Brake mechanism for coil spring-type operation device

A technology of operating device and braking mechanism, which is applied to the power device inside the switch, etc., can solve the problems of poor reliability of the mechanism, difficult spring opening, closing function, large volume, etc., and achieve simplified structure, good reliability and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

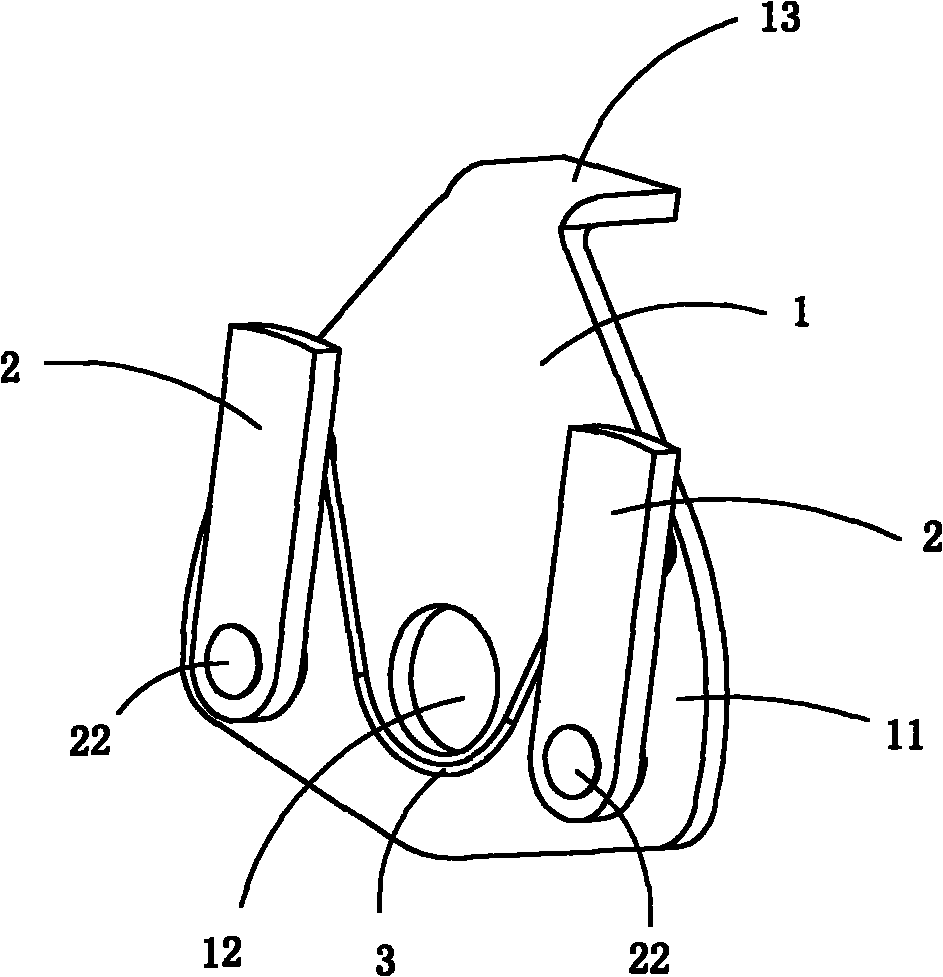

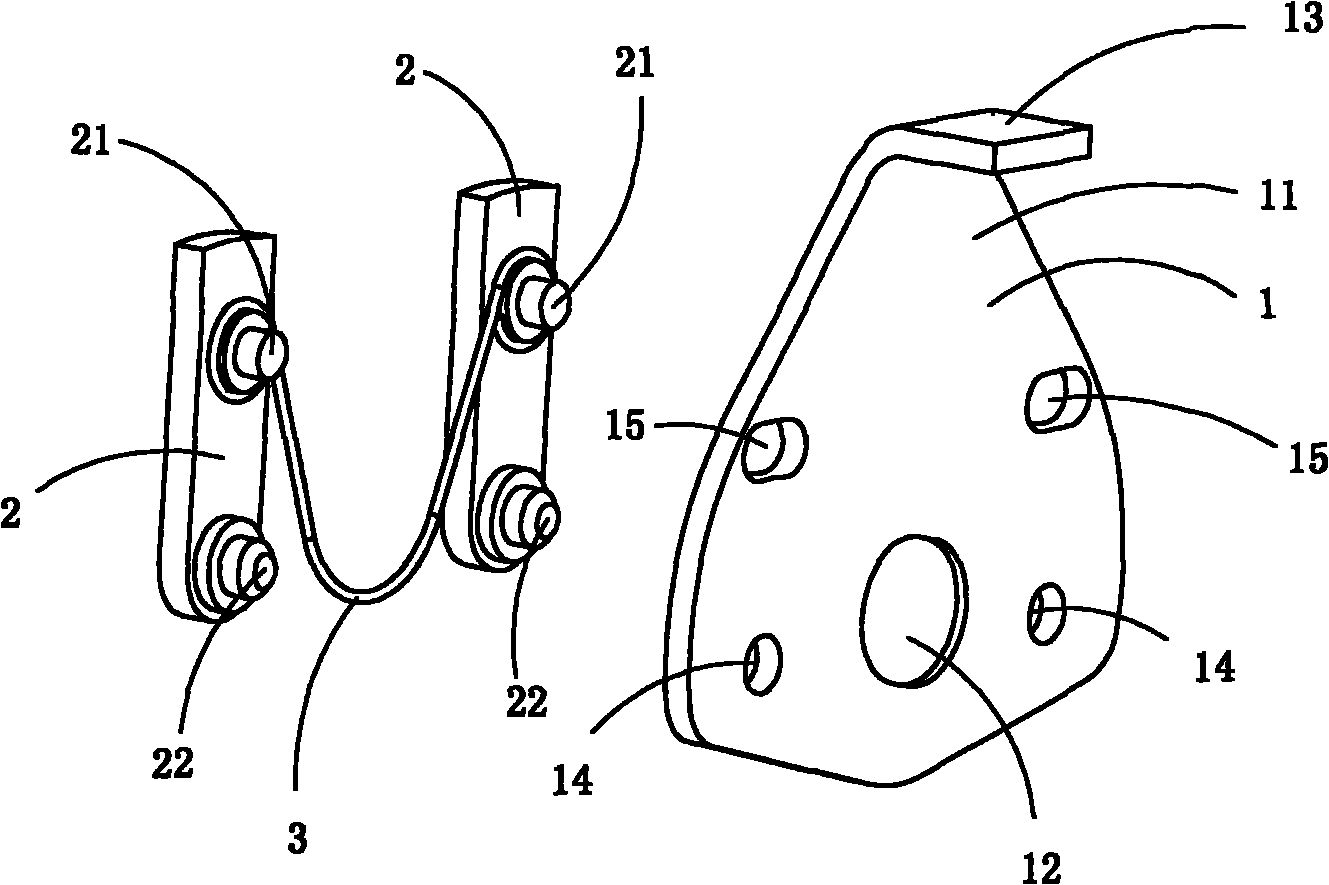

