Method for cleaning silicon wafer at room temperature

A technology for cleaning silicon wafers at room temperature, applied in chemical instruments and methods, detergent compositions, non-surface-active detergent compositions, etc., can solve problems such as high cost and potential safety hazards, and achieve the effect of reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

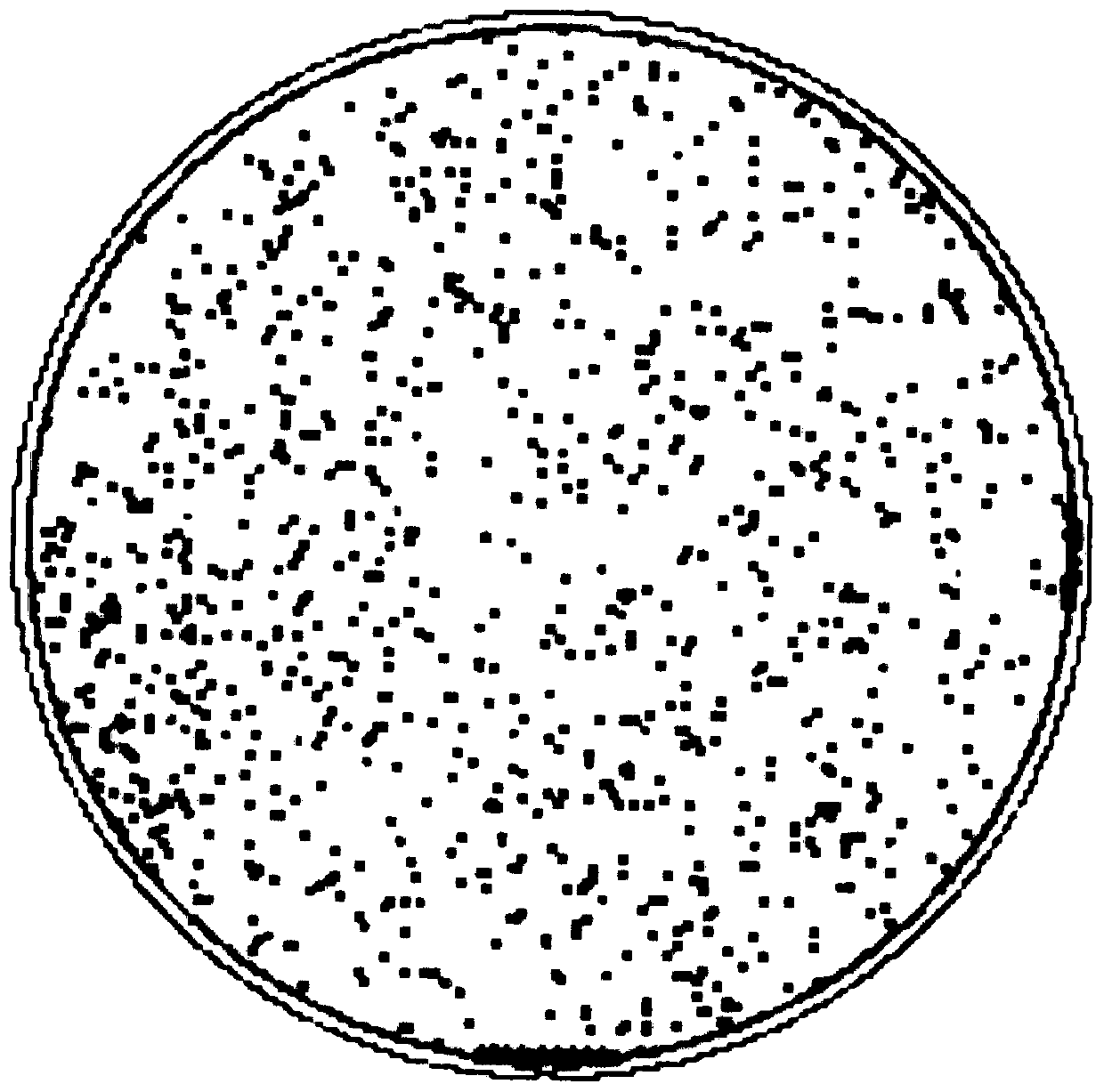

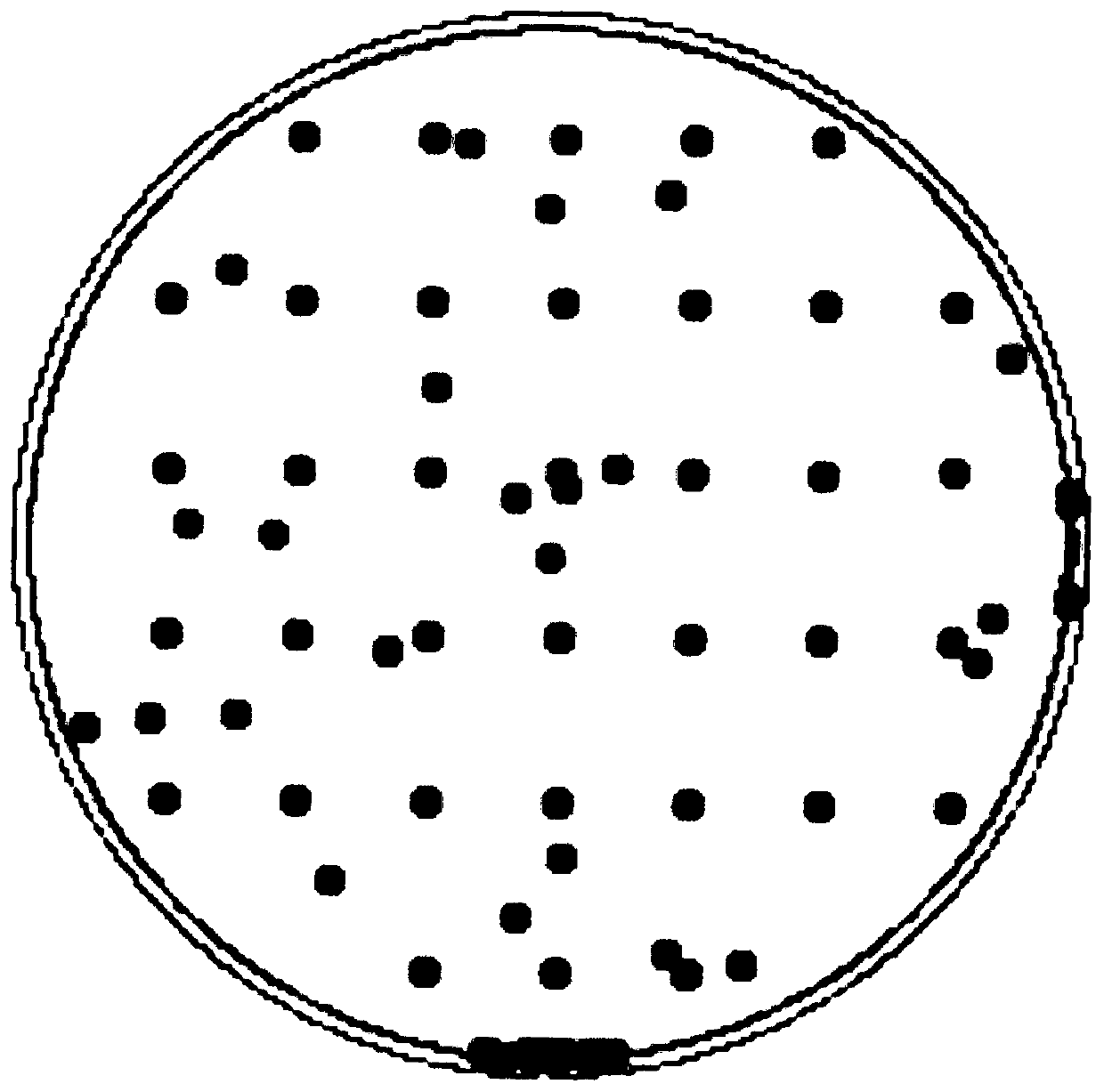

