Integrated supporting saddle for mounting upper-down double-gas bottles

A dual-cylinder, integrated technology, applied in the direction of power plant, transportation and packaging, and layout combined with the fuel supply of internal combustion engines, etc., can solve the problem of reducing the safety of use, hidden dangers of use, and extrusion of LNG cylinders. problems, to achieve the effect of high safety, convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

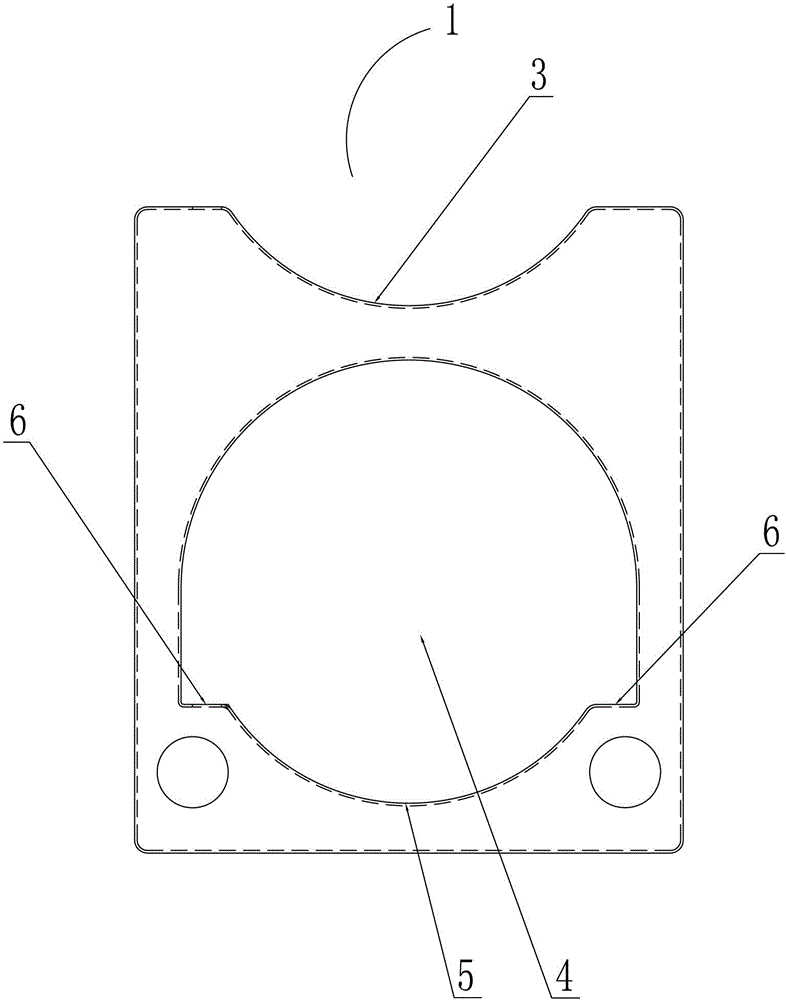

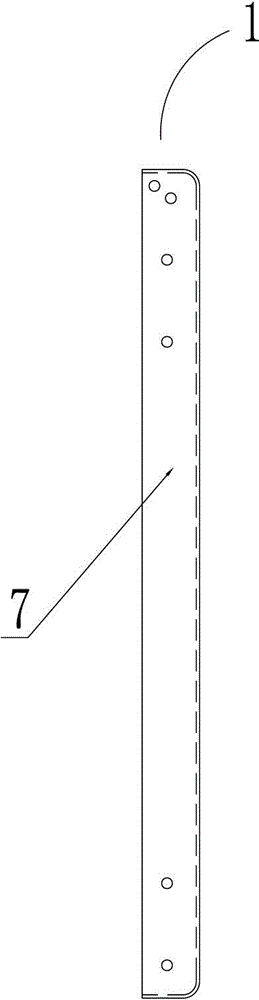

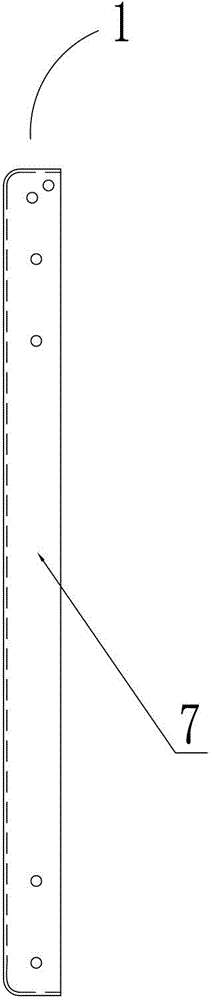

[0018] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the integral support saddle for installing the upper and lower double gas cylinders includes an integrally formed upper and lower double gas cylinder support formwork frame 1, and a liquefied natural gas cylinder is provided on the top of the upper and lower double gas cylinder support formwork frame 1. The upper arc-shaped gas cylinder seat 3 that is compatible with the bottle body of 2, and the upper and lower double gas cylinder support formwork frame 1 below the upper arc-shaped gas cylinder seat 3 is provided with a mounting hole 4 that can pass through for the liquefied natural gas cylinder 2, The bottom side of the mounting hole 4 is provided with a lower arc-shaped cylinder seat 5 that is compatible with the body of the liquefied natural gas cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com