Automatic calibration compensation method and device for Hall flow sensor

A flow sensor, automatic calibration technology, applied in test/calibration devices, measurement devices, and electromagnetic flowmeters to detect fluid flow, etc., can solve problems such as flowmeter calibration that cannot be automatically batched and liquid density is variable, and achieve good expansion. The effect of stability, simple measurement and accurate weight data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

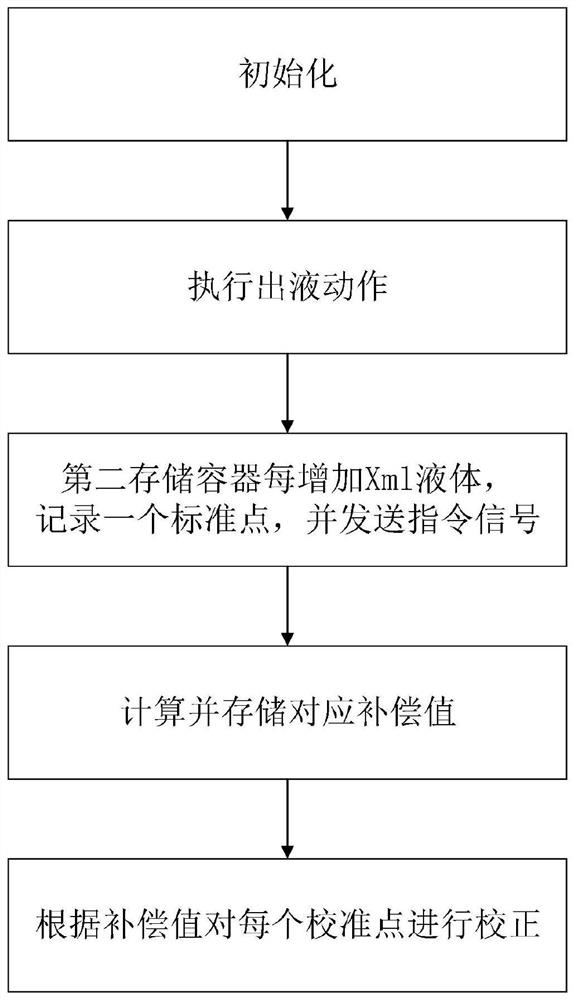

[0039] Such as figure 1 As shown, an automatic calibration and compensation method for a Hall flow sensor includes the following steps:

[0040] S1: Initialize the calibration device; the initialization includes performing weight calibration and tare operations. Wherein, the weight calibration step only needs to be performed before the first use, and does not need to be repeated after calibration.

[0041] S2: Execute the liquid discharge action, and transport the measurement liquid from the first storage container to the second storage container through the sensor to be calibrated; wherein, the volume of the measurement liquid=the maximum range of the sensor to be calibrated+transport loss value, the The magnitude of the transmission loss value is preset according to the type and volume of the liquid to be measured.

[0042] S3: Every time Xml of the weight of the measurement liquid increases in the second storage container, it is recorded as a calibration point, and an ins...

