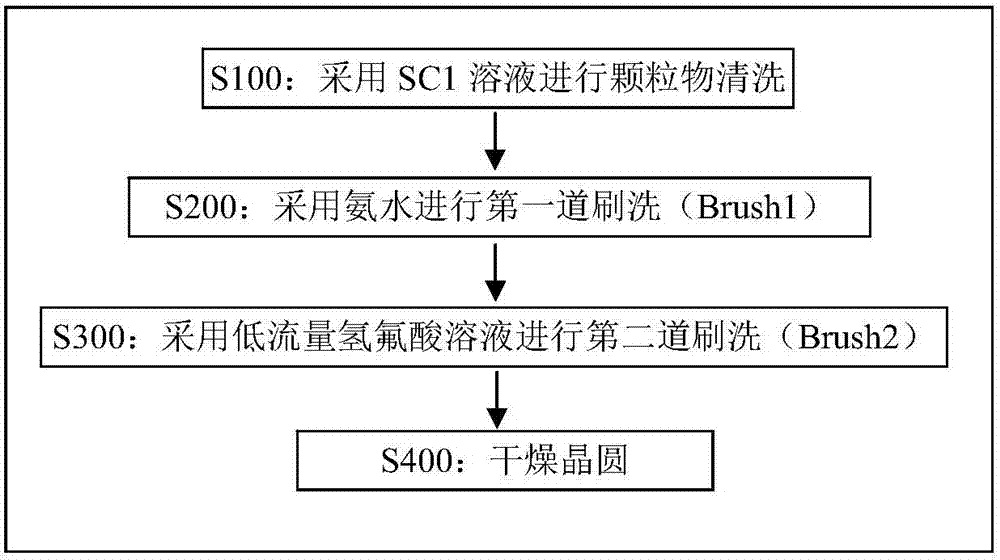

Cleaning method of chemically and mechanically grinded polycrystalline silicon

InactiveCN107993920AAvoid destructionAvoid Roughening DamageSolid-state devicesSemiconductor/solid-state device manufacturingHydrofluoric acidParticulates

The invention provides a cleaning method of chemically and mechanically grinded polycrystalline silicon. The cleaning method is characterized by including the steps: cleaning particulate matters; firstly brushing surfaces of wafers by matching ammonium hydroxide serving as a cleaning agent with a brush (Brush 1); secondly brushing the surfaces of the wafers by matching hydrofluoric acid solution serving as a cleaning agent with a brush (Brush 2). Brushing process orders in a conventional cleaning process are adjusted, a brushing procedure of the hydrofluoric acid solution has obvious destructive effect on silicon oxide and is postponed, the working procedure is adjusted, so that the surface of the polycrystalline silicon can be protected by a silicon oxide layer generated in the cleaning process of the particulate matters when being brushed by the ammonium hydroxide, roughened damage to the surface of the polycrystalline silicon caused by corrosion of the ammonium hydroxide is avoided,flow of the hydrofluoric acid solution is decreased in the brushing process of the hydrofluoric acid solution, the hydrofluoric acid solution is decreased, cost is saved, and damage of the hydrofluoric acid solution to the surface of the polycrystalline silicon can be reduced.

Owner:YANGTZE MEMORY TECH CO LTD

Automatic rain boot cleaning machine

InactiveCN103371790ALiberate labor productivityReduce labor intensityFootwear cleanersWater dischargeElectrical control

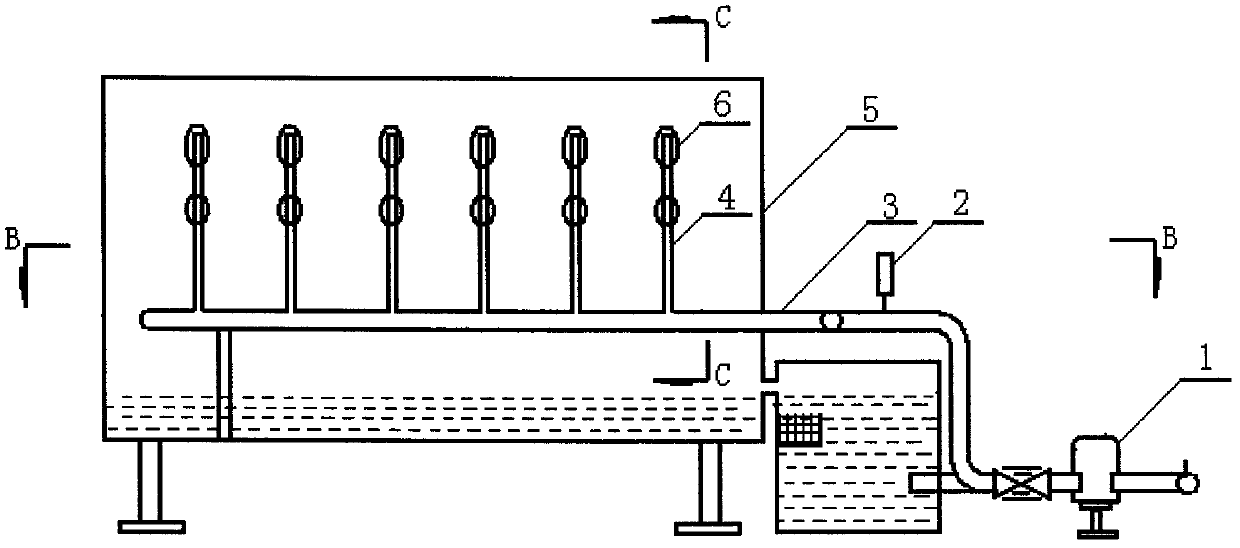

Disclosed is an automatic rain boot cleaning machine aiming at solving the problem of difficulty in large-batch manual cleaning of rain boots for labor protection. The automatic rain boot cleaning machine is characterized in that the automatic rain boot cleaning machine comprises a water tank, a water pump, a water pipe, a valve, cleaning heads, a spraying chamber and an electrical control system, a water incoming end of the water pump is connected with the water tank, a water outgoing end of the water pump is communicated into the spraying chamber, a main water pipe in the spraying chamber is divided into a plurality of branches, each branch is connected with one cleaning head which is formed by a spraying head, and a sole rack and a boot barrel support which are arranged around the spraying head, and the spraying chamber is provided with a water discharging port. The automatic rain boot cleaning machine depends on the quincuncial spraying heads to spray large-coverage-area and high-impact-force water flow to wash and brush inner cavities of boots, and dirt and sweat in the rain boots can be quickly washed and cleaned while no detergent is needed. Cleaning can be completed in only 1-3 minutes, and 15-35 pairs of the rain boots can be cleaned simultaneously. The automatic rain boot cleaning machine is short in cleaning cycle, high in working efficiency, good in cleaning effect and suitable for all walks of life like coal mines, all places needing the rain boots to be worn for operation and all units needing large-batch cleaning of the rain boots.

