Auxiliary device for welding copper-aluminum pipe in refrigeration part and process of auxiliary device

An auxiliary device, copper and aluminum technology, applied in the direction of auxiliary devices, welding/cutting auxiliary equipment, manufacturing tools, etc., can solve the problems of low welding precision, cumbersome process, and low welding quality, so as to reduce labor intensity, improve stability, Improved stability and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

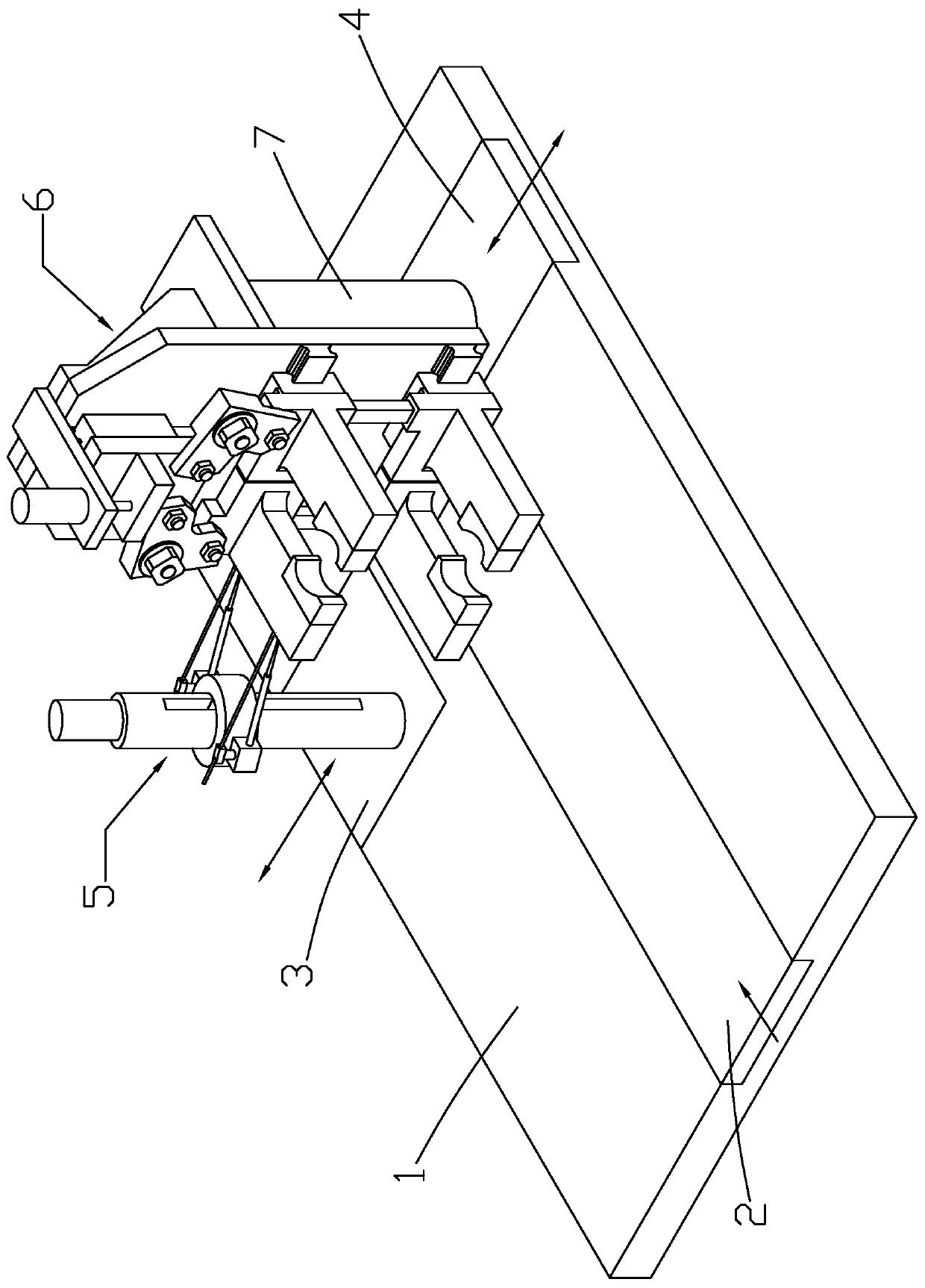

