Corrosion resistant clad plate with flame resisting construction and preparation method thereof

A composite board, corrosion-resistant technology, used in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of acid resistance, poor pollution resistance, poor fire resistance, acid resistance and heat resistance of metal materials Not ideal and other problems, to achieve the effect of no pollution in the production process, good social and economic benefits, and broadening the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

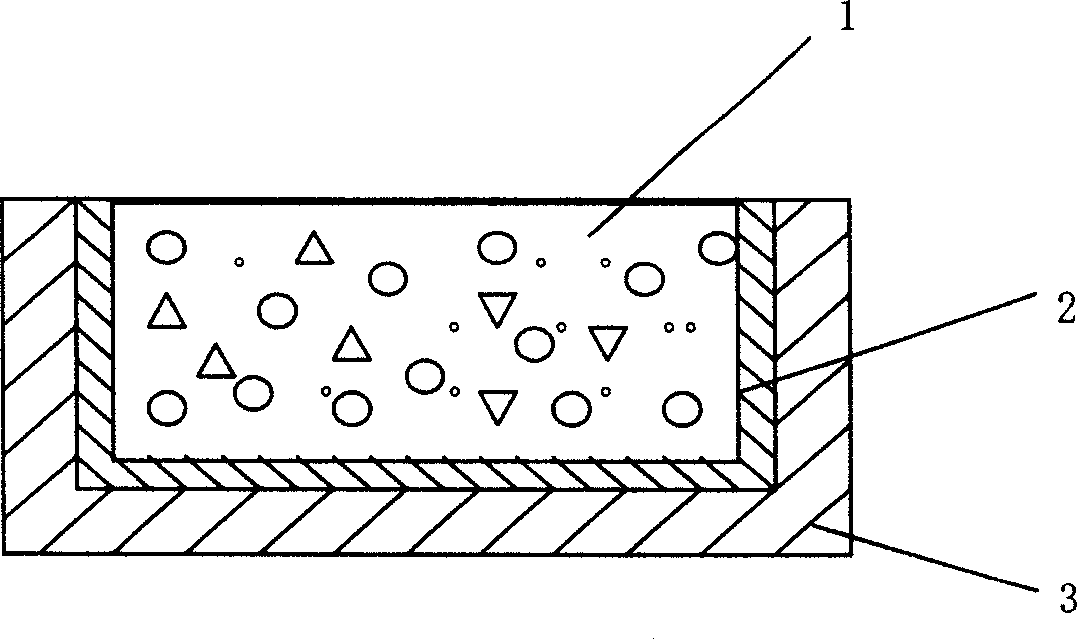

[0019] See attached figure 1 , the preparation weight ratio is the mixed resin that the phenolic resin and epoxy resin of 1: 1 are mixed, the above-mentioned mixed resin, 400 mesh talcum powder, carbon black, ammonium polyphosphate, glass fiber, hexabromocyclododecane are weighed Mix and stir at a ratio of 100:120:1:30:1:10, then add the curing system diethylenetriamine, the amount of which accounts for 15% of the total weight of the mixed resin, and pour it into the mold after stirring evenly. After being naturally cured for 20-40 minutes at 20° C., and then cured at 90° C. for 100 minutes, the polymer material cladding layer 3 is prepared with a thickness of about 3 mm.

[0020] Mix the above mixed resin and diethylenetriamine, wherein the amount of the curing system diethylenetriamine accounts for 15% of the total weight of the mixed resin, and then mix it with No. 425 Portland cement in a weight ratio of 1:4 to make a transition layer , uniformly covered on the cladding l...

Embodiment 2

[0024] See attached figure 1 , unsaturated resin and epoxy resin are mixed into mixed resin, and its weight ratio is 1: 1, with above-mentioned mixed resin, 500 mesh kaolin, carbon black, ammonium polyphosphate, polypropylene fiber, brominated epoxy resin by 100 : 100: 1: 40: 1: 20 after mixing in weight ratio, stir evenly, then add the composition of triethylamine, methyl ethyl ketone peroxide and cobalt naphthenate in the curing system, the weight ratio of each component in the composition is 1: 1 : 1, its consumption accounts for 25% of the total weight of the mixed resin, pour it into a mold after stirring evenly, and after curing naturally at 20°C for 20-40min, solidify at a temperature of 70°C for 40min to prepare a polymer material covering layer 3, Its thickness is about 3mm.

[0025] Add curing system in the above mixed resin, the curing system is composed of triethylamine, methyl ethyl ketone and cobalt naphthenate in a weight ratio of 1: 1: 1, and its consumption a...

Embodiment 3

[0029] See attached figure 1 , mixed into mixed resin with phenolic resin and unsaturated resin, its weight ratio is 1: 1, above-mentioned mixed resin, 400 order calcium carbonate, carbon black, magnesium hydroxide, polybutadiene glycol, chlorinated paraffin- 70 is mixed according to the weight ratio of 100:120:1:30:5:15, stirred evenly, and then added to the curing system, which is composed of dimethylaniline and benzoyl peroxide, and the weight ratio of each component is 1 : 1, the amount of curing system accounted for 10% of the total weight of the mixed resin, stirred evenly and poured into the mold, naturally cured at 20°C for 200-40min, and then cured at 100°C for 40min to prepare a polymer material covering protective layer 3. Its thickness is about 3mm.

[0030] Mix the above-mentioned mixed resin, dimethylaniline, and benzoyl peroxide with Portland cement No. 425 in a 1:1 weight ratio to make a transition layer, wherein the weight ratio of dimethylaniline and benzoyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com