Owner:张勤

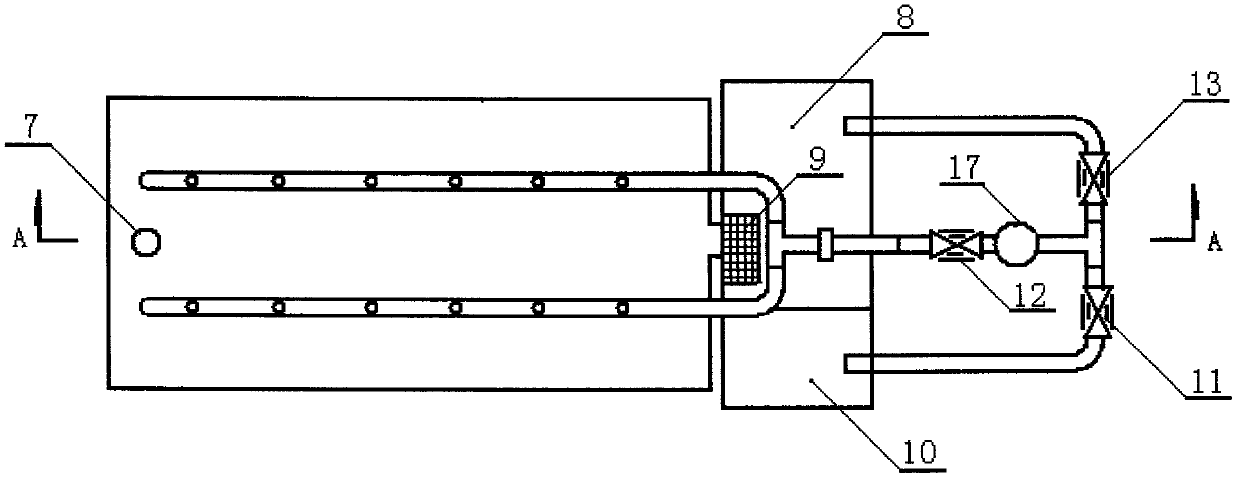

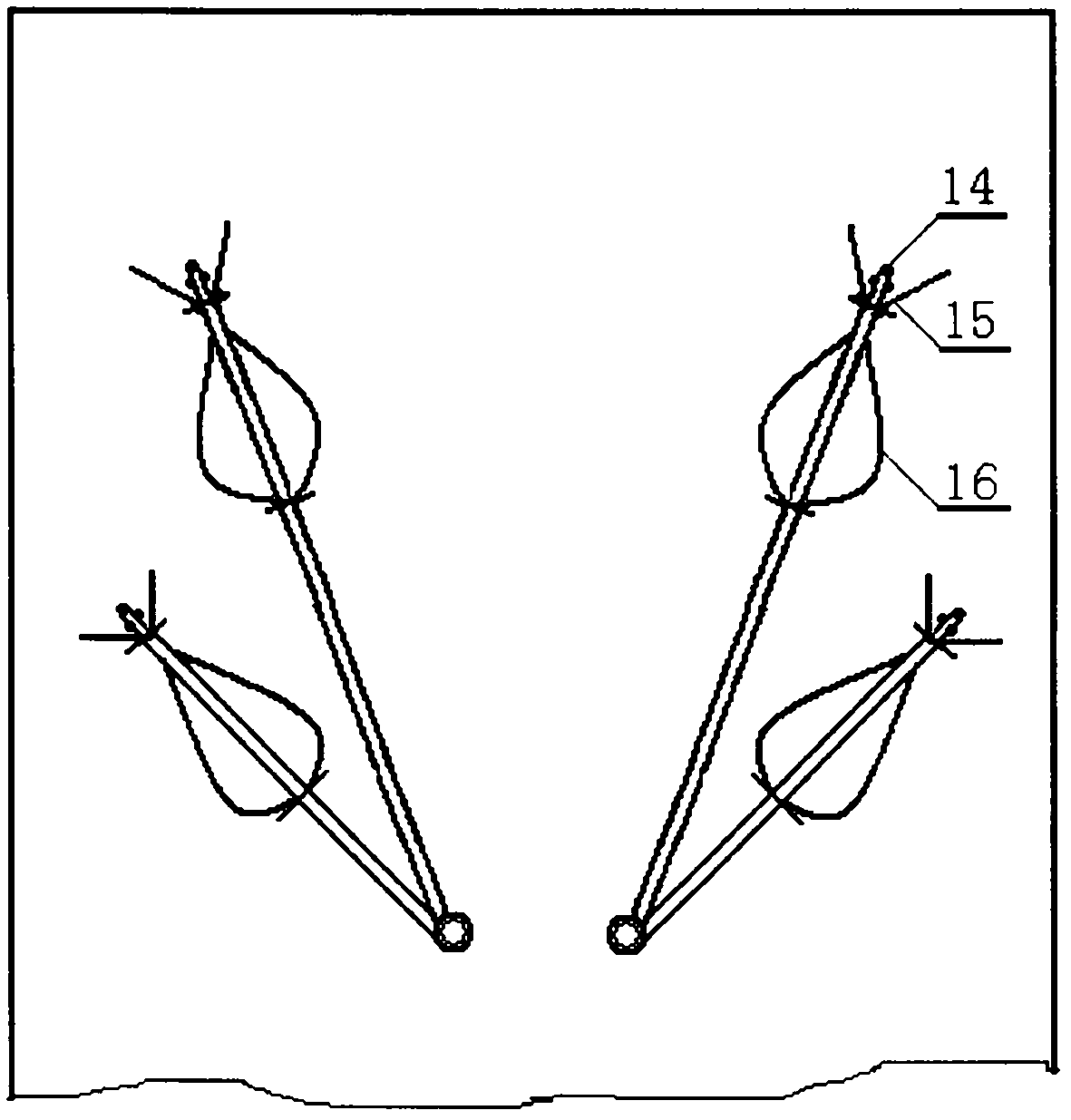

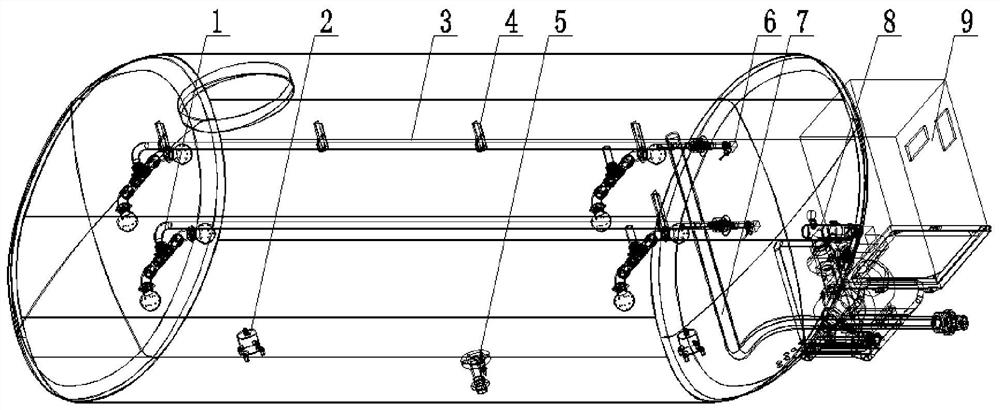

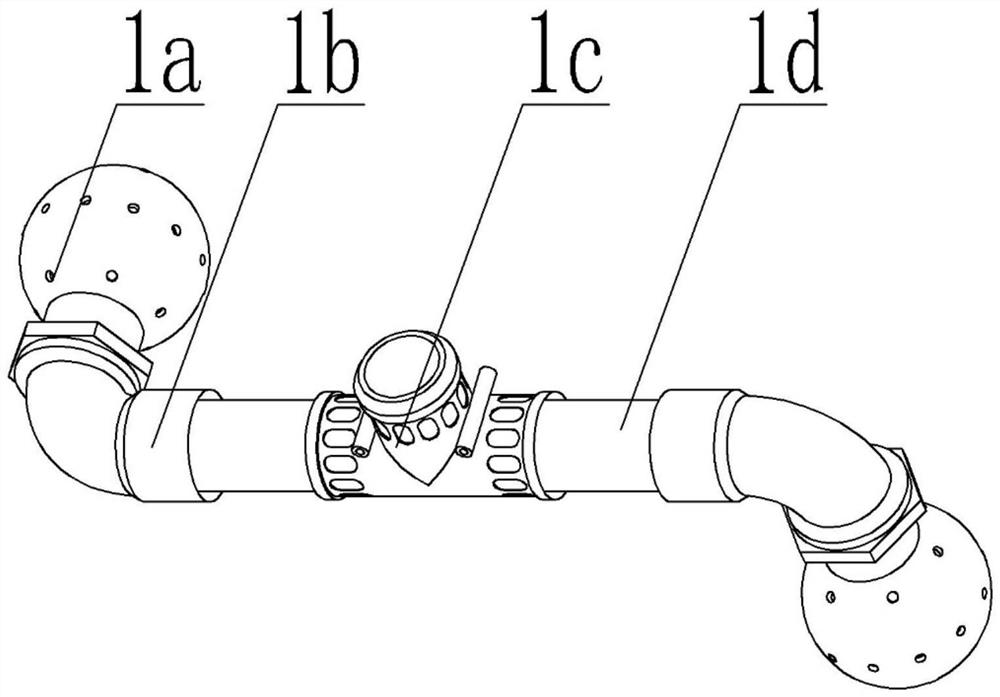

Automatic cleaning system and method for water transporting tank

ActiveCN111618054AReduce labor intensityImprove cleaning efficiencyHollow article cleaningProcess engineeringWater quality

The invention discloses an automatic cleaning system for a water transporting tank. The automatic cleaning system is characterized by comprising a flushing device, a water quality monitoring sensor, acleaning liquid conveying pipeline, a cleaning agent draining pipeline, a cleaning pipeline control device, a cleaning agent injecting pipeline, a circulating pump and a water quality monitoring andcomparing system. Through adoption of the automatic cleaning system, the problem that the cleaning of the water transporting tank is limited by manpower in the normal state is solved; the labor strength in the tank body cleaning process is lowered; the possible safety risks of asphyxia, collision and the like for workers are reduced; the cleaning efficiency is improved; and the cleaning effect isvisible. Meanwhile, the advantage of selecting different cleaning agents (such as acids and alkalis) is realized, and the cleaning effect is improved further. The cleaning environment can be an all-weather environment which is not limited by cold or heat, day or night and the like, so that a tank body is kept clean continuously. In addition, the water quality monitoring sensor is built in the automatic cleaning system, so that the pollution condition in the tank can be monitored in real time even in the normal using state, and the cleaning plan for the tank body is more scientific.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Operating method of curtain wall cleaning machine

InactiveCN105361821ALarge cleaning areaImprove efficiencyCarpet cleanersFloor cleanersSewageControl theory

The invention discloses an operating method of a curtain wall cleaning machine which has a good cleaning effect and high cleaning efficiency and is stable in walking. A motor is utilized to drive roll brushes to clean curtain walls. Sewage produced after cleaning is recovered by a recovery pipe to avoid secondary influence to cleaned surfaces of glass curtain walls. Walking stability of the curtain wall cleaning machine is guaranteed by a walking way of combination of four suckers.

Owner:重庆市南川区泰城钢化玻璃制品有限责任公司

Method for cleaning silicon wafer at room temperature

InactiveCN110660645AReduce usageReduce volatilitySemiconductor/solid-state device manufacturingInorganic non-surface-active detergent compositionsSemiconductor chipEngineering

The invention discloses a method for cleaning a silicon wafer at room temperature and belongs to the field of semiconductor chip processing and manufacturing. The method comprises steps of mixing ammonium hydroxide, hydrogen peroxide and deionized water according to a volume ratio of 1: 2: 50, and controlling the temperature of the silicon wafer cleaning solution to be room temperature when the silicon wafer is cleaned. After the silicon wafer is cleaned, the silicon wafer with a clean and stain-free surface can be obtained through the spin-drying process. The ammonium hydroxide, the hydrogenperoxide and the deionized water are mixed according to the volume ratio of 1: 2: 50, the use amount of the ammonium hydroxide and the hydrogen peroxide can be effectively reduced, volatilization of chemicals can be greatly weakened when the cleaning agent is utilized at the room temperature, and the cleaning agent can be stored for three days without affecting the cleaning effect of the cleaningagent. The method is advantaged in that the diluted cleaning fluid has significant improvement in safety and health, and production costs are reduced due to reduction in the amount of chemicals used.

