Patents

Literature

127results about How to "Correction accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for non-invasive measurement of glucose in humans

InactiveUS6865408B1Efficient collectionMaximize glucose net analyte signal-to-noise ratioRadiation pyrometryDiagnostics using spectroscopyData acquisitionNon invasive

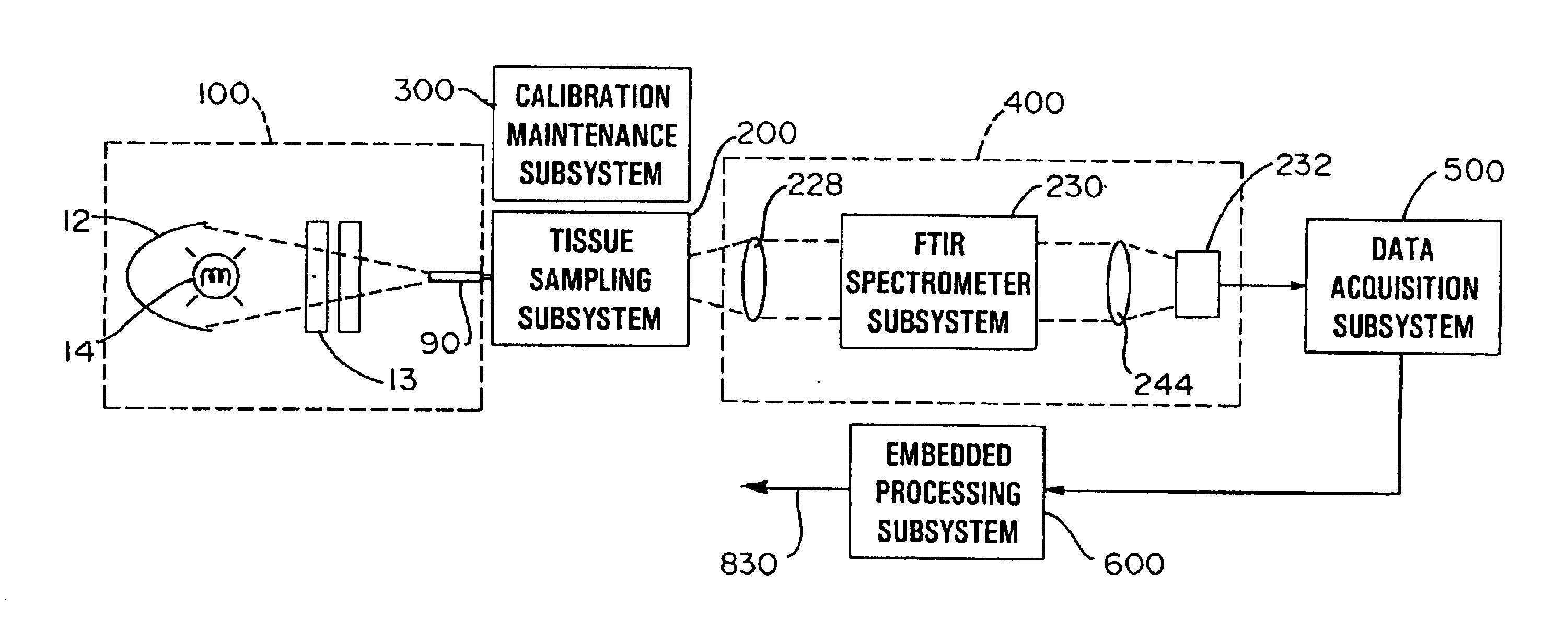

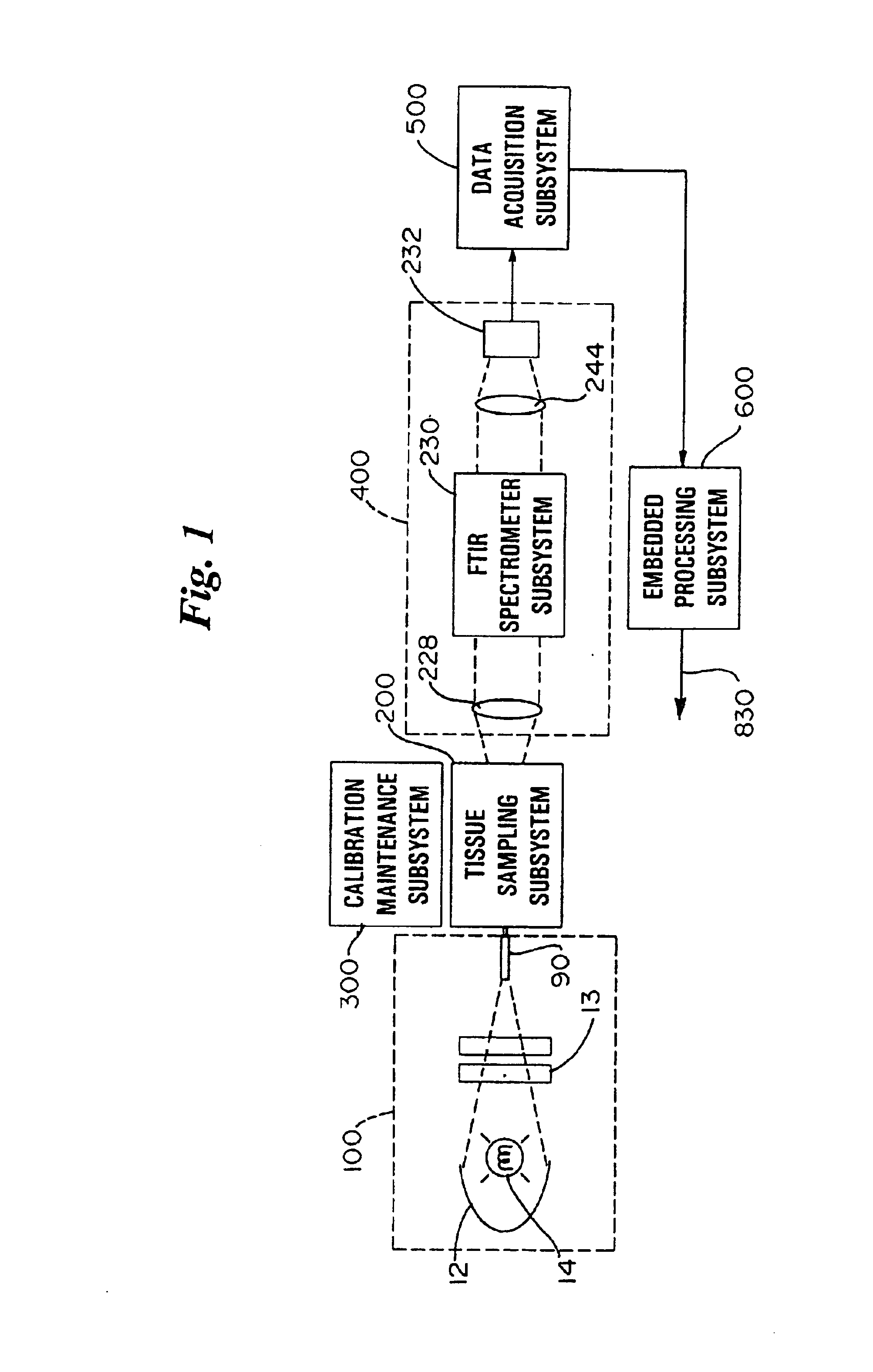

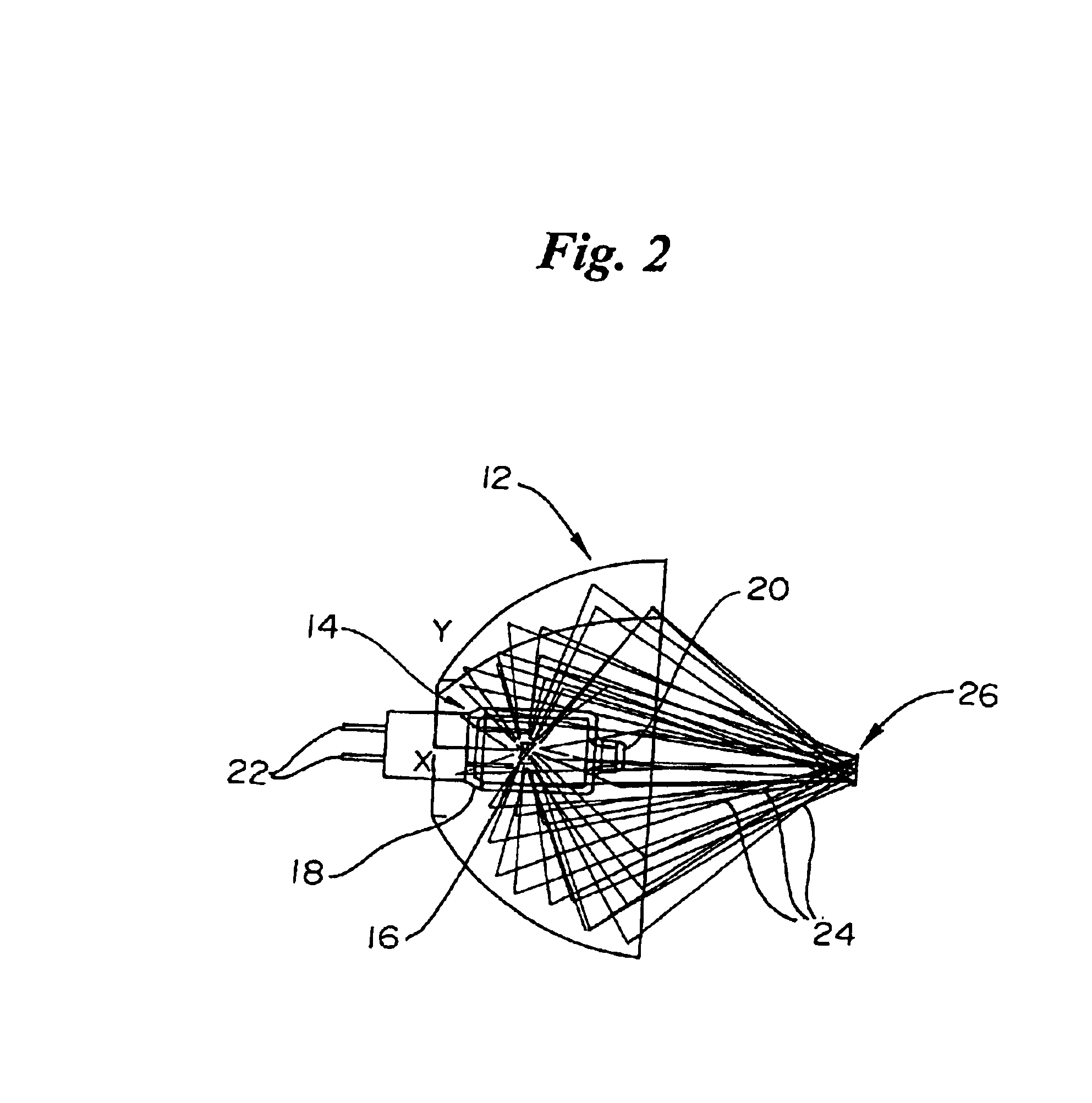

An apparatus and method for non-invasive measurement of glucose in human tissue by quantitative infrared spectroscopy to clinically relevant levels of precision and accuracy. The system includes six subsystems optimized to contend with the complexities of the tissue spectrum, high signal-to-noise ratio and photometric accuracy requirements, tissue sampling errors, calibration maintenance problems, and calibration transfer problems. The six subsystems include an illumination subsystem, a tissue sampling subsystem, a calibration maintenance subsystem, an FTIR spectrometer subsystem, a data acquisition subsystem, and a computing subsystem.

Owner:INLIGHT SOLUTIONS

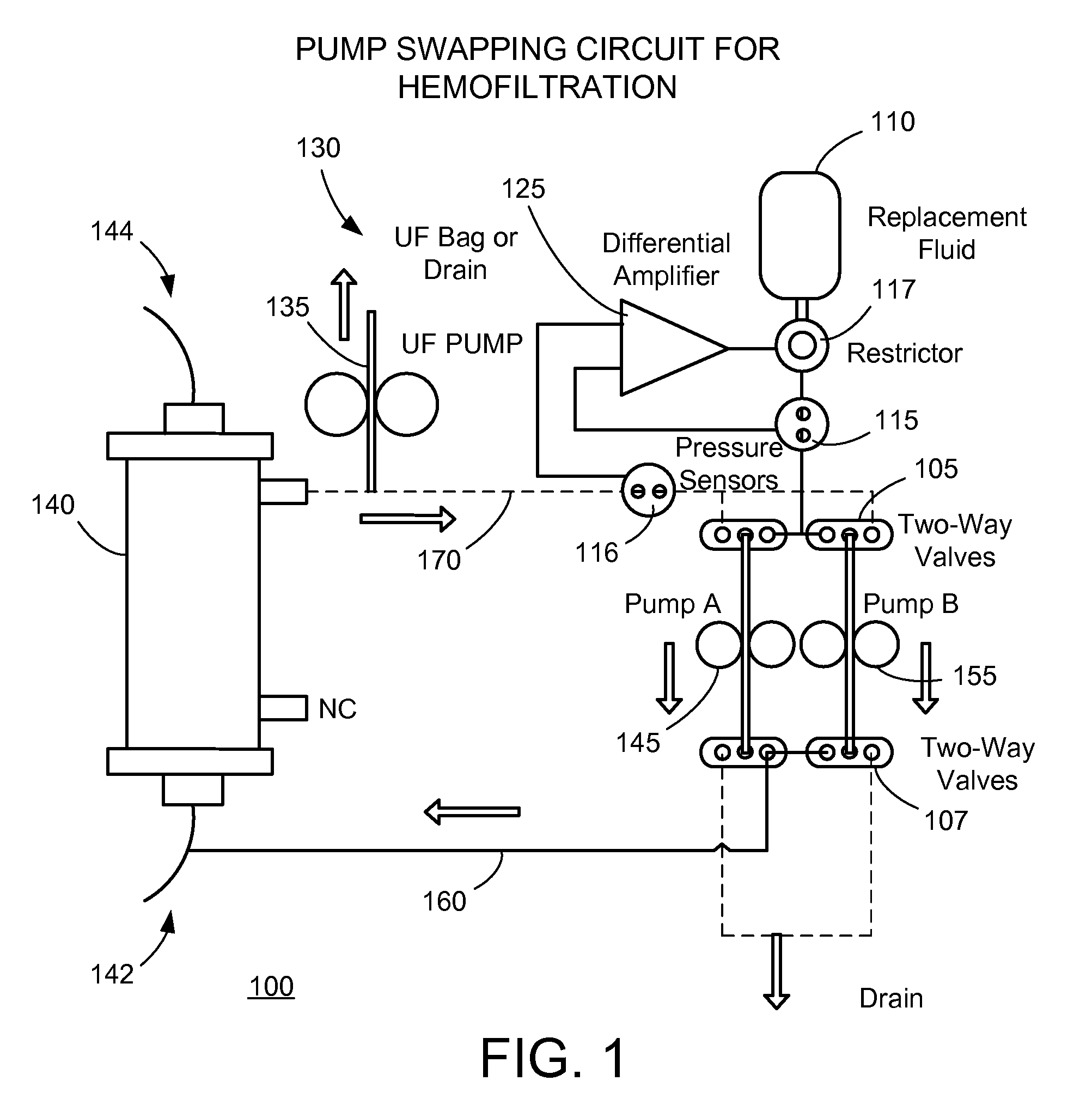

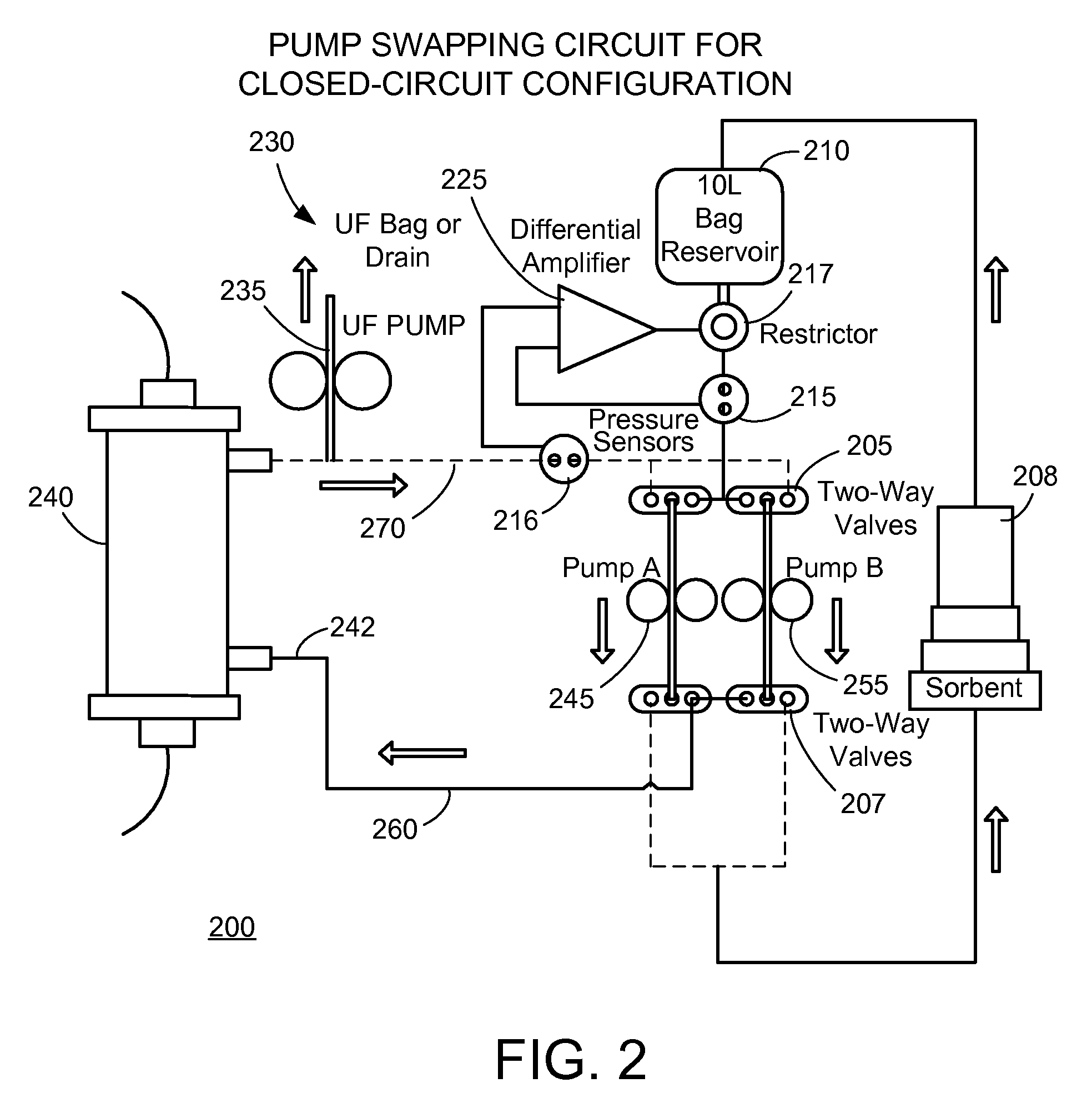

Method and System for Achieving Volumetric Accuracy in Hemodialysis Systems

InactiveUS20090076434A1Accurate for volumetric accuracyLow implementation costHaemofiltrationMedical devicesHaemodialysis machineClosed loop

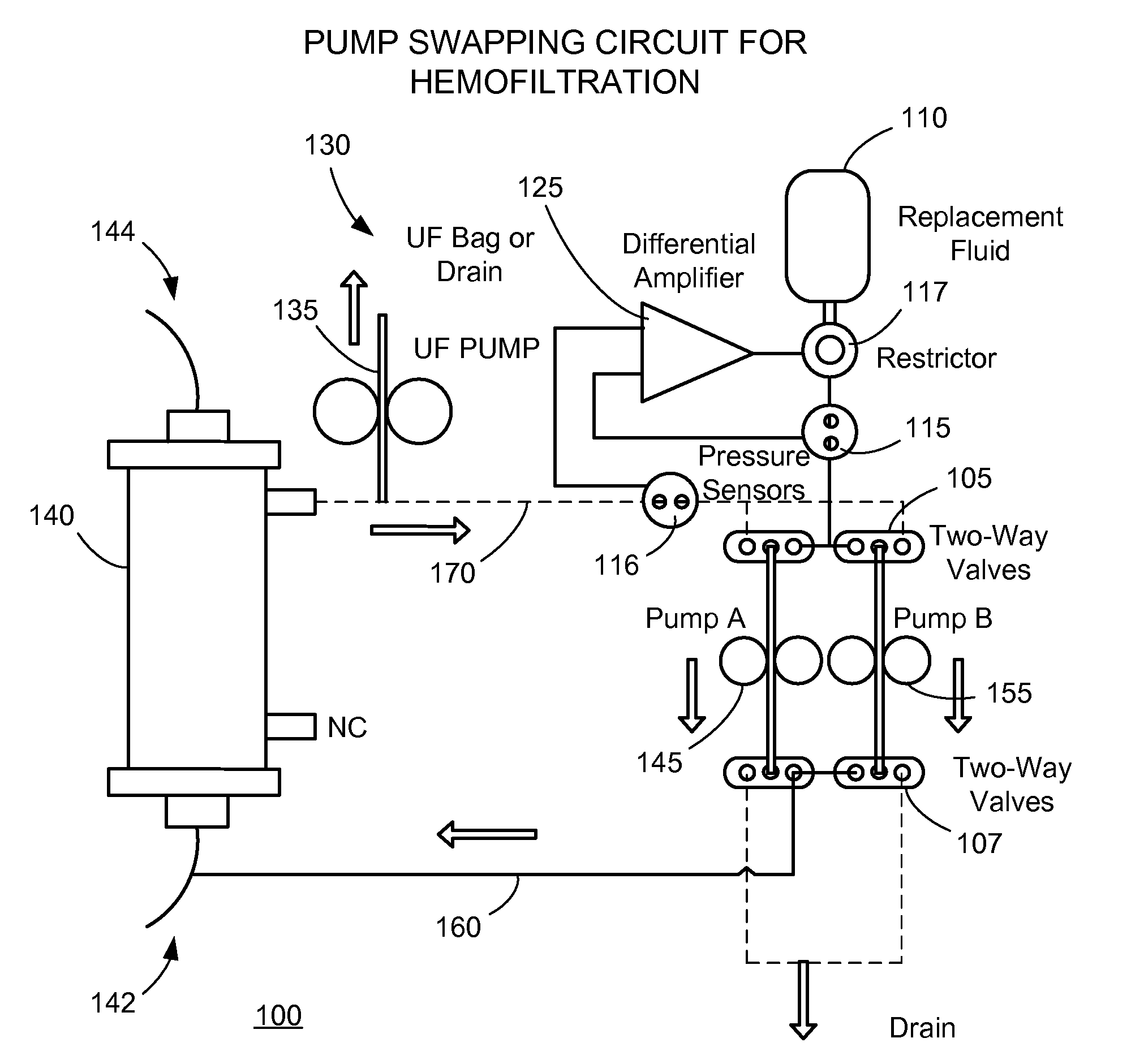

Volumetric accuracy in hemodialysis systems is provided by swapping pumps between the replacement fluid side and the output side for a hemofiltration system and between the return fluid side and the sorbent side for a closed-loop, sorbent-based system, such that same quantity of fluid is pumped at each point after the end of an even number of pump swaps. A method for calculating the time interval between swaps is provided based on an allowable difference in amount pumped in the two functions at any given time. A mechanism is provided for compensating for the differences in head pressure presented to the pumps for fluid coming from the replacement-fluid containers or the reservoir and that coming back from the patient through the dialyzer. The pump-swapping system provides an accurate means that can be inexpensively implemented, including using a disposable device.

