Anti-clogging extruder for wet garbage

An anti-clogging, extrusion machine technology, applied in the direction of presses, filtration separation, filtration circuits, etc., can solve the problems of repeated shutdown and cleaning, easy clogging, etc., and achieve the effect of not being easy to squeeze and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The wet garbage anti-clogging extruder of the present invention can be made of the following materials, but not limited to the following materials, for example: stainless steel, permanent magnets, aluminum alloys, plastics, rubber rollers, steel wire mesh, shaped steel, etc.

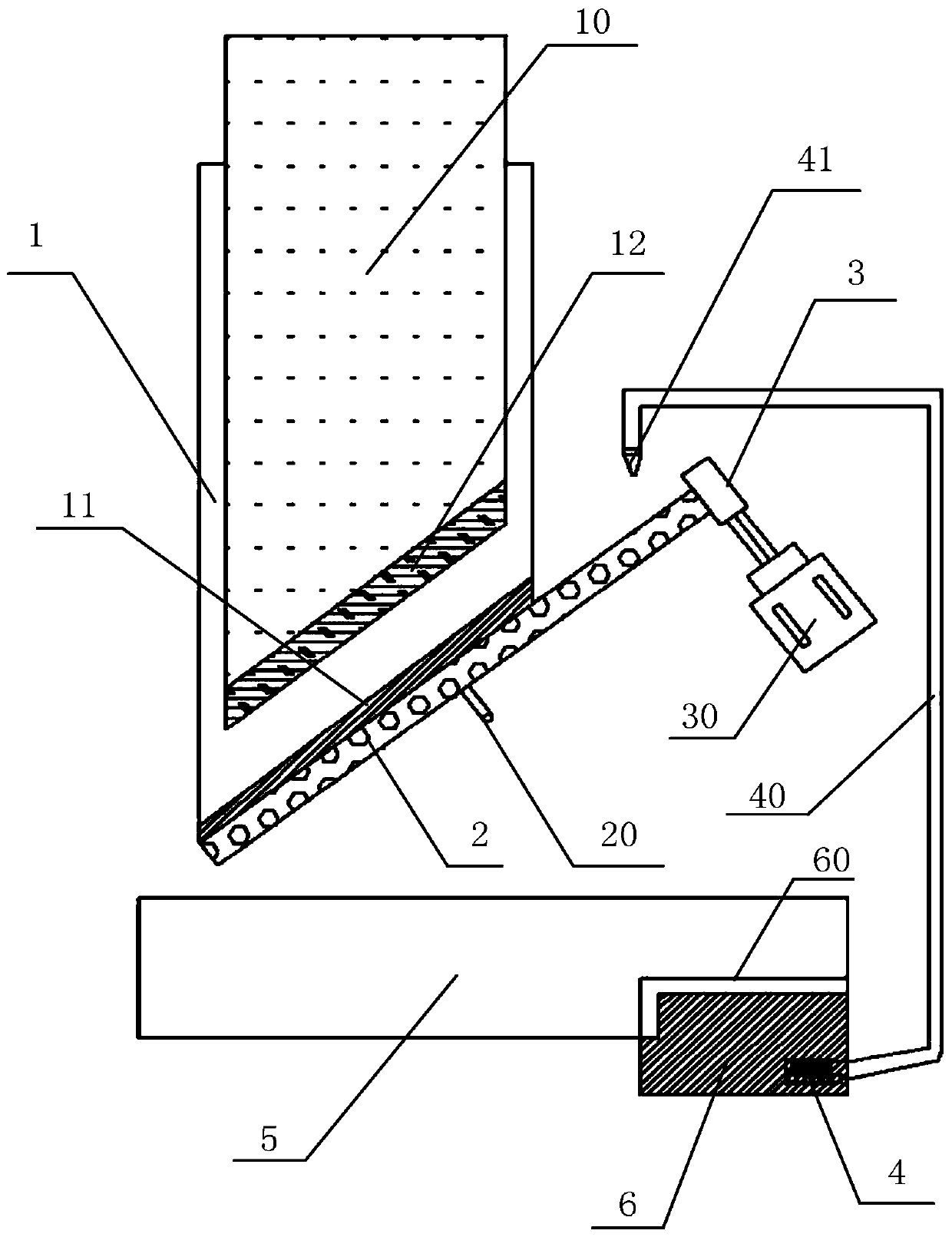

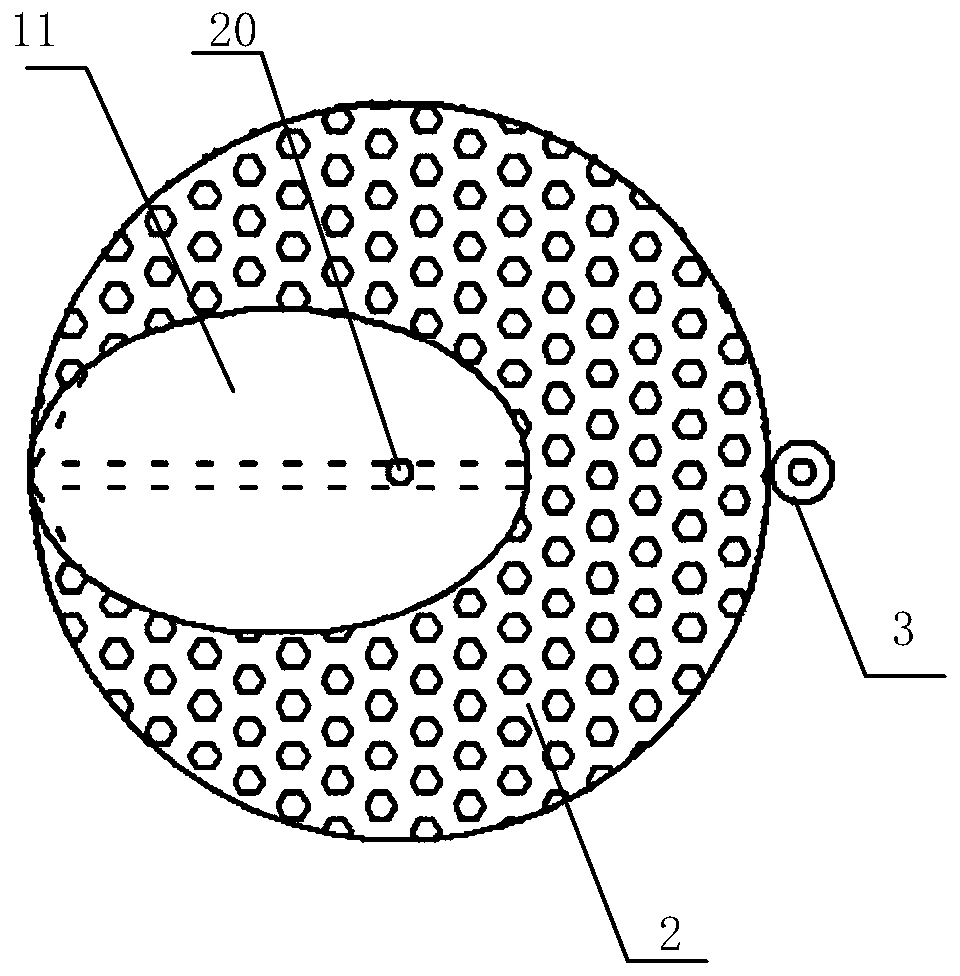

[0028] Such as figure 1 Shown is the side structural view of the wet garbage anti-clogging extruder of the embodiment of the present invention, and with reference to figure 2 The wet garbage anti-clogging extruder of the embodiment of the present invention comprises: extruding tube 1, piston 10 and grid plate 2; Grid plate is porous screen type structure, plays the effect of filter screen, is used for further Filter out moisture from wet waste. The extruder in this embodiment is a plunger extruder.

[0029] The extrusion cylinder 1 is a tubular structure with two ends open, and the bottom of the extrusion cylinder 1 is provided with a filter plate 11 for sealing the bottom opening of the extrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com