Owner:长春长光圆辰微电子技术有限公司

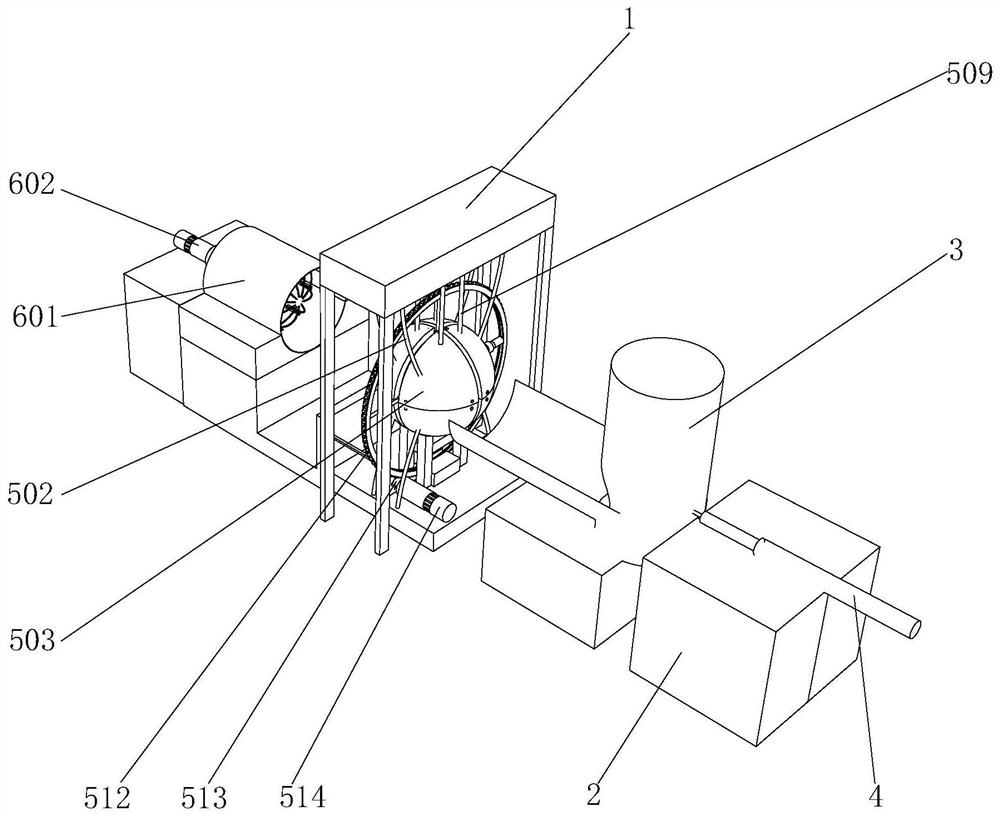

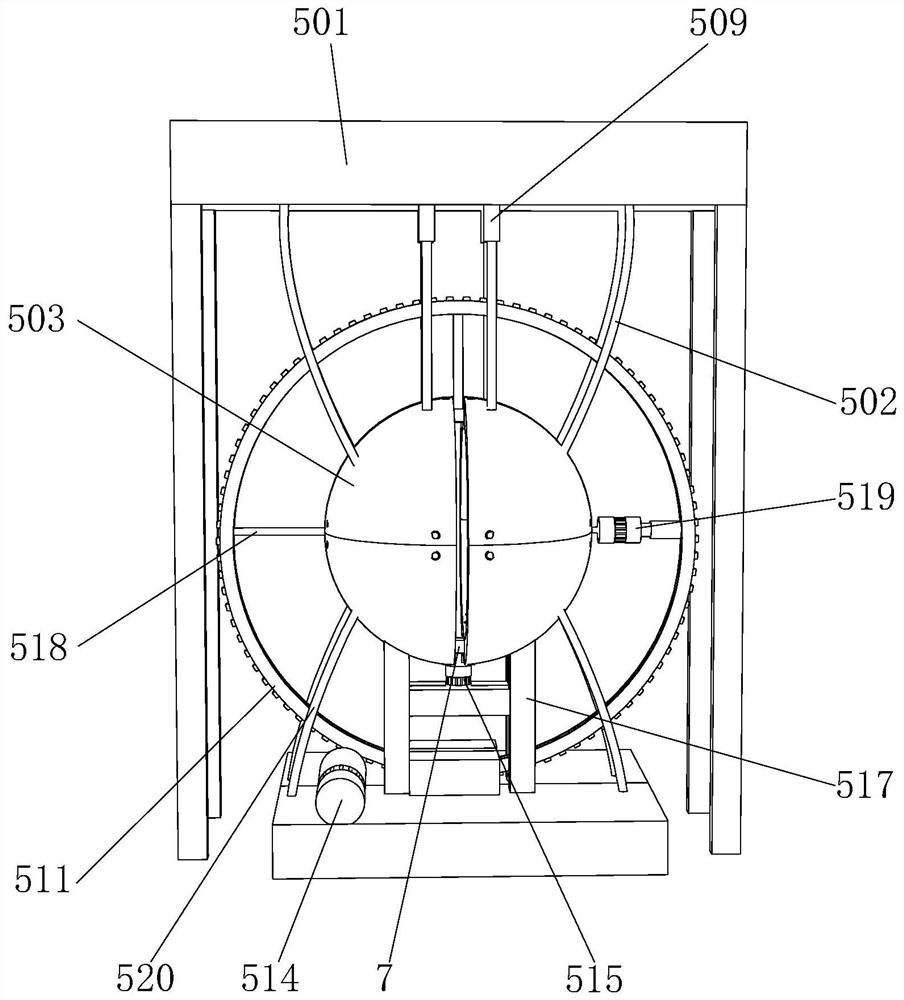

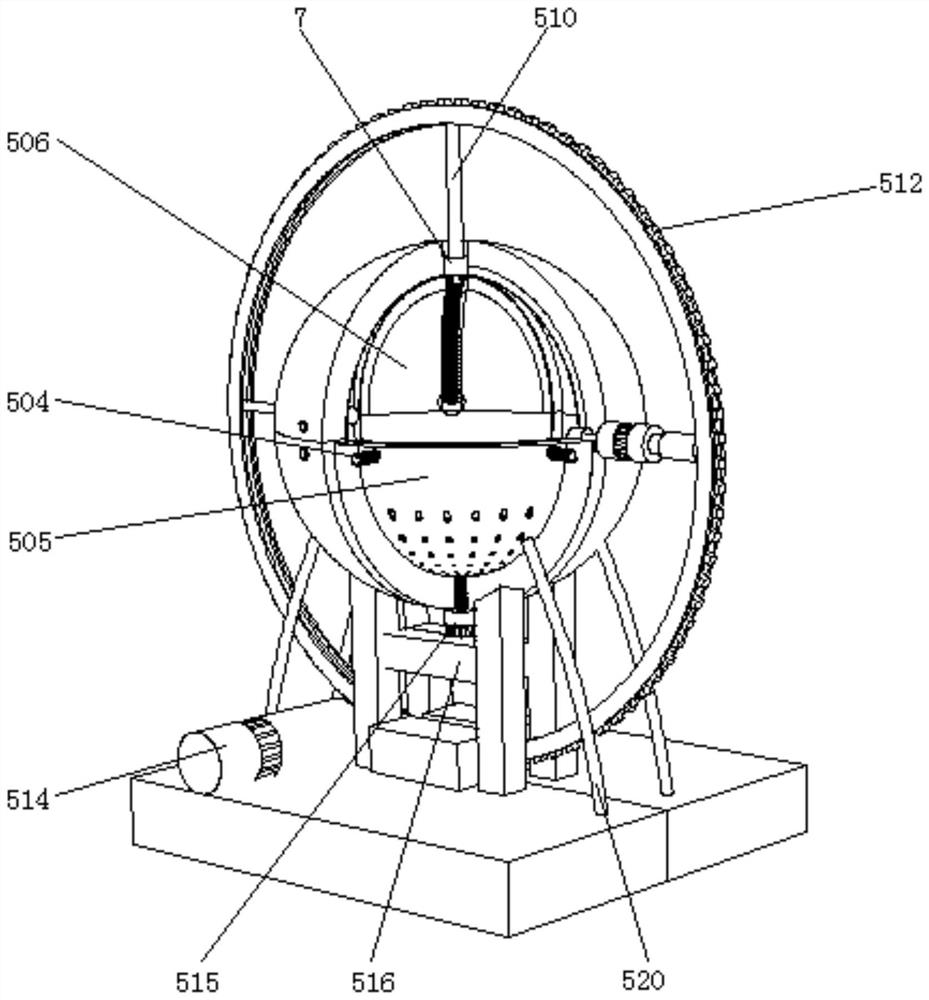

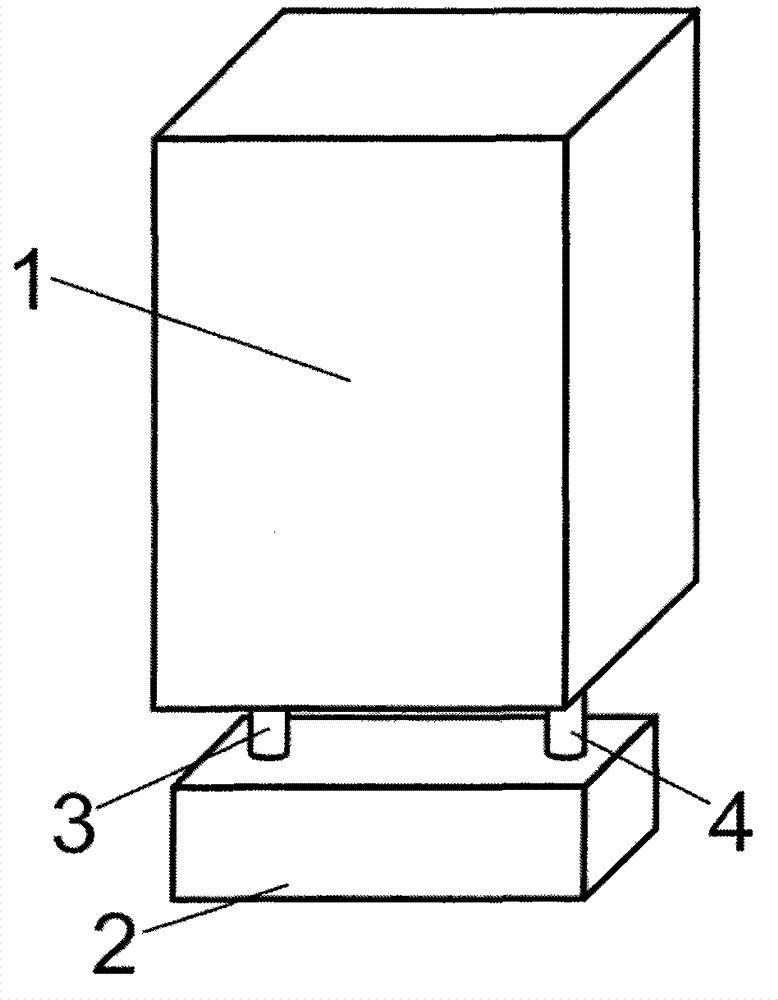

Basketball cleaning device

ActiveCN112274886ADoes not affect the cleaning effectFully cleanedDrying gas arrangementsBall sportsStructural engineeringMechanical engineering

The invention provides a basketball cleaning device, and relates to the technical field of sports goods cleaning. The basketball cleaning device comprises a supporting frame, a base, a feeding pipe, atelescopic ball pushing rod, a cleaning mechanism, a drying mechanism and a fixing disc. The base is arranged below the supporting frame, the cleaning mechanism is arranged below a support and abovethe base, the bottom end of the cleaning mechanism is fixedly connected with the bottom end of the base, the telescopic ball pushing rod is arranged at the top end of the right side of the base, the telescopic ball pushing rod is slidably connected with the top end of the support, the fixing disc is arranged at the left end of the telescopic ball pushing rod and fixedly connected with the left endof the telescopic ball pushing rod, the feeding pipe is arranged at the top end of the base on the right side of the cleaning mechanism, the bottom end of the feeding pipe is fixedly connected with the base, and the cleaning mechanism is arranged at the top end of the left side of the base and fixedly connected with the top end of the base. The problems that gaps between concave-convex particleson the surface of a basketball are not cleaned thoroughly when the basketball is cleaned, and the surface of the basketball is abraded when the basketball is cleaned are solved.