Owner:FRESENIUS MEDICAL CARE HLDG INC

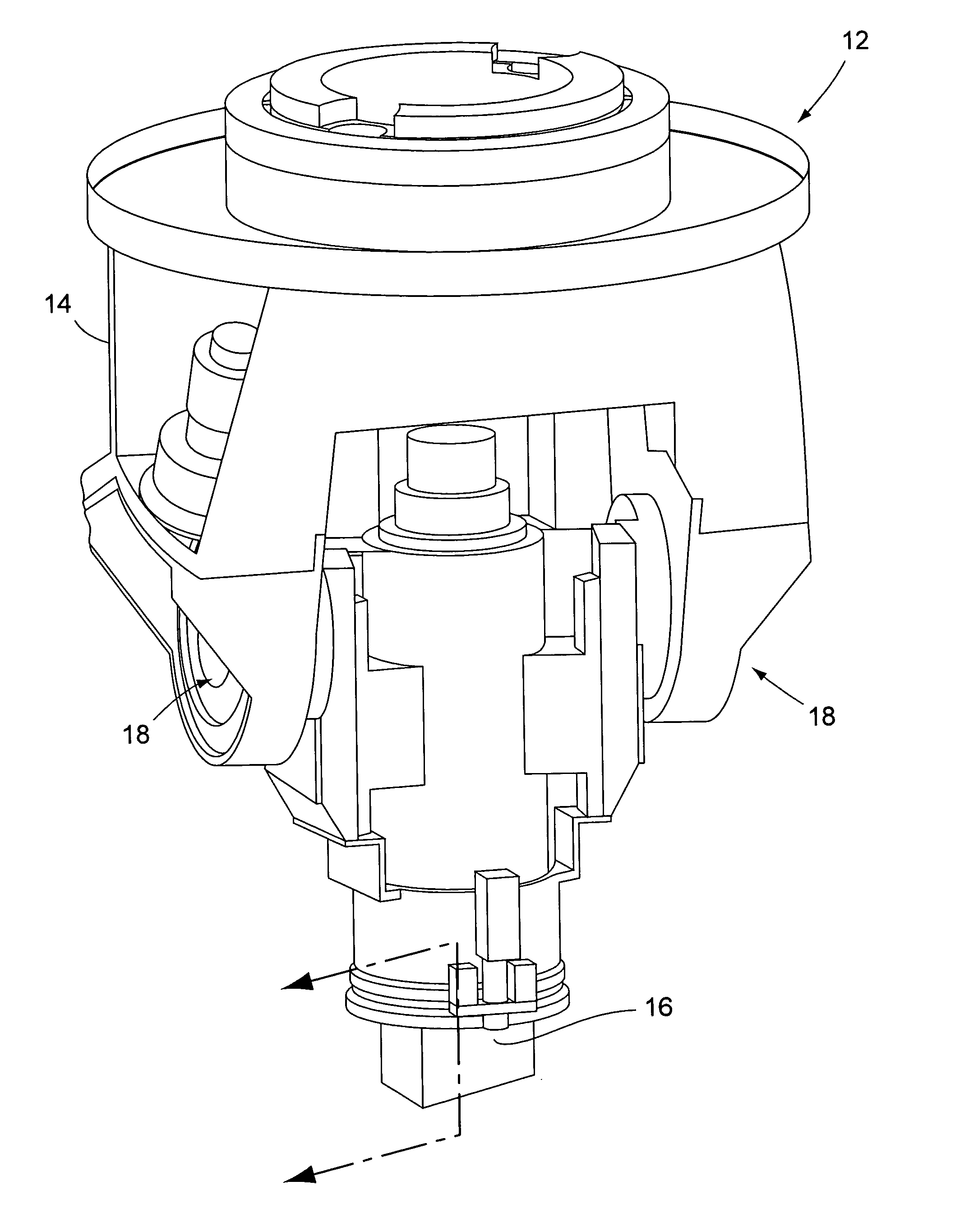

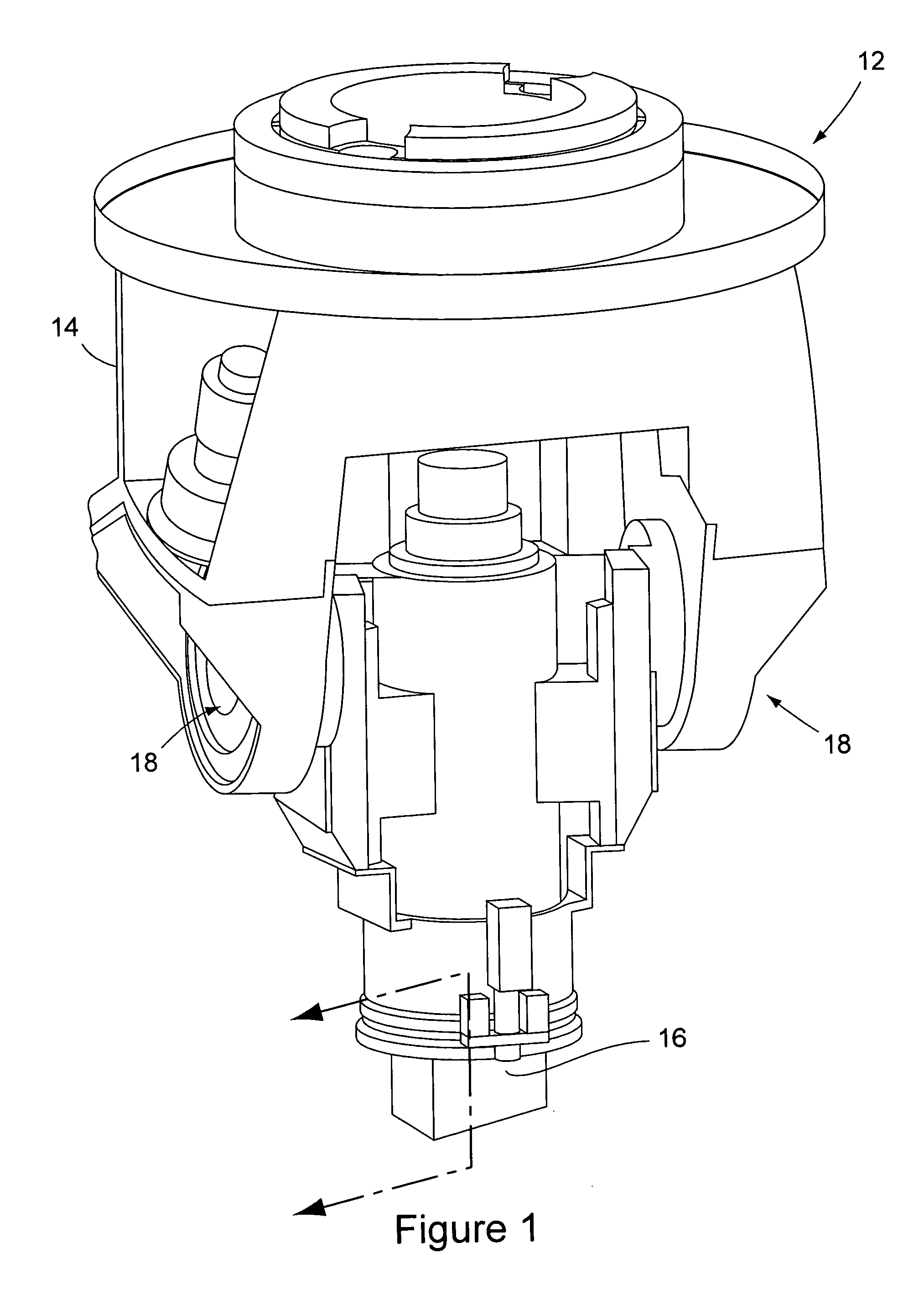

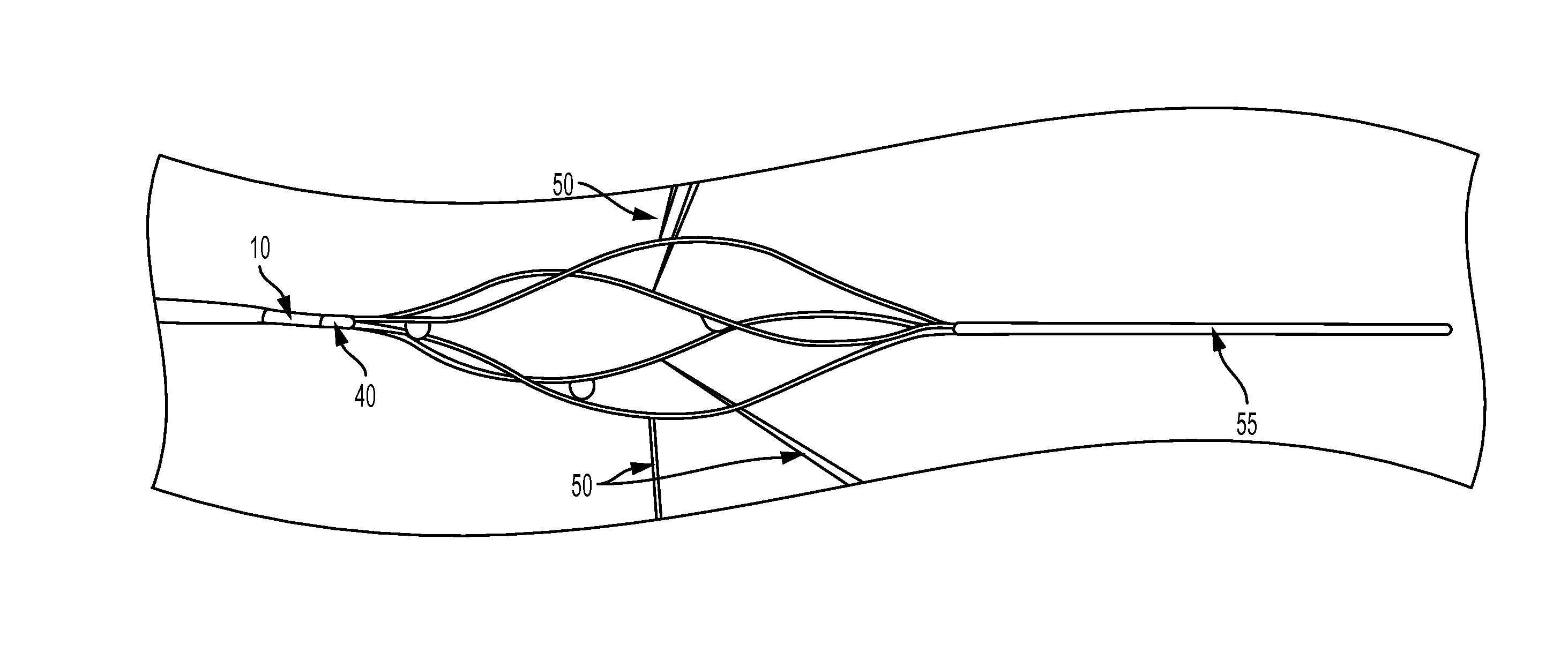

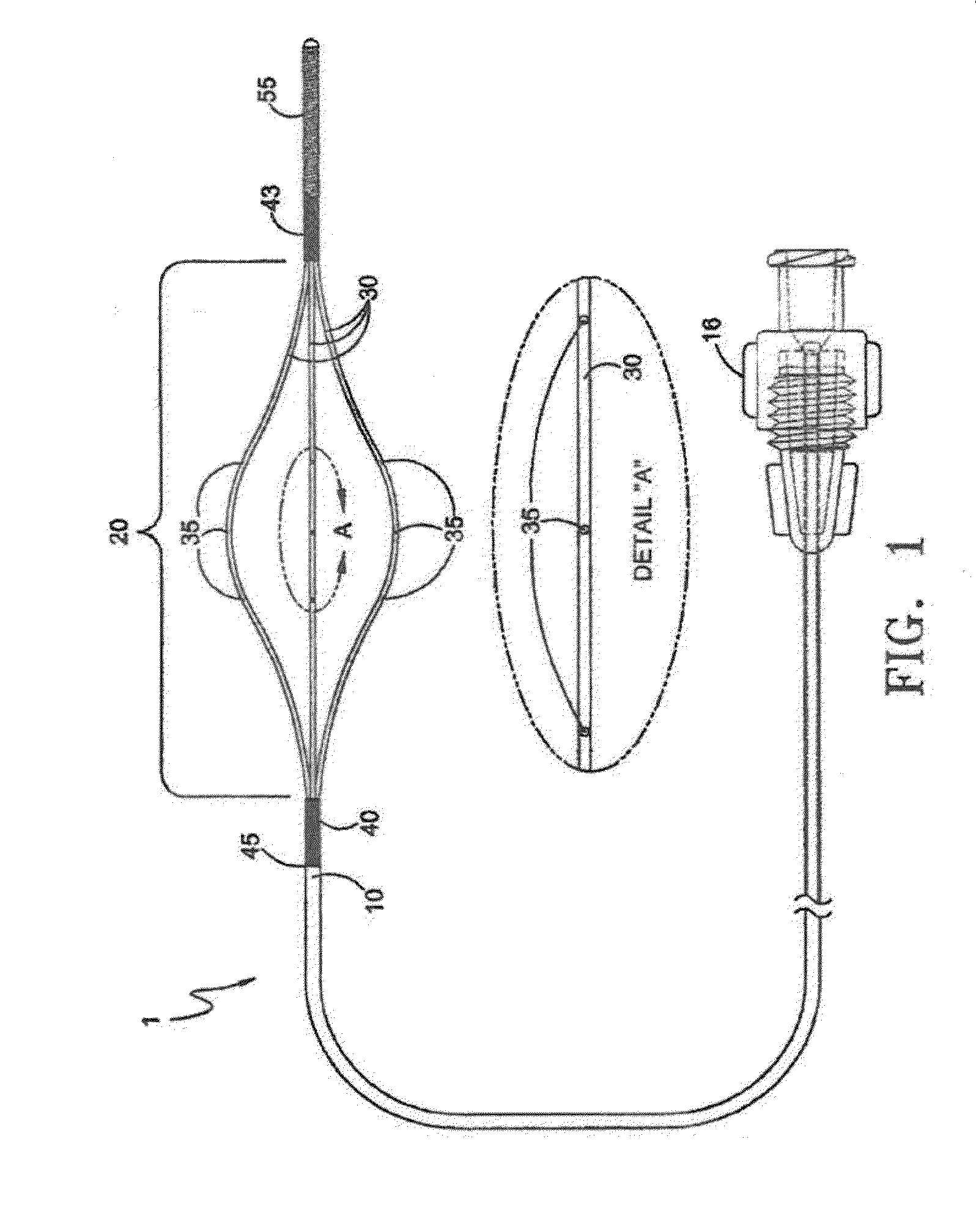

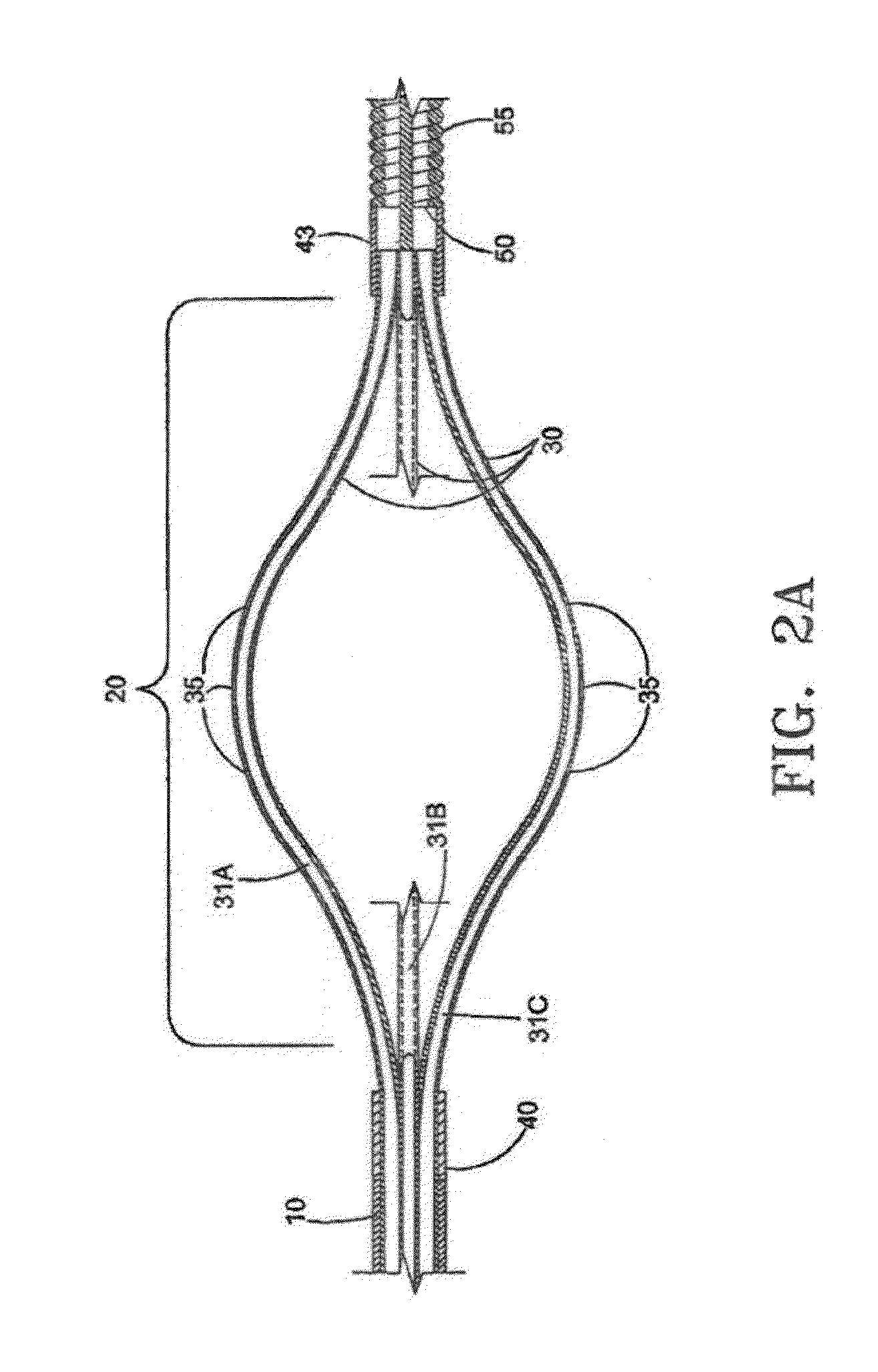

Fluid Delivery and Treatment Device and Method of Use

ActiveUS20120059309A1Facilitate formation of newPromote disseminationStentsBalloon catheterFluid infusionMedical device

A medical device system is provided herein which has an elongated, flexible hollow member with an expandable infusion segment attached at the most distal end of the device. The device has a plurality of fluid infusion ports on the expandable infusion segment for delivering an intended fluid to a target site in a body lumen. Additionally, a method is provided herein for infusing an intended fluid to a target site within a body lumen.