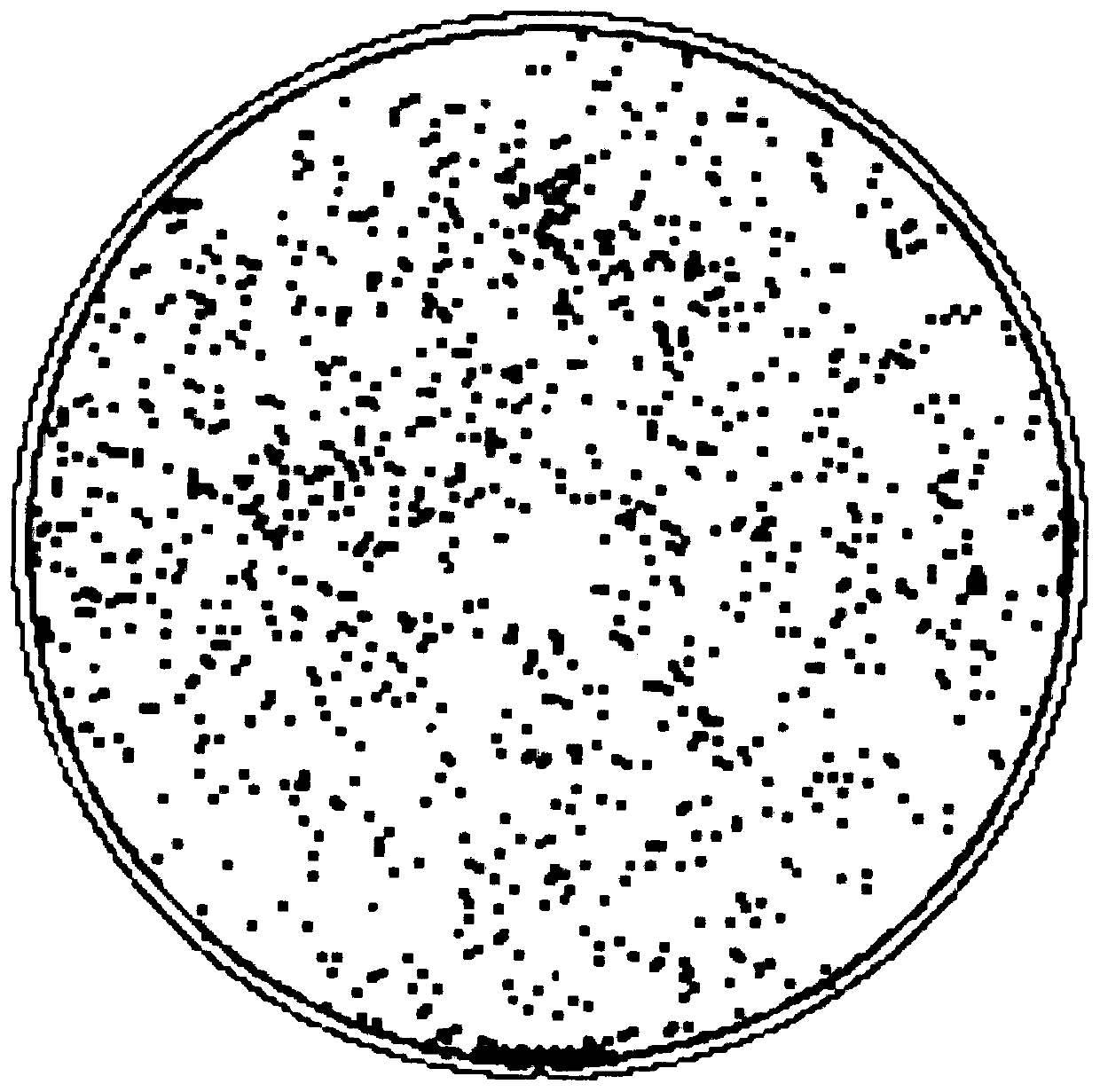

Image

Examples

Embodiment Construction

[0020] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. It should be understood by those skilled in the art. The content specifically described below is illustrative rather than restrictive. Users can make various changes to the following parameters without departing from the mechanism and scope of the invention set forth in the claims. In order not to obscure the essence of the present invention, well-known methods and procedures have not been described in detail.

[0021] A method for cleaning silicon wafers at room temperature comprises the following steps, and the following steps are carried out in order:

[0022] Step 1. Configure the cleaning solution:

[0023] Mix ammonium hydroxide with a concentration of 29%, hydrogen peroxide with a concentration of 31%, and deionized water at a volume ratio of 1:2:50 to obtain a cleaning solution, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com