Owner:义乌市牵手电子商务有限公司

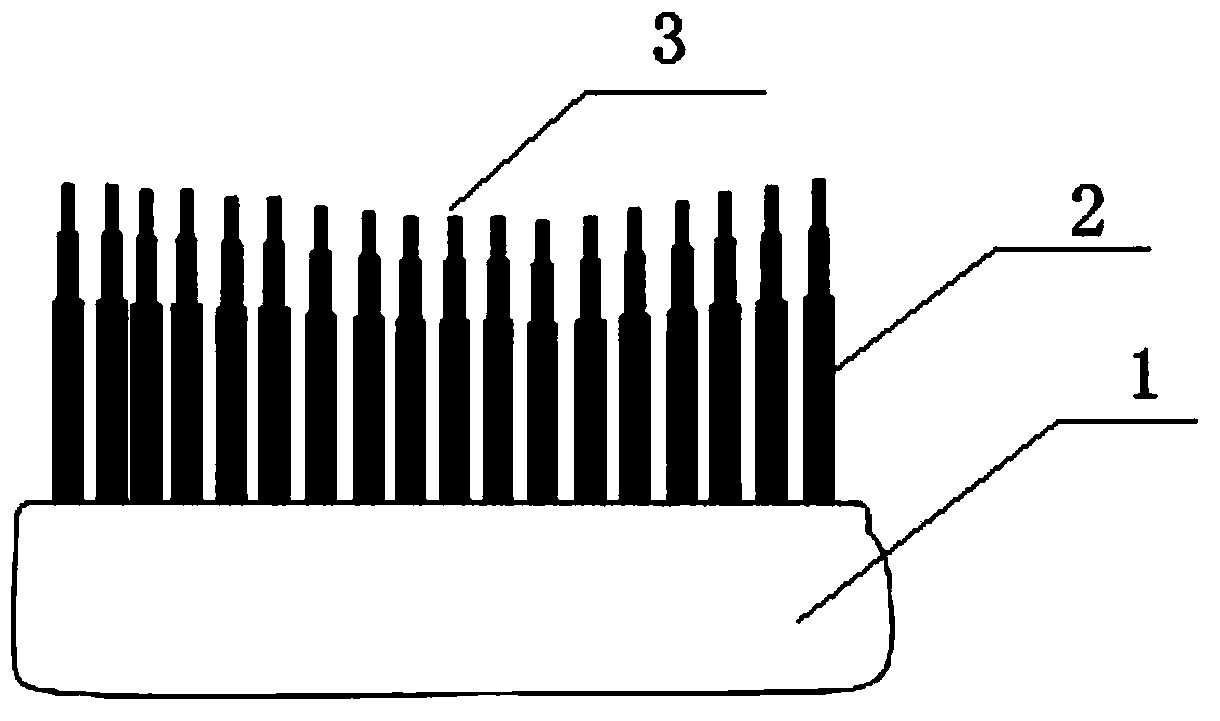

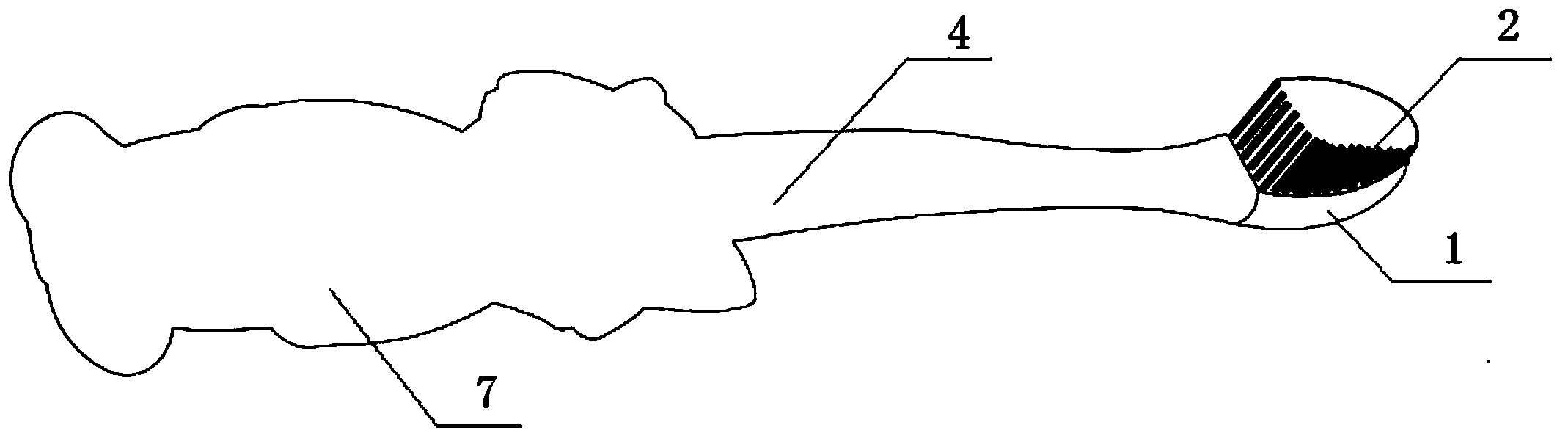

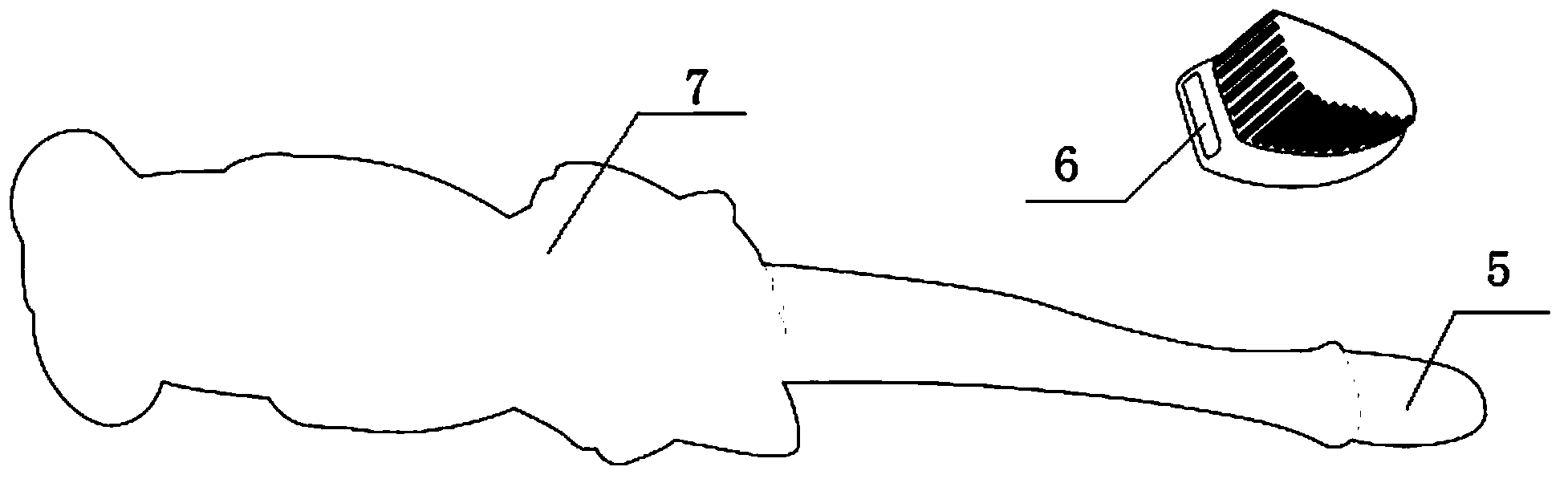

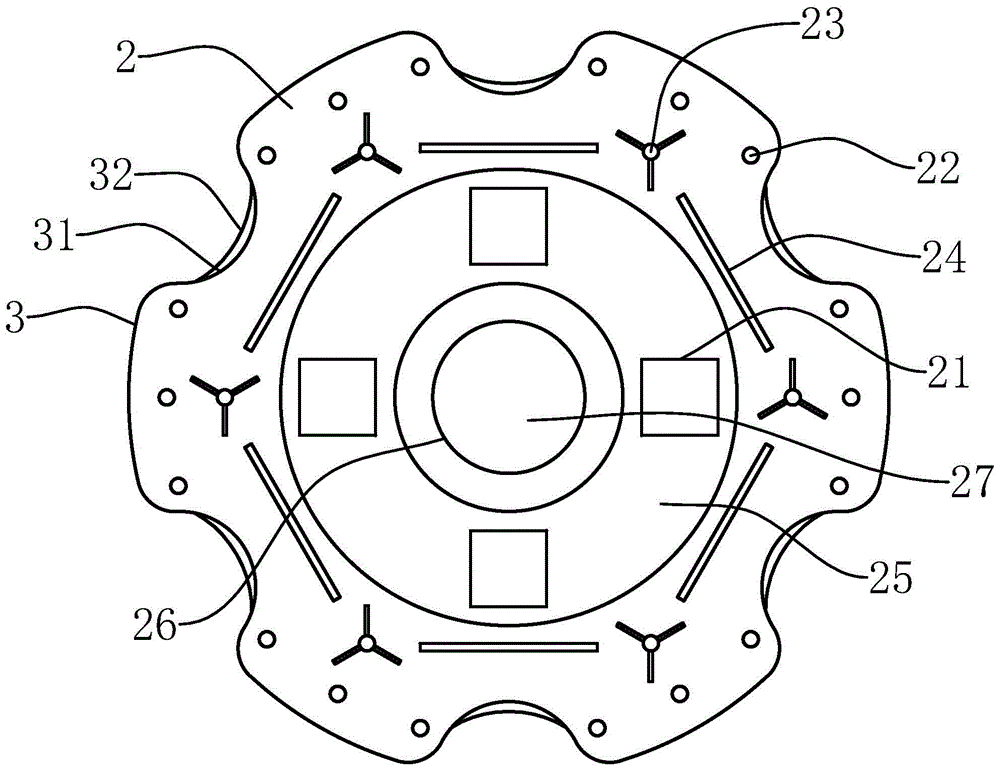

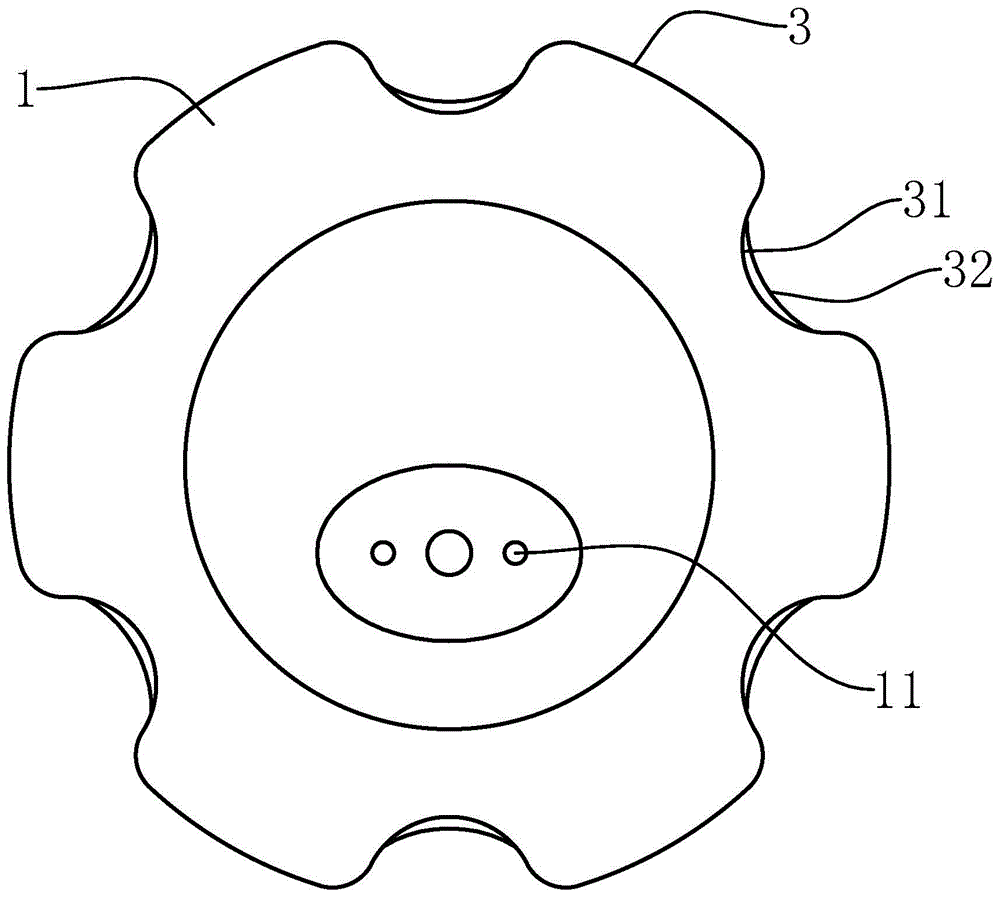

Child toothbrush head and toothbrush

InactiveCN103815657ASolve sheddingSolve the problem of excessive hardnessBristle carriersBristleBristleEngineering

The invention relates to a toothbrush, in particular to a toothbrush head specially designed for children and a toothbrush comprising the same. The child toothbrush head comprises a base (1) and bristles (2), and the base (1) and the bristles (2) are fully made of silica gel and integrally formed. The toothbrush head and a toothbrush handle are detachable. The child toothbrush head and the toothbrush have the advantages that the base and the bristles are fully made of silica gel and integrally formed, so that shedding of the bristles is effectively prevented, and service life of the toothbrush is prolonged; the bristles are designed to be multistep cylindrical, so that hardness of the bristles is effectively lowered, proneness to bending due to excessive softness of the bristles is avoided, and cleaning strength is improved; a holding handle position of the toothbrush handle is designed to be in the shape of an animal, so that the toothbrush handle is easy to hold by a child, damage to the oral cavity due to hand sliding in the process of toothbrushing is prevented, interest of the child in active toothbrushing can be increased, and pleasure can be brought to the child during toothbrushing.

Owner:王道民

Formula and production process of makeup removerwhich does not hurt skin

InactiveCN110638710AImprove functionalityDoes not affect the cleaning effectCosmetic preparationsMake-upBiotechnologyGrape seed

The invention discloses aformulation and production processof makeup removerwhich does not hurt skin. The makeup remover is prepared from the following raw materials in percentage by weight:7.5% to 8.5% ofglycerol, 10% to 15% of olive oil lipids, 1.2% to 1.5% of trehalose, and 0.5%to 1.5% of cocoyl amphoteric disodium diacetate. According to theformulation and production process of the makeup removerwhich does not hurt skin, the vitamin E in use adoptsan extraction mixture of various plants such as roselle extract, grape seed extract, sweet orange flower water, wild chrysanthemum extract, andmulberry root extract, wherein the grape seed extract has a whitening effect and enhances the functionality of the makeup remover, so that skin care and whitening can also be performed when removing makeup, meanwhile other plant extracts have certain fragrances, so that the product smells less irritating and more gentle, in addition, disodium EDTA is used as an antioxidant and can neutralize the stimulus brought by a surfactant, the cleaning effect of the surfactant is unaffected,thus the product is significantly less irritating and suitable for most skins, and adaptability of the product is improved.

Owner:GUANGZHOU HWASUEN HEALTH IND CO LTD

Jet-flowtype wearproof washing machine

InactiveCN102828377AReduce wearExtended service lifeWashing machine with receptaclesTextiles and paperWater flowSmall hole

