Ultrasonic cleaning device

A cleaning device and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of gasoline volatile, flammable and explosive, waste, etc., to reduce work intensity, ensure Safety, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

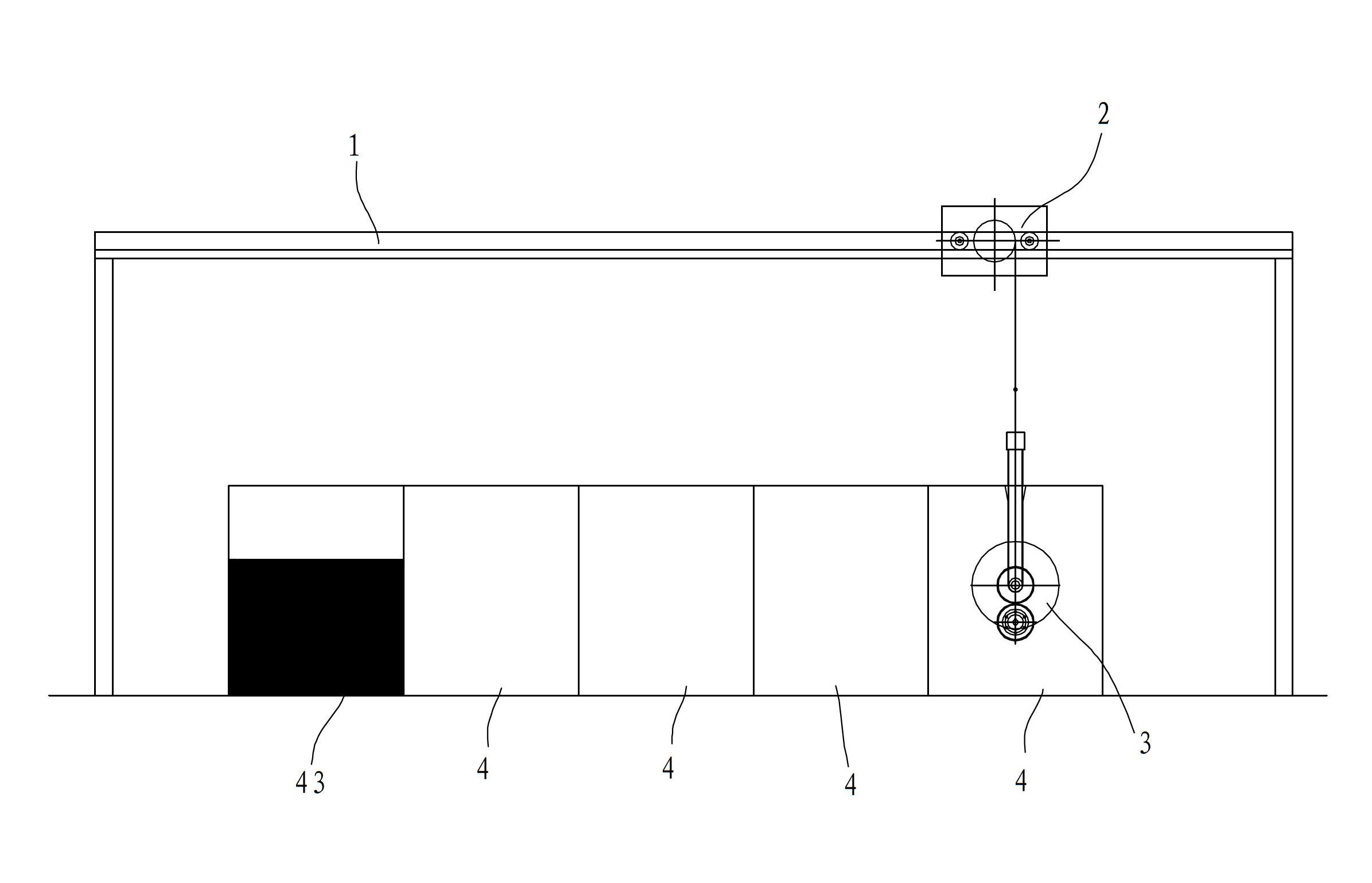

