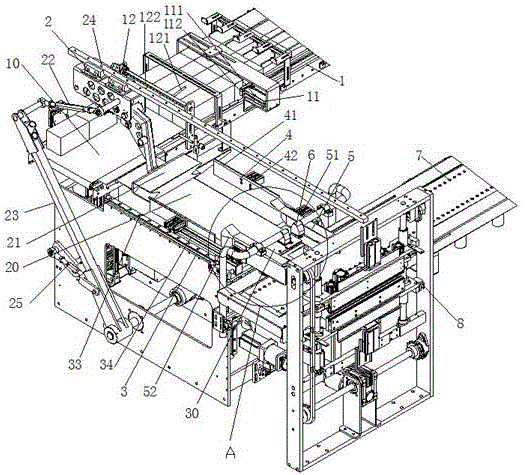

Material conveying and pushing method for prefabricated bag packaging machine

A technology of prefabricated bags and packaging machines, applied in packaging, transportation and packaging, single objects, etc., can solve the problems of easy dumping, poor packaging effect, low packaging efficiency, etc., to reduce time, reduce procedures, and improve packaging efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

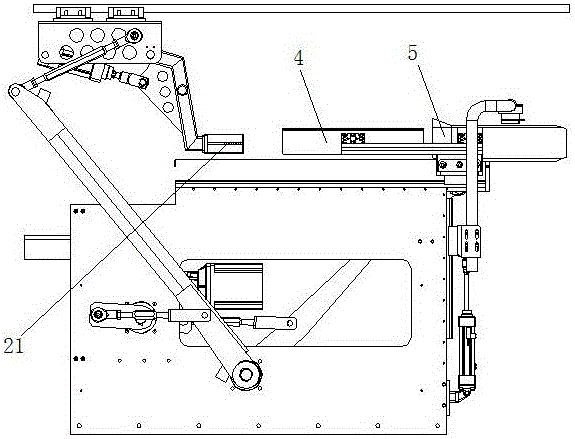

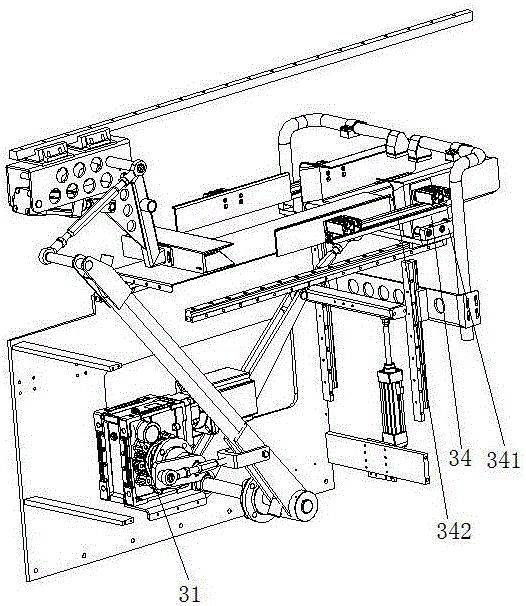

[0072] This embodiment discloses: a method for conveying and pushing materials of a prefabricated bag packaging machine, in which the materials are conveyed to the station 10 to be clamped;

[0073] The material transported to the station to be clamped 10 is clamped and transported to the station to be pushed 20;

[0074] During the process that the material is transported to the station to be clamped 10 or to the station to be pushed 20, the prefabricated bag is transported to the bag opening station 30 and opened at the bag opening station 30;

[0075] While the material to be clamped at station 10 is clamped and conveyed to station 20 to be pushed, the prefabricated bag is opened;

[0076] When the material is pushed, the prefabricated bag and the material move towards each other;

[0077] The materials are pushed into the prefabricated bags that move towards each other, and the prefabricated bags wrapped with materials are pushed to the predetermined position along the di...

Embodiment 2

[0080] This embodiment discloses a method for conveying and pushing materials of a prefabricated bag packaging machine. The materials are conveyed to the station 10 to be clamped;

[0081] The material transported to the station to be clamped 10 is clamped and transported to the station to be pushed 20;

[0082] During the process that the material is transported to the station to be clamped 10 or to the station to be pushed 20, the prefabricated bag is transported to the bag opening station 30 and opened at the bag opening station 30;

[0083] While the material to be clamped at station 10 is clamped and conveyed to station 20 to be pushed, the prefabricated bag is opened;

[0084] When the material is pushed, the prefabricated bag and the material move towards each other;

[0085] The materials are pushed into the prefabricated bags that move in opposite directions, and the prefabricated bags wrapped with materials are pushed to the predetermined position along the direction ...

Embodiment 3

[0088] This embodiment discloses a method for conveying and pushing materials of a prefabricated bag packaging machine. The materials are conveyed to the station 10 to be clamped;

[0089] The material transported to the station to be clamped 10 is clamped and transported to the station to be pushed 20;

[0090] During the process that the material is transported to the station to be clamped 10 or to the station to be pushed 20, the prefabricated bag is transported to the bag opening station 30 and opened at the bag opening station 30;

[0091] While the material to be clamped at station 10 is clamped and conveyed to station 20 to be pushed, the prefabricated bag is opened;

[0092] When the material is pushed, the prefabricated bag and the material move towards each other;

[0093] The materials are pushed into the prefabricated bags that move in opposite directions, and the prefabricated bags wrapped with materials are pushed to the predetermined position along the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com