The invention discloses a jet-flow type wearproof washing machine, which is mainly composed of a washing bucket, a water pump system, a water inlet system and a water outlet system. A water pump generates water pressure, so that a water stream flows into the washing bucket through a large water inlet hole and a small water inlet hole on the wall and bottom of the washing bucket; after water is injected into the washing bucket, the water entering the washing bucket through a large water inlet hole and the water flowing out of the washing bucket through a large water outlet hole form a horseshoe circulating stream inside the washing bucket; the circulating stream drives clothes to turn up and down inside the washing bucket, and rinses and softly rubs the clothes at the same time; the water flowing into the washing bucket from the wall of the washing bucket and the bottom edge of the bucket along the small water inlet holes uniformly distributed can rinse the clothes and prevent the clothes from rubbing with the wall and bottom of the washing bucket in the turn-over cleaning process at the same time. According to the jet-flow type wearproof washing machine, the abrasion of the clothes in the cleaning process is reduced to the minimal degree, and the service life of the clothes is effectively prolonged under the premise of not affecting the cleaning effect.

Owner:王新力

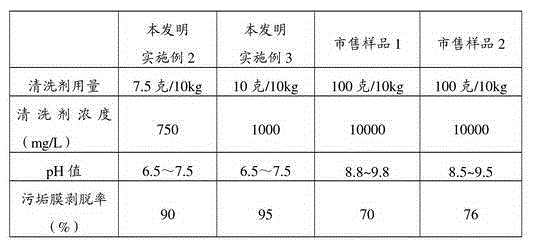

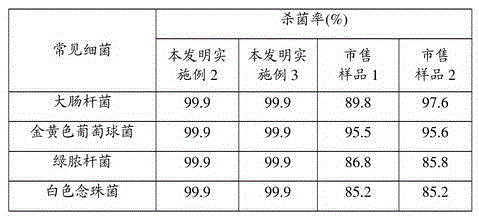

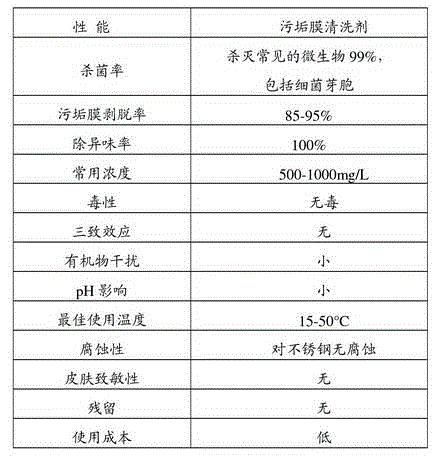

Washing machine tank surface dirt membrane cleaning agent

InactiveCN104560422ACause corrosionBroad-spectrum bactericidalInorganic/elemental detergent compounding agentsCationic surface-active compoundsEnvironmental resistanceSludge

The invention provides a washing machine tank surface dirt membrane cleaning agent. The washing machine tank surface dirt membrane cleaning agent comprises an oxidation bleaching agent, a surface dirt stripping agent, a washing and dirt-removing auxiliary agent, a metal protecting agent and chlorate. The washing machine tank surface dirt membrane cleaning agent has broad-spectrum and efficient bactericidal, algae removal, scale removal and sludge removal capability and can effectively remove bacteria, algae, and sticky sludge on and peculiar smell of the surfaces of an inner lining and an outer lining of a washing machine tank, so that clothes can be prevented from being polluted by the bacteria in the washing process; during use, the washing machine tank surface dirt membrane cleaning agent is not influenced by water hardness, can be used at the water temperature of 15-50 DEG C without influencing the cleaning effect, and does not corrode a washing machine; the using amount of the washing machine tank surface dirt membrane cleaning agent is only 1 / 10 that of an existing similar cleaning agent product, so that the requirement for environmental protection is met; the washing machine tank surface dirt membrane cleaning agent is good in safety, high in reliability and high in stability, can be stored in the dark for 6 months at the room temperature of 25 DEG C, but does not become invalid, and can be stored in the dark for 12 months at the temperature of 0 DEG C, but does not become invalid.

