Jet-flowtype wearproof washing machine

A washing machine and anti-wear technology, which is applied to washing machines with containers, washing devices, textiles and papermaking, etc. It can solve the problems of strong friction, high water flow rate, and reduced service life of clothes, so as to prolong the service life and lighten the rubbing effect Slow and wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

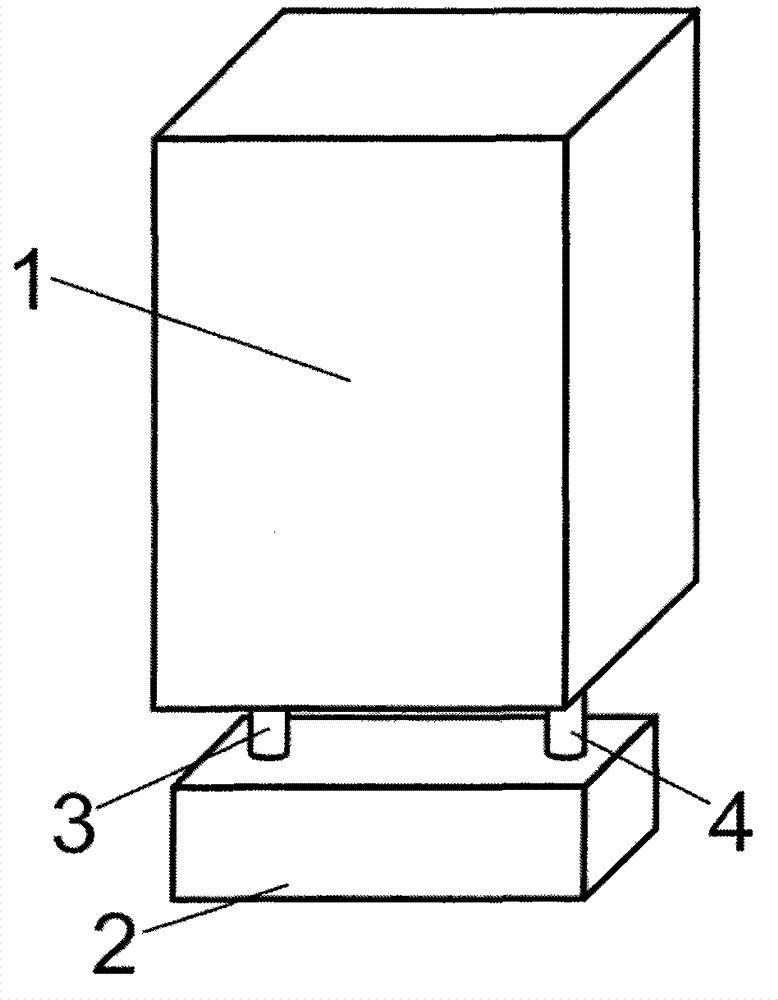

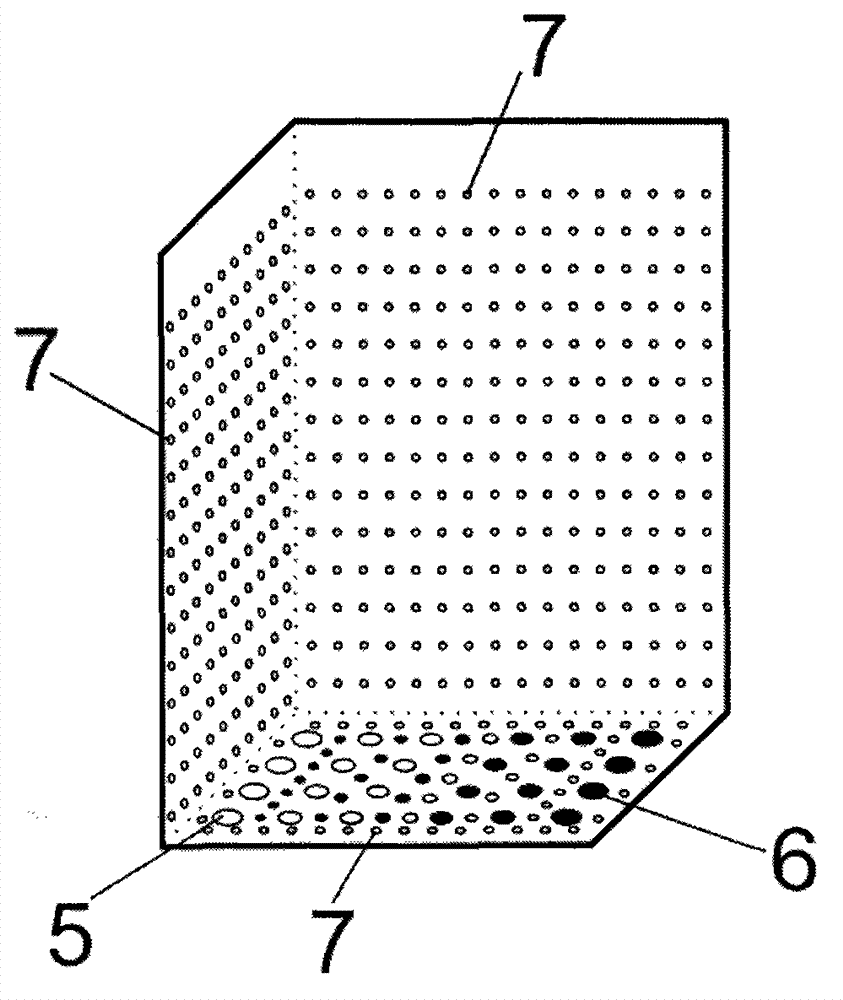

[0014] according to figure 1 and figure 2 As shown, before starting to work, the jet-flow anti-wear washing machine injects water into the washing tub (1), then turns on the water pump system (2), and the washing machine starts to work. The high-pressure water flow generated by the water pump system (2) flows into the washing tub (1) from the large water inlet hole (5) and the small water inlet hole (7) through the water inlet system (3). Simultaneously, the water in the washing bucket (1) flows out of the washing bucket (1) from the water outlet hole (6) at the bottom of the bucket, and returns to the water pump system (2) through the water outlet system (4), forming a water circulation system. The water flowing in the washing tub (1) moves due to the impact of the high-pressure water in the large water inlet hole (5) and the suction force of the large water outlet hole (6), forming a horseshoe-shaped water circulation that moves from left to right and down. The washing tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com