Owner:ANGIODYNAMICS INC

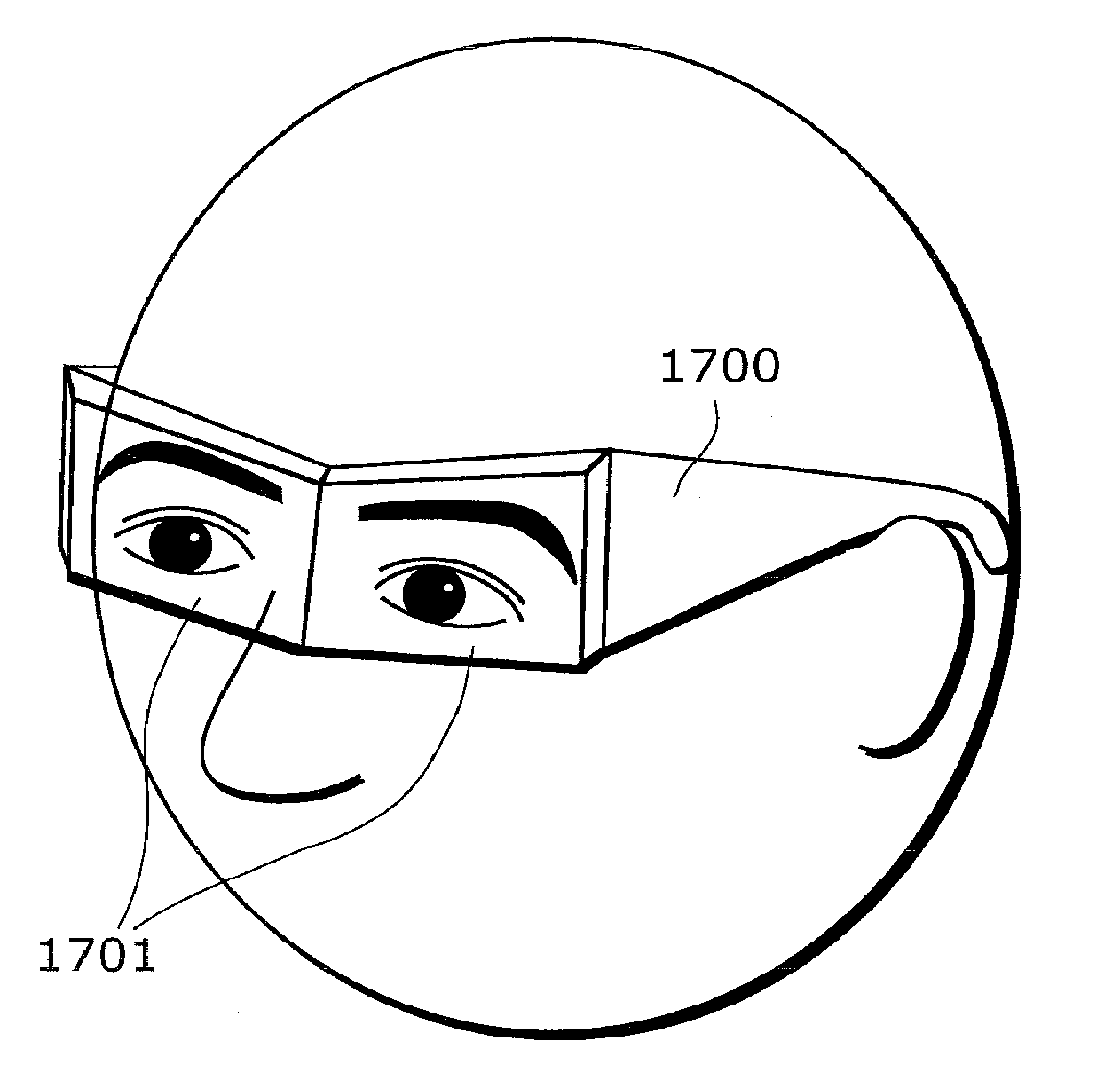

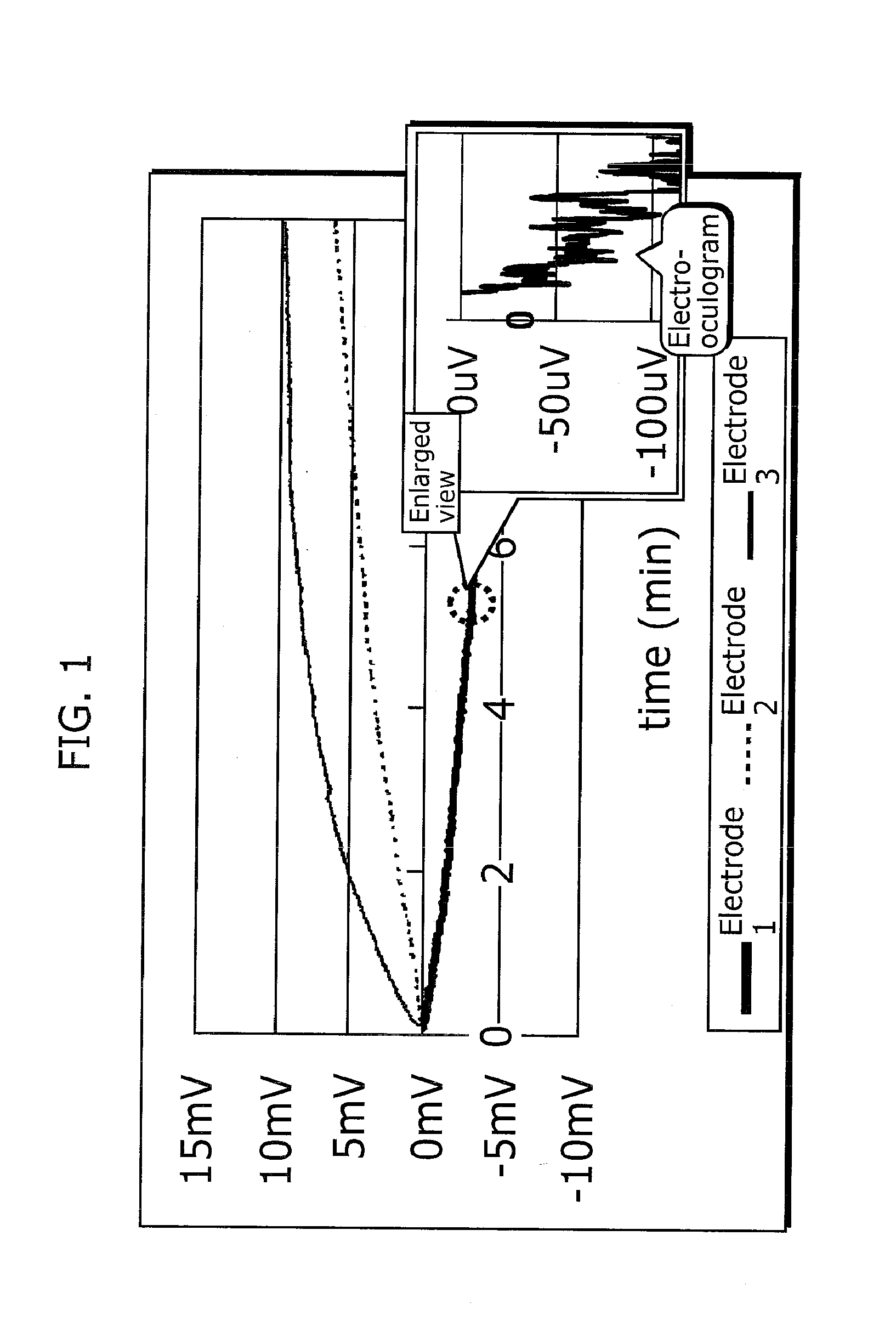

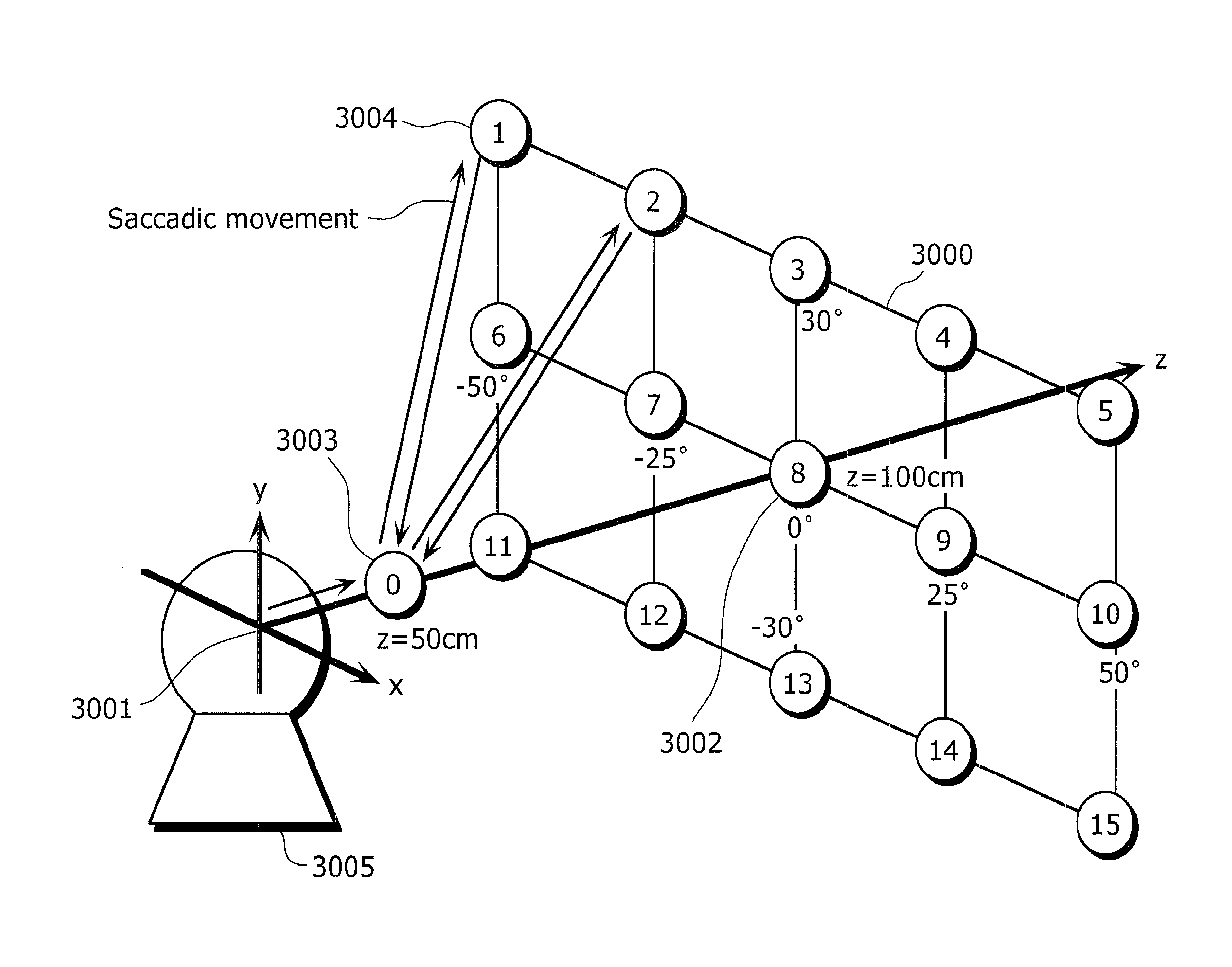

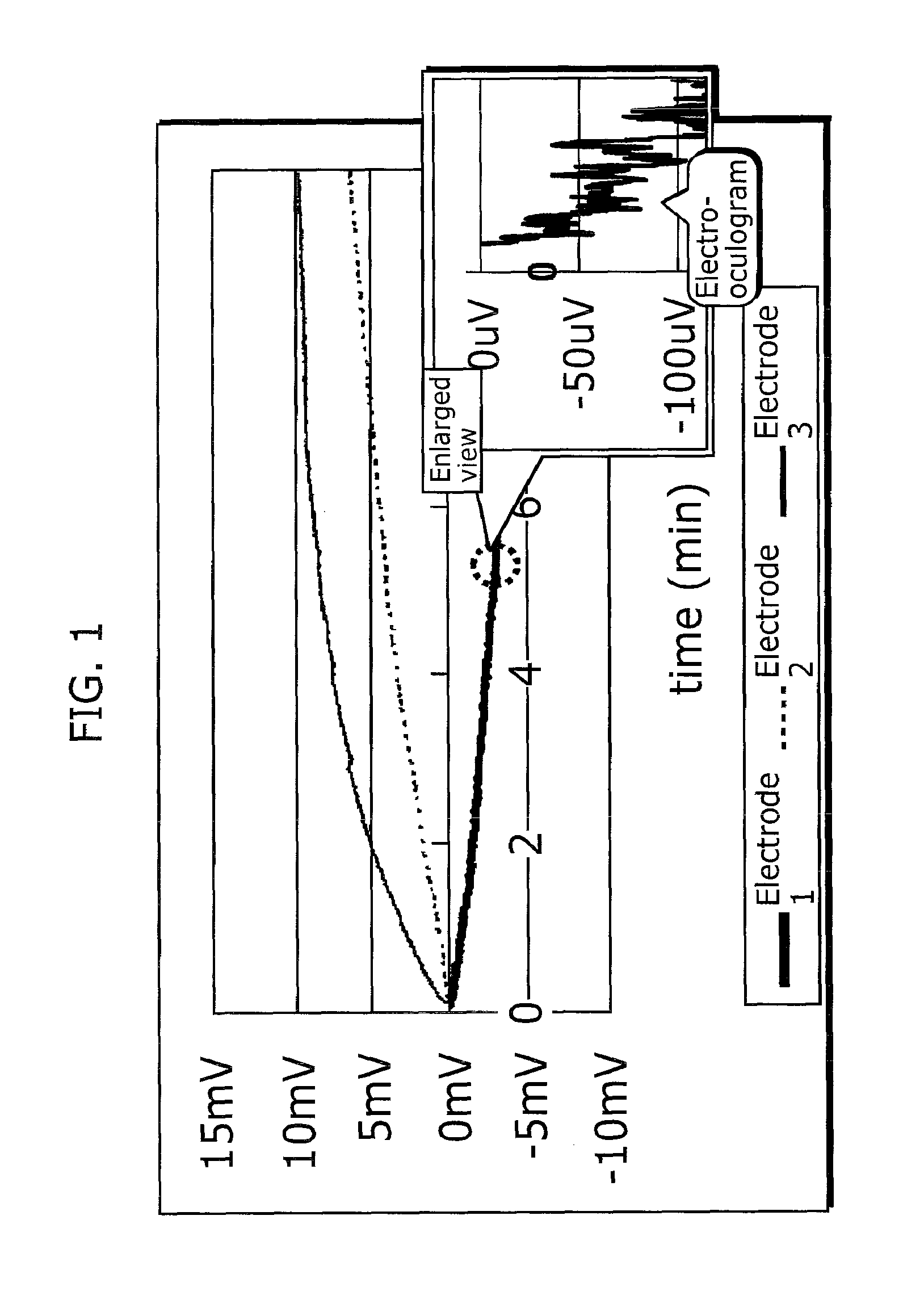

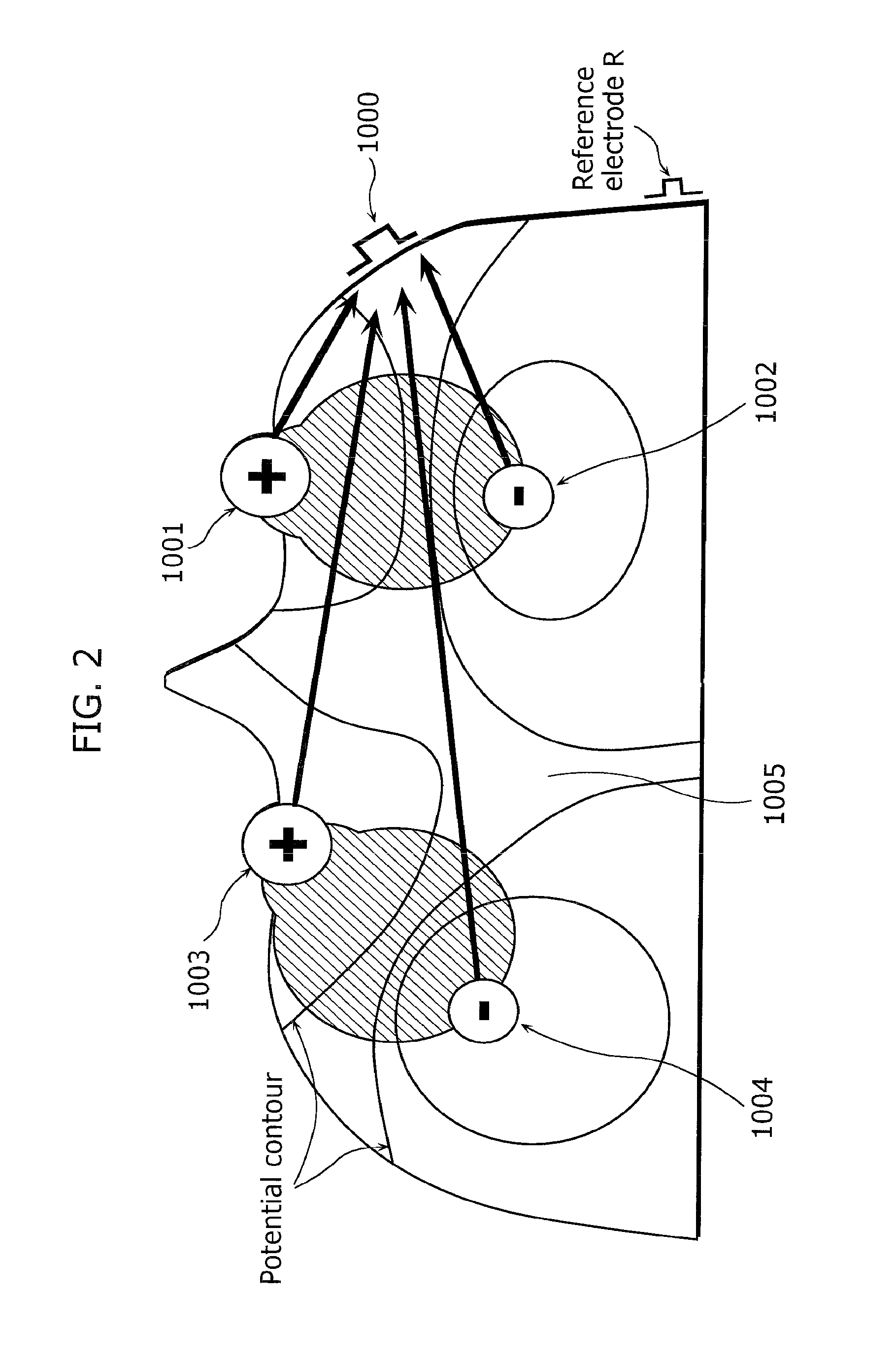

Eye-gaze tracking device, eye-gaze tracking method, electro-oculography measuring device, wearable camera, head-mounted display, electronic eyeglasses, and ophthalmological diagnosis device

ActiveUS20110170067A1Low accuracyImprove accuracyTelevision system detailsElectro-oculographyDisplay deviceGaze directions

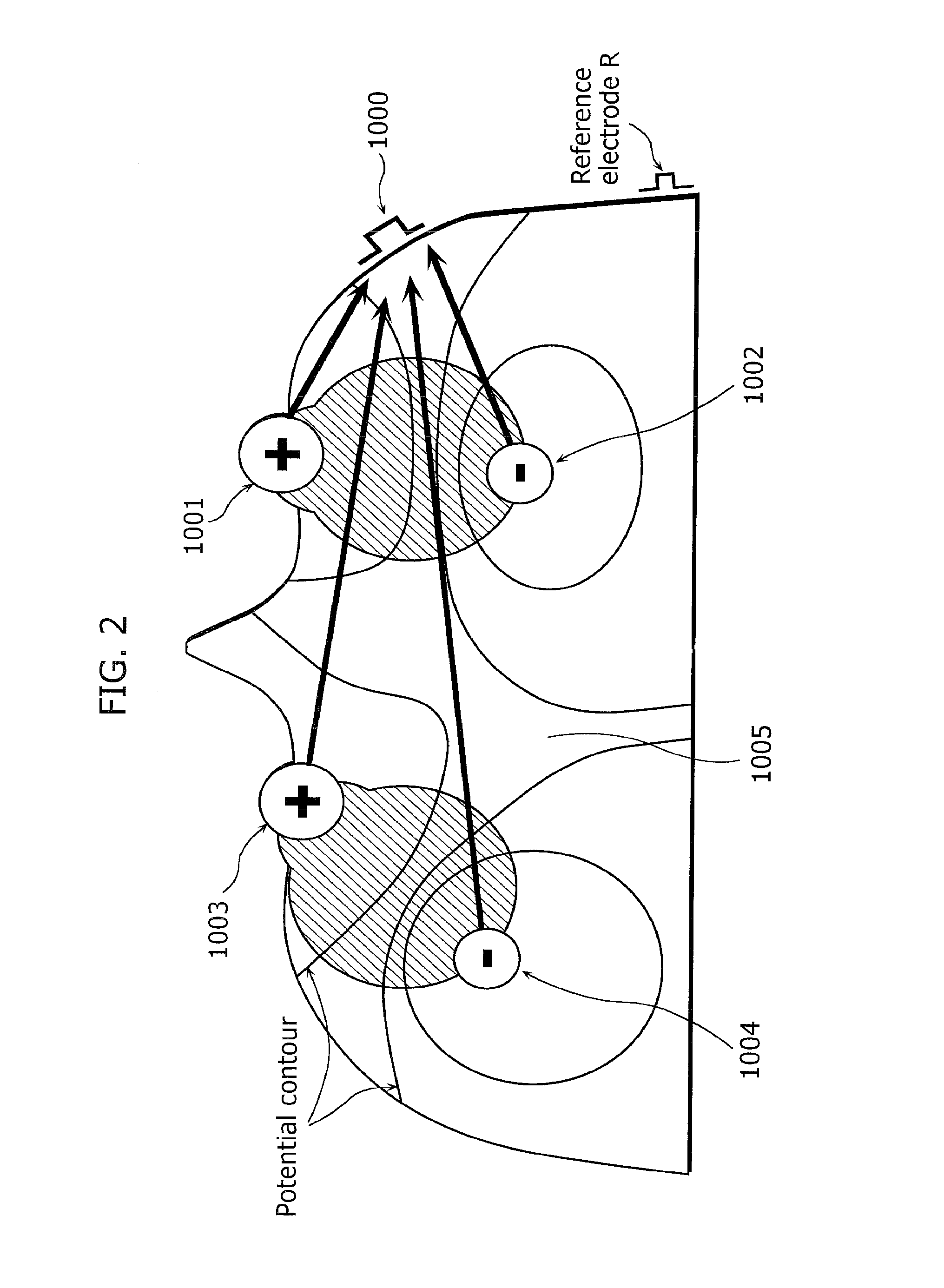

An eye-gaze tracking device, which detects a gaze direction of a user based on an electro-oculogram, includes: a drift estimating unit which estimates drift noise included in a set of observation voltages among observation voltages that are electro-oculograms generated in a living body and observed at the plurality of electrodes, based on a component outside an electro-oculography subspace that is an assembly of sets of electro-oculograms theoretically observed at a plurality of electrodes; and an eye-gaze tracking unit which detects la the gaze direction of the user, based on a signal generated by removing, from the observation voltages, the drift noise estimated by the drift estimating unit.

Owner:PANASONIC CORP

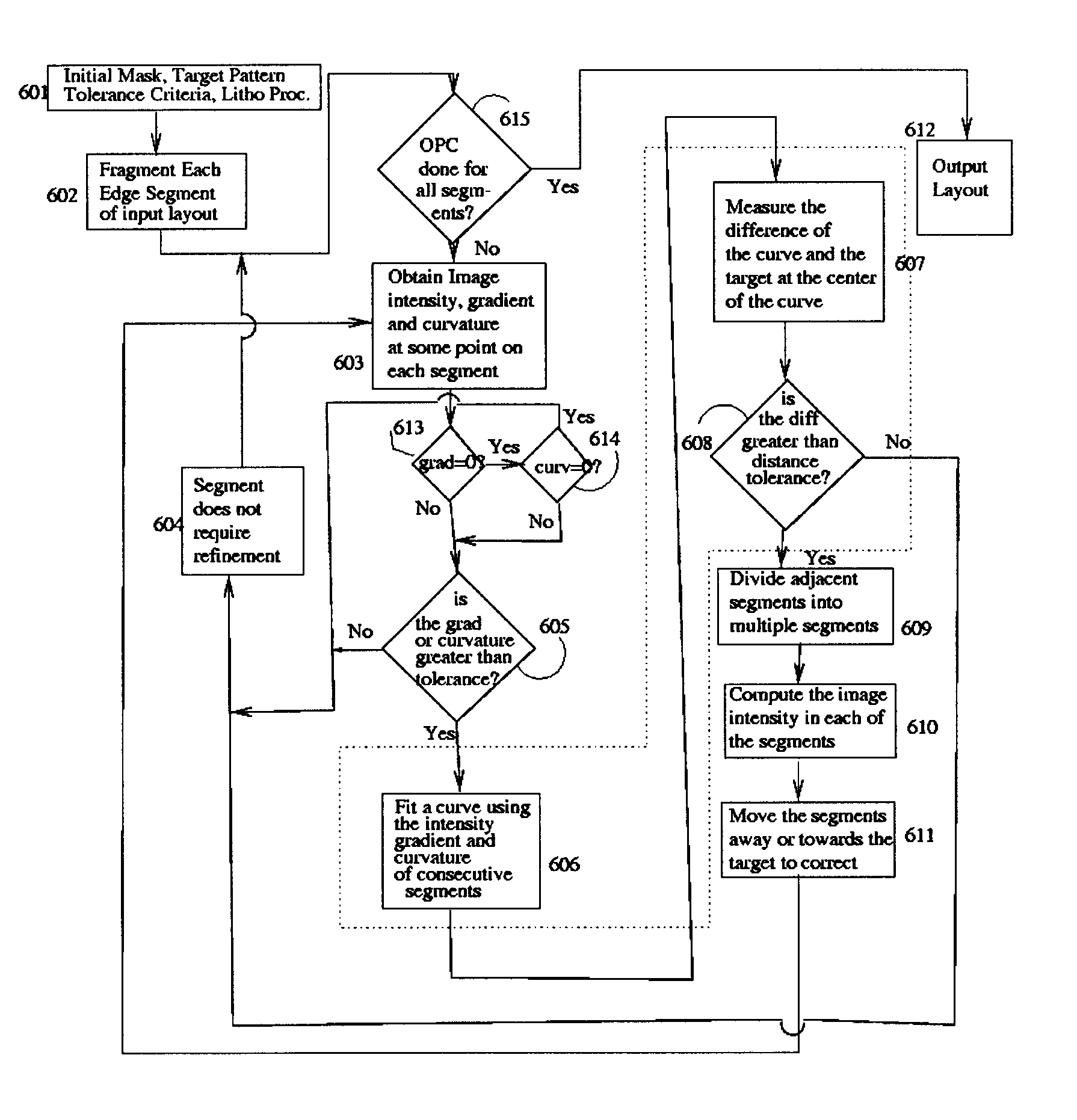

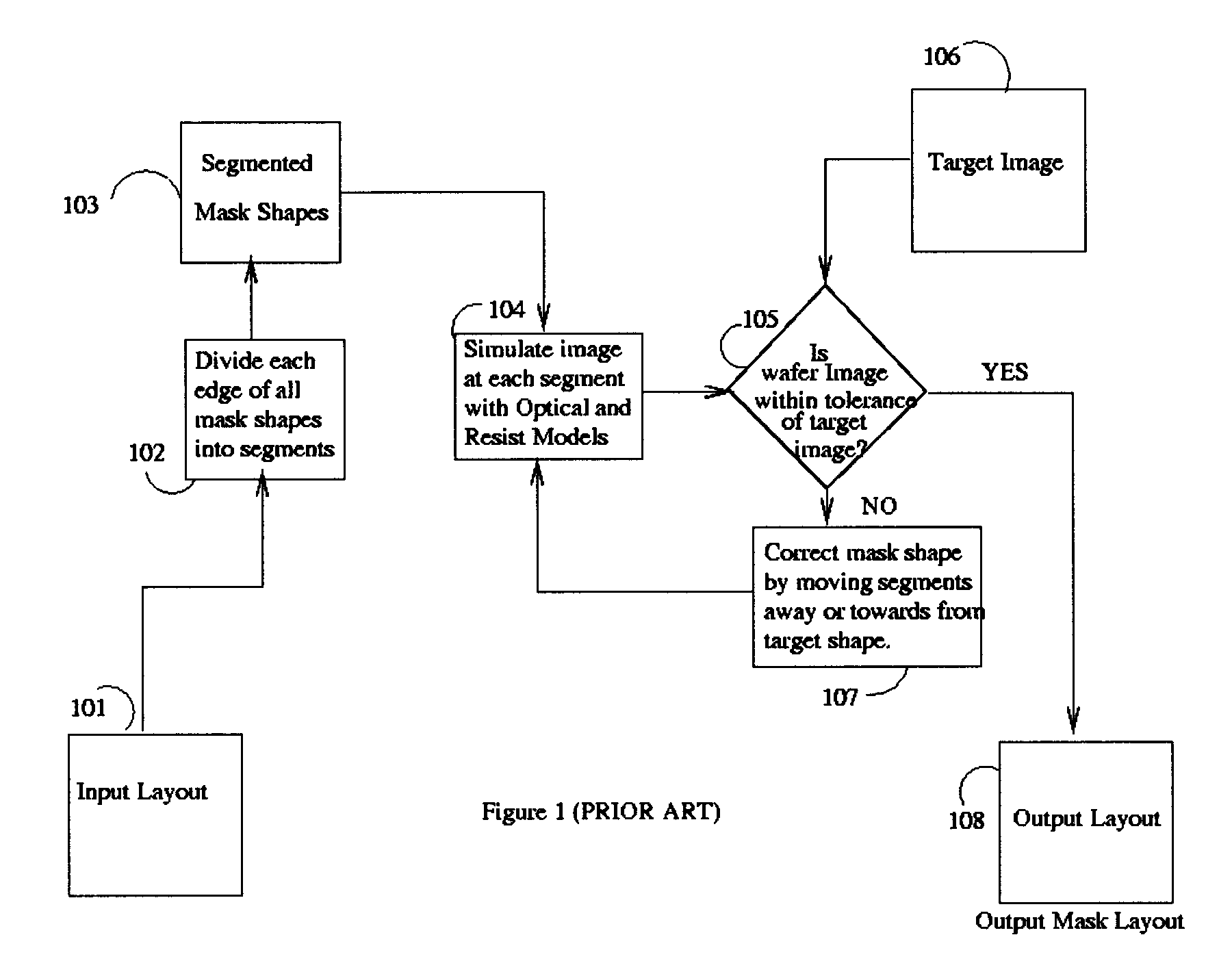

Method for adaptive segment refinement in optical proximity correction

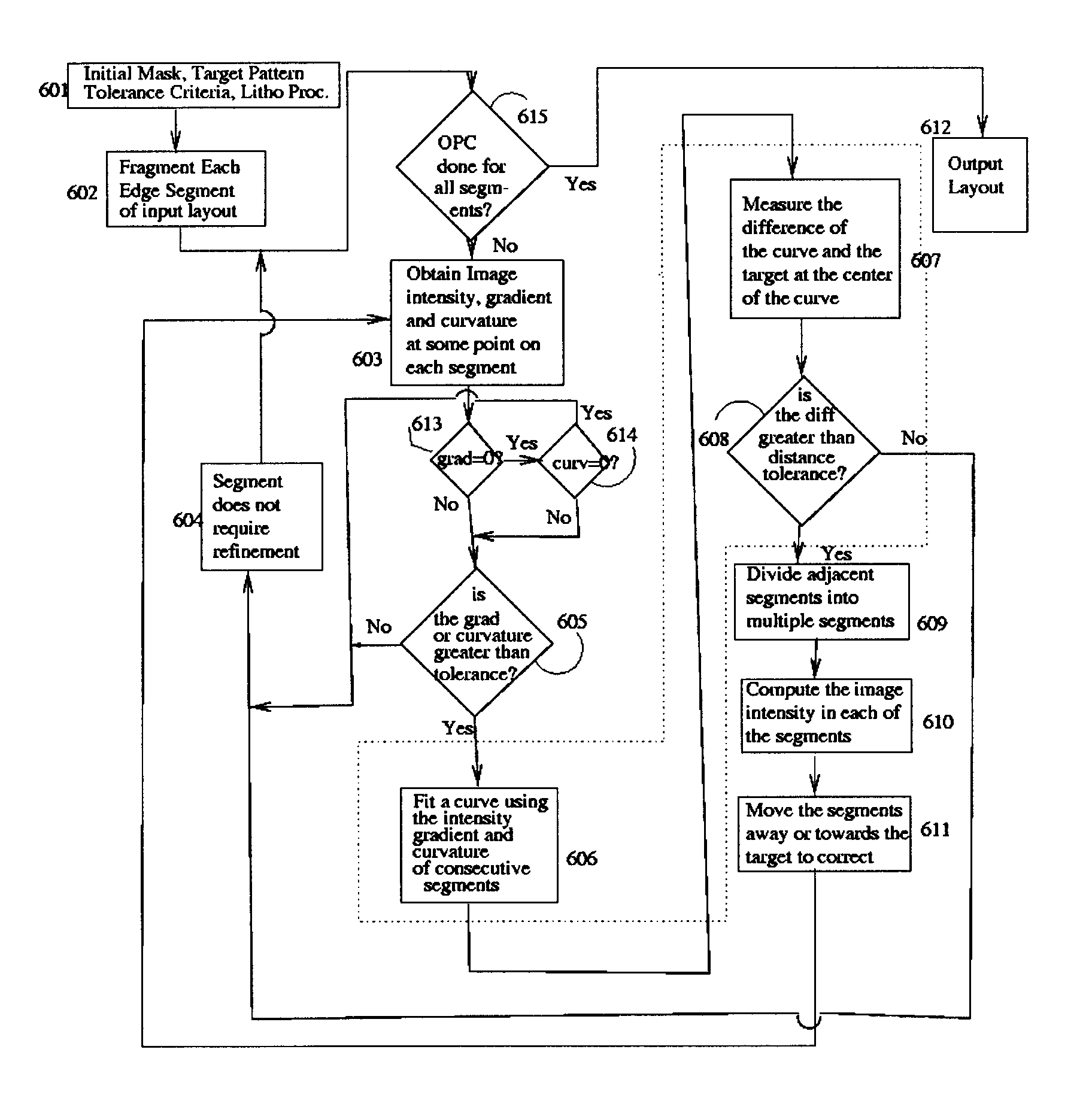

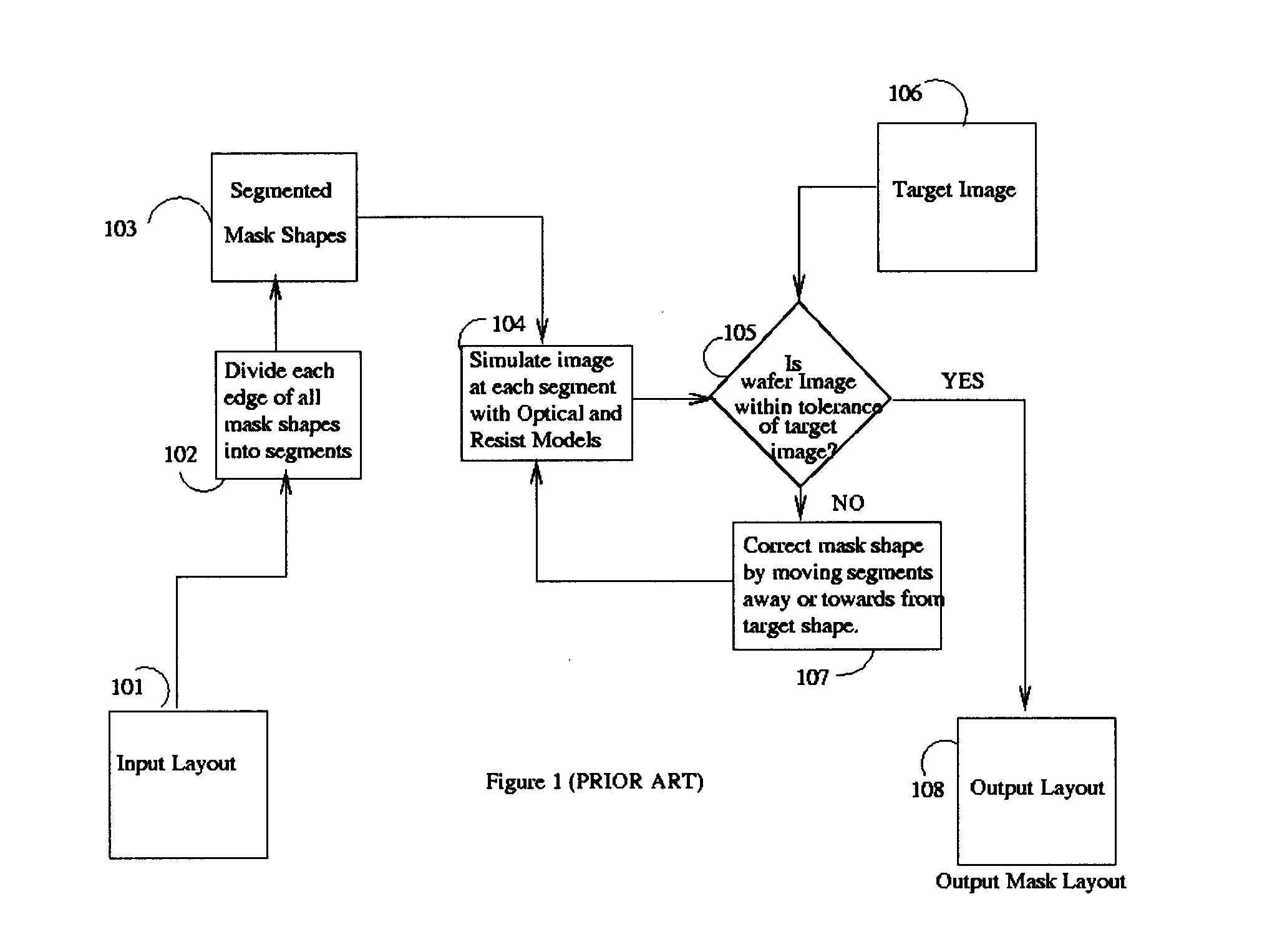

InactiveUS20050055658A1Increase computational costAccurate representationOriginals for photomechanical treatmentComputer aided designPattern recognitionCurve fitting

A method of designing lithographic masks is provided where mask segments used in a model-based optical proximity correction (MBOPC) scheme are adaptively refined based on local image information, such as image intensity, gradient and curvature. The values of intensity, gradient and curvature are evaluated locally at predetermined evaluation points associated with each segment. An estimate of the image intensity between the local evaluation points is preferably obtained by curve fitting based only on values at the evaluation points. The decision to refine a segment is based on the deviation of the simulated image threshold contour from the target image threshold contour. The output mask layout will provide an image having improved fit to the target image, without a significant increase in computation cost.