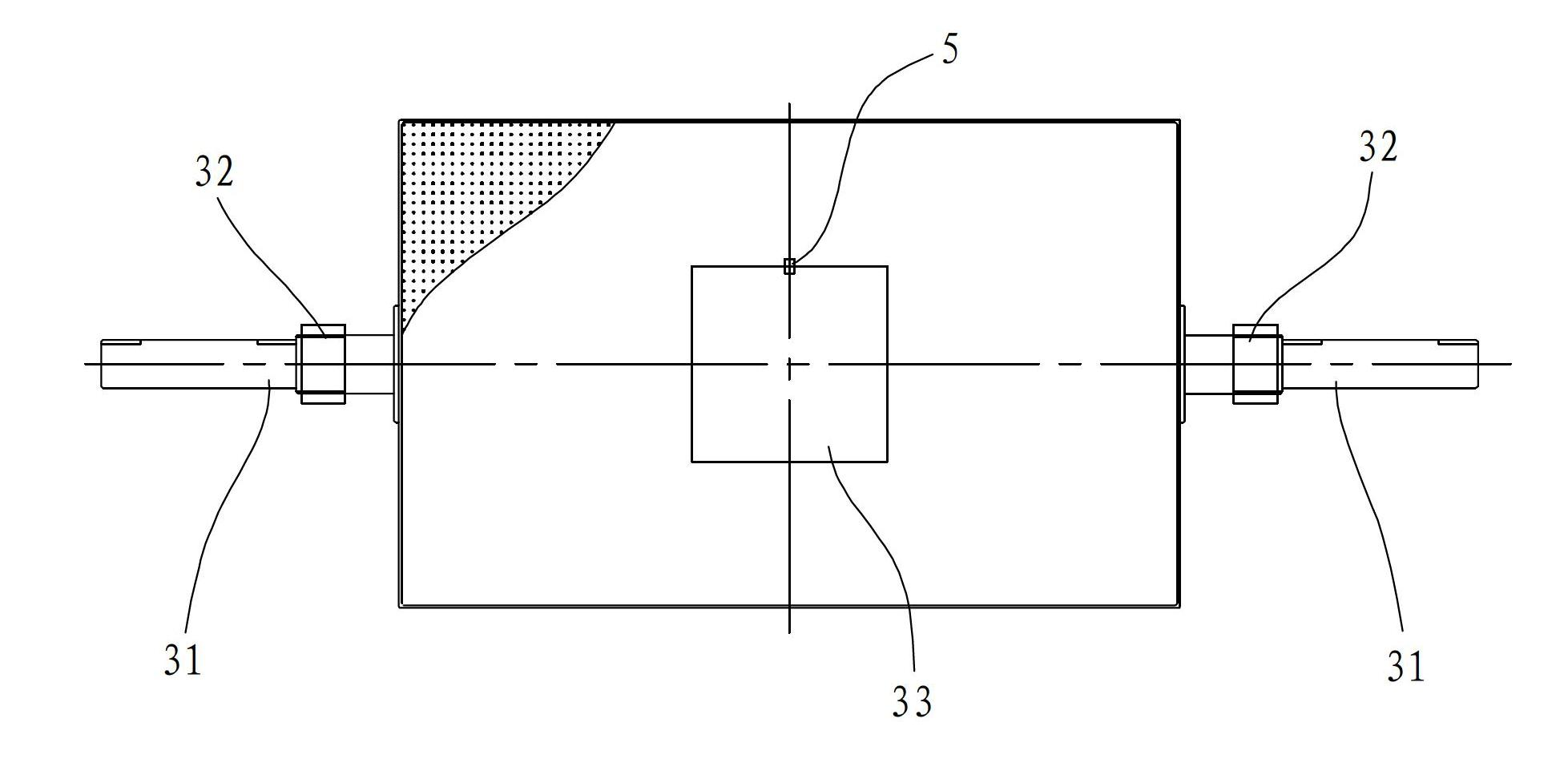

[0016] see figure 1 , an ultrasonic cleaning device, comprising a gantry 1, a crane 2 that can move linearly on the gantry 1, a cleaning tank 3 is telescopically connected to the bottom of the crane 2, and the cleaning tank 3 is placed in a cleaning tank 4 for cleaning.