Owner:陈红锋 +1

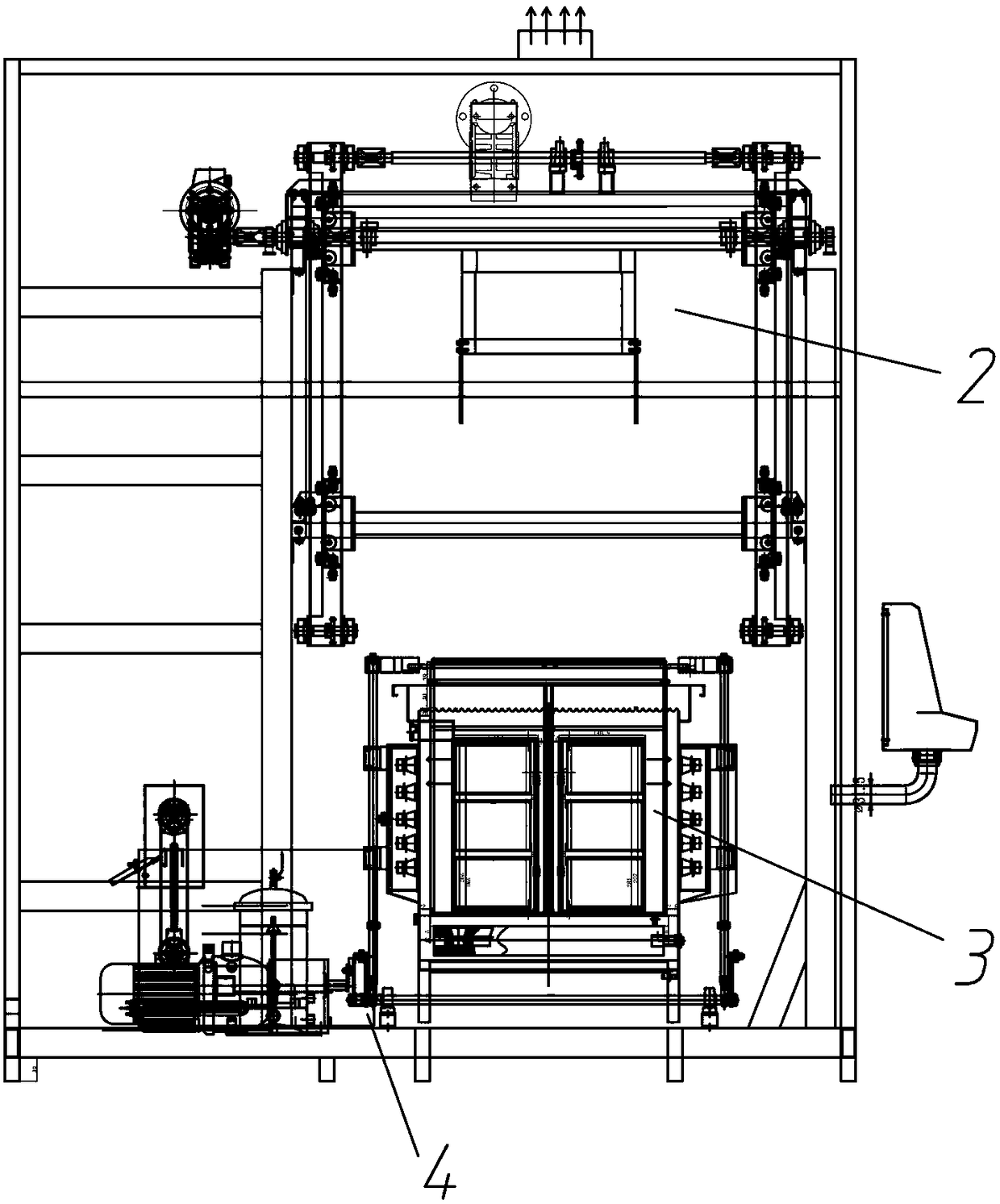

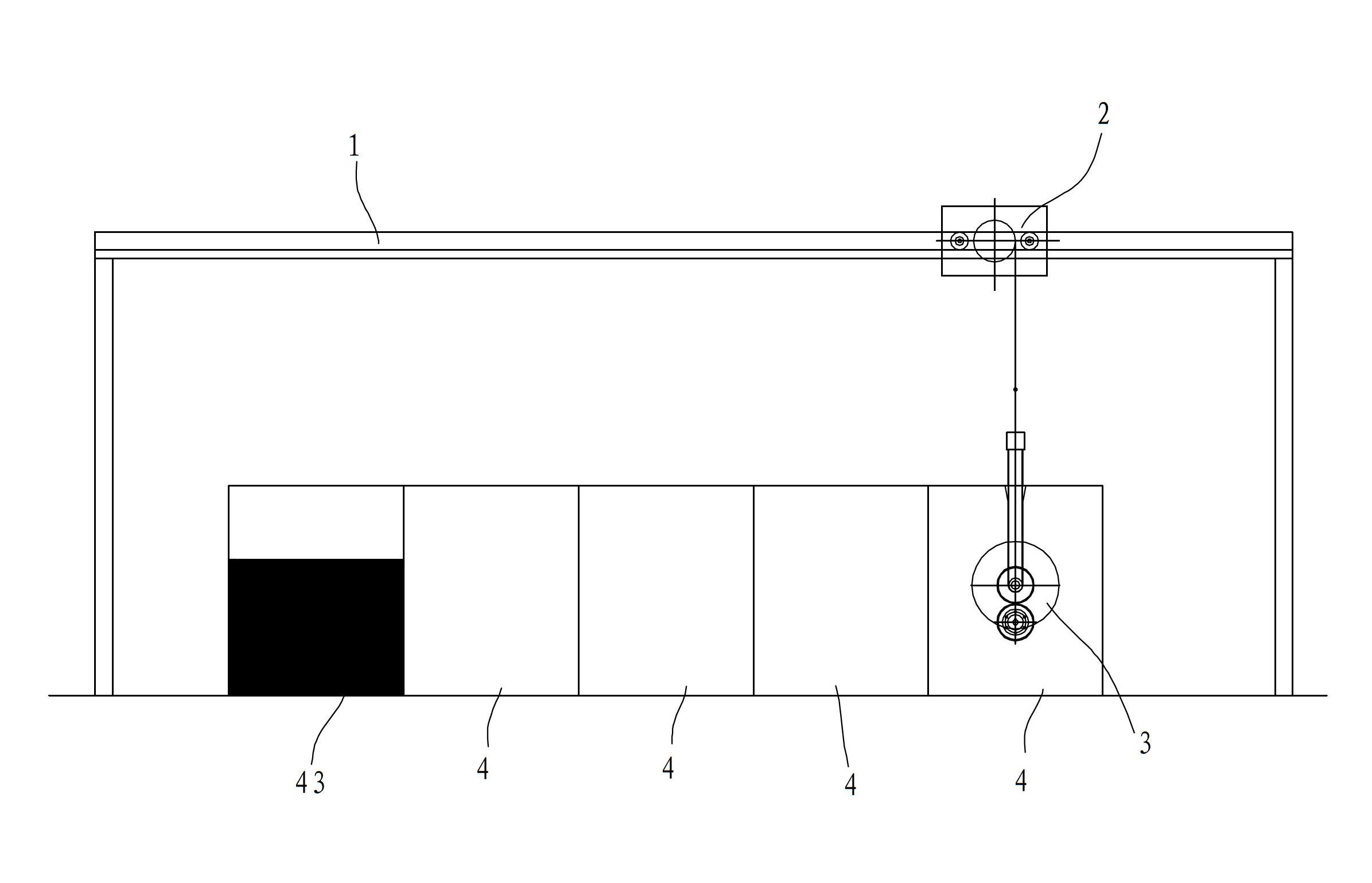

Ultrasonic cleaning device

InactiveCN102626701AEasy to removeDoes not affect the cleaning effectCleaning using liquidsElectric machineryUltrasonic generator

The invention discloses an ultrasonic cleaning device, which comprises a portal frame, a traveling crane capable of moving linearly on the portal frame and a cleaning tank filled with cleaning liquid, and an ultrasonic generator is arranged in the cleaning tank. The ultrasonic cleaning device is characterized in that the traveling crane is connected with a cleaning cylinder driven by a motor to rotate through a transmission mechanism in telescopic mode, and the cleaning cylinder can be placed in the washing tank. The ultrasonic cleaning device further comprises a control system controlling the traveling crane, the ultrasonic generator and the motor to act. By means of arrangement of the control system, the ultrasonic cleaning device reduces working intensity. Workers only need to fill the cleaning liquid before cleaning, other work procedures are finished in a control chamber, and operation safety is ensured. The cleaning liquid can be recycled, waste of the cleaning liquid is reduced, and cost is greatly reduced.

Owner:ZHOUSHAN JINQIU MACHINERY

Cleaning device for improved winding machine

The invention discloses a cleaning device for an improved winding machine. The cleaning device for the improved winding machine comprises a U-shaped installation frame and two cleaning rollers, wherein three limited blocks are uniformly arranged on an output shaft of the motor; limited grooves matched with the limited blocks are formed in the inner sides of the cleaning rollers; fixed screws are arranged between the cleaning rollers and the limited blocks; and an air outlet pipe is arranged in the U-shaped installation frame and is located in a collecting groove. According to the cleaning device for the improved winding machine provided by the invention, the motor and the cleaning rollers are arranged, and the motor rotates to drive the cleaning rollers to rotate, so that yarns are cleanedthrough the cleaning rollers; the cleaning rollers always keep the rotating state, so that yarns in mess can be dropped down easily; meanwhile, by utilizing a high pressure gas, the yarns in mess areblown away from the yarns through the air outlet pipe so as to be prevented from re-contacting the yarns, so that a cleaning effect cannot be influenced; and the cleaning rollers and the output shaftof the motor are clamped by utilizing the limited blocks and the limited grooves and are fixed by utilizing the fixed screws so as to be conveniently disassembled and cleaned.