Owner:IBM CORP

Method for adaptive segment refinement in optical proximity correction

InactiveUS7043712B2Increase computational costAccurate representationOriginals for photomechanical treatmentComputer aided designPattern recognitionCurve fitting

A method of designing lithographic masks is provided where mask segments used in a model-based optical proximity correction (MBOPC) scheme are adaptively refined based on local image information, such as image intensity, gradient and curvature. The values of intensity, gradient and curvature are evaluated locally at predetermined evaluation points associated with each segment. An estimate of the image intensity between the local evaluation points is preferably obtained by curve fitting based only on values at the evaluation points. The decision to refine a segment is based on the deviation of the simulated image threshold contour from the target image threshold contour. The output mask layout will provide an image having improved fit to the target image, without a significant increase in computation cost.

Owner:IBM CORP

Eye-gaze tracking device, eye-gaze tracking method, electro-oculography measuring device, wearable camera, head-mounted display, electronic eyeglasses, and ophthalmological diagnosis device

ActiveUS8434868B2Correction accuracyLow accuracyElectro-oculographyAcquiring/recognising eyesBiological bodyMeasurement device

An eye-gaze tracking device, which detects a gaze direction of a user based on an electro-oculogram, includes: a drift estimating unit which estimates drift noise included in a set of observation voltages among observation voltages that are electro-oculograms generated in a living body and observed at the plurality of electrodes, based on a component outside an electro-oculography subspace that is an assembly of sets of electro-oculograms theoretically observed at a plurality of electrodes; and an eye-gaze tracking unit which detects the gaze direction of the user, based on a signal generated by removing, from the observation voltages, the drift noise estimated by the drift estimating unit.

Owner:PANASONIC CORP

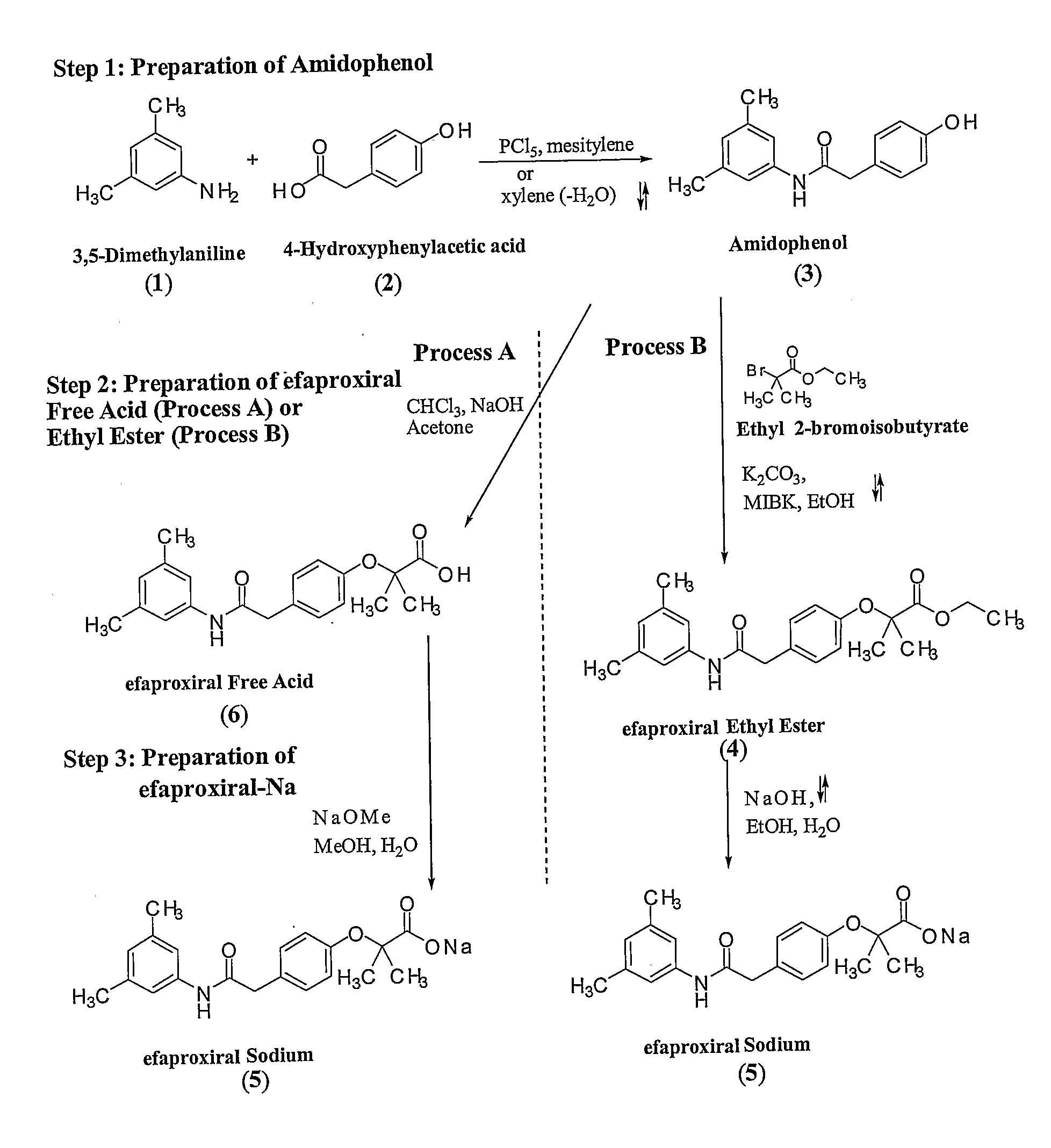

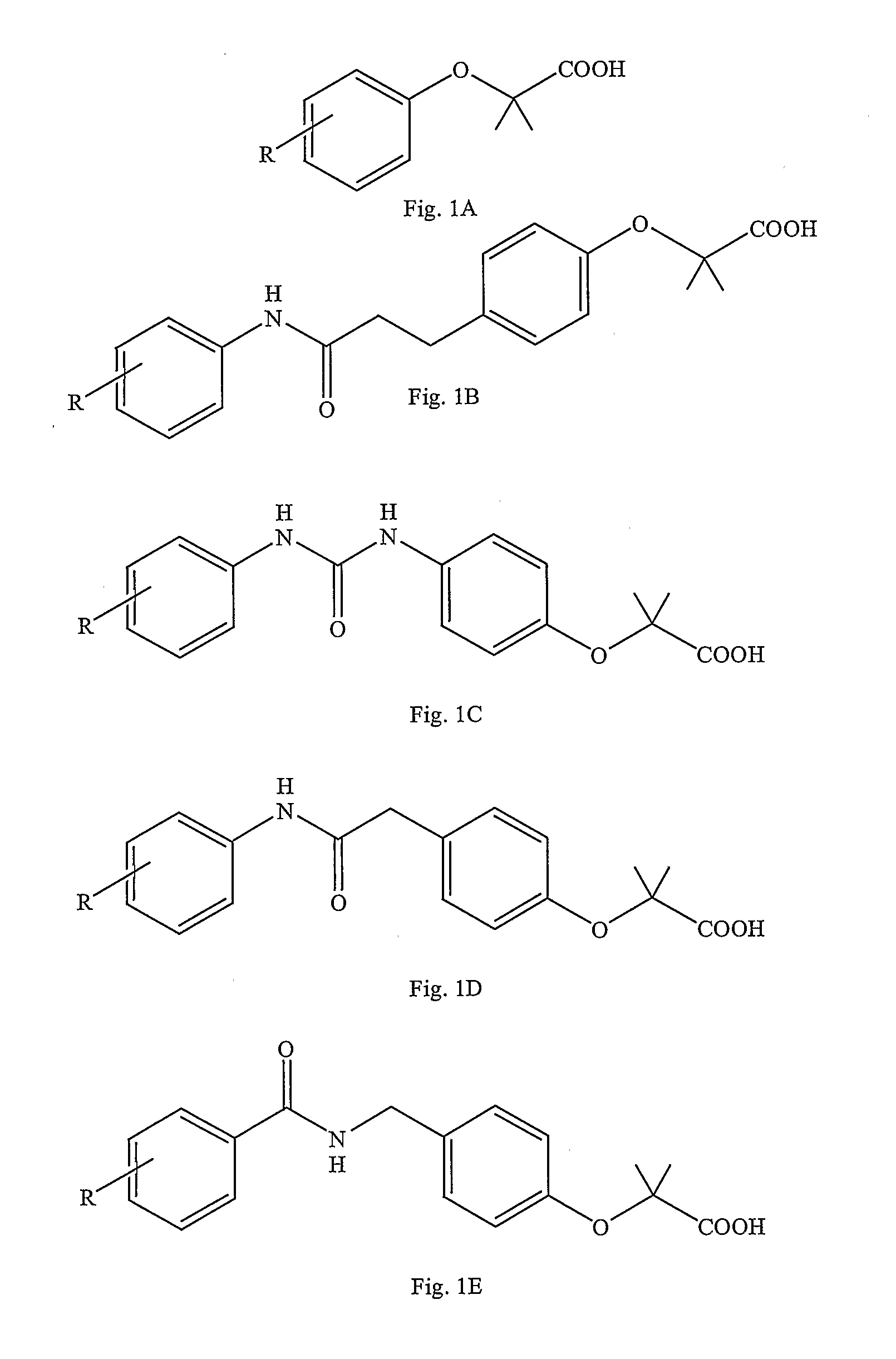

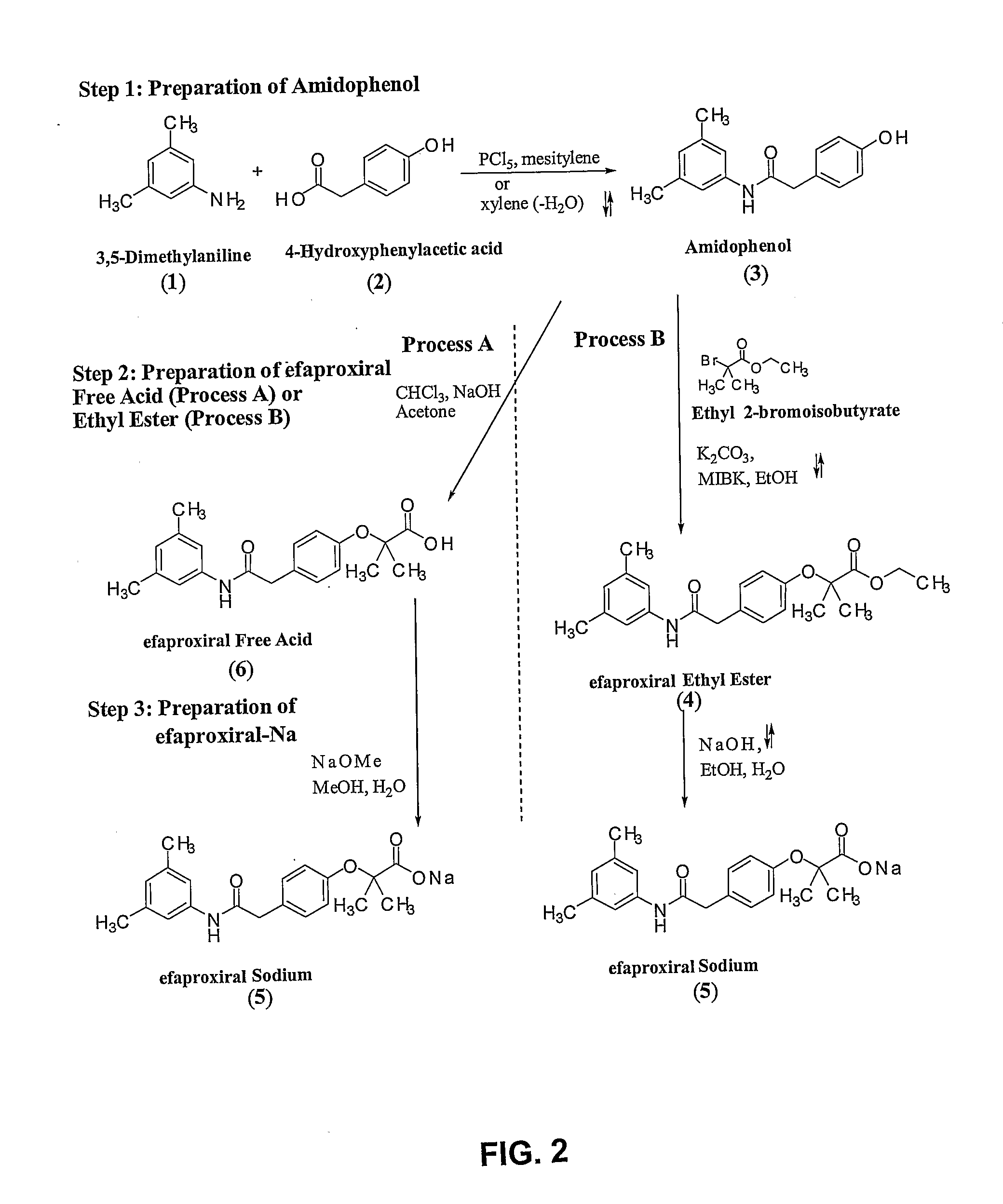

Compositions of Allosteric Hemoglobin Modifiers and Methods of Making the Same

InactiveUS20070293698A1High sensitivityCorrection accuracyOrganic active ingredientsPeptide/protein ingredientsMethyl isobutyl ketoneFiltration

The present invention provides novel compositions of allosteric hemoglobin modifiers which are substantially free of impurities, specifically polymeric impurities. In one embodiment, the novel compositions contain an allosteric hemoglobin modifier compound and less than 100 ppm of the polymeric impurities generated during the preparation of this compound. Included in the present invention are novel methods for preparing allosteric hemoglobin modifiers that are substantially free of polymeric impurities. Also included in the present invention are improved methods for the purification of the product formed by the method of this invention. The novel methods of purification comprise extracting the crude composition with a water immiscible or partially immiscible solvent such as methylisobutyl ketone (MIBK) to lower amounts of impurities, specifically polymeric impurities. Also included are methods to reduce impurities by recrystallization of the crude synthesized product, followed by filtration of the recrystallized product. The present invention also includes the products made by the processes of the invention and methods for analyzing compositions comprised of these products.

Owner:ALLOS THERAPEUTICS

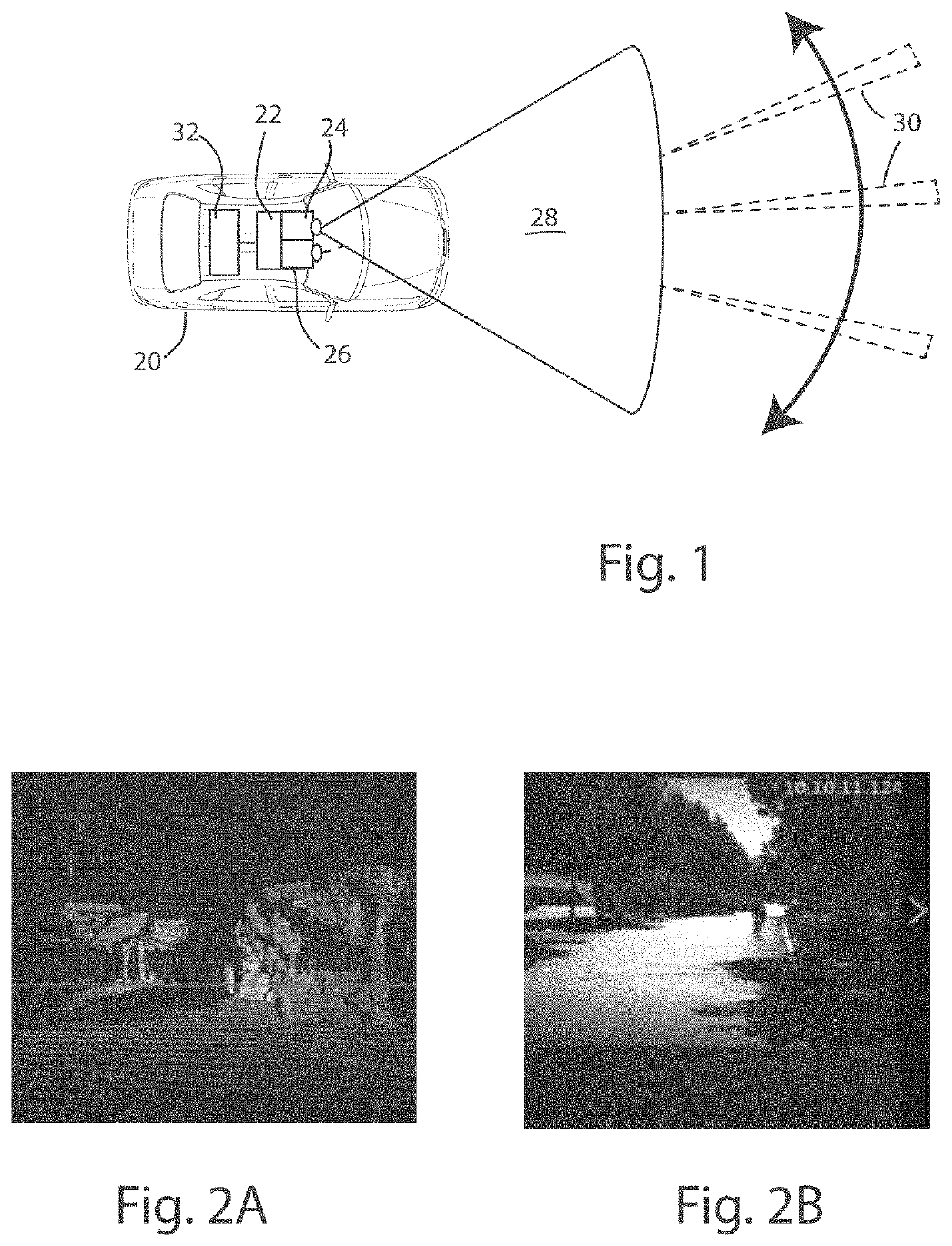

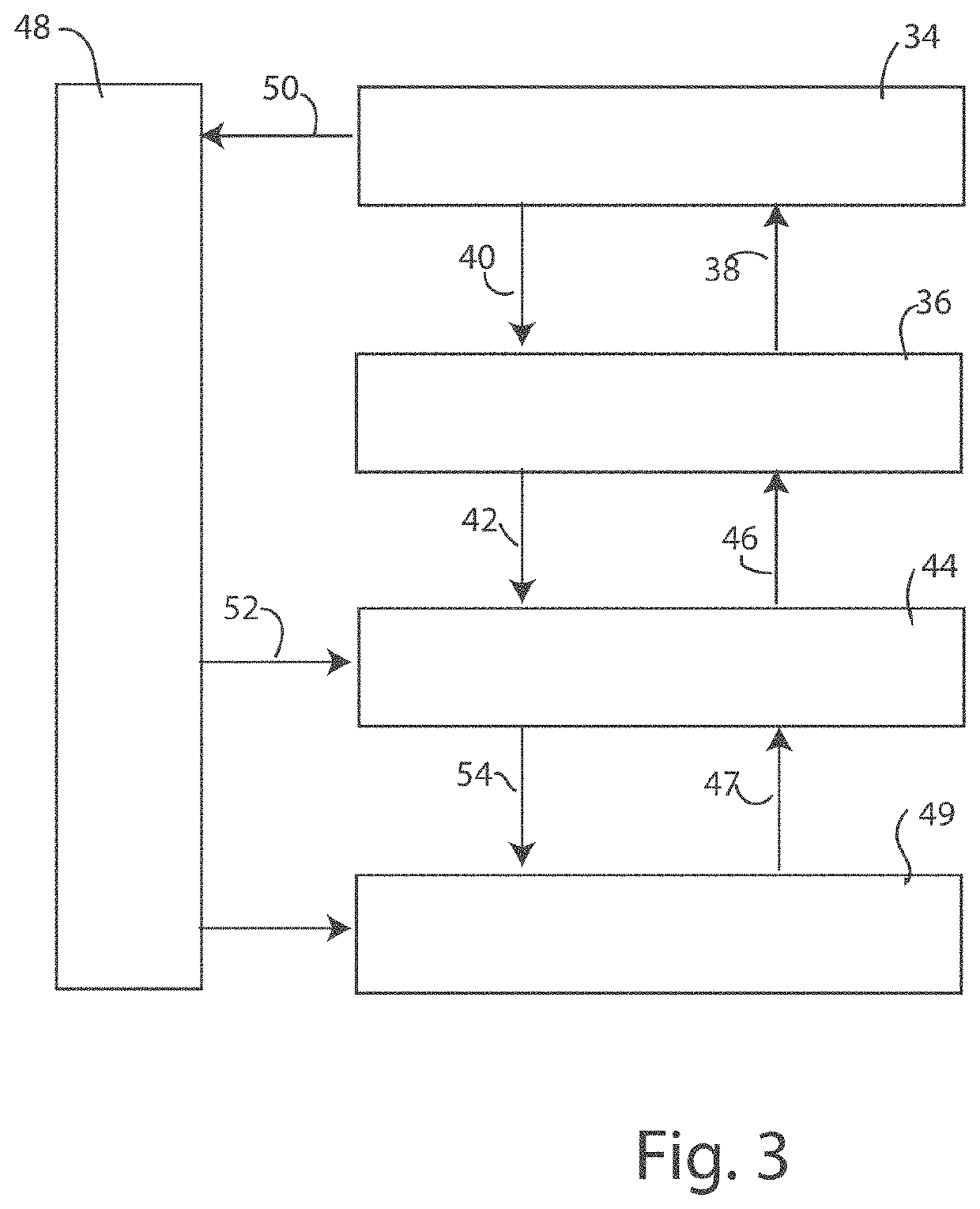

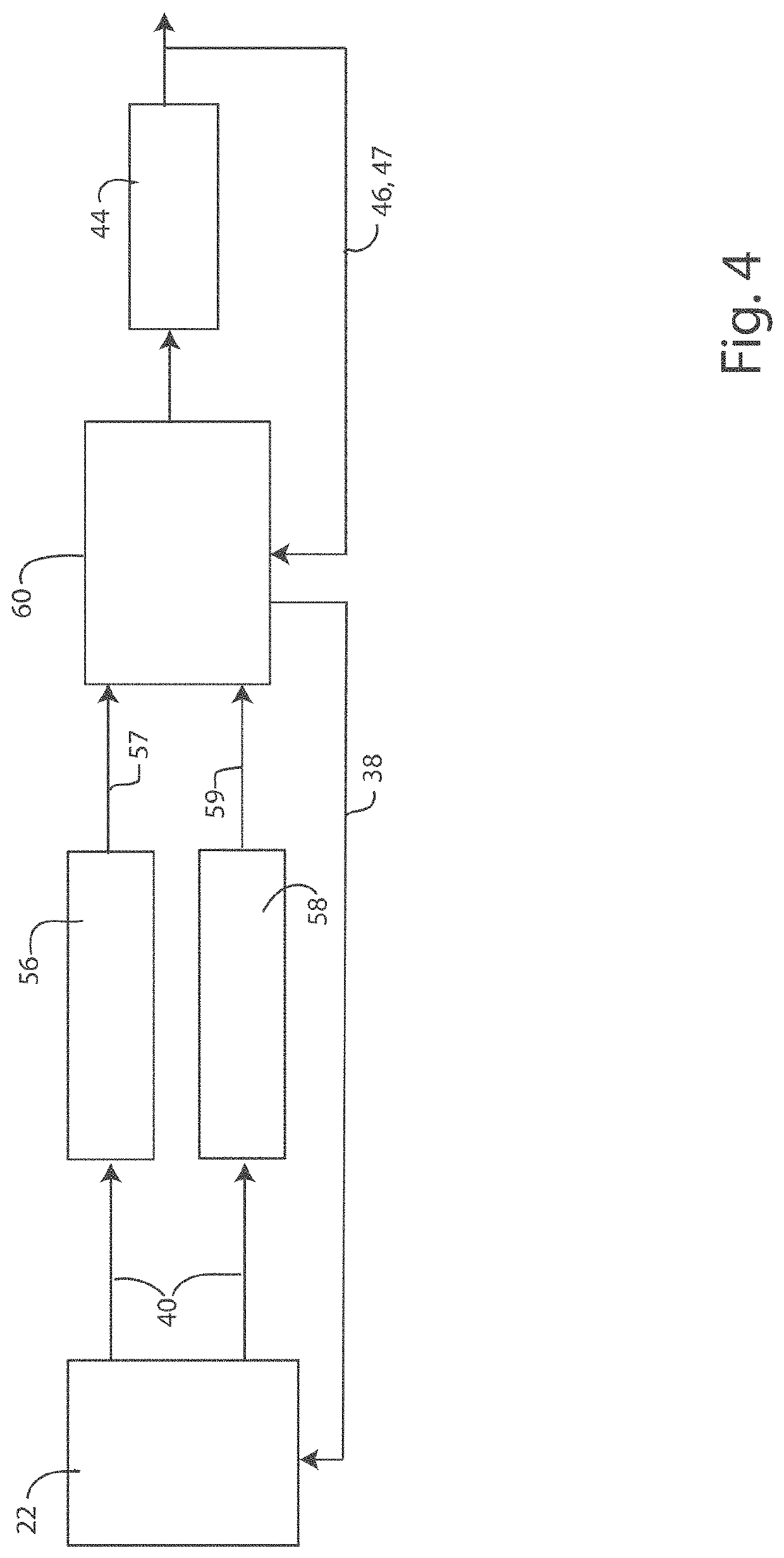

Selective attention mechanism for improved perception sensor performance in vehicular applications

ActiveUS20200355820A1Deep acuityCorrection accuracyCharacter and pattern recognitionRadio wave reradiation/reflectionIn vehicleEnvironmental perception

The vehicle mounted perception sensor gathers environment perception data from a scene using first and second heterogeneous (different modality) sensors, at least one of the heterogeneous sensors is directable to a predetermined region of interest. A perception processor receives the environment percpetion data and performs object recognition to identify objects each with a computed confidence score. The processor assesses the confidence score vis-à-vis a predetermined threshold, and based on that assessment, generates an attention signal to redirect the one of the heterogeneous sensors to a region of interest identified by the other heterogeneous sensor. In this way information from one sensor primes the other sensor to increase accuracy and provide deeper knowledge about the scene and thus do a better job of object tracking in vehicular applications.

