Automatic error correcting system of short leather belt and its method

An automatic deviation correction and belt technology, which is applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the physical and mental health and personal safety threats of workers, affect work efficiency, and interrupt the unloading process, etc., to achieve a reasonable deviation correction method Feasible, improve work efficiency, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

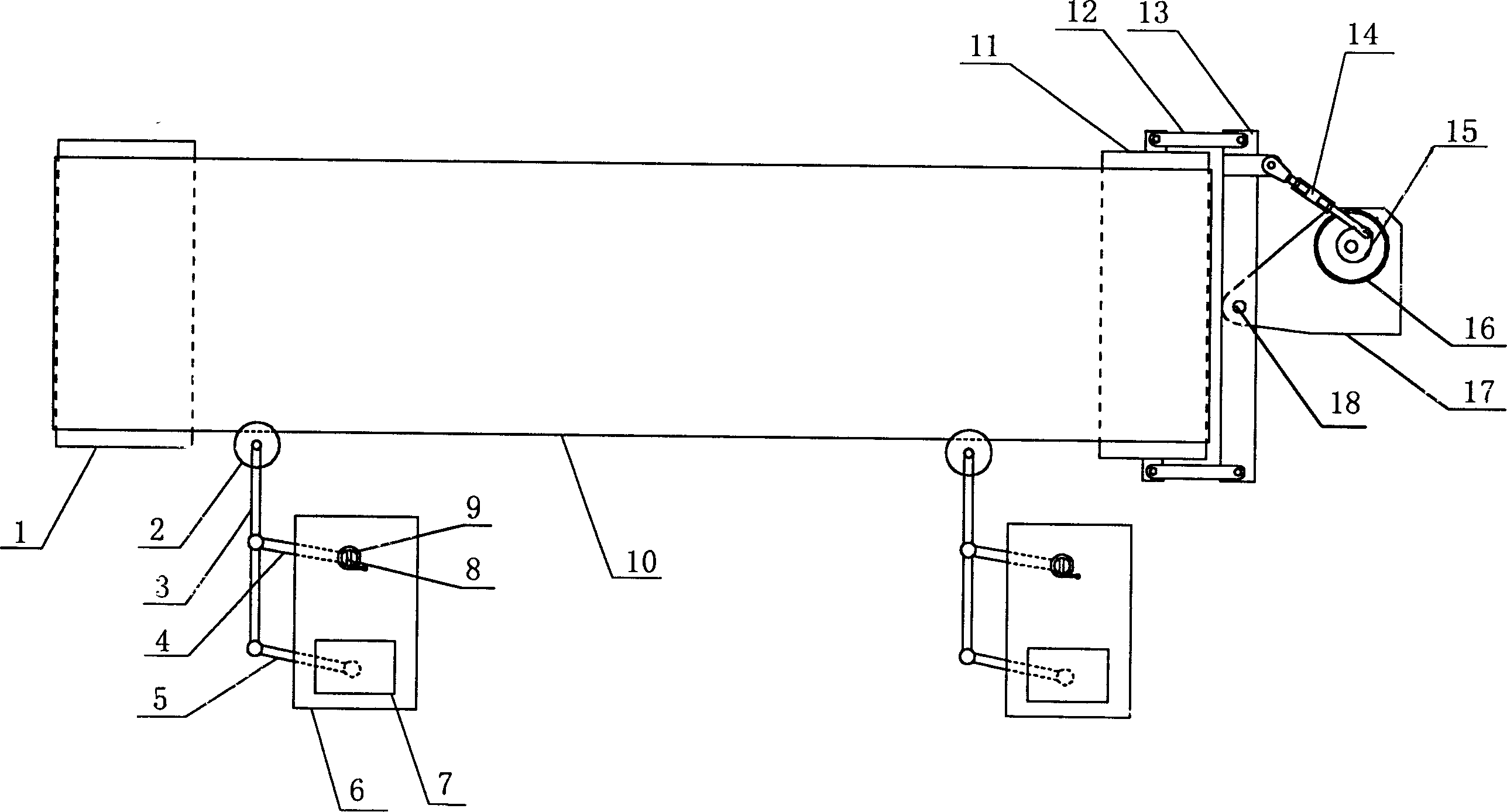

[0017] see figure 1 , is an embodiment of an automatic deviation correction system for a short belt of the present invention, including a belt 10, a driving drum 1, a reversing drum 11, a belt deviation detection mechanism, an automatic deviation correction mechanism and a computer control system.

[0018] The automatic deviation correction mechanism is that the two ends of a mobile support rod 13 are respectively hinged with the two ends of the redirection roller 11 shaft through two connecting rods 12 to form a parallel four-bar linkage mechanism. The mobile support rod 13 can rotate around the rotating shaft 18, and the rotating shaft 18 is installed on the fixed seat 17. There is a cam drive motor 16 fixed on the fixed seat 17 to rotate the cam 15 driven by the cycloidal pin wheel planetary reducer with high reduction ratio. Hinged at one end.

[0019] The belt deviation detection mechanism is a front end of a detection rod 3 perpendicular to the belt 10 sides with a run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com