Automatic ink box sealing device

A sealing device and ink cartridge technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of uneven sealing surface, easy folding, waste of aluminum film materials, etc., to improve efficiency and sealing effect, stability and Good reliability, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

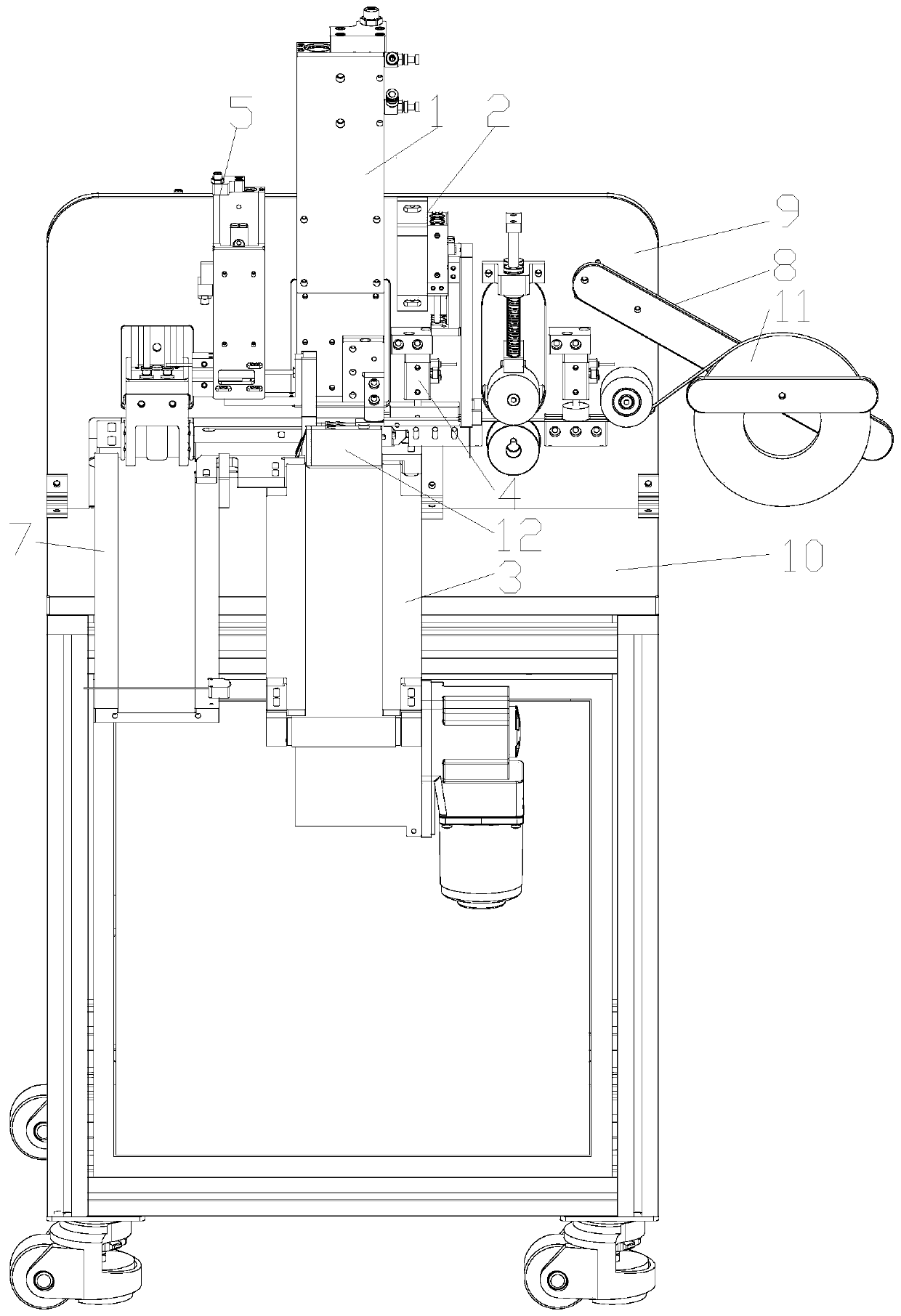

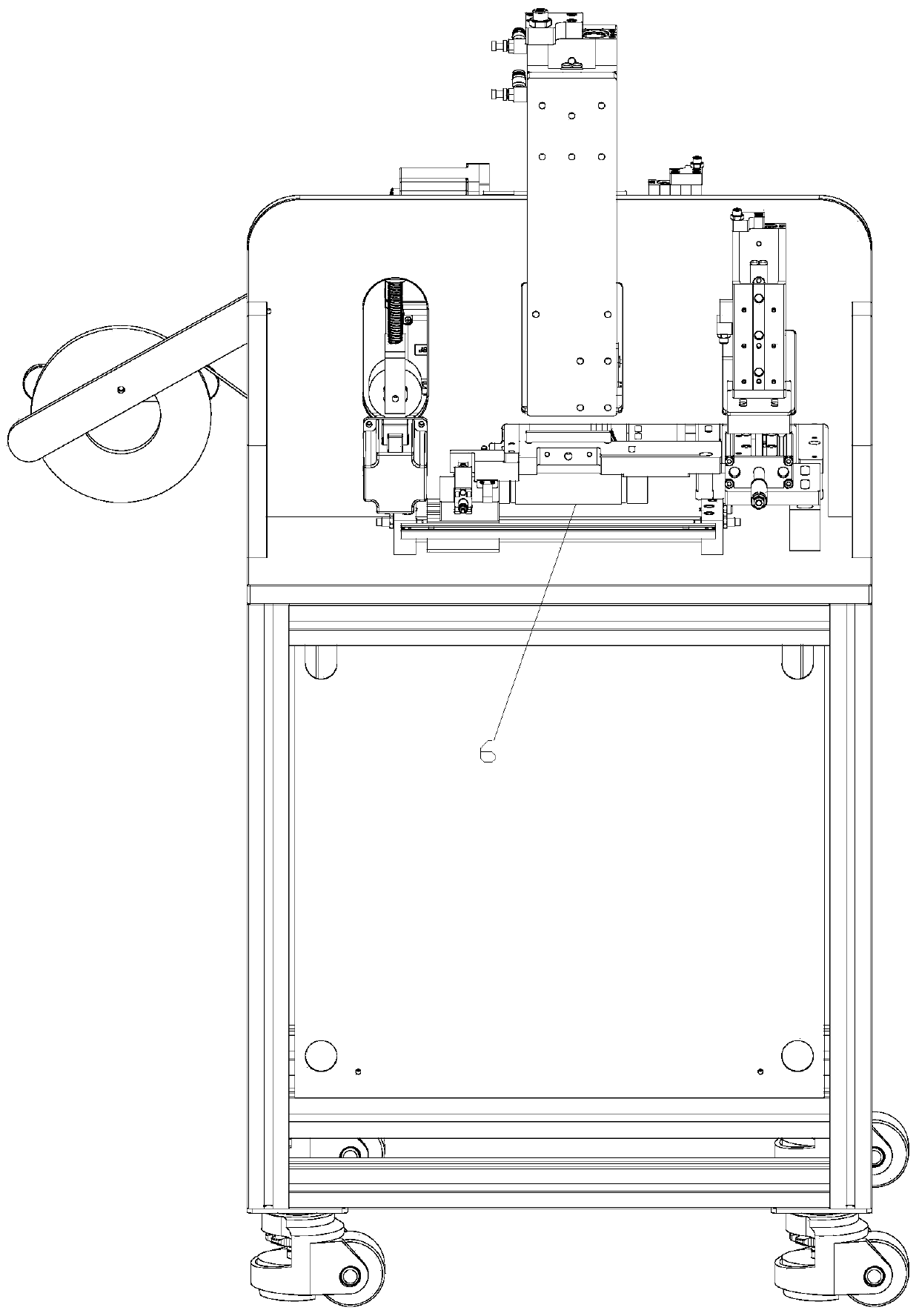

[0096] Automatic cartridge sealer, such as Figure 1~4 Shown, comprise frame 9, machine table 10, first guide mechanism 5, second guide mechanism 6, ironing mechanism 1, unwinding mechanism 81, pressing mechanism 83 and first delivery mechanism 3, frame 9 is located at On the machine table 10, the first guide mechanism 5 includes a first push plate 51 and a first guide member, the first guide member is used to push the first push plate 51 to move along the length direction of the machine table 10, and the second guide mechanism 6 includes a first push plate 51 to move along the length direction of the machine table 10. Two push plates 61 and a second guide, the second guide is used to push the second push plate 61 to move along the width direction of the machine table 10, the ironing mechanism 1 is located between the first push plate 51 and the second push plate 61, The cutting mechanism 2 includes a cutting piece and a cutting guide. The cutting guide is used to push the cut...