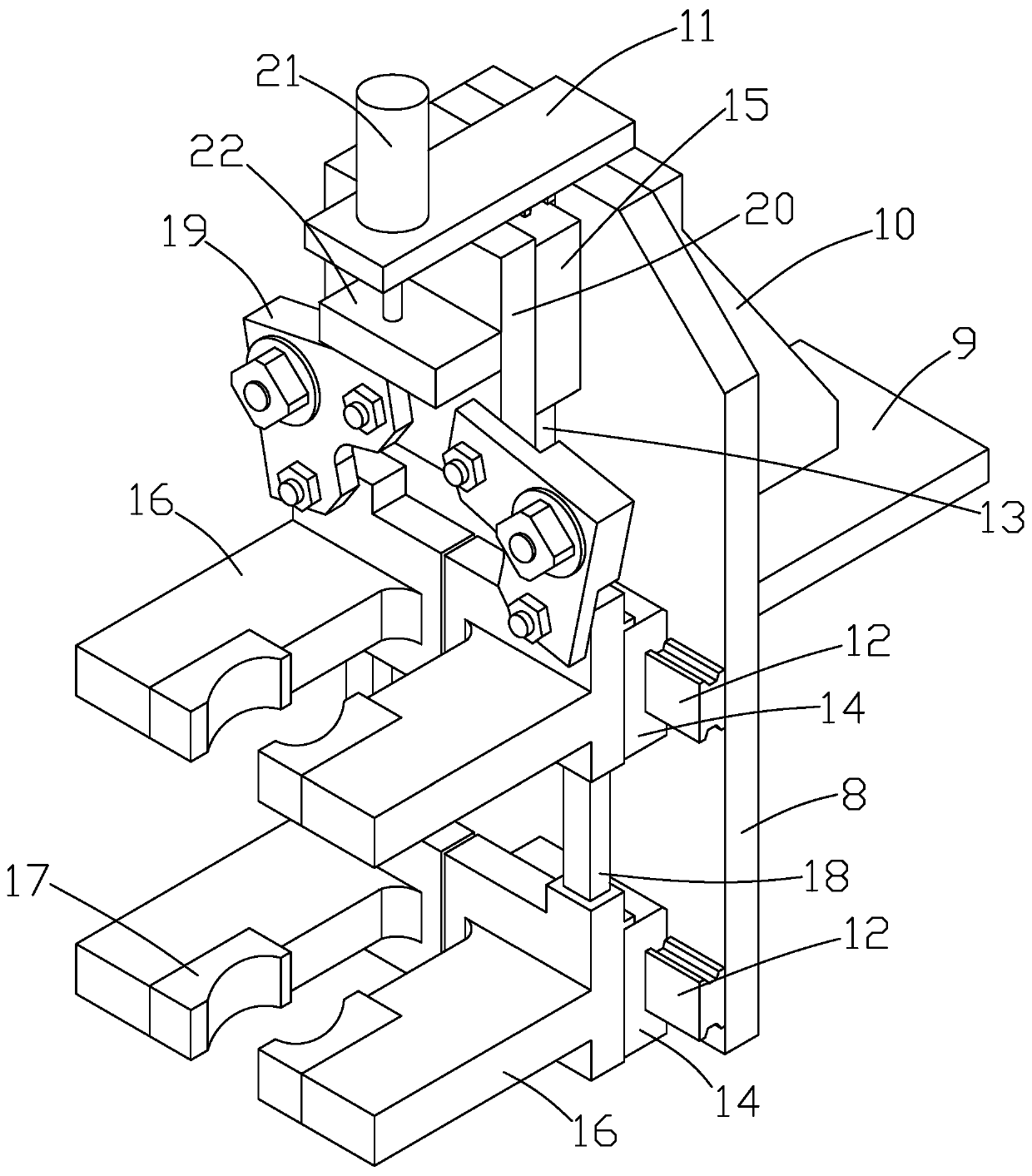

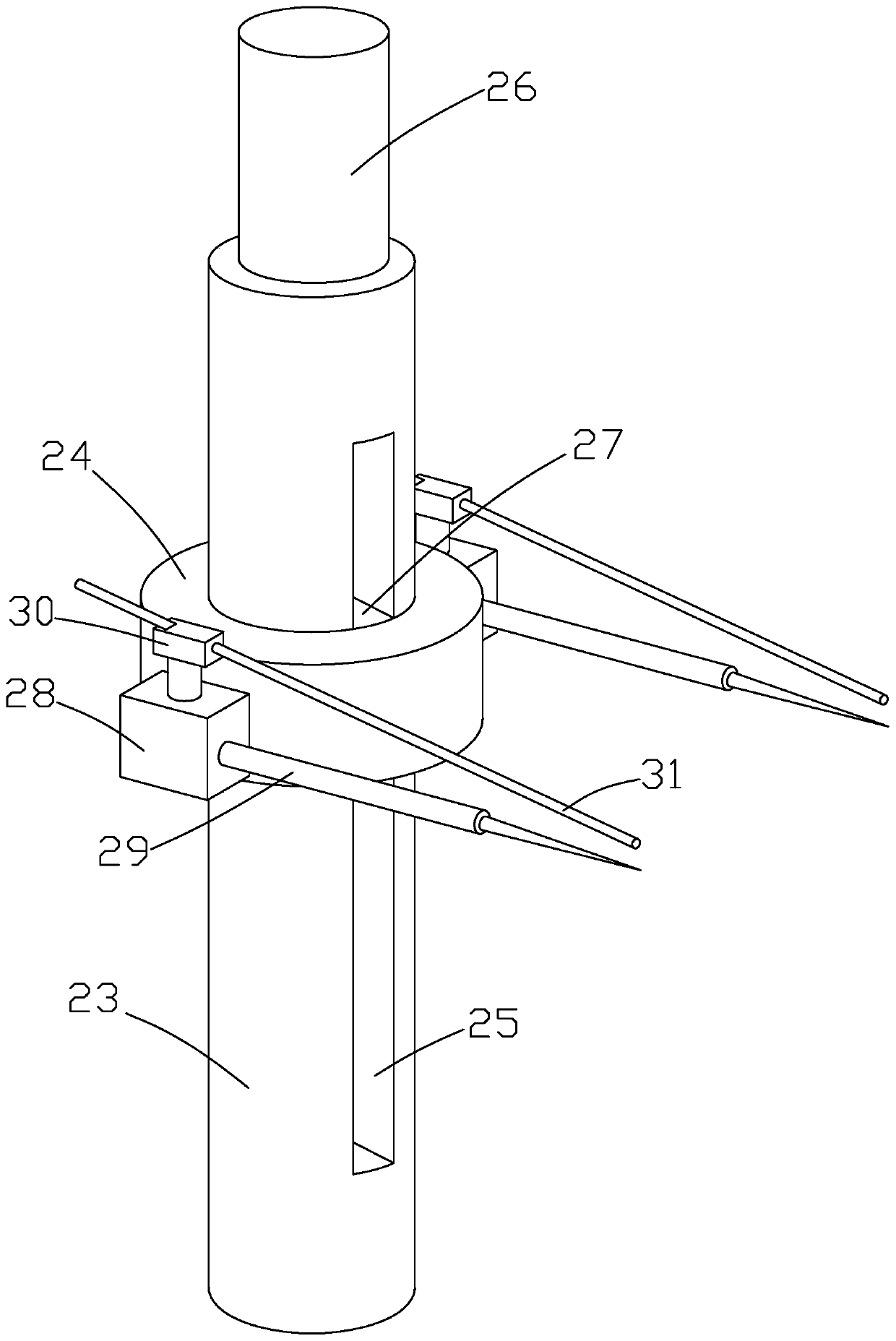

[0049] Such as Figure 1 to Figure 5 As shown, it is an auxiliary device for copper-aluminum welding of refrigeration accessories according to the present invention, which includes a welding table 1, a conveyor belt 2, a first horizontal moving plate 3, a second horizontal moving plate 4, a welding mechanism 5 and an auxiliary mechanism 6, and the welding mechanism 5 is fixedly connected on the top surface of the first horizontally moving plate 3, the welding mechanism 5 includes a supporting column 23, a first motor 26, a lifting ring 24 and a welding assembly, the supporting column 23 is fixedly connected on the first horizontally moving plate 3, and supports A guide groove 25 is vertically arranged on the side of the column 23, the first motor 26 is fixedly connected to the top of the support column 23, the first motor 26 is connected with a first screw rod 32, and the first screw rod 32 is sleeved with a second lifting block 27. The second lifting block 27 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com