Owner:江苏汤氏纺机集团有限公司

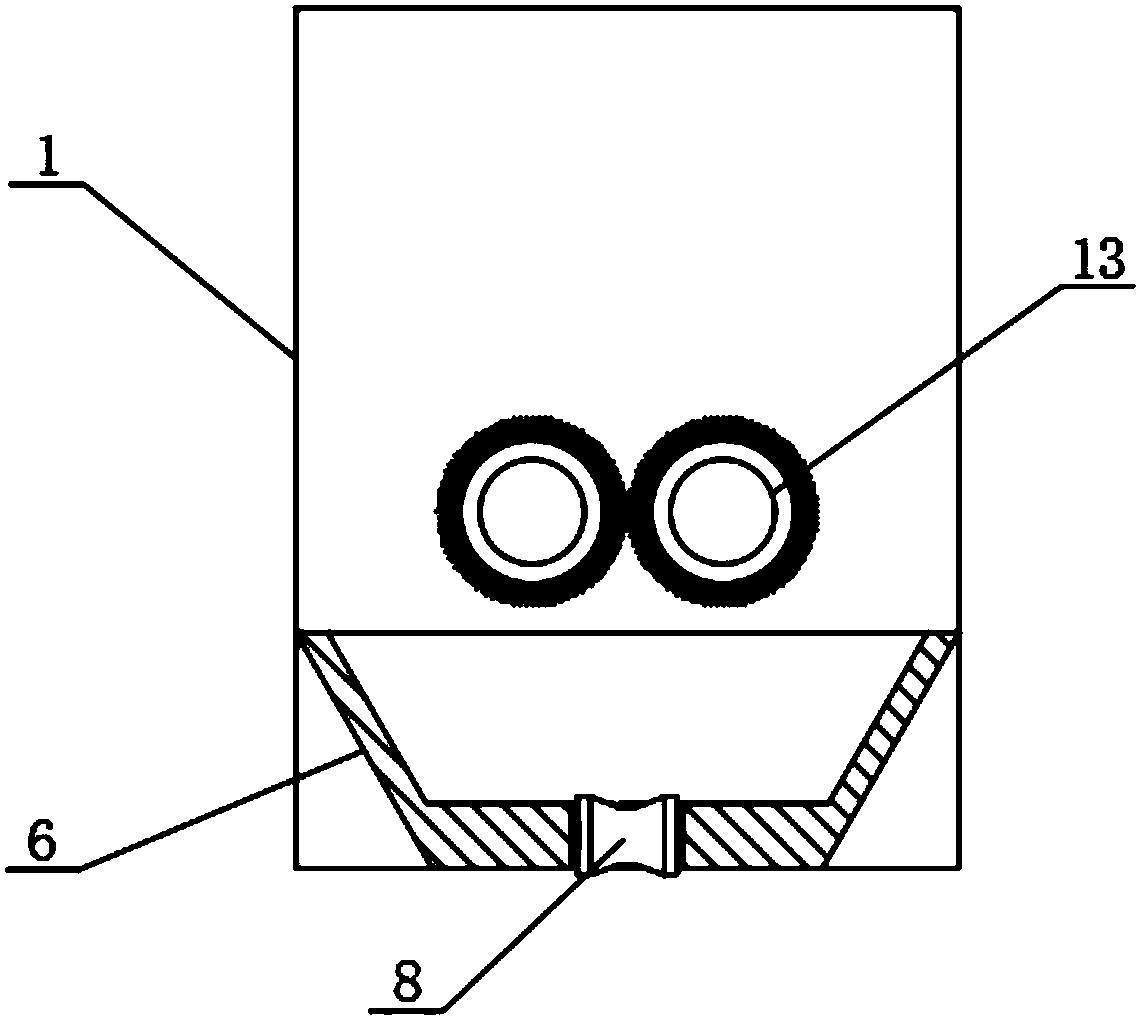

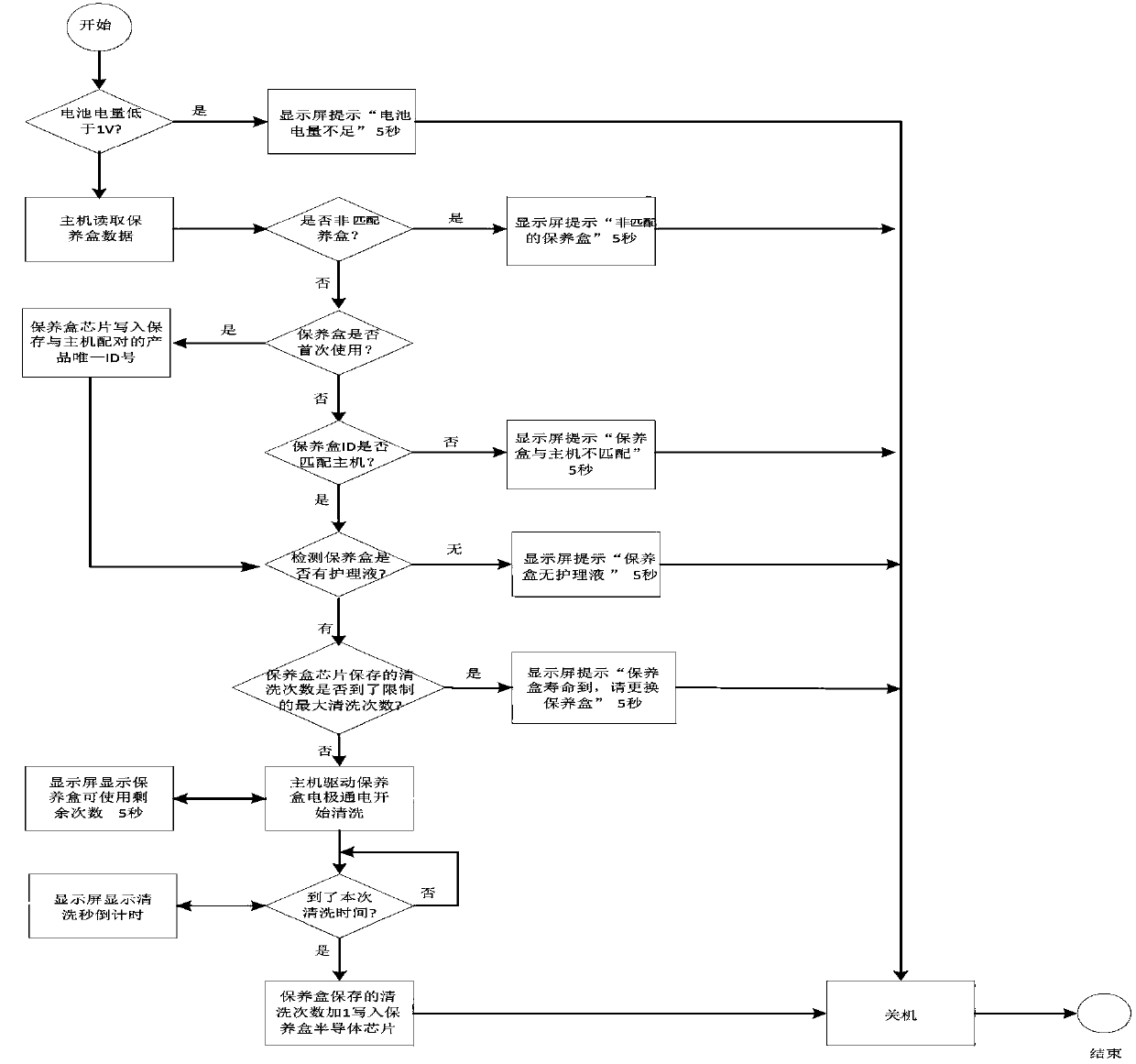

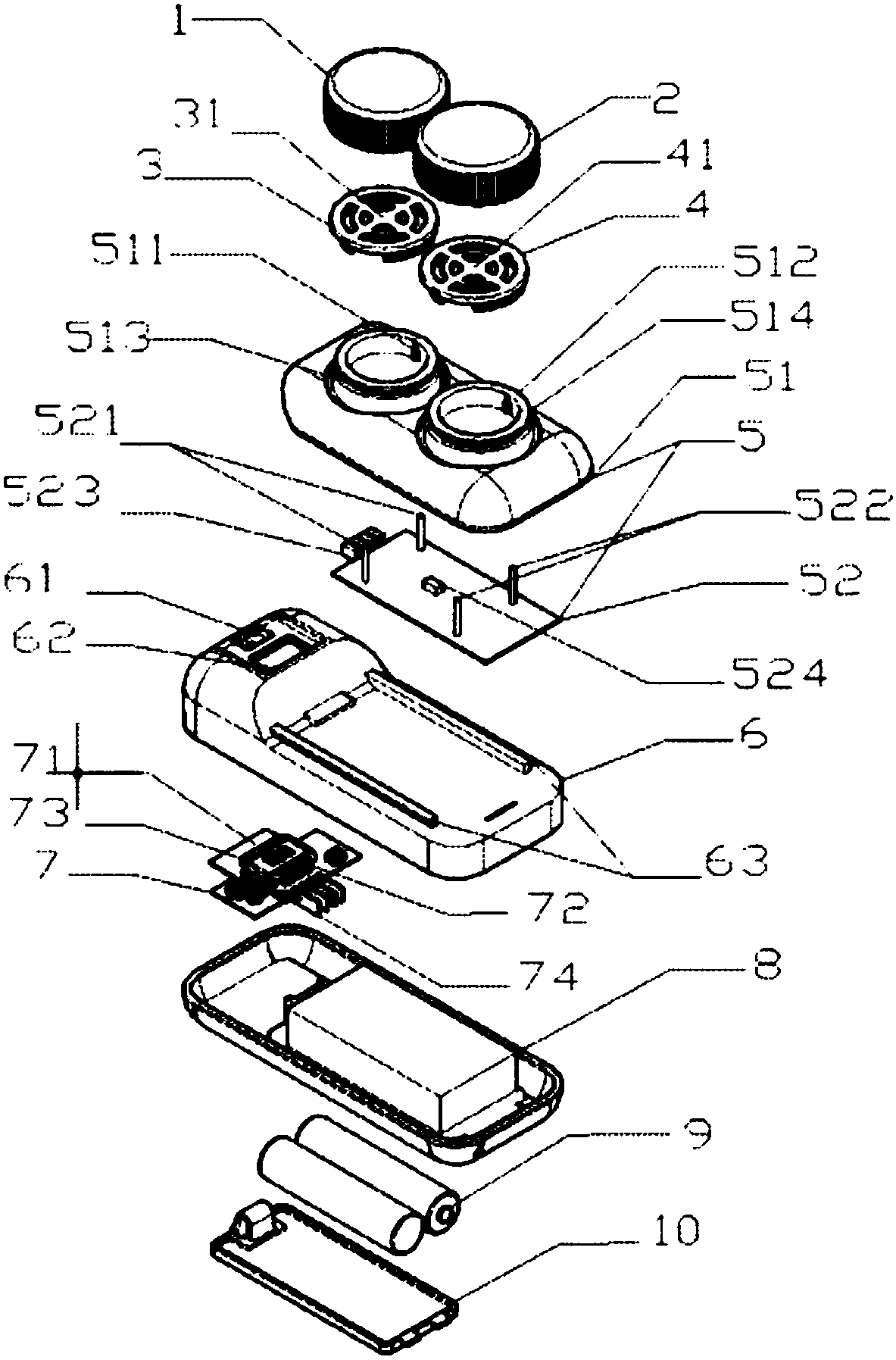

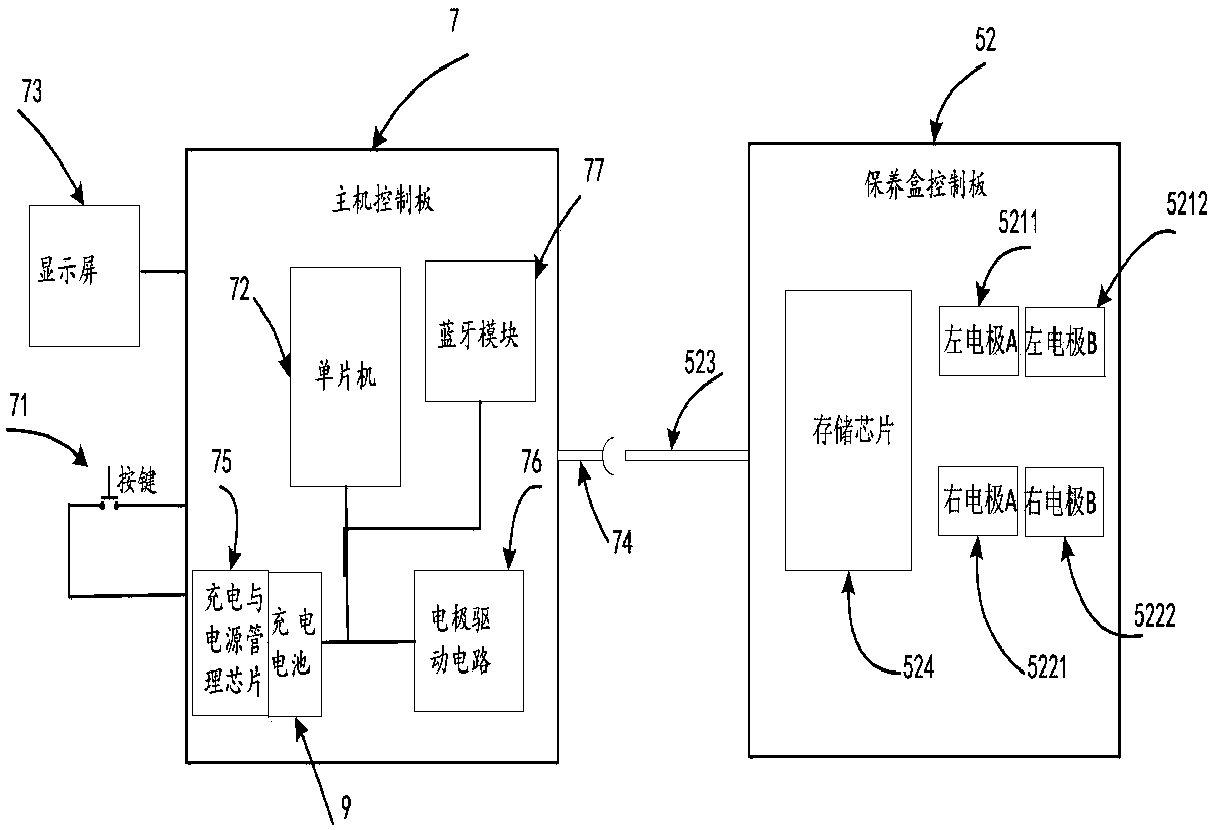

Intelligent cleaner of contact glasses and use method of cleaner

ActiveCN107589563AAvoid cross usageReduce cross infectionSpectales/gogglesEngineeringBattery capacity

The invention discloses an intelligent cleaner of contact glasses and a use method of the intelligent cleaner. A low battery, not matching, no contact glasses care solution or not a maintenance box containing contact glasses care solution is removed according to battery capacity, number of use, a product ID number, first use identification, availability of the contact glasses care solution or thecontact glasses care solution or not; if the maintenance box is matched and the contact glasses care solution is available, the number of the use is judged; the cleaning is started; and the number isincreased after the cleaning. The ID of the maintenance box is paired; the cleaner cannot be used if the ID is unmatched; cross use of products among users can be avoided; eye disease transmission andcross infection are reduced.

Owner:苏州森克尔生物医疗科技有限公司

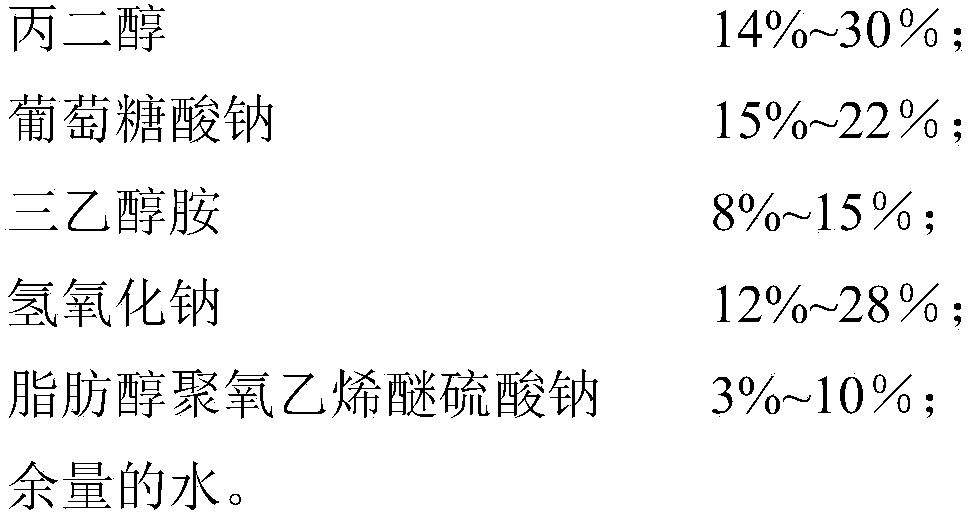

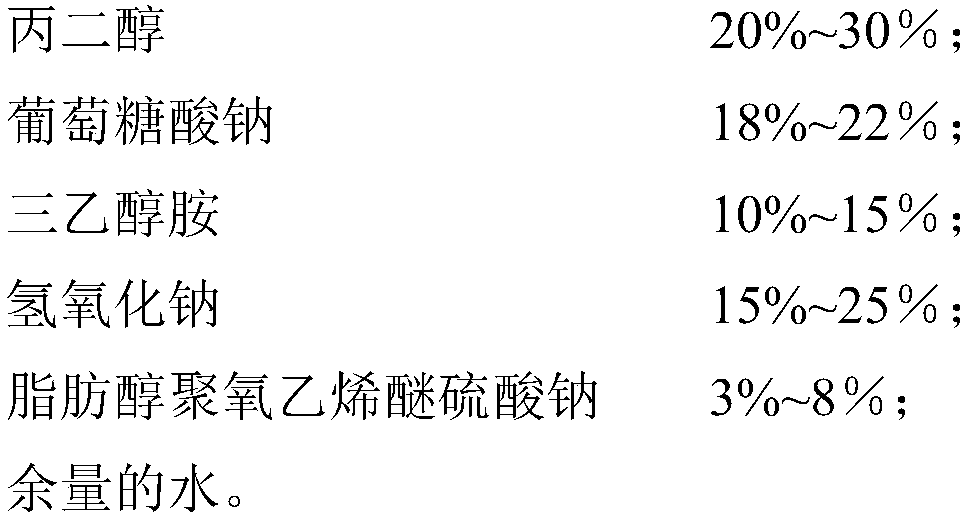

Cleaning agent for metal part

The invention discloses a cleaning agent for a metal part. The cleaning agent for the metal part is composed of, by mass, 14-30% of propylene glycol, 15-22% of sodium gluconate, 8-15% of triethanolamine, 12-28% of sodium hydroxide, 3-10% of fatty alcohol-polyoxyethylene ether sodium sulfate and the balance water. The cleaning agent for the metal part is high in permeating performance and detergency and capable of effectively removing all kinds of dirt and impurities on the surface of the metal part and guaranteeing the machining precision of metal equipment. The cleaning agent for the metal part is free of corrosiveness to the metal part, makes rinsing easy, is biodegradable and environmentally friendly, and does not contain benzene type organic solvent, halogenated hydrocarbon type organic solvent and other kinds of organic solvent and toxic and harmful substances.

Owner:苏州市神顺新晨生物科技有限公司

Novel intelligent dust collector