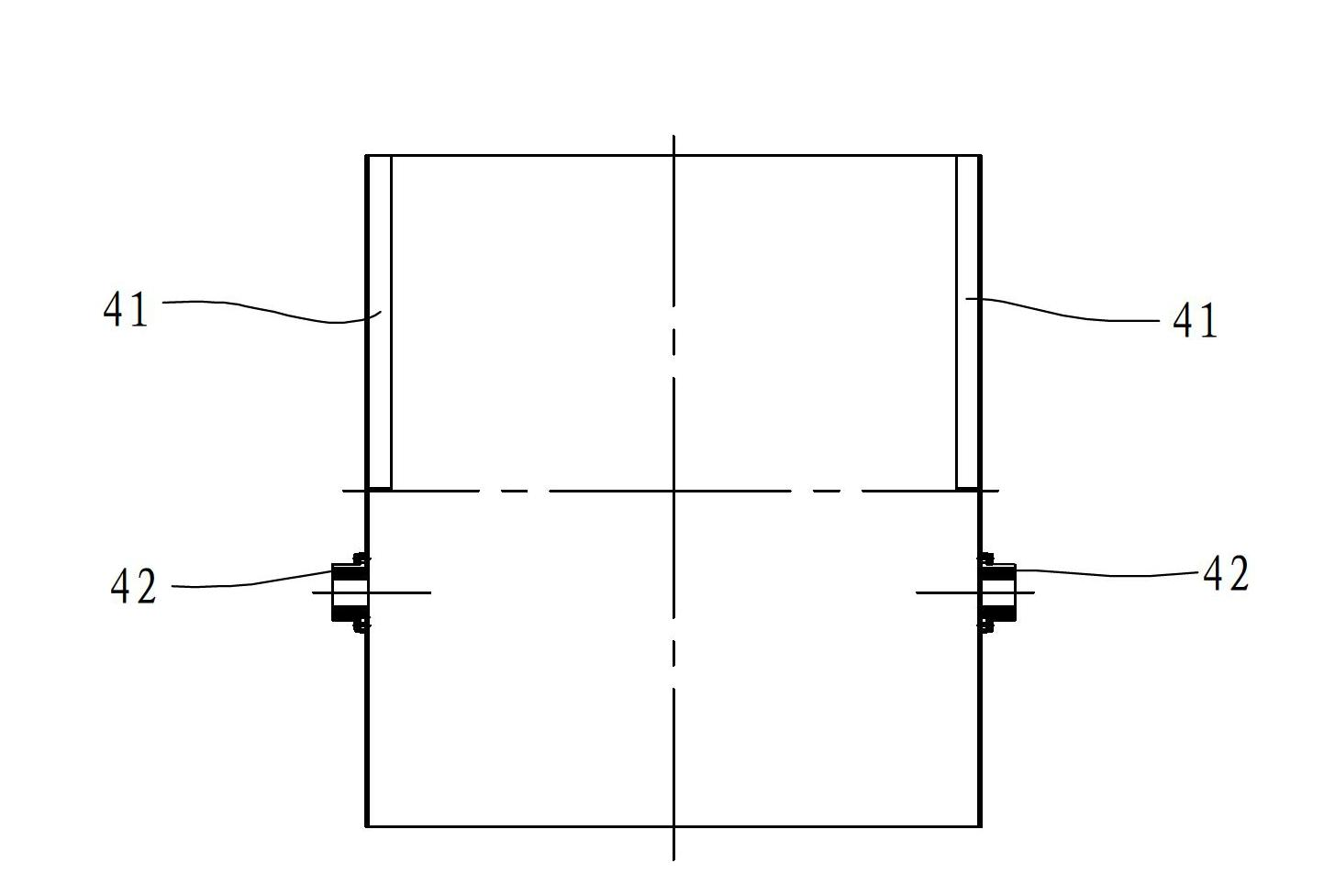

[0017] The cleaning device comprises at least one cleaning tank 4, and the two side walls of the cleaning tank 4 are provided with guide grooves 41, see figure 2 , used to guide the cleaning tank 3 into the cleaning tank 4. On the two side walls of the cleaning tank 4, at the corresponding position below the guide groove 41, a driving gear 42 is provided, which is driven by a motor (not shown).

[0018] The cleaning tank 4 is provided with an ultrasonic generator and a cleaning liquid recycling device 43. The cleaning liquid recycling device 43 includes a circulation pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com