Embodiment 2

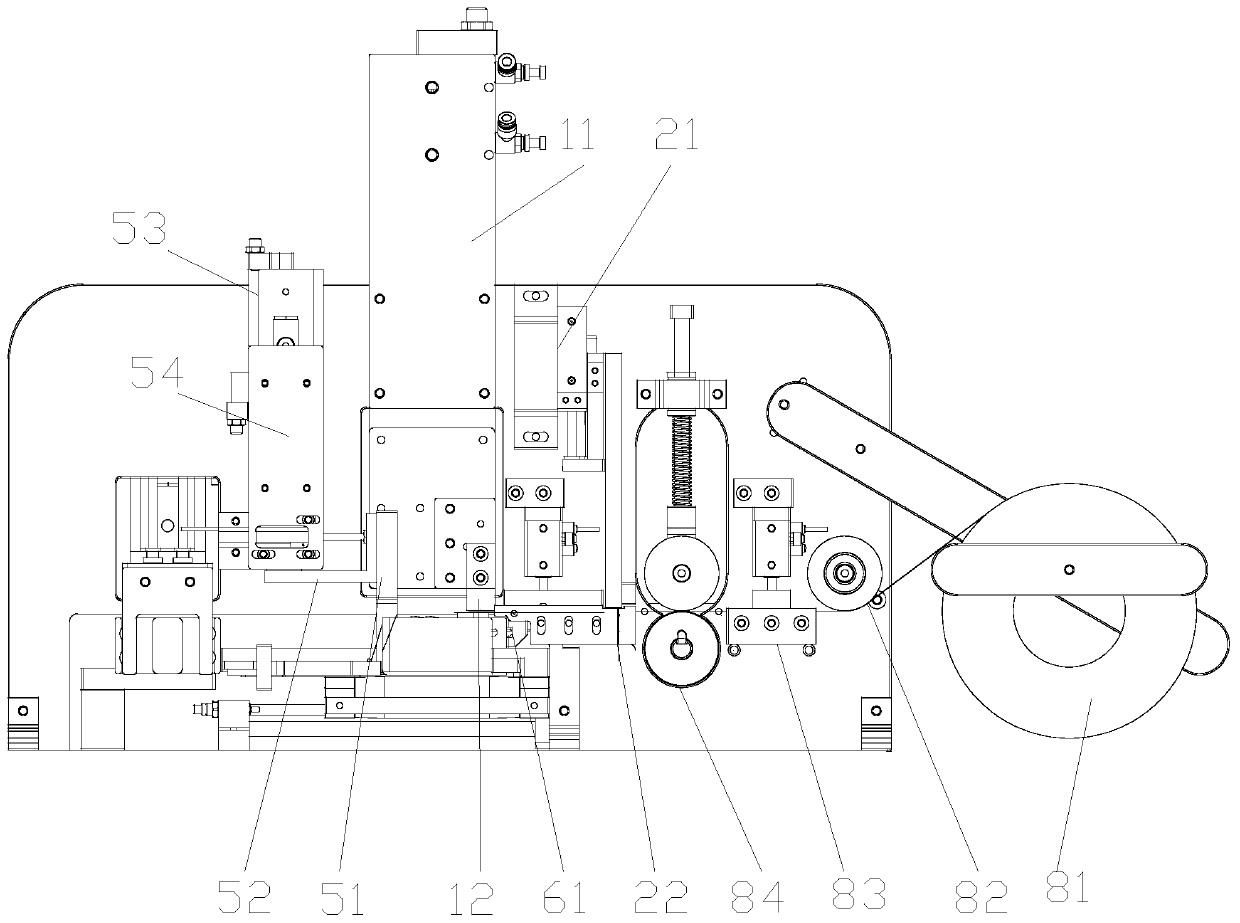

[0100] On the basis of Example 1, such as Figure 1~2 As shown, the first guide mechanism 5 also includes a third guide, the third guide includes a third cylinder 53 and a first moving plate 54, the third cylinder 53 is arranged on the frame 9 and arranged along the up and down direction, the third cylinder 53 is connected with the first moving plate 54 to push the first moving plate 54 to move up and down, and the first moving plate 54 is provided with a first guide piece.

[0101] As its preferred embodiment, the first guide is a first cylinder 52, the first cylinder 52 is arranged along the length direction of the machine, and the first cylinder 52 is connected with the first push plate 54 to push the first push plate 54 along the length of the machine 10. movement in the length direction.

[0102] In this embodiment, under the action of the third cylinder, the first moving plate can move up and down, thereby driving the first cylinder and the first push plate connected wi...

Embodiment 3

[0104] On the basis of embodiment 2 or its preferred embodiment, as Figure 3-4 As shown, the second guide mechanism 6 also includes a first guide rail 62, the first guide rail 62 is arranged on the machine platform and arranged along the length direction of the machine platform, the first guide rail 62 is provided with a second moving plate 63, and the second moving plate 63 is provided with a second guide.

[0105] As its preferred embodiment, the second guide includes a second guide rail 64, a guide block 65 and a second cylinder 66, the second guide rail 64 is arranged on the second moving plate 63 and is arranged along the width direction of the machine table, and the guide block 65 Located on the second guide rail 64 , the second air cylinder 66 is arranged along the width direction of the machine, and the second air cylinder 66 is connected with the guide block to push the guide block to move along the second guide rail 64 .

[0106] In this embodiment, when the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com