Waterproof coil winding and cutting process system capable of realizing effective alignment

A waterproof coiled material and cutting process technology, which is applied in the direction of coiling strip material, thin material processing, transportation and packaging, etc., can solve the problems of increasing production process, low efficiency, and non-conforming coil material, so as to improve production efficiency, The effect of improving packaging quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

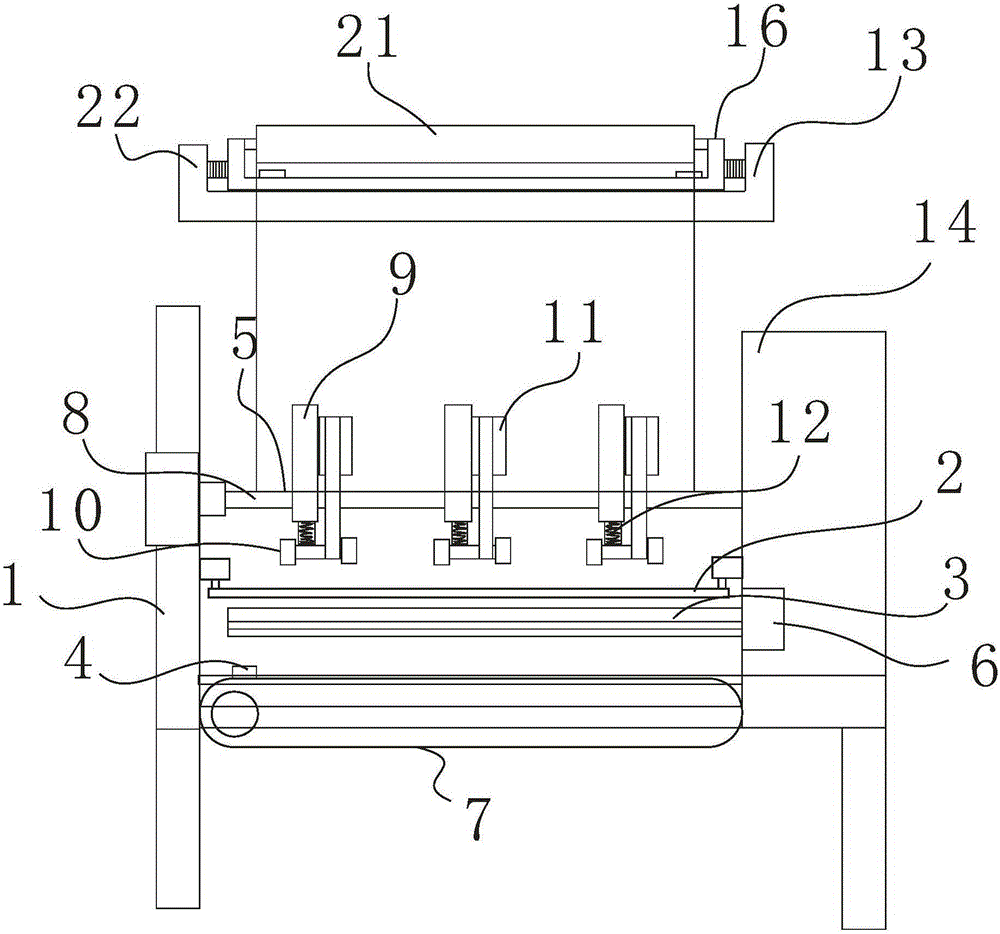

[0017] As shown in the figure, the present invention includes a deviation correction device 13 and a winding and cutting device 14 arranged at the rear end of the deviation correction device,

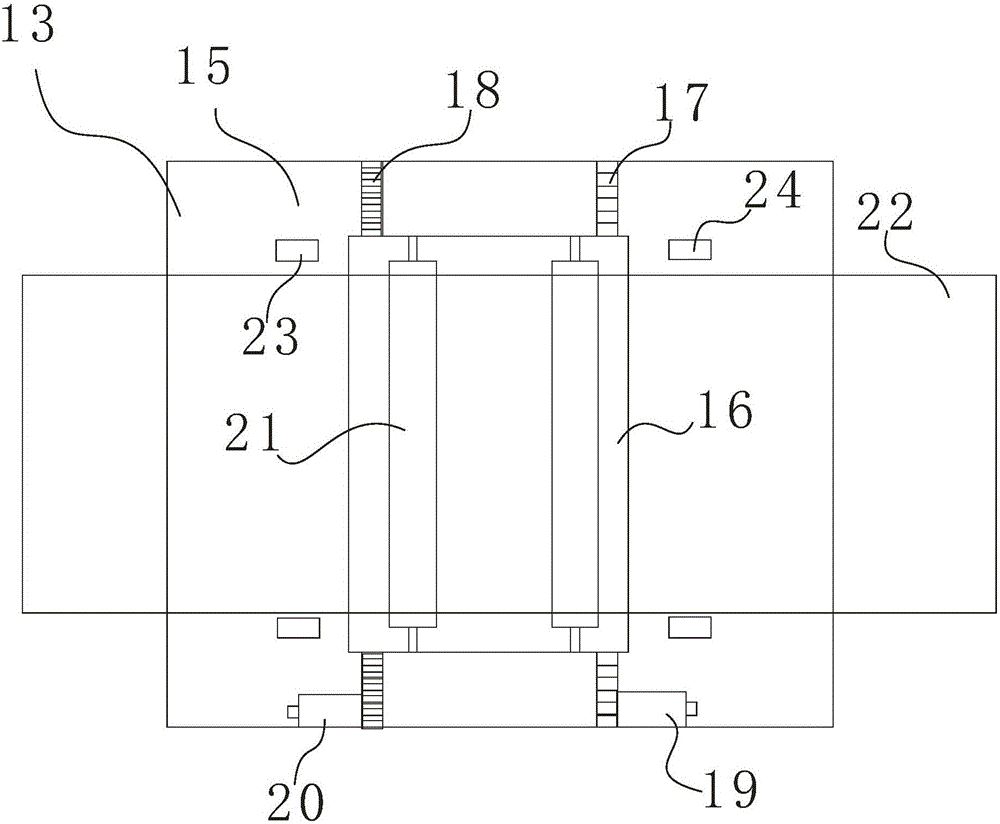

[0018] The deviation correction device includes a fixed seat 15, a mobile frame 16 located on the fixed seat and a lead screw distance adjustment mechanism that drives the mobile frame to move. The lead screw distance adjustment mechanism includes a coarse adjustment screw 17 and a fine adjustment screw 18 arranged side by side. Coarse-tuning driving motor 19 that cooperates with coarse-tuning leading screw and fine-tuning driving motor 20 that cooperates with fine-tuning leading screw, mobile frame is provided with two horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com