Owner:GM GLOBAL TECH OPERATIONS LLC

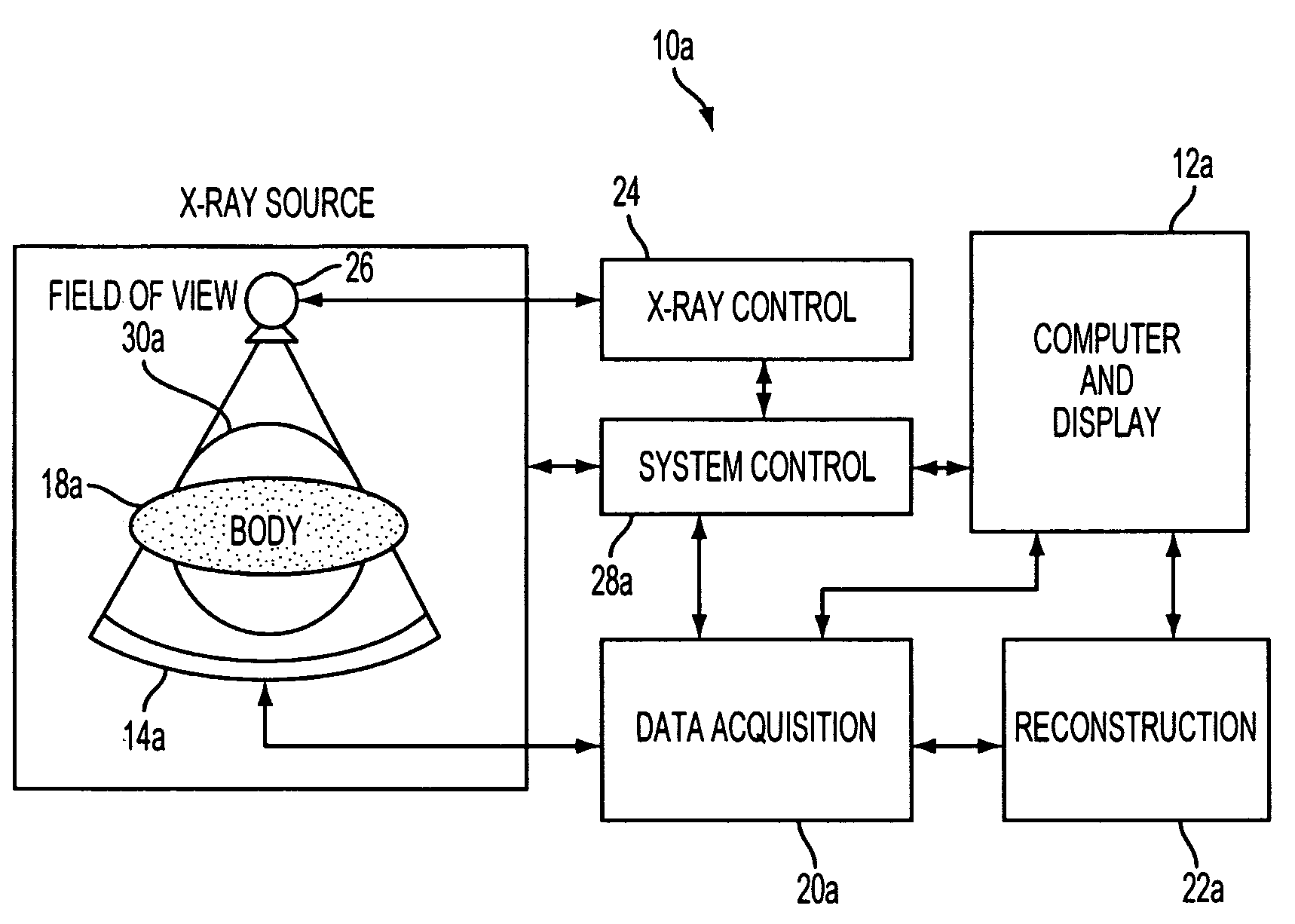

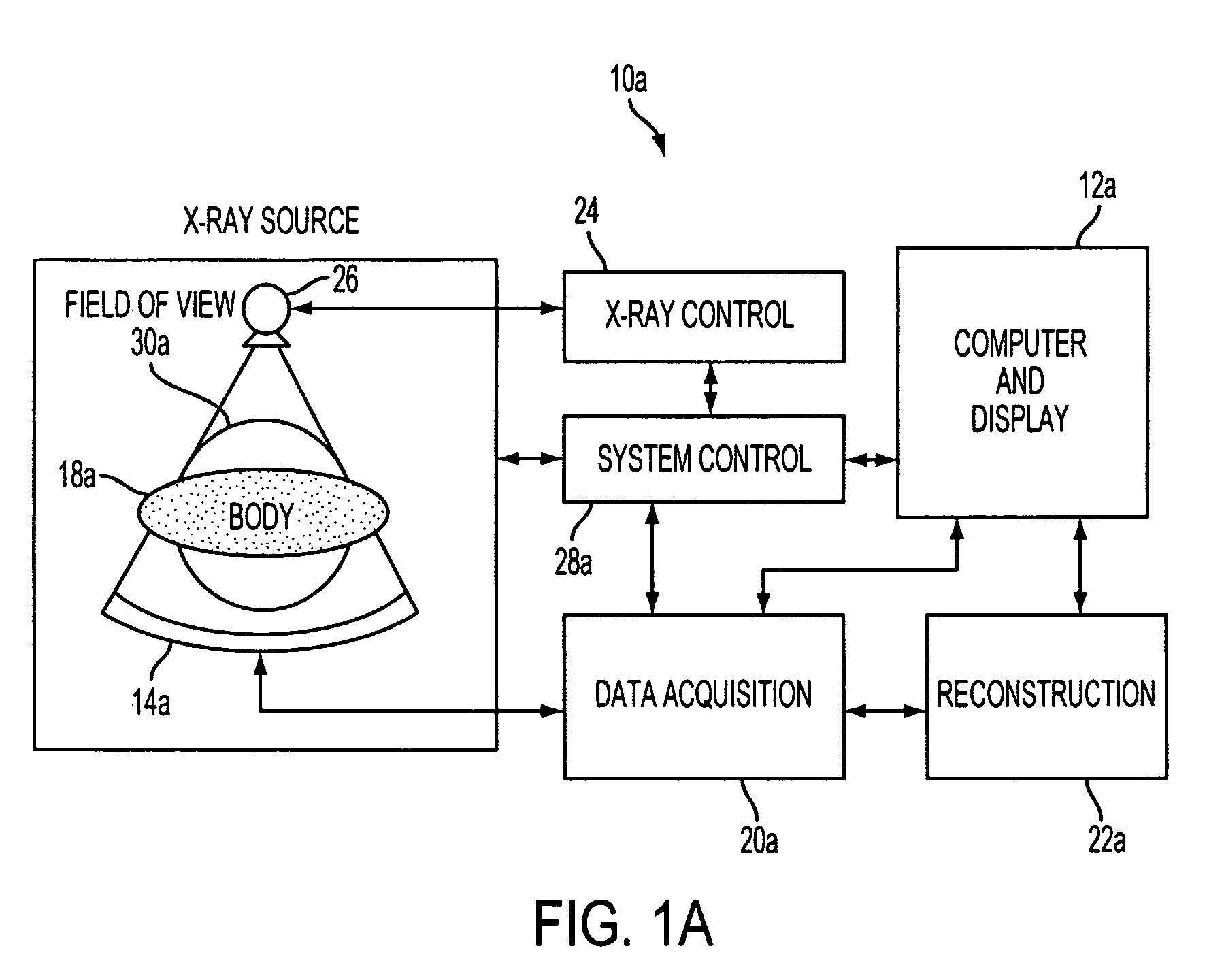

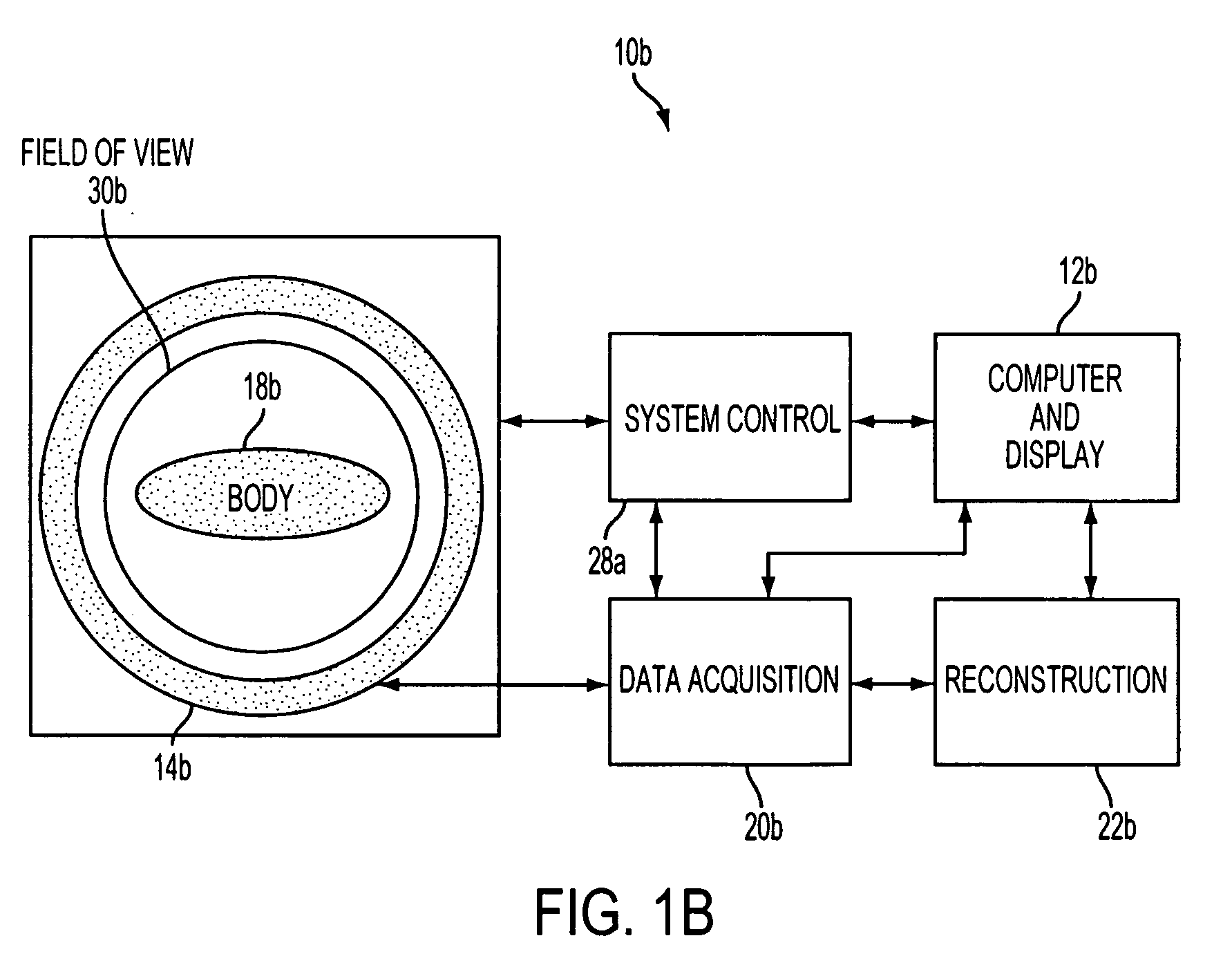

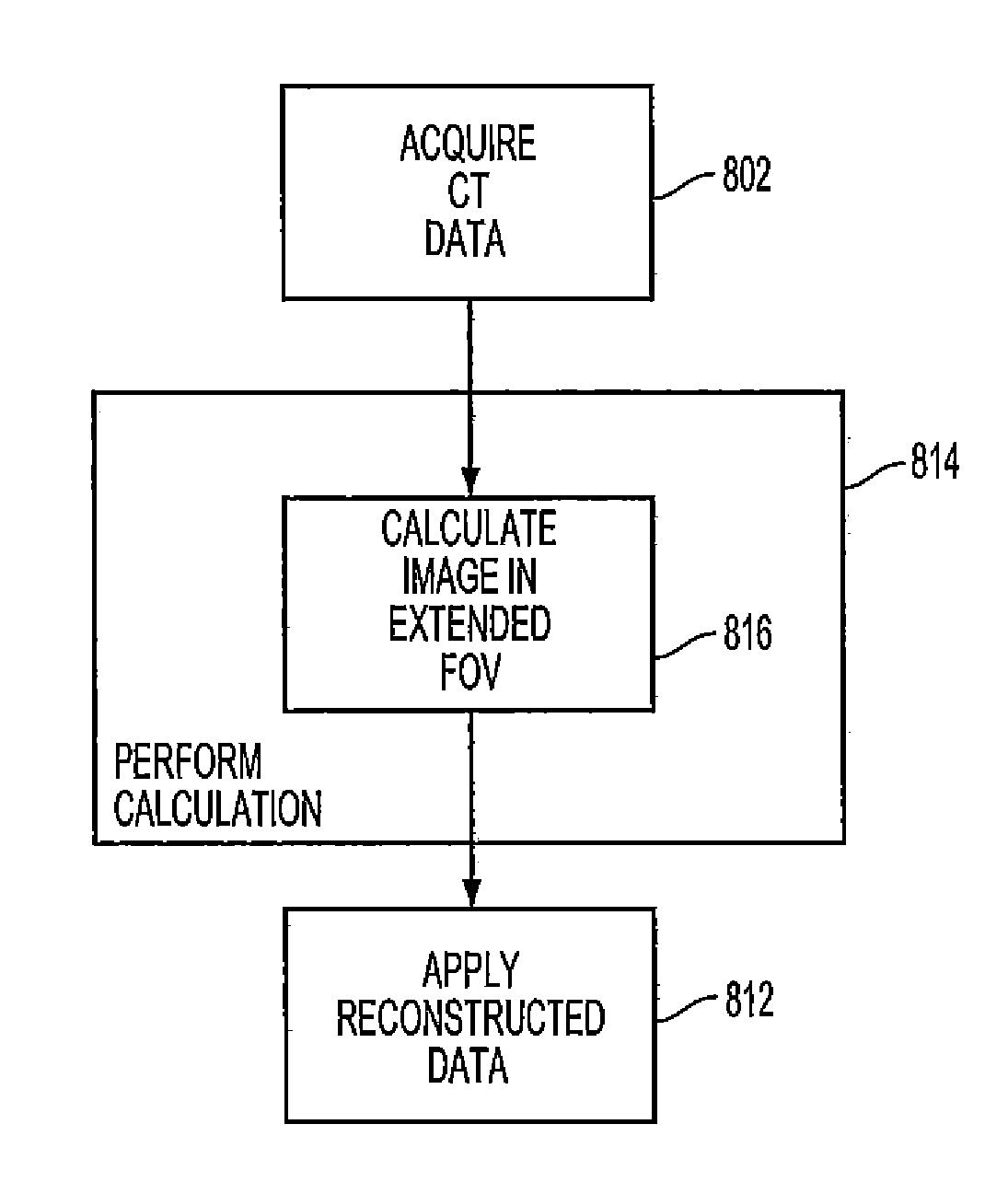

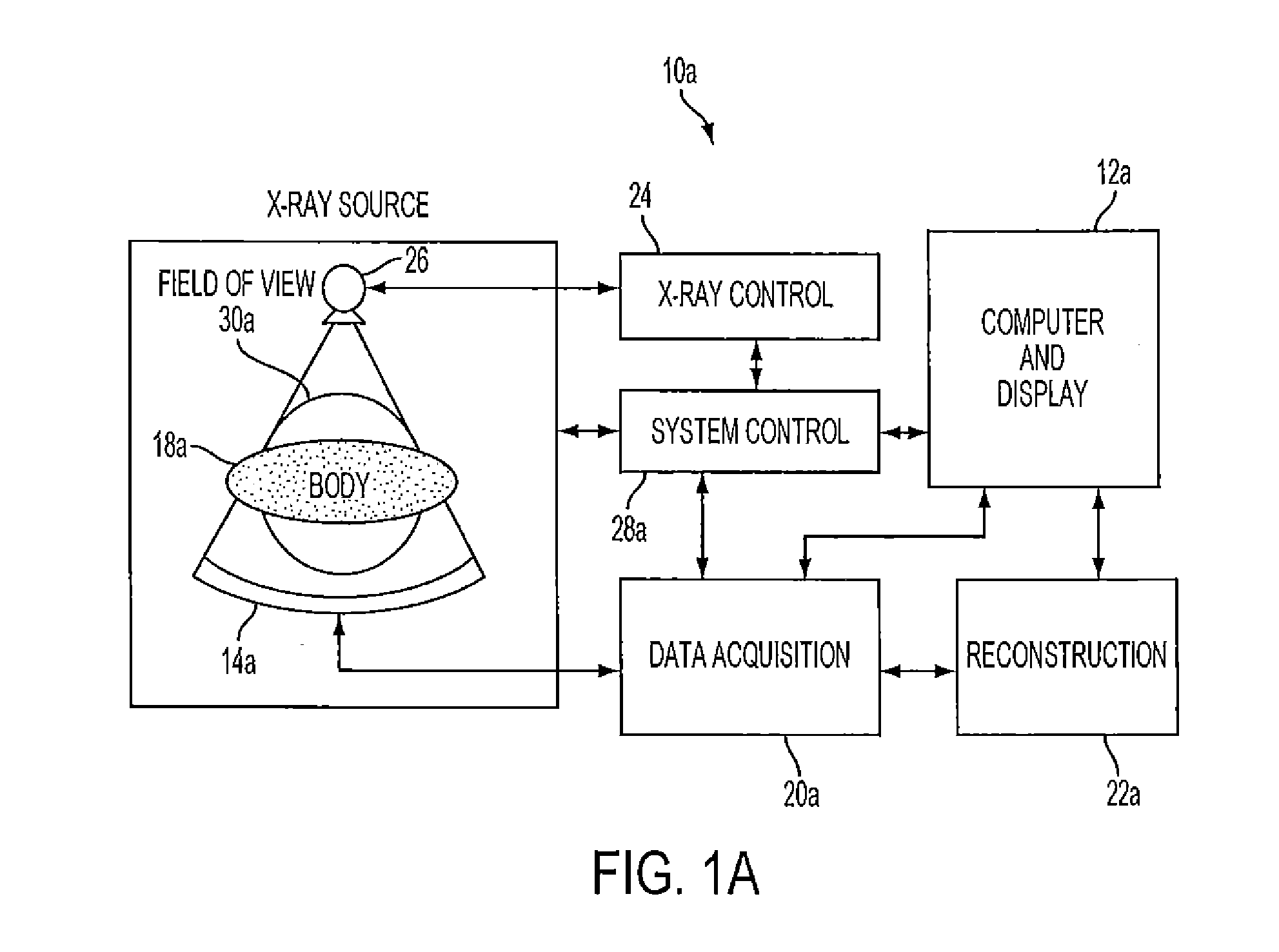

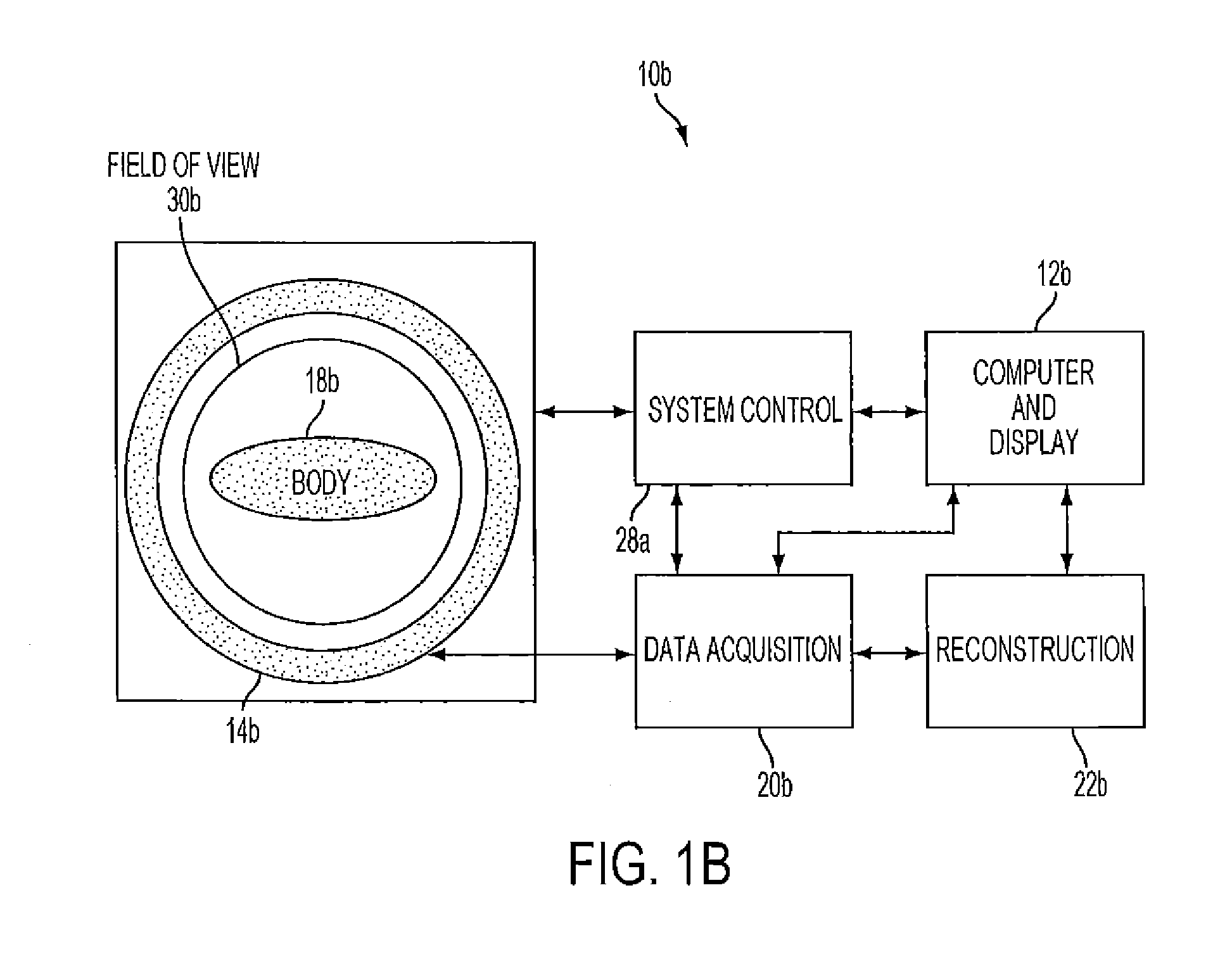

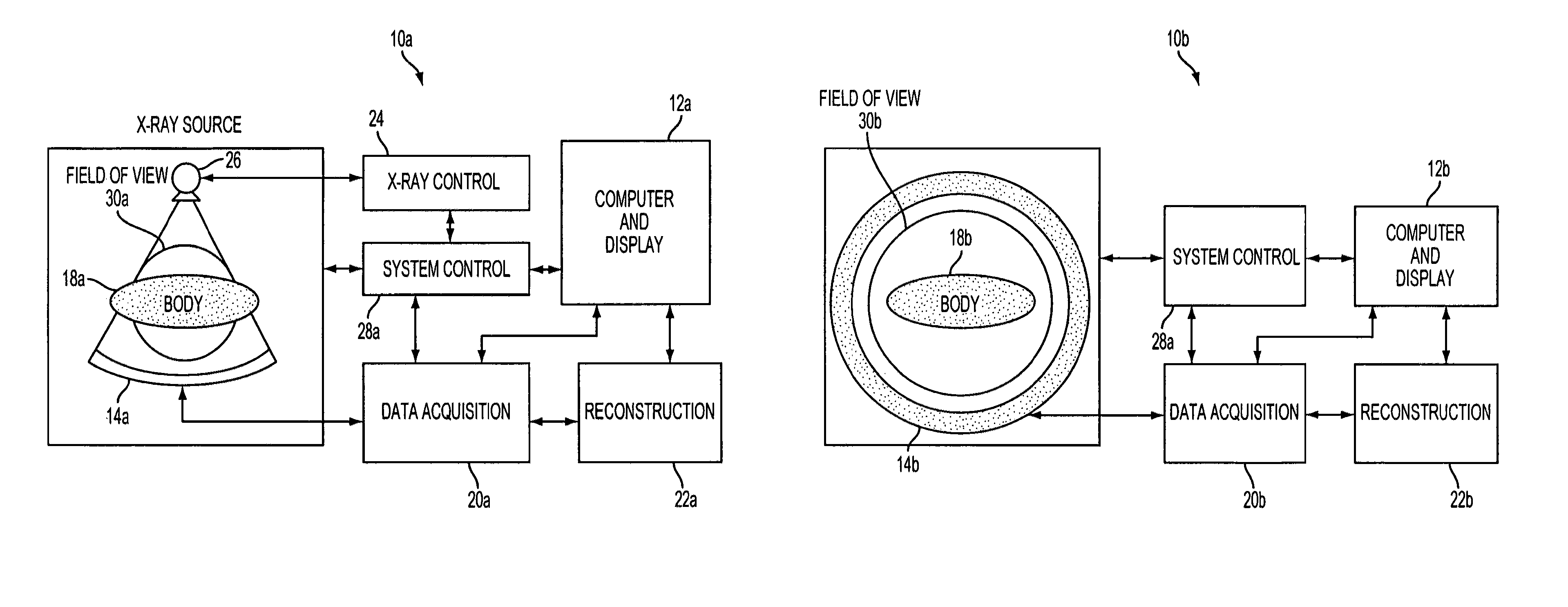

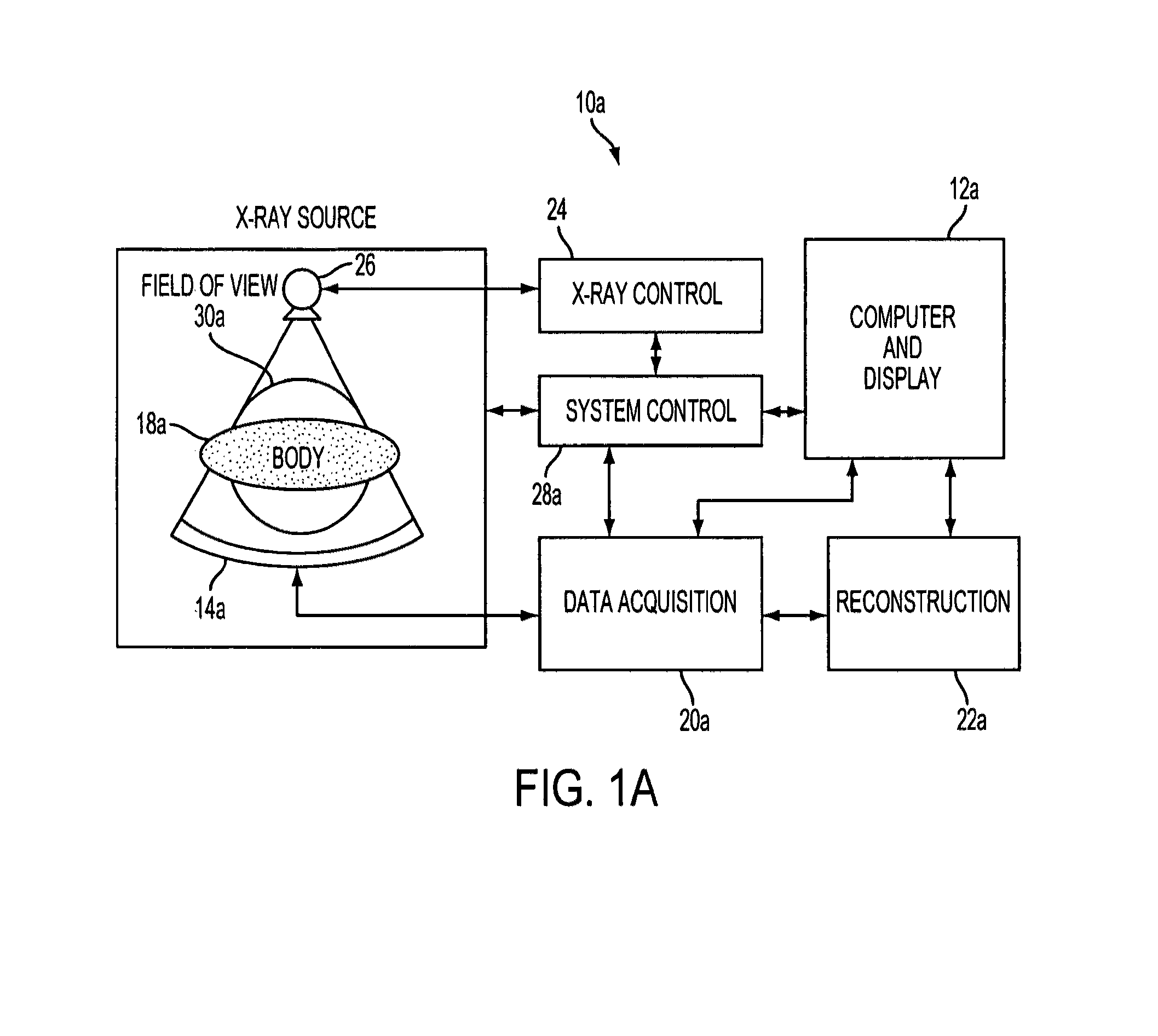

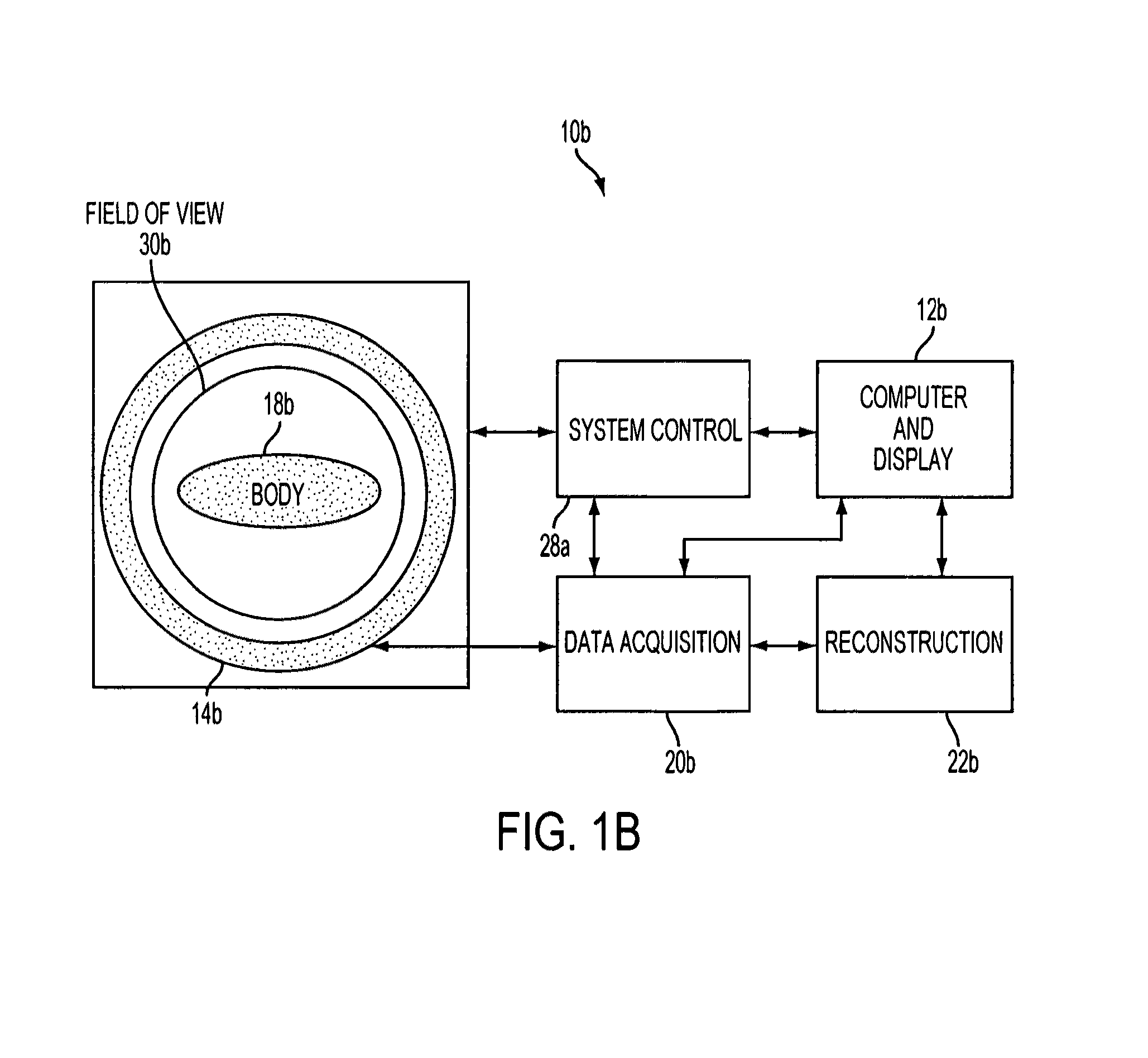

Extension of Truncated CT Images For Use With Emission Tomography In Multimodality Medical Images

ActiveUS20080219534A1Reduce areaReduce computing timeReconstruction from projectionCharacter and pattern recognitionComputed tomographyTomography

An apparatus and method for expanding the FOV of a truncated computed tomography (CT) scan. An iterative calculation is performed on the original CT image to produce an estimate of the image. The calculated estimate of the reconstructed image includes the original image center and a estimate of the truncated portion outside the image center. The calculation uses an image mask with the image center as one boundary.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