Embodiment 2

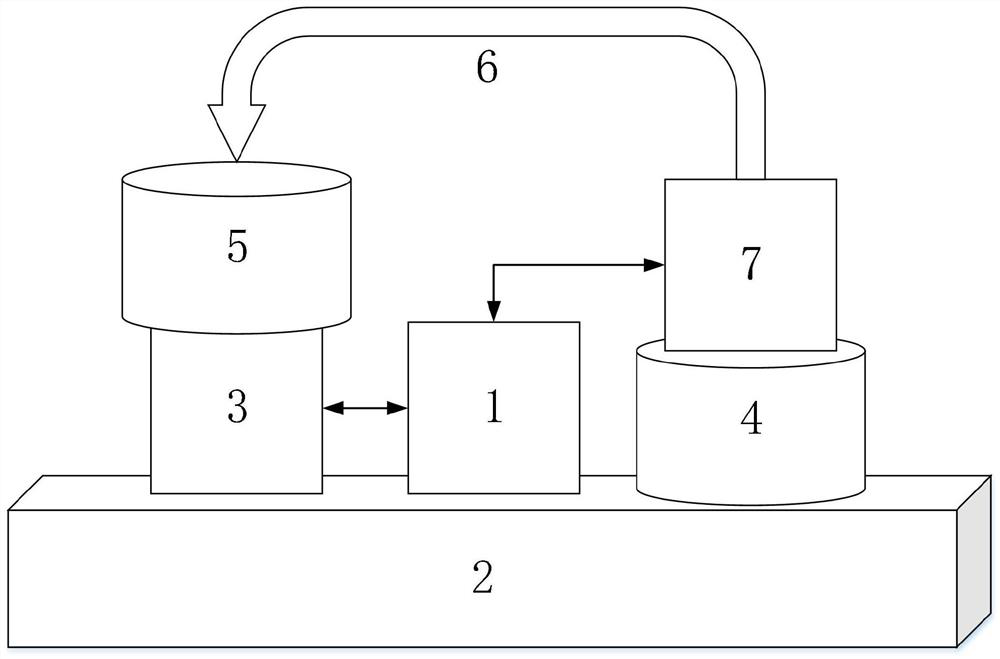

[0049] Such as figure 2 As shown, an automatic calibration and compensation device for a Hall flow sensor includes a control module 1 , a workbench 2 and a weighing assembly electrically connected to the control module 1 .

[0050] The weighing assembly includes a weight sensor 3 and a liquid outlet module; the liquid outlet module includes a first storage container 4, a second storage container 5, and a liquid outlet pipe 6, and the first storage container 4 passes through the waiting The calibration sensor 7 and the liquid outlet pipe 6 transfer the liquid to the second storage container 5 ; the weight sensor 3 is used to detect the weight of the second storage container 5 .

[0051] The workbench 2 is used for installing the sensor 7 to be calibrated, the control module 1 and the weighing assembly.

[0052] The control module 1 is electrically connected to the sensor 7 to be calibrated. The weight sensor 3 collects weight data through an AD sampling module. Wherein, the...

Embodiment 3

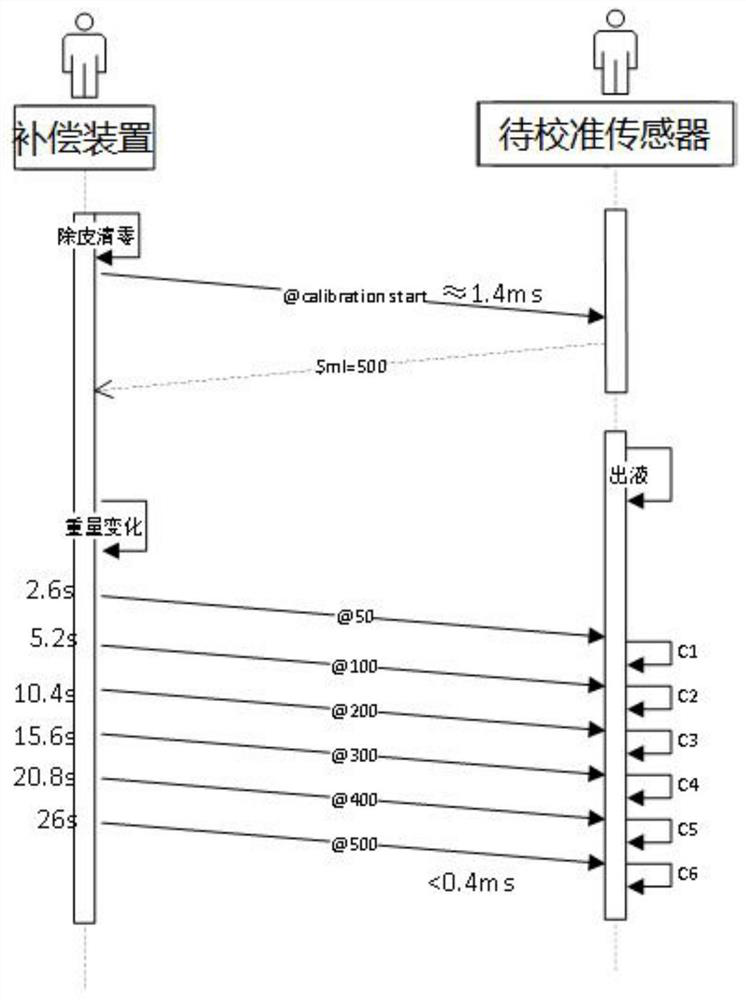

[0057] This embodiment is a specific application example of using the device described in embodiment 2 to implement the method of embodiment 1.

[0058] After actual testing, the present invention can accurately measure the number of pulse deviations of each calibration point after a full-scale discharge, and the corrected and compensated sensor to be calibrated is obtained based on this method. Then carry out quantitative liquid verification to it, the flow rate error range measured at each calibration point is less than 2ml, and the calibration point is randomly sampled, and the measured error is less than 3ml.

[0059] In addition, if image 3 As shown, according to the liquid discharge speed of the tested sensor to be calibrated, the liquid discharge time of 500ml liquid is 26 seconds, and the entire calibration process takes about 30 seconds, and does not increase with the increase of the number of calibration points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com