Metal sheet bending machine

A bending machine and metal plate technology, which is applied in the field of metal plate bending machines, can solve the problems that the contact surface of the slider and the fixed block is also very worn, wasteful, and workers' fingers are caught

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

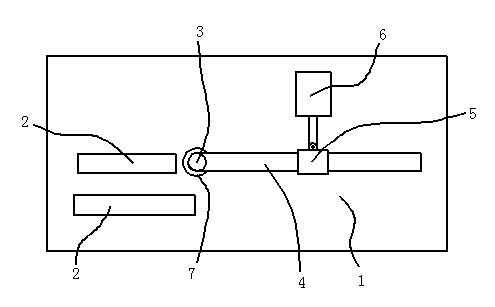

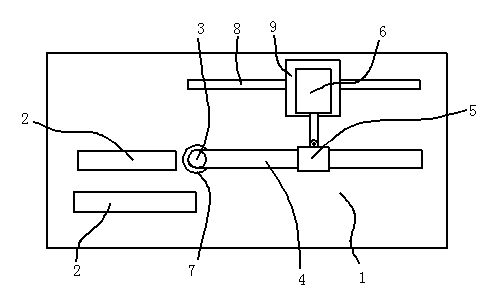

[0015] see figure 1 , Embodiment 1, a metal plate bending machine, including a base 1, two fixed blocks 2 and a rotating shaft 3 are arranged on the base 1, and a long rod 4 is connected to the rotating shaft 3, and the long rod 4 is covered with A sliding sleeve 5 is provided, and the sliding sleeve 5 is rotatably connected with a power device 6 , and the power device 6 is fixedly arranged on the base 1 . In this embodiment, the power device 6 is a cylinder, the cylinder rod is marked with a scale, and the corresponding bending angle is marked beside the scale. The scale and angle are marked on the cylinder rod so that the workers can directly read the bending angle of the metal plate from the protruding length of the cylinder rod, making the processing convenient and easy to control.

[0016] A bearing 7 is installed between the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com