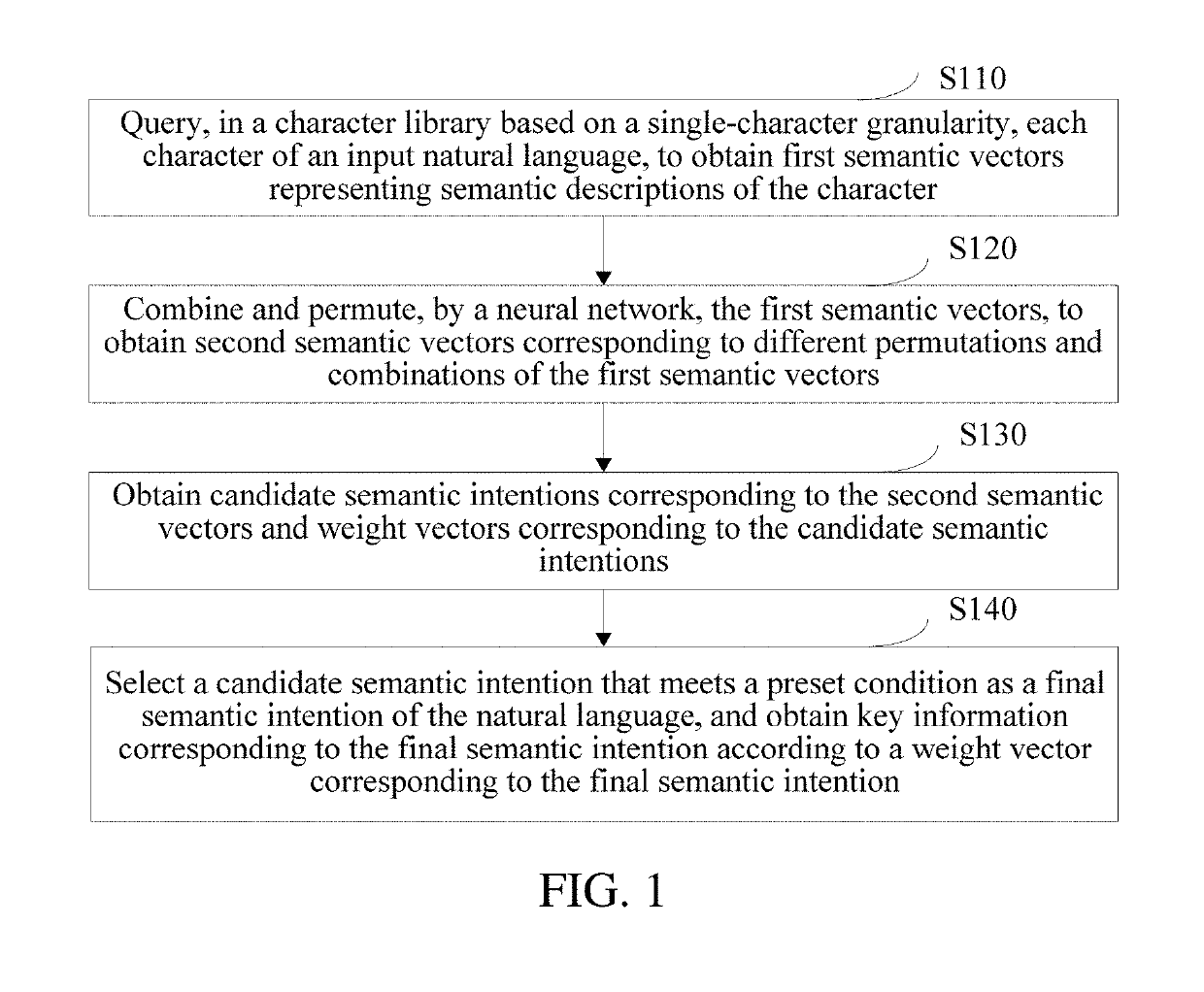

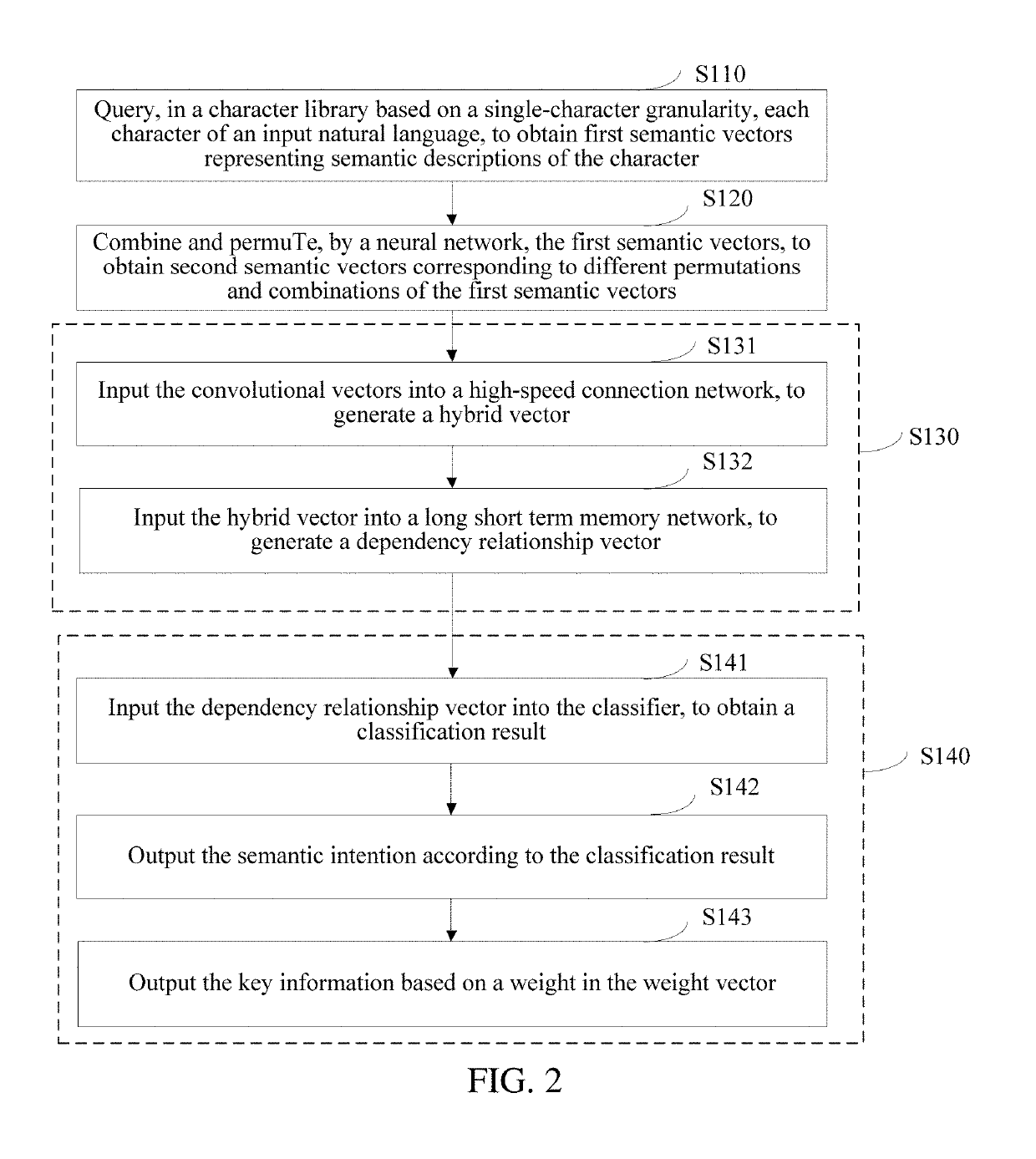

Semantic extraction method and apparatus for natural language, and computer storage medium

ActiveUS20190278846A1Correction accuracyAccurate ratingSemantic analysisSpeech recognitionSemantic vectorGranularity

A semantic extraction method based on a natural language is provided. In a character library based on a single-character granularity, a character of an input natural language is queried, to obtain first semantic vectors representing semantic descriptions of the character. Candidate semantic intentions corresponding to second semantic vectors and weight vectors corresponding to the candidate semantic intentions are obtained, wherein the second semantic vectors are obtained by using a neural network and correspond to different permutations and combinations of the first semantic vectors. A candidate semantic intention is selected as a final semantic intention of the natural language based on a preset condition, and key information is obtained corresponding to the final semantic intention according to a weight vector corresponding to the final semantic intention.

