Efficient swing wheel sorting machine

A sorter and high-efficiency technology, which is applied to conveyor objects, transportation and packaging, rollers, etc., can solve the problems of heavy workload of operators, low sorting efficiency, and increased labor costs, and achieves good conveying stability. Low production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

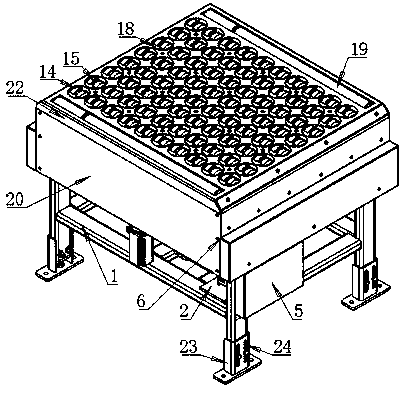

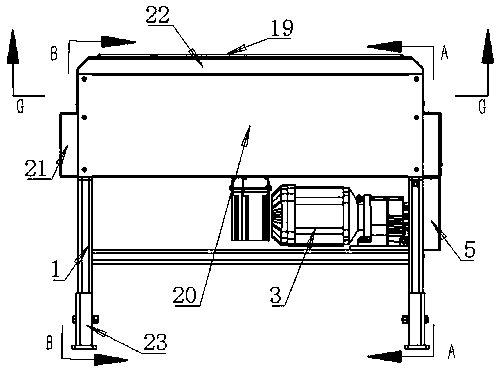

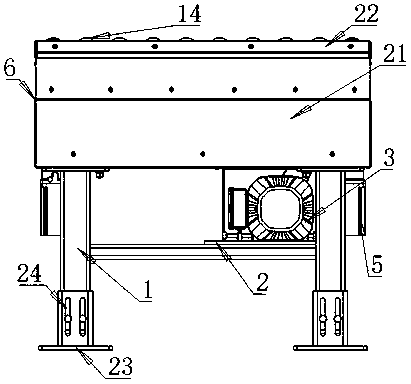

[0029] Such as Figure 1 to Figure 15As shown in the figure, a high-efficiency balance wheel sorting machine adopts the structure of the balance wheel for sorting control, and can perform different convenient sorting operations for different items according to different transportation needs, which can greatly improve the efficiency of sorting , which makes the sorting process more stable and smoother. It can be used alone or in multiple splicing ways at the same time, which can meet more application environments and is more convenient to use. It adopts The modular production method makes it more stable during use, more convenient in the later repair and maintenance process, lower maintenance cost, it produces less noise during use, and protects the environment The effect is better, it occupies less space, the practical area is large, and the space utilization rate is higher. This structure can increase or decrease the length and width according to the needs, and the sorting po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com