Laser directional drilling tool for coal-bed-methane level development hole and drilling method using same

A directional drilling and hole laser technology, which is used in directional drilling, earth-moving drilling, surveying, etc., can solve the problems of high drill bit consumption, poor drilling tool direction control performance, low drilling efficiency, etc., and achieves high drilling efficiency, The drill bit consumption is small and the effect of reducing the drill bit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

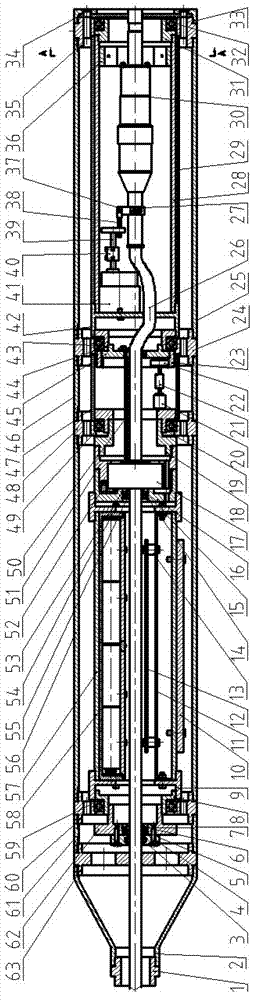

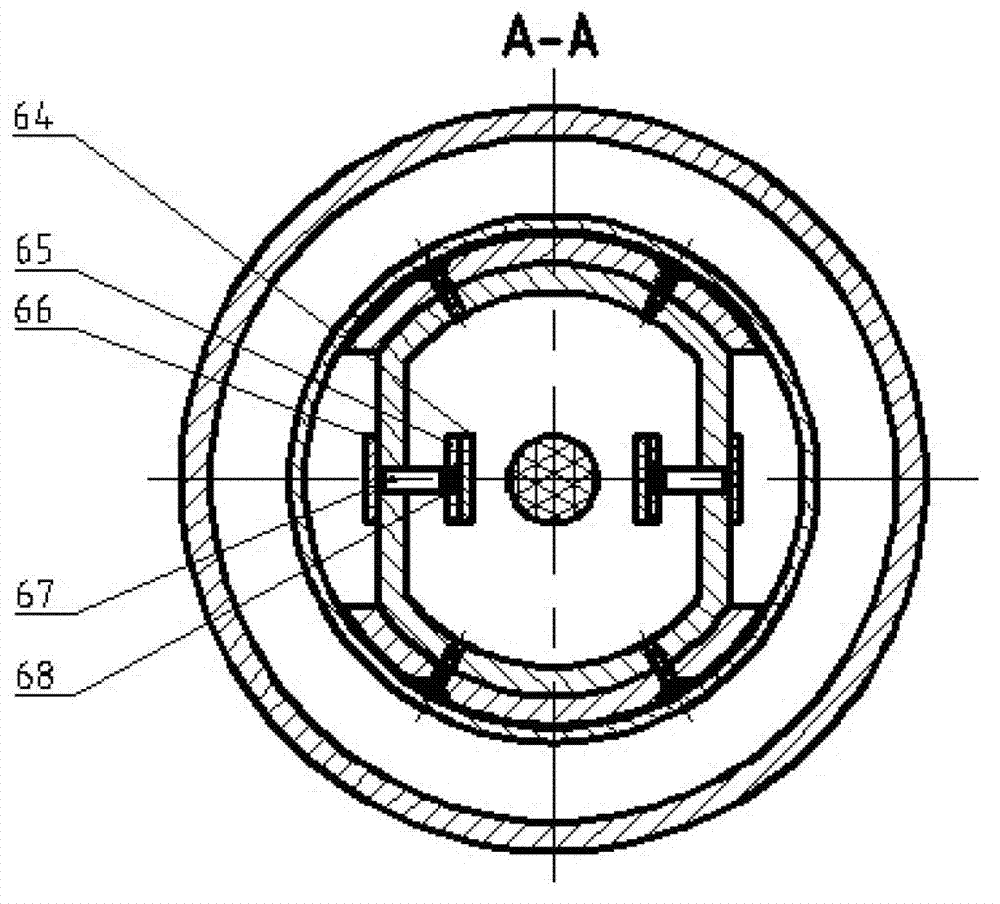

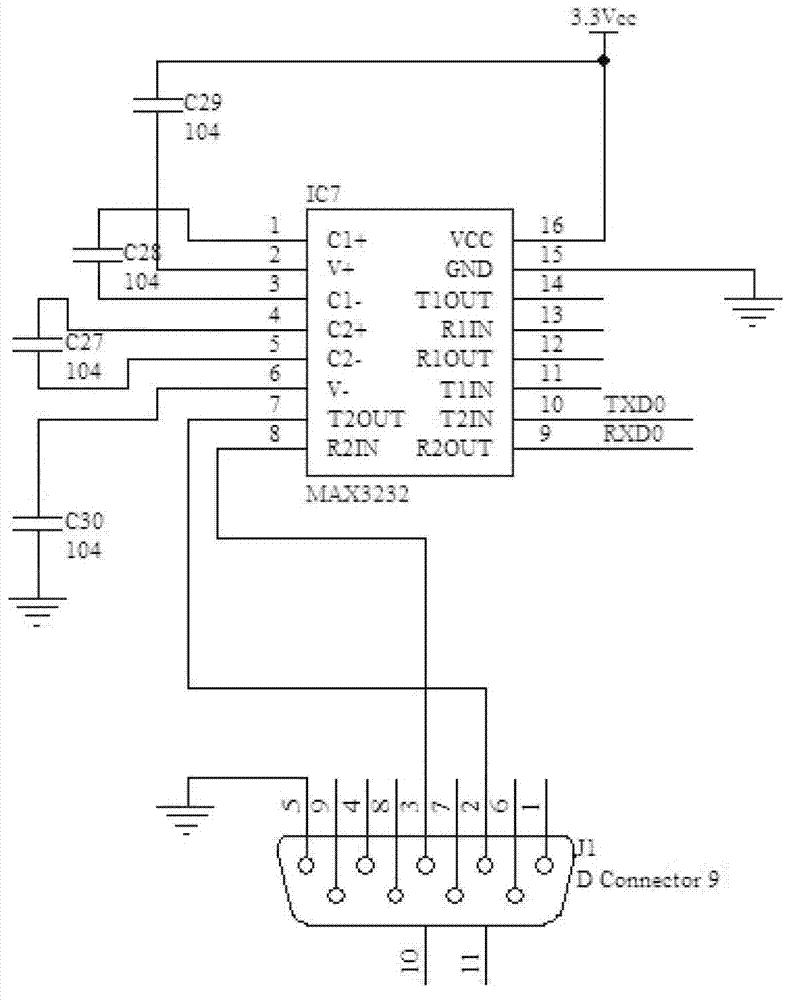

[0041] Embodiment 1: The structure of a laser directional drilling drilling tool for horizontal mining holes of coalbed methane in the present invention is as follows: figure 1 , 2 As shown, the drilling tool includes a laser emitting head and its deflection control parts, deflection execution parts and circuit parts. The laser emitting head adopts the LLK-HP model in the HIGHYAG series products.

[0042] The laser emitting head deflection control components include drill pipe joint 1, transition pipe joint 2, bearing cap A4, fiber optic ring A7, bearing connection inner ring CA8, battery box 58, circuit board support seat 11, bearing connection inner ring BB55 And the collector ring 17, the drill pipe joint 1 is threadedly connected with the drill pipe, the drill pipe joint 1, the transition pipe joint 2, the shell connecting ring E63, the shell A61, the shell connecting ring A60, the shell B56, and the shell are connected The ring B48 and the shell C46 are connected by thre...

Embodiment 2

[0054] Embodiment 2: A kind of drilling method of the present invention applying the laser directional drilling drilling tool for the horizontal mining hole of coalbed methane described in Embodiment 1 of the present invention specifically has the following steps:

[0055](1) Prepare the laser directional drilling tool for the horizontal mining hole of coalbed methane, and prepare the drill pipe matched with the drilling tool at the same time. The drill pipe is provided with a thickened iron ring every 5m on the drill pipe shell;

[0056] (2) Lower the drilling tool to the position where the coal rock needs to be drilled. When drilling, turn on the auxiliary airflow pump, and let the auxiliary airflow take away the cuttings while drilling;

[0057] (3) When drilling, the depth signal receiving circuit passes through the HMC1021Z reluctance sensor to detect the reluctance of the thickened iron ring set every 5m on the drill pipe shell, judge whether it has drilled 5m, and calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com