Owner:TENCENT TECH (SHENZHEN) CO LTD

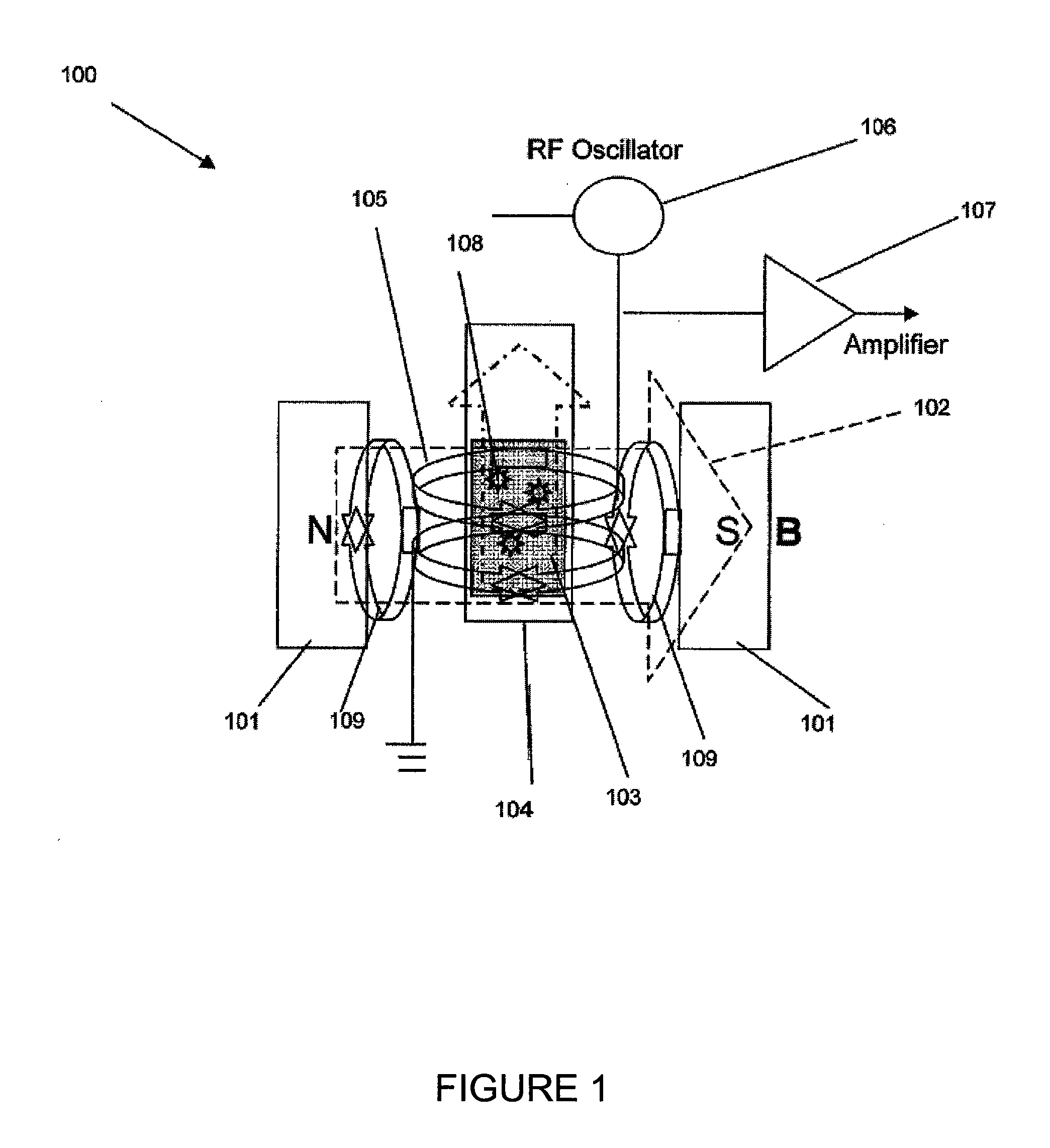

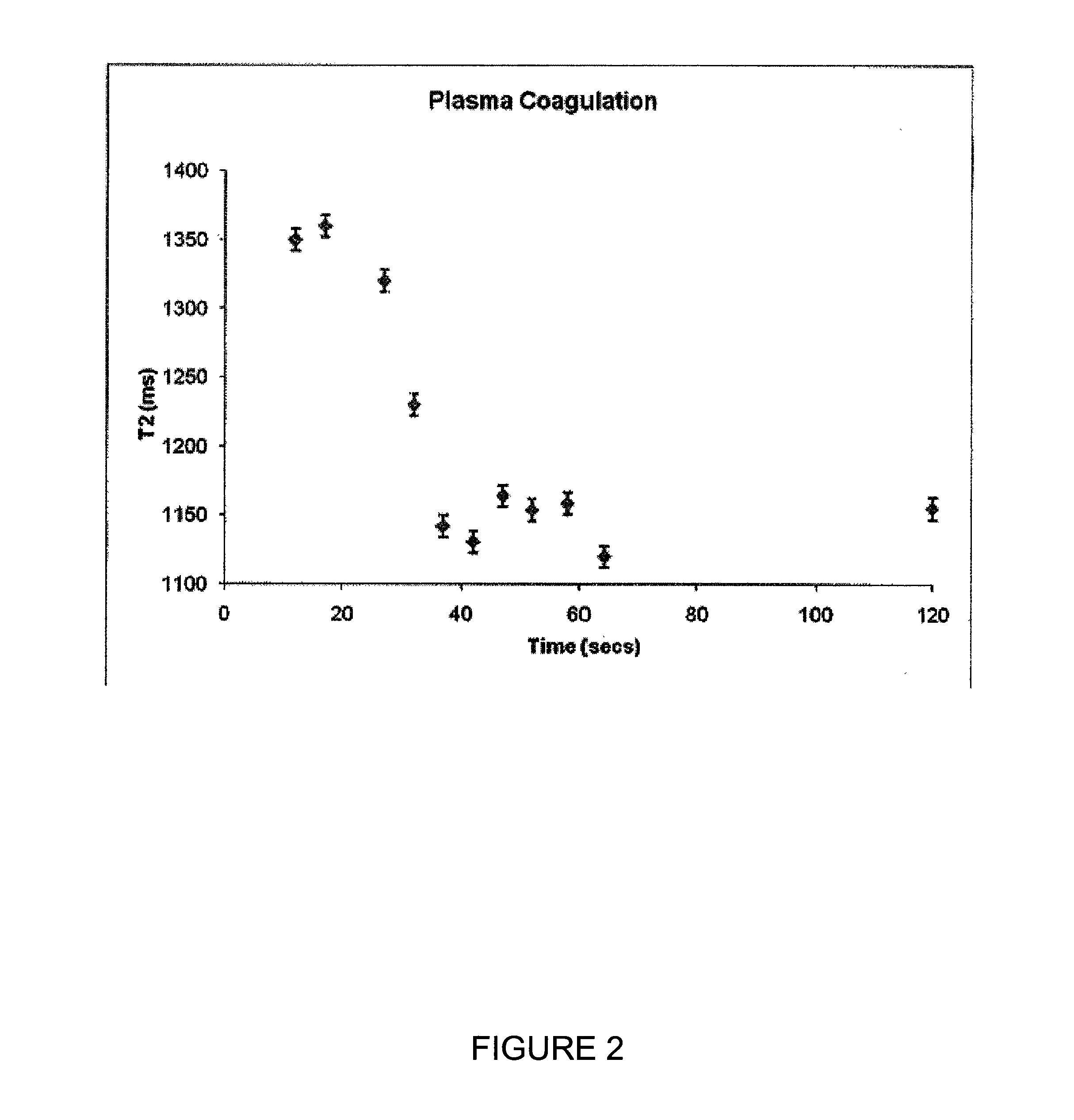

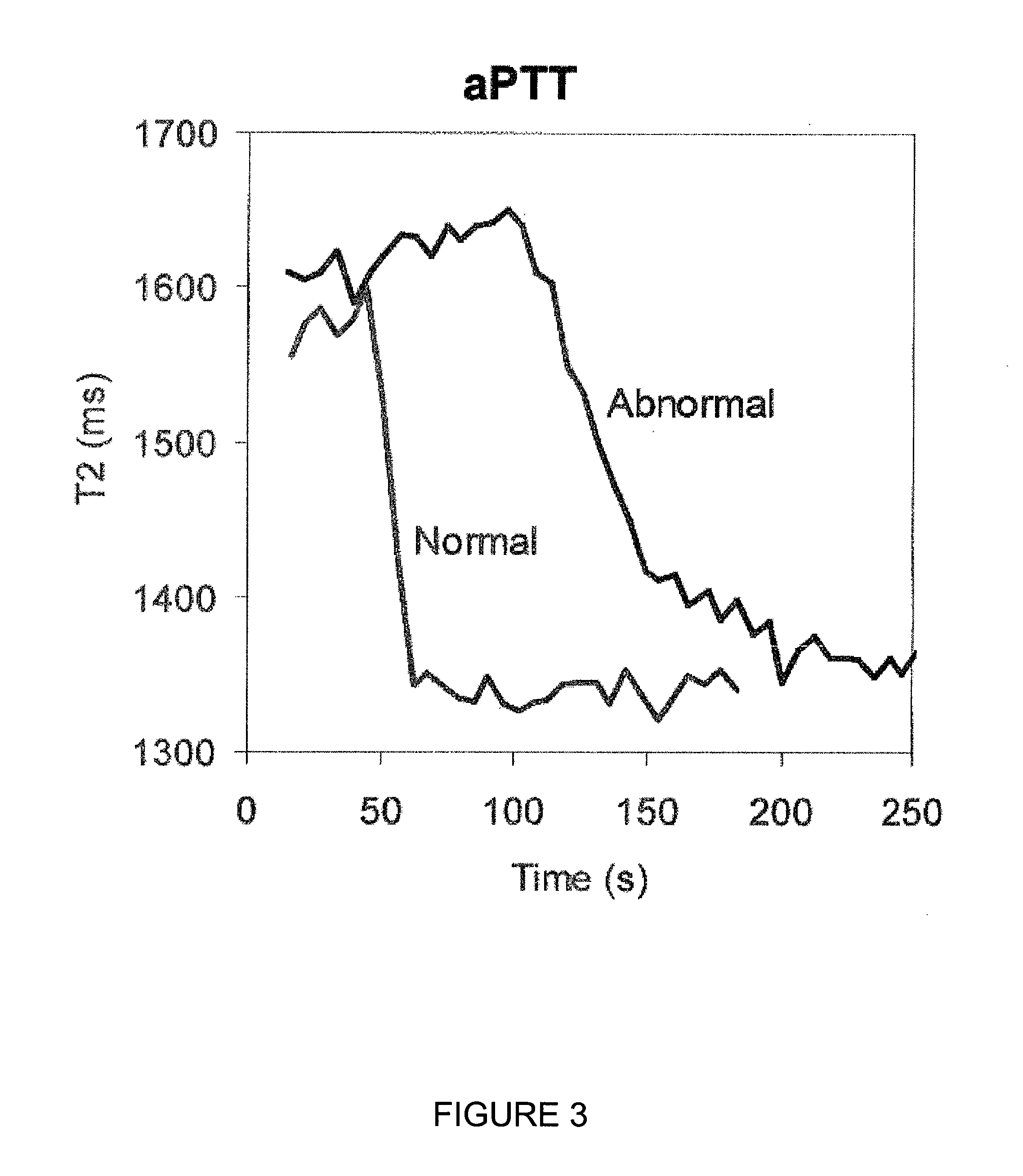

Nmr detection of coagulation time

ActiveUS20110312002A1Correction accuracyPointing accuratelyMicrobiological testing/measurementMeasurements using NMR imaging systemsCoagulation timeFibrinolysis

The invention relates to detecting coagulation and coagulation-related activities including agglutination and fibrinolysis of samples. More particularly the invention relates to methods and apparatus for monitoring coagulation and / or obtaining a coagulation time of a sample using NMR-based detectors.

Owner:T2 BIOSYST

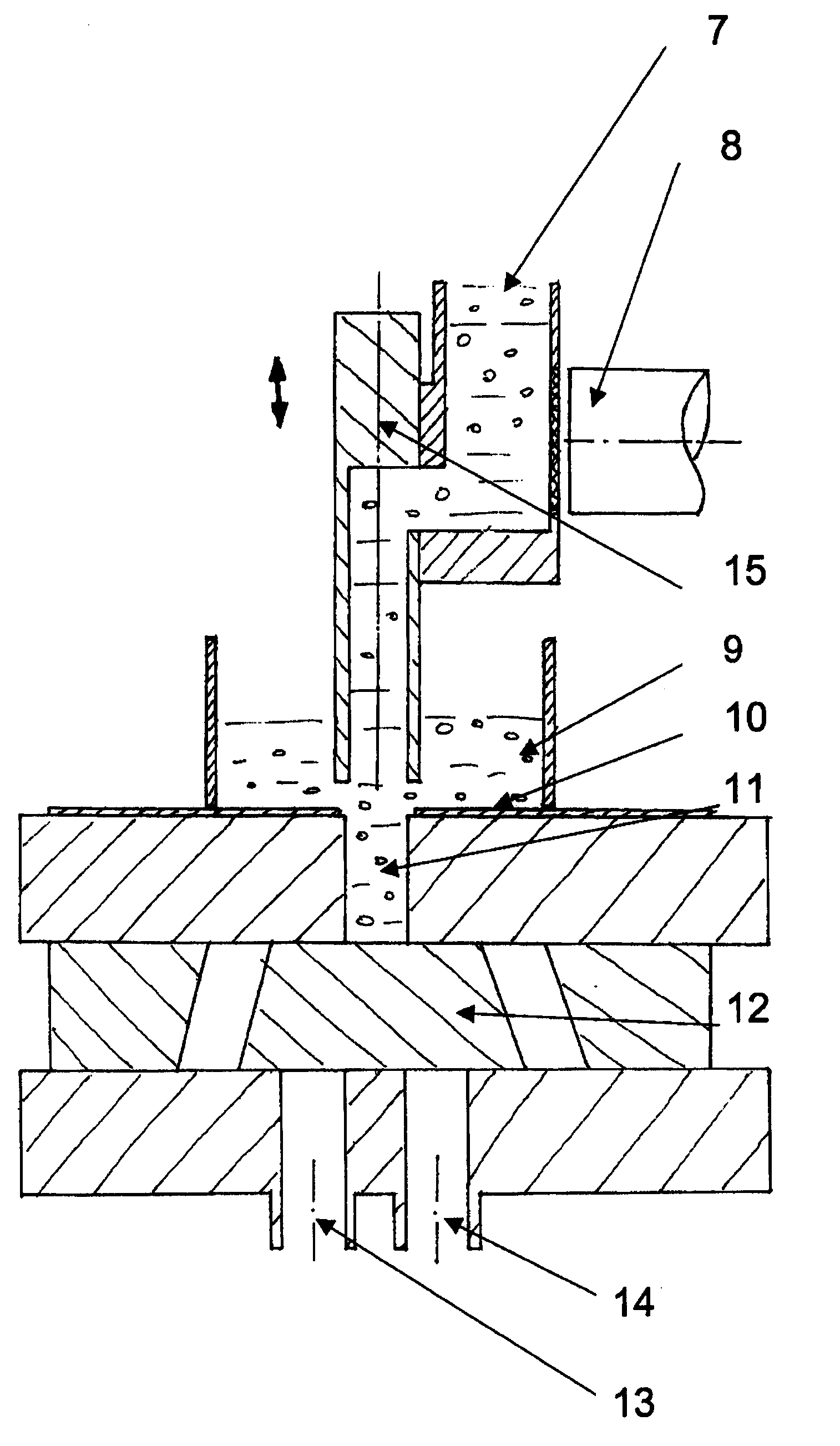

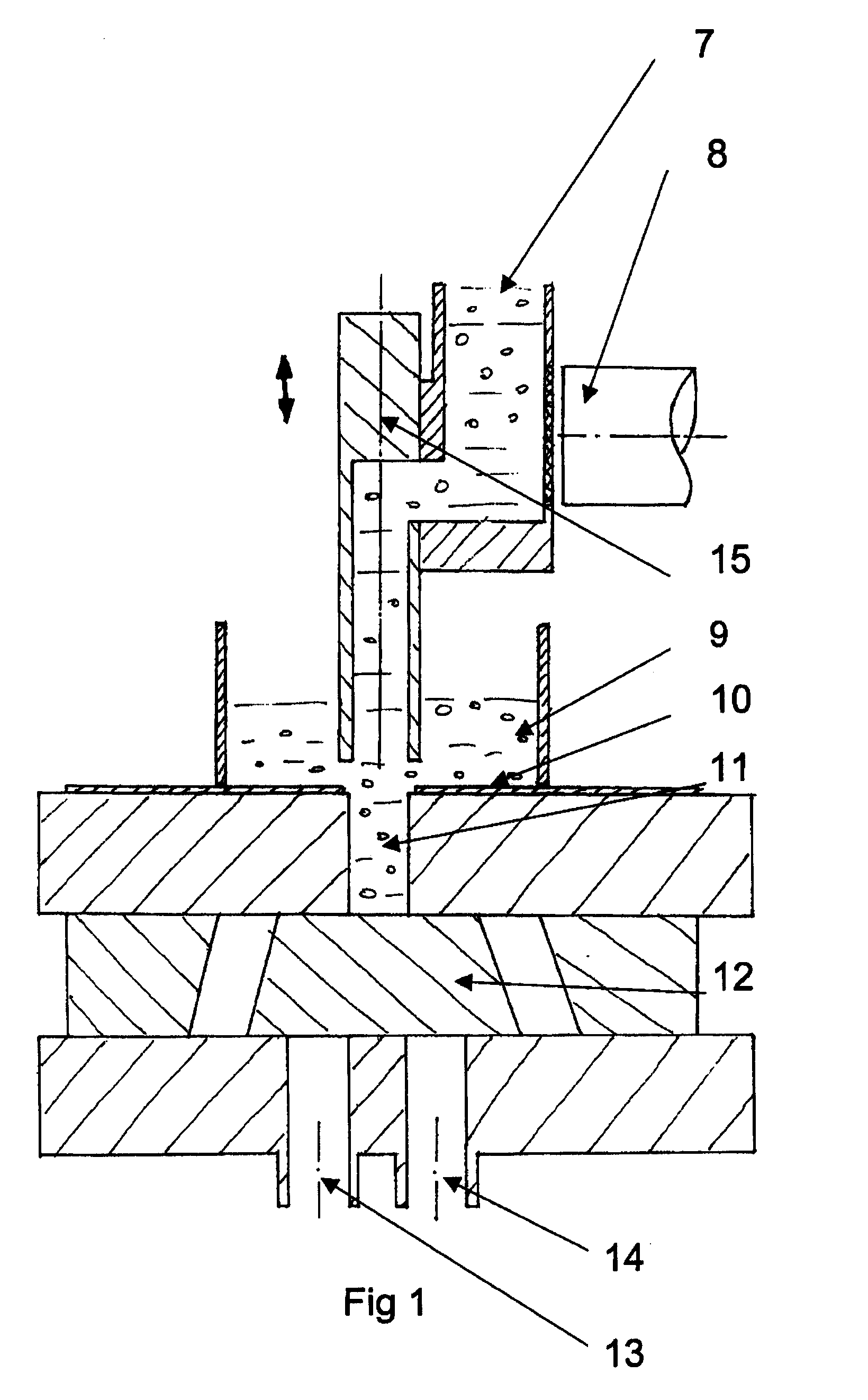

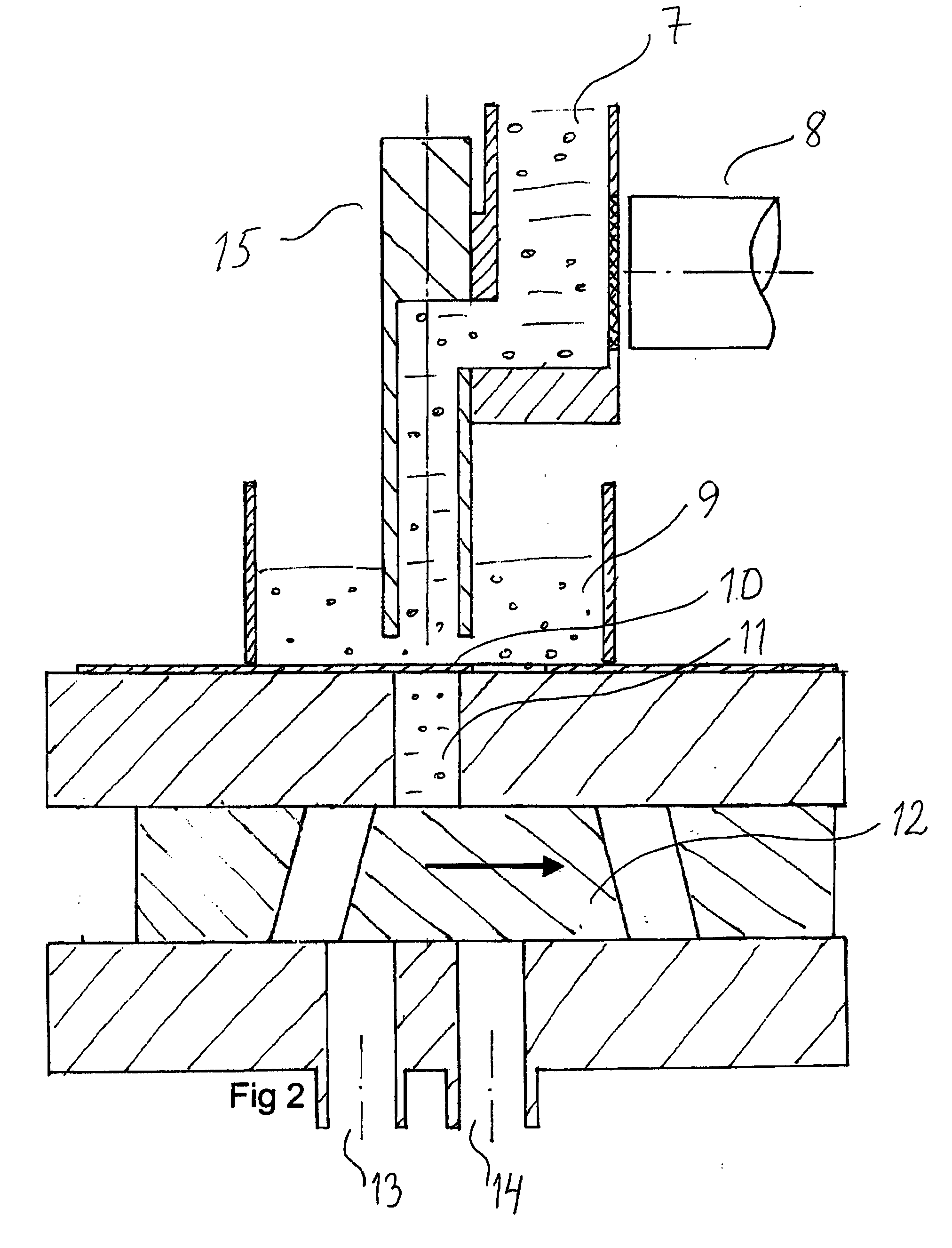

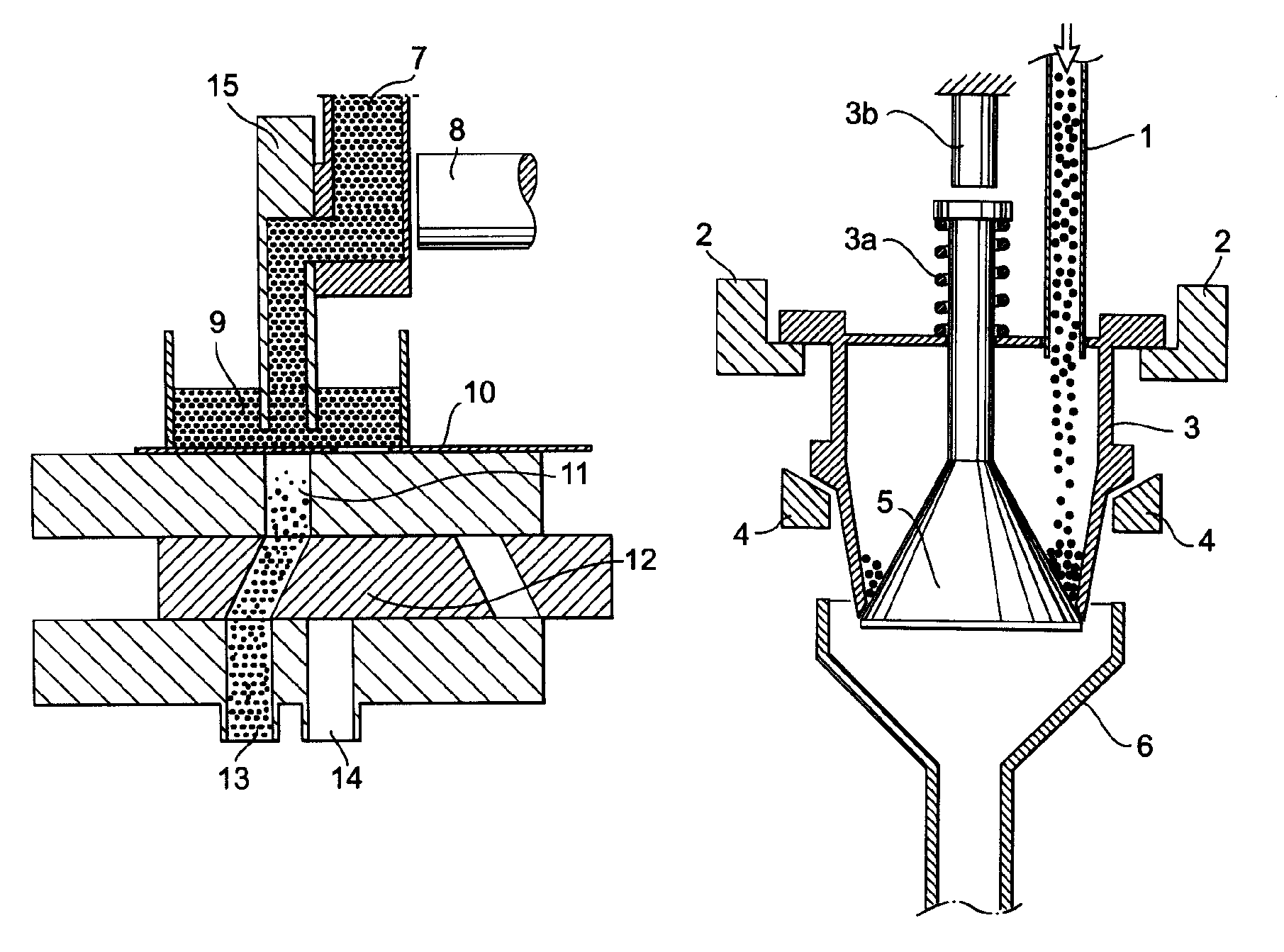

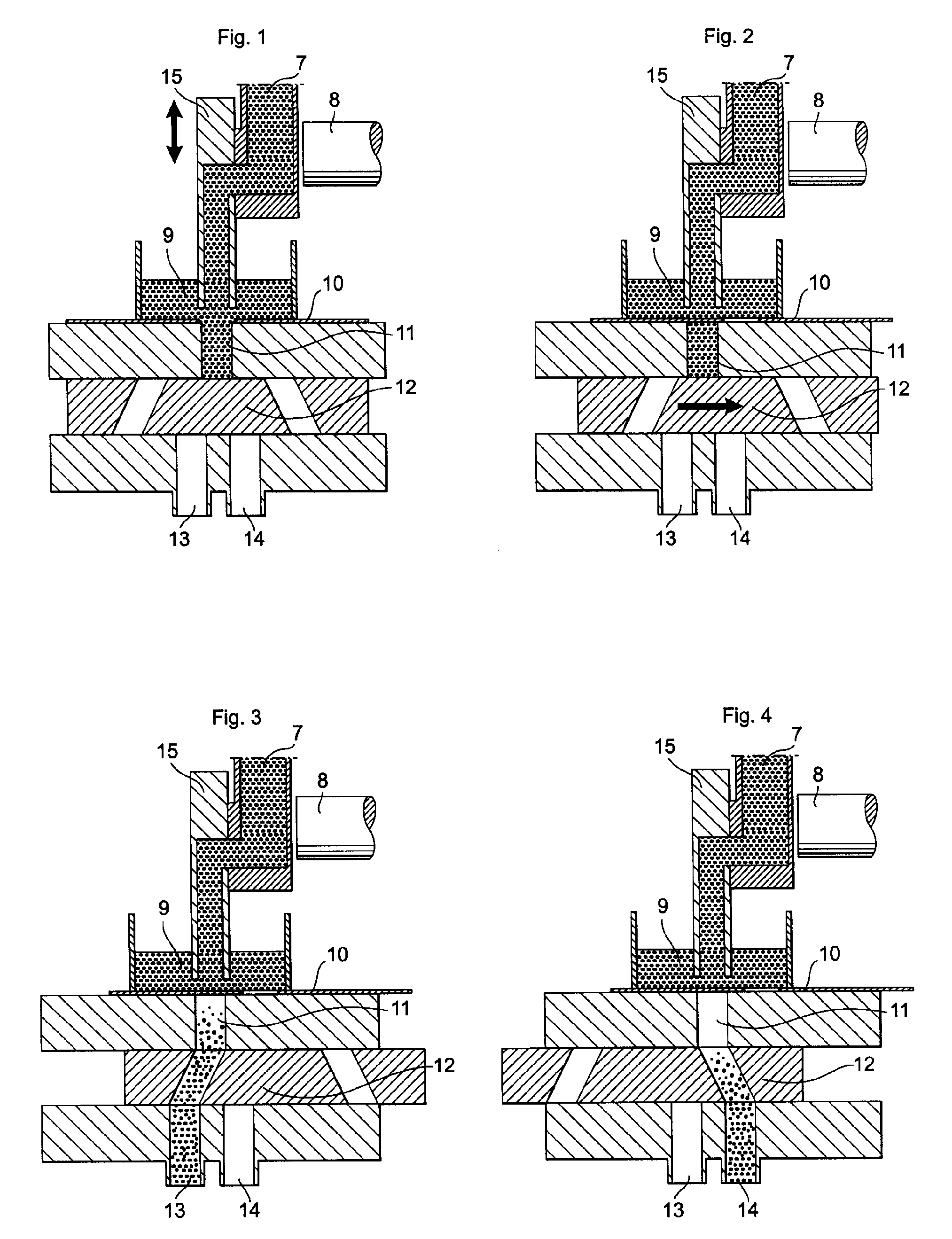

Method and System

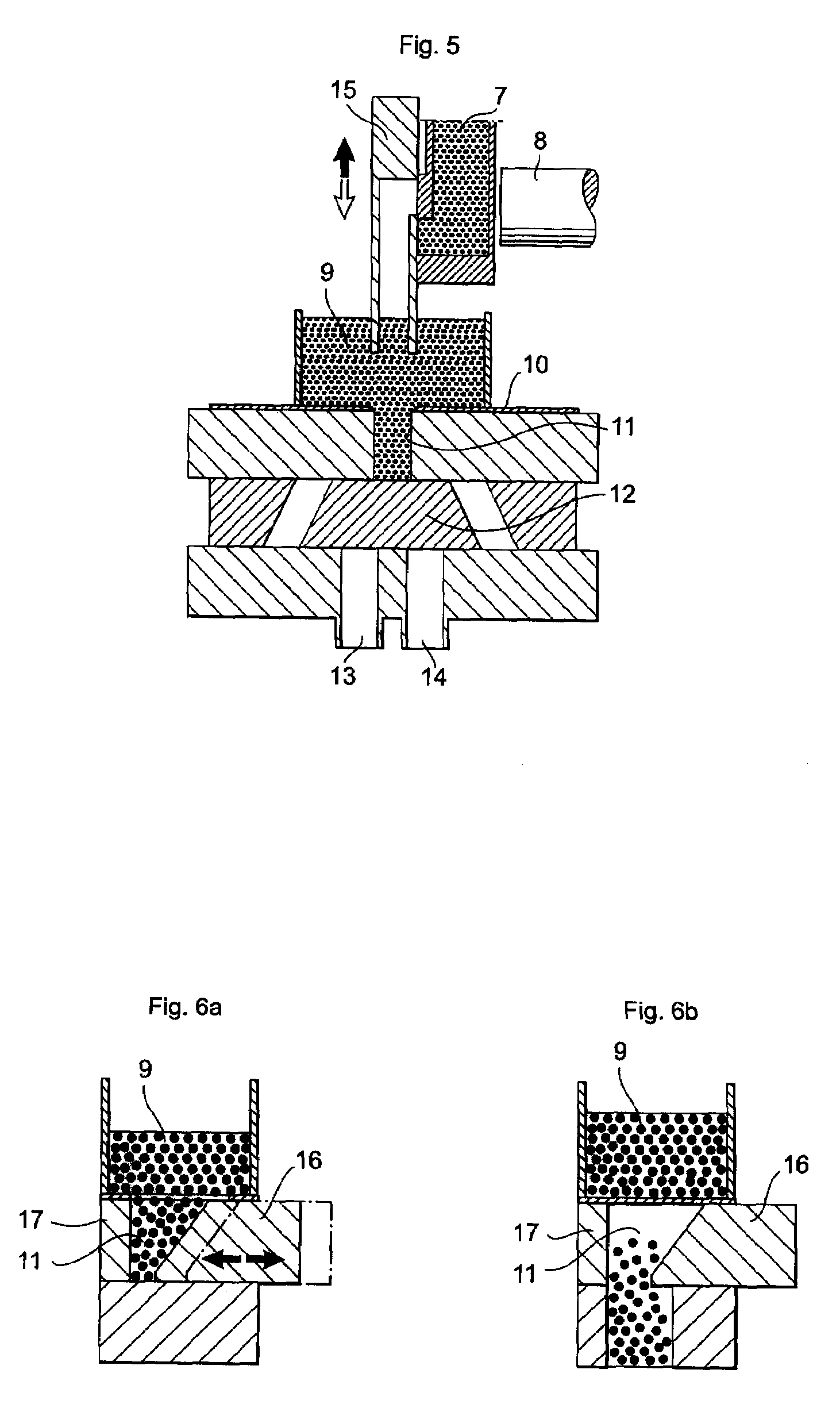

InactiveUS20070169836A1Minimize doseRisk minimizationSolid materialCapsule deliveryDosing unitsPackaging machine

The present invention relates to a method for dosing a pharmaceutical product in a packaging machine comprising at least one volumetric dosing unit with a dosing chamber. The method comprises metering a volume of a first component, weighing the first component, introducing the first component into a package and metering a volume of a second component, introduceg the second component into the package and weighing of the package into which the components have being introduced.The invention further relates to a system for dosing a pharmaceutical product in a packaging machine comprising at least one volumetric dosing unit with a dosing chamber. The system comprises at least one volumetric dosing unit for metering a volume of the components. Further, means for introducing the said components into a package and means for weighing the components and the package are comprised. The means for weighing comprises a first weighing unit for weighing the package and the components, and a second weighing unit for weighing the first component after metering the first component by volume and before introducing the first component into the package.