The invention provides a novel intelligent dust collector, and belongs to the technical field of dust collectors. The problem that an existing intelligent dust collector cannot sweep away dust completely is solved. The novel intelligent dust collector comprises a shell. The top face of the shell and the bottom face of the shell are provided with functional buttons and rollers respectively. The section of the side face of the shell is circular. Inward-concaved sunken parts are arranged in the peripheral direction of the side face of the shell at equal angles. The sunken parts form a tooth-shaped structure on the side face of the shell. Due to the fact that the inward-concaved sunken parts are arranged in the peripheral direction of the side face of the shell at equal angles, when the intelligent dust collector collects dust and the sunken parts enter and abut against a table corner or a chair leg, the intelligent dust collector will rotate around the center of the table corner or the chair leg for dust collection and removal, and the phenomenon that the sweeping effect is affected due to the fact that no supporting point is formed and the direction is changed when a traditional intelligent dust collector meets a table corner or a chair leg is avoided.

Owner:鲁杨

Device for cleaning inner wall and outer wall of can

InactiveCN107803380AEffectively go outImprove cleaning efficiencyHollow article cleaningHydraulic cylinderEngineering

The invention discloses a device for cleaning the inner and outer walls of cans, relates to the technical field of cleaning devices and solves the problem of poor cleaning effect of existing can cleaning devices. The present invention is characterized in that it includes a lower hydraulic cylinder, an upper hydraulic cylinder, a feeding table and a water tank, the upper end of the lower hydraulic cylinder is connected with a cap, and an outer cleaning layer and an inner cleaning layer are connected above the cap, and the feeding The platform can transport the cans to the designated position. The lower end of the upper hydraulic cylinder is connected with the bottom cleaning layer. The water tank is connected with the lower water inlet channel connected with the outer cleaning layer and the inner cleaning layer. Connected upper water inlet channel. The invention has the advantages of high cleaning efficiency and good effect.

Owner:成都尚智恒达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com