Automatic cleaning machine for steel dies

An automatic cleaning and cleaning machine technology, which is applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of unreliable cleaning, unclean cleaning, and inaccurate alignment of steel mold joints and other problems, to achieve the effect of simple structure, easy promotion, and remarkable cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

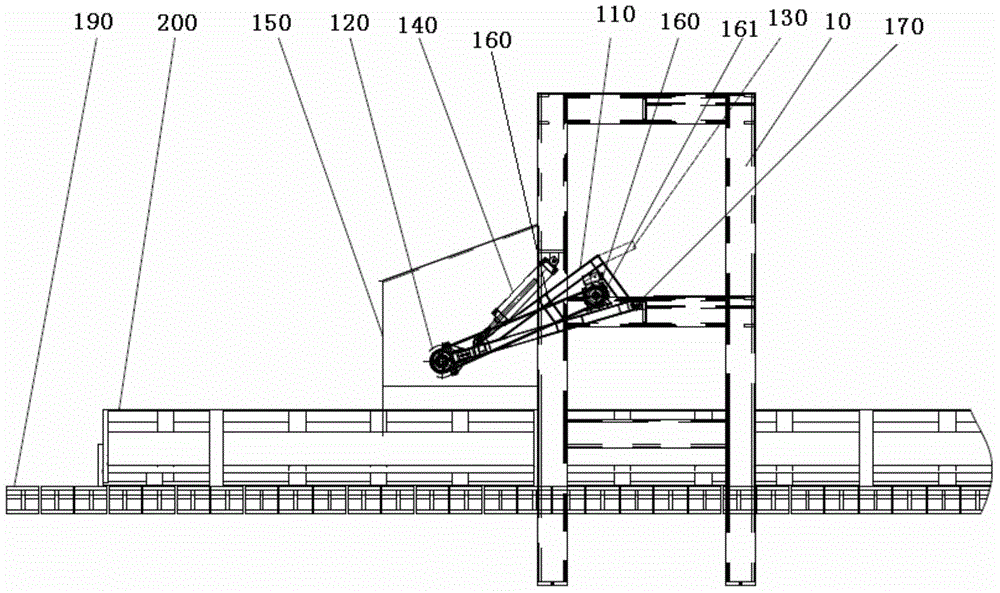

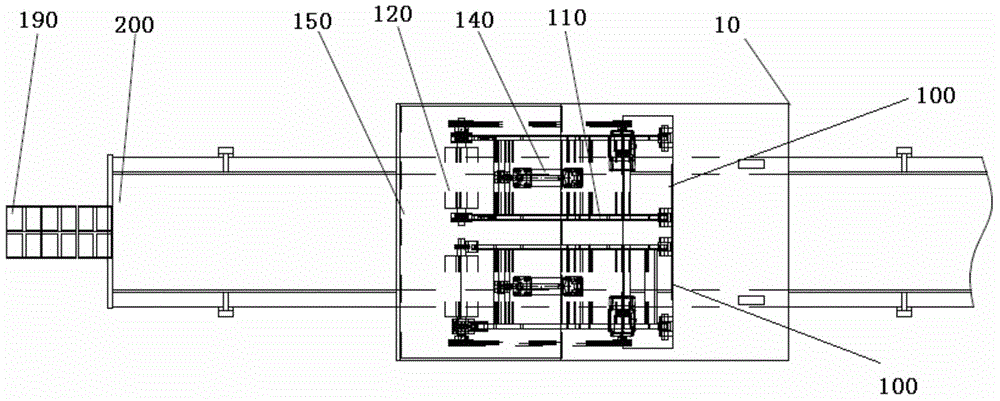

[0023] see figure 1 and figure 2 As shown, the present invention discloses a steel mold automatic cleaning machine, including a cleaning machine frame 10 and a PLC control system (not shown in the figure) for controlling the operation of the cleaning machine; the steel mold automatic cleaning machine also includes two symmetrically installed The cleaning device 100 on the cleaning machine frame has the same structure as the two cleaning devices, and both of them work independently during work without affecting each other.

[0024] The two cleaning devices 100 of the present invention all comprise lifting frame 110, wire brush 120, counterweight 130, cylinder 140, dust collection cover 150, drive motor 160 and belt 170; On the cleaning machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com