Owner:ASTRAZENECA AB

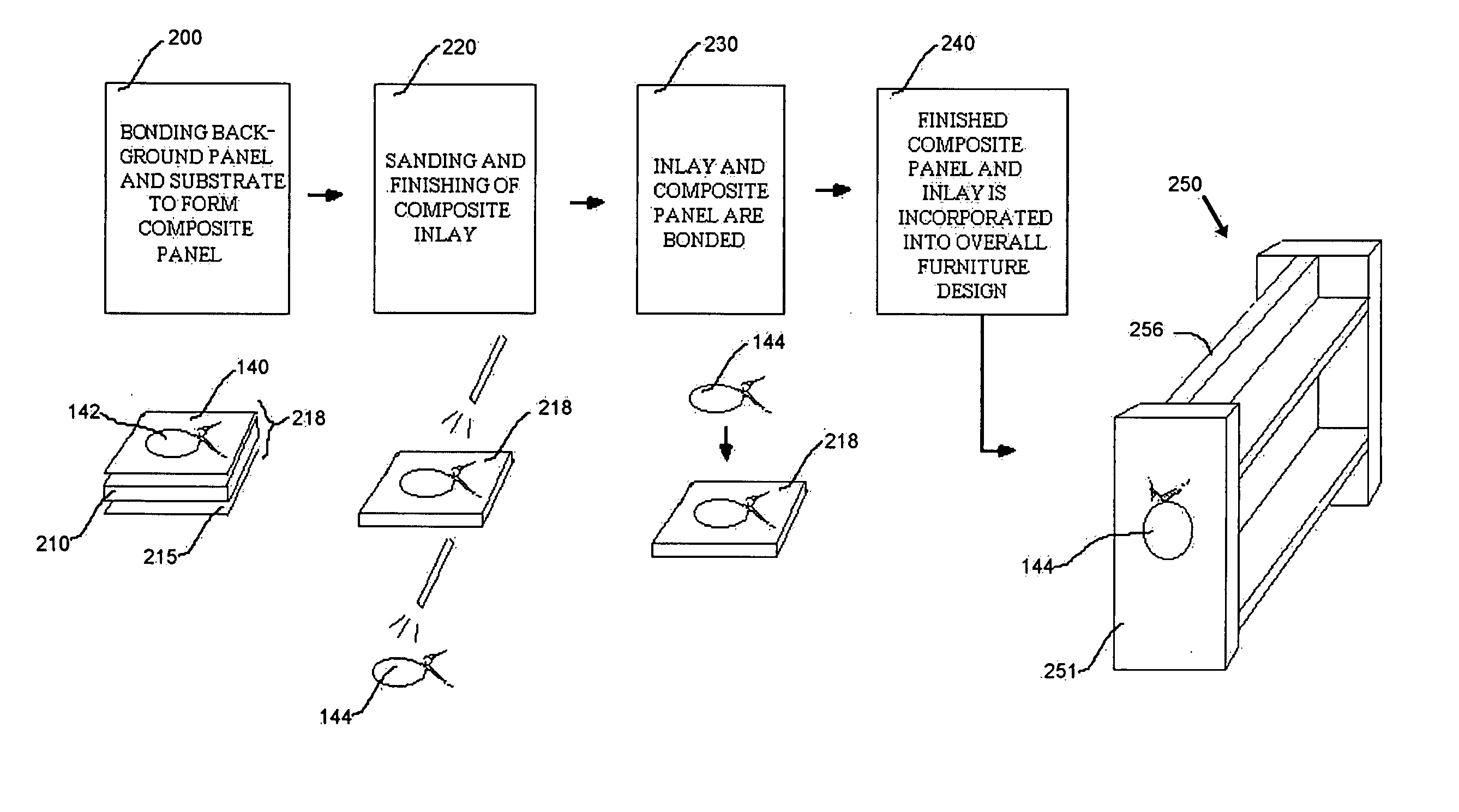

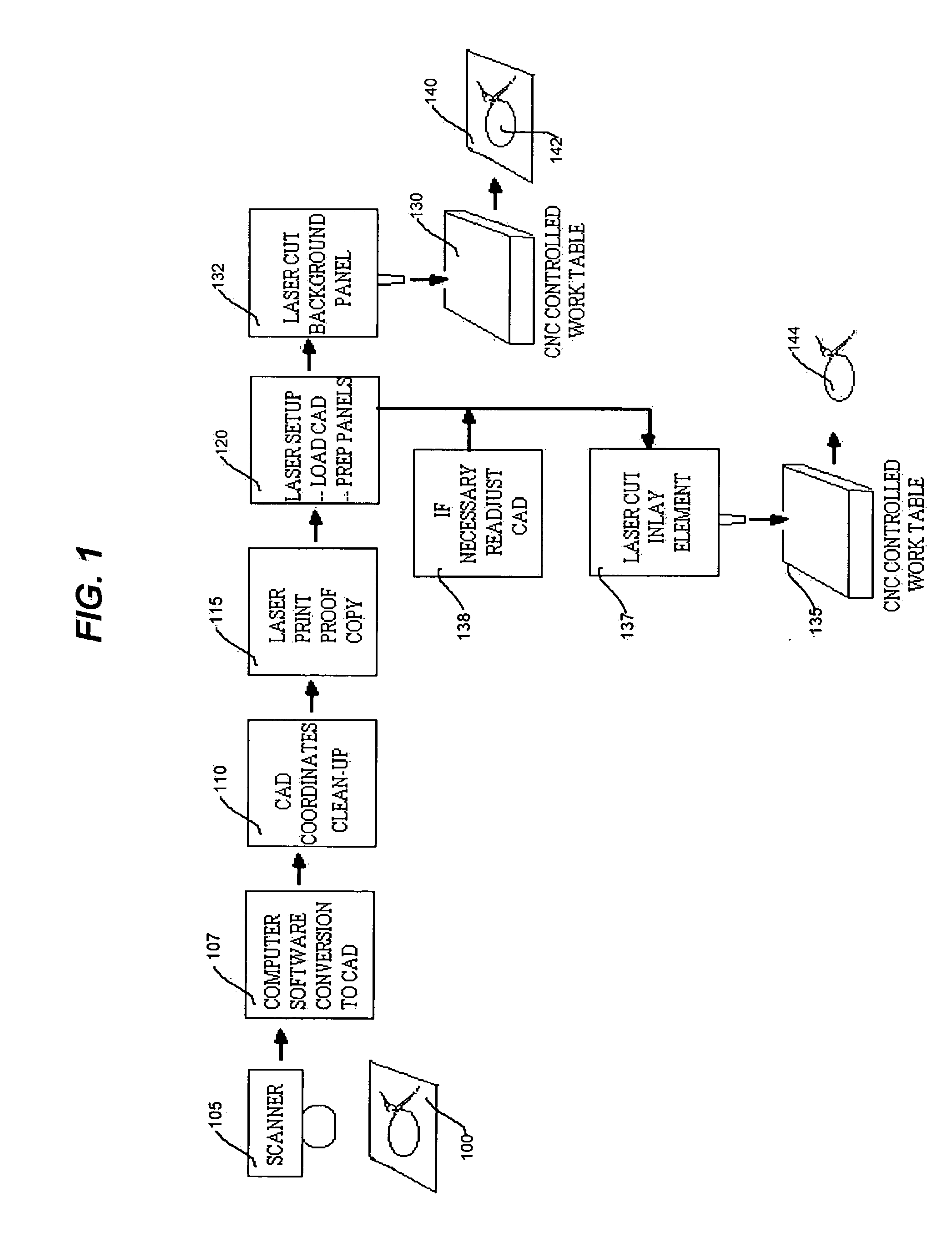

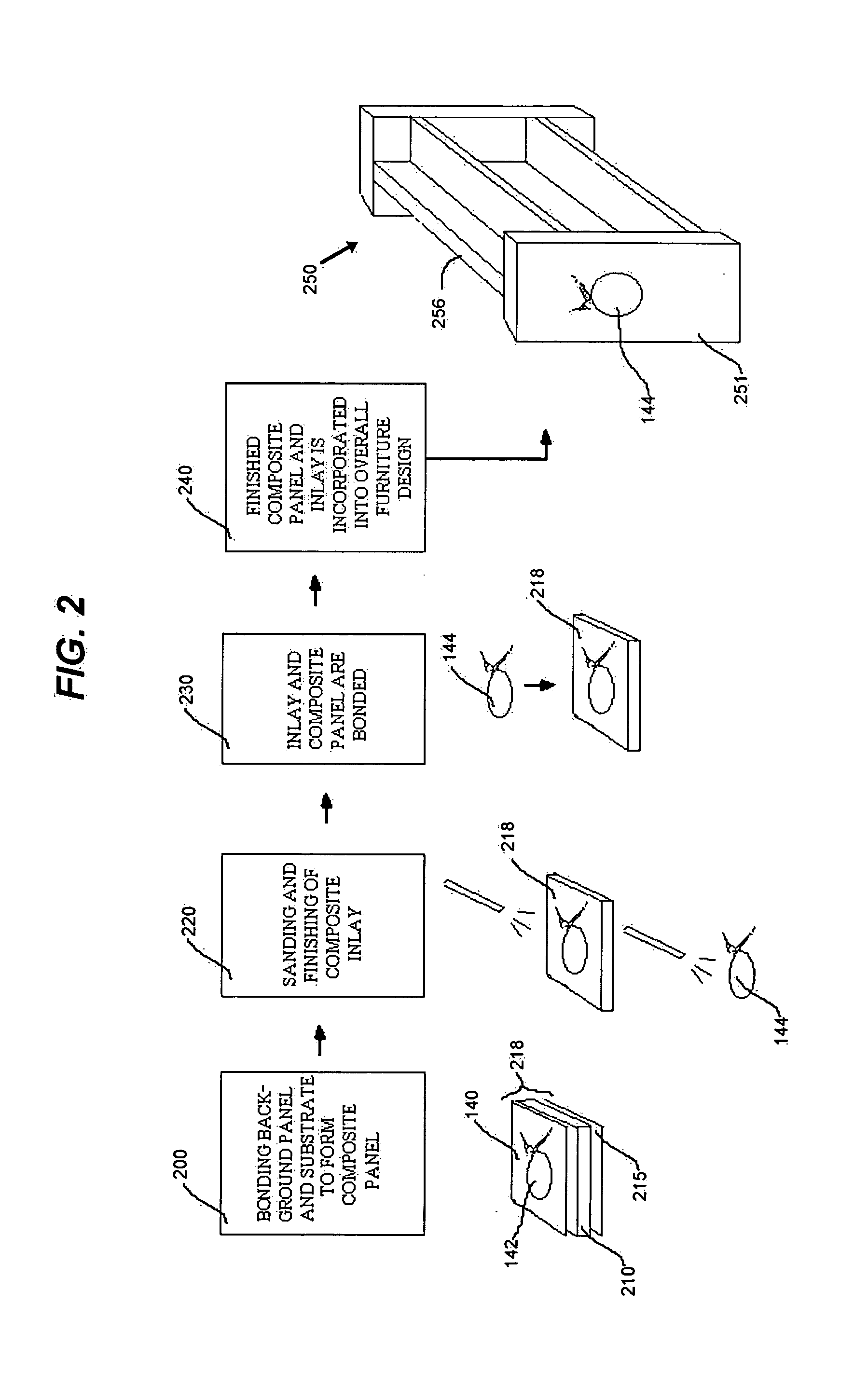

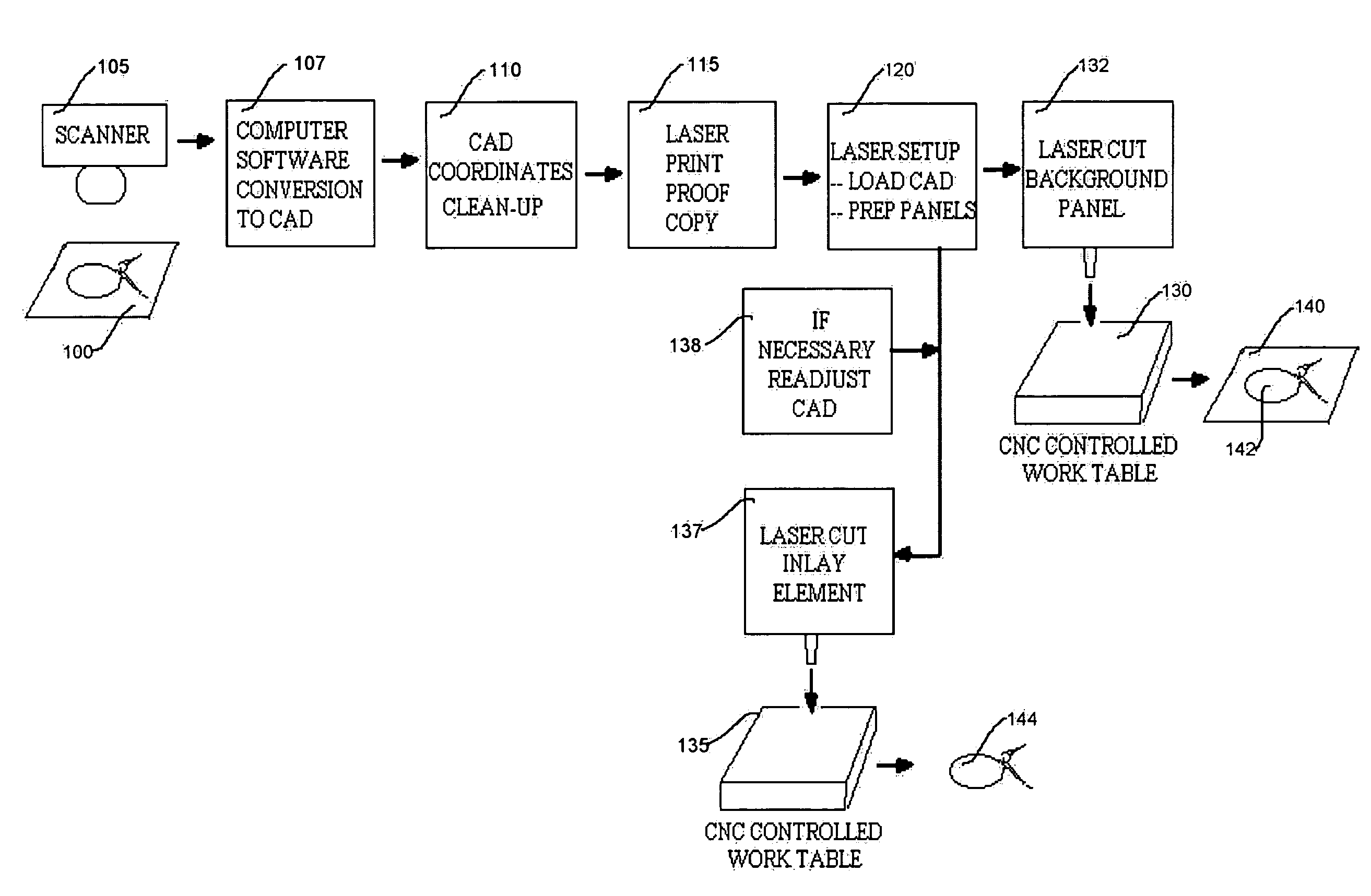

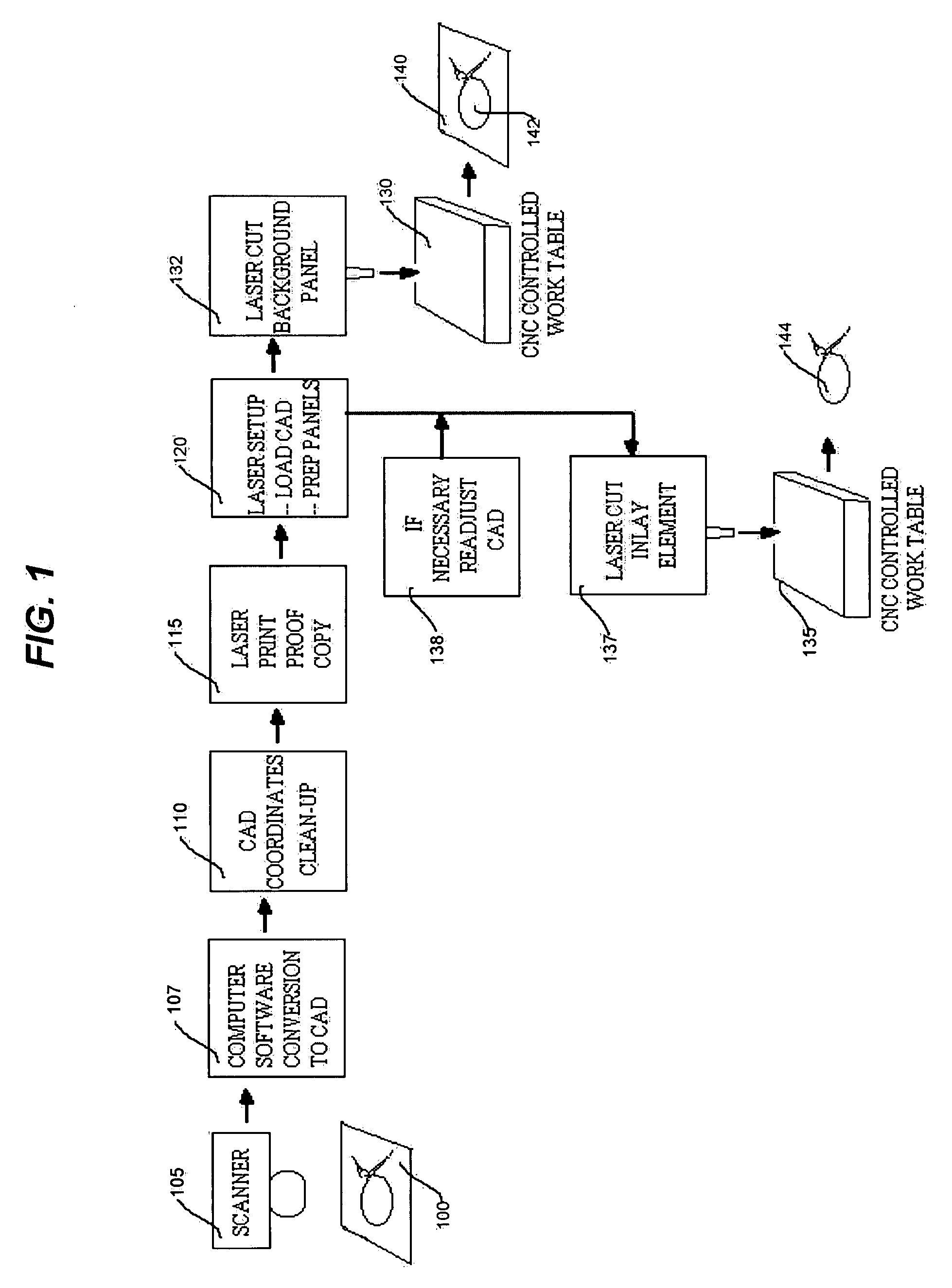

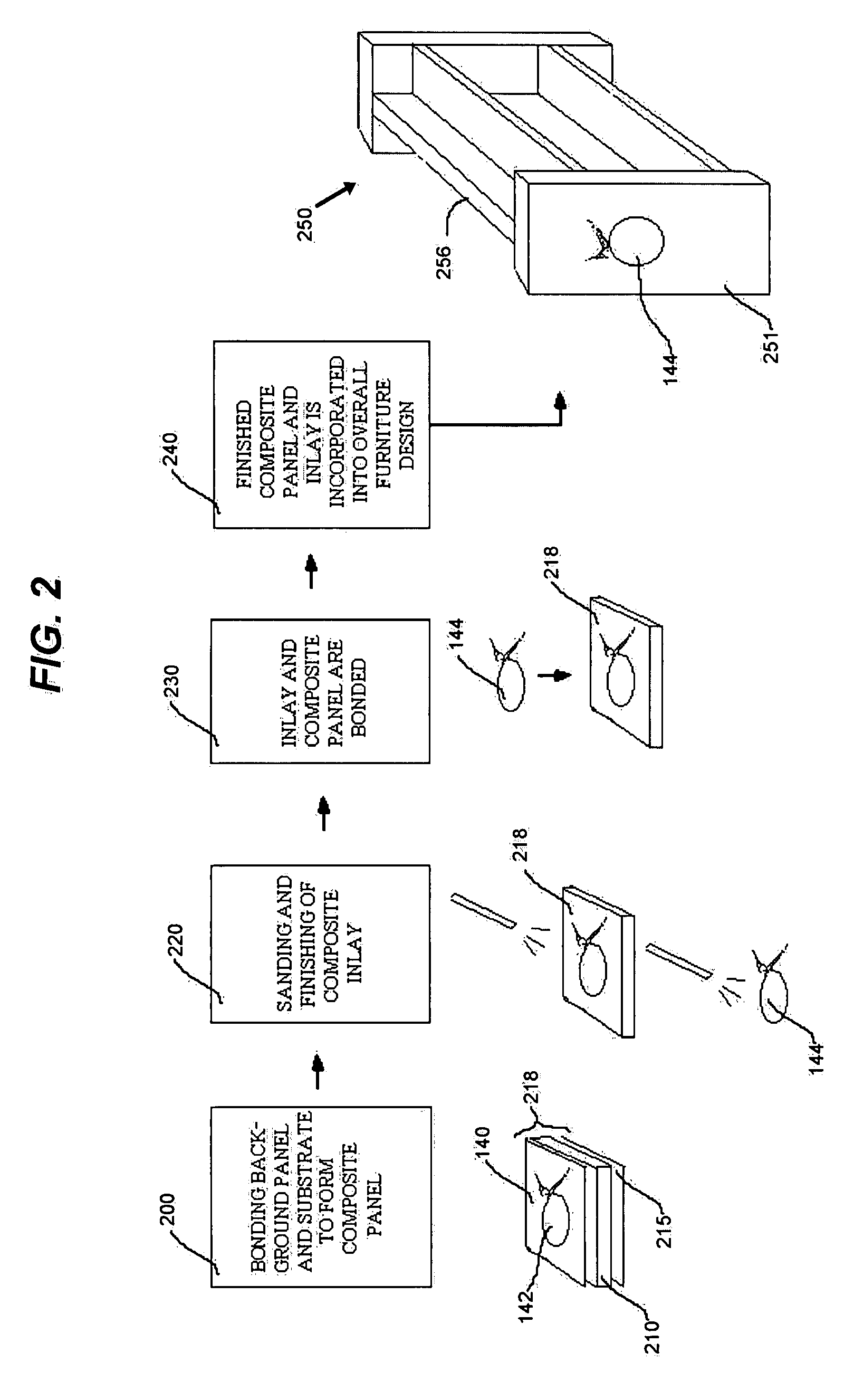

System for manufacturing an inlay panel using a laser

InactiveUS20050006019A1Straightening imperfect linesSimple designLamination ancillary operationsDecorative surface effectsGraphicsSoftware system

A method of manufacturing an inlayed panel uses the steps of providing an art master rendering as constitute a decorative design for the inlaid panel; scanning electronically the art master to form an art master data file; transferring the art master data file to a CAD software system to form an art master CAD file; coordinating a laser beam to cut-through a first background panel and create negative image voids; driving a CNC laser cutting machine in response to the machine code coordinates; coordinating a laser beam to cut through a second panel for forming positive images that become inlay elements; bonding the first background panel and the second panel; placing the inlay element in appropriate voided spaces; and finishing the composite panel and the inlay elements. A decorative panel is also formed of panel portions cut by laser using data inputted directly into a computer graphics system.

Owner:TMC FURNITURE