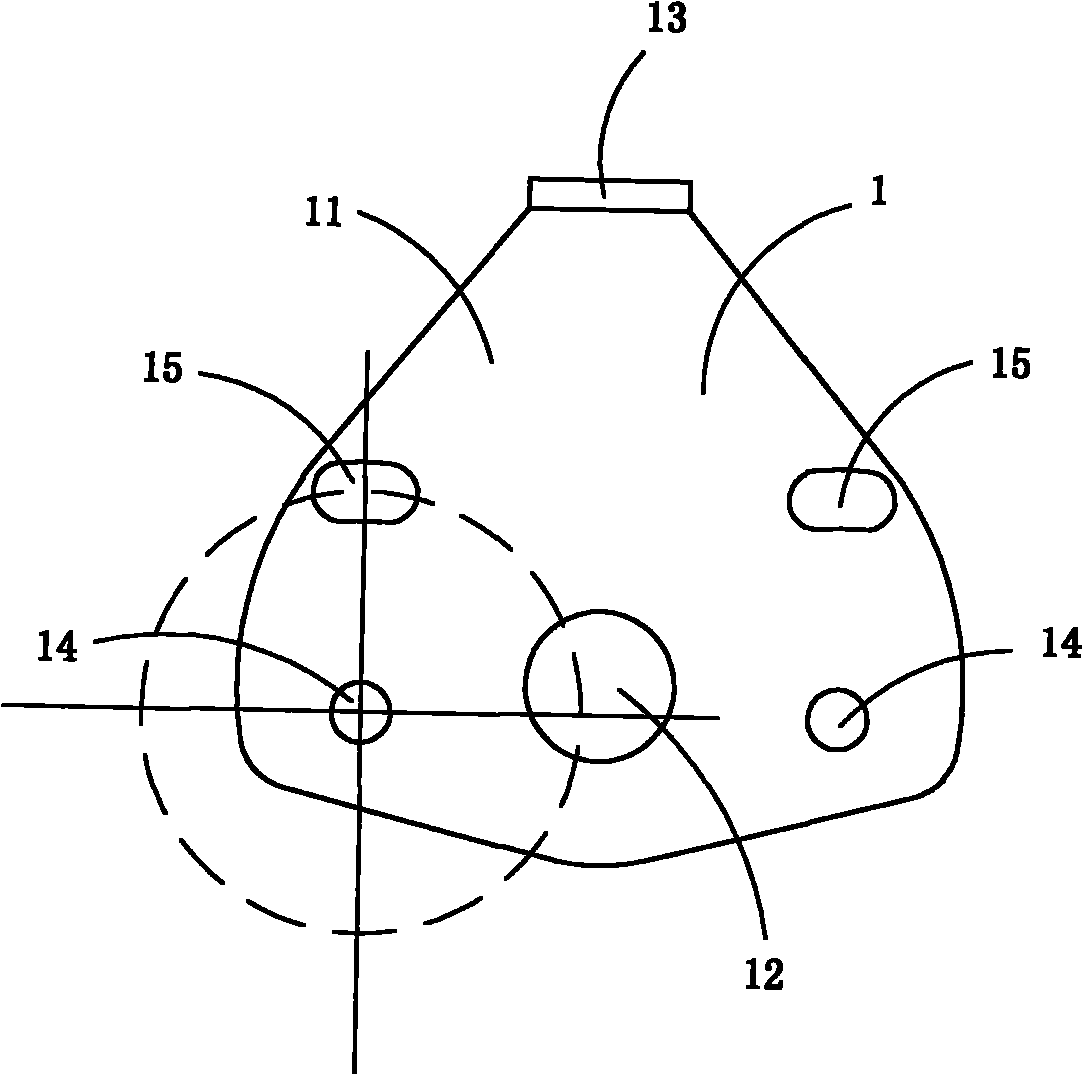

[0015] Figure 1 to Figure 3 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 An exploded view of the brake mechanism shown; image 3 for figure 1 A front view of the output plate in the brake mechanism shown.

[0016] This embodiment is a brake mechanism used in a scroll spring type operating device, including an output plate 1, two brake detents 2 and a support spring 3 for providing return elastic force for the detents 2;

[0017] It is characterized in that: the output plate 1 includes a plate-shaped body 11, and the body 11 is provided with a shaft hole 12, a baffle plate 13, two installation holes 14 for installing the detent 2 and two for limiting Limiting holes 15 for the rotation angle of the detent 2; each limiting hole 15 is arranged directly above a corresponding mounting hole 14;

[0018] The two detents 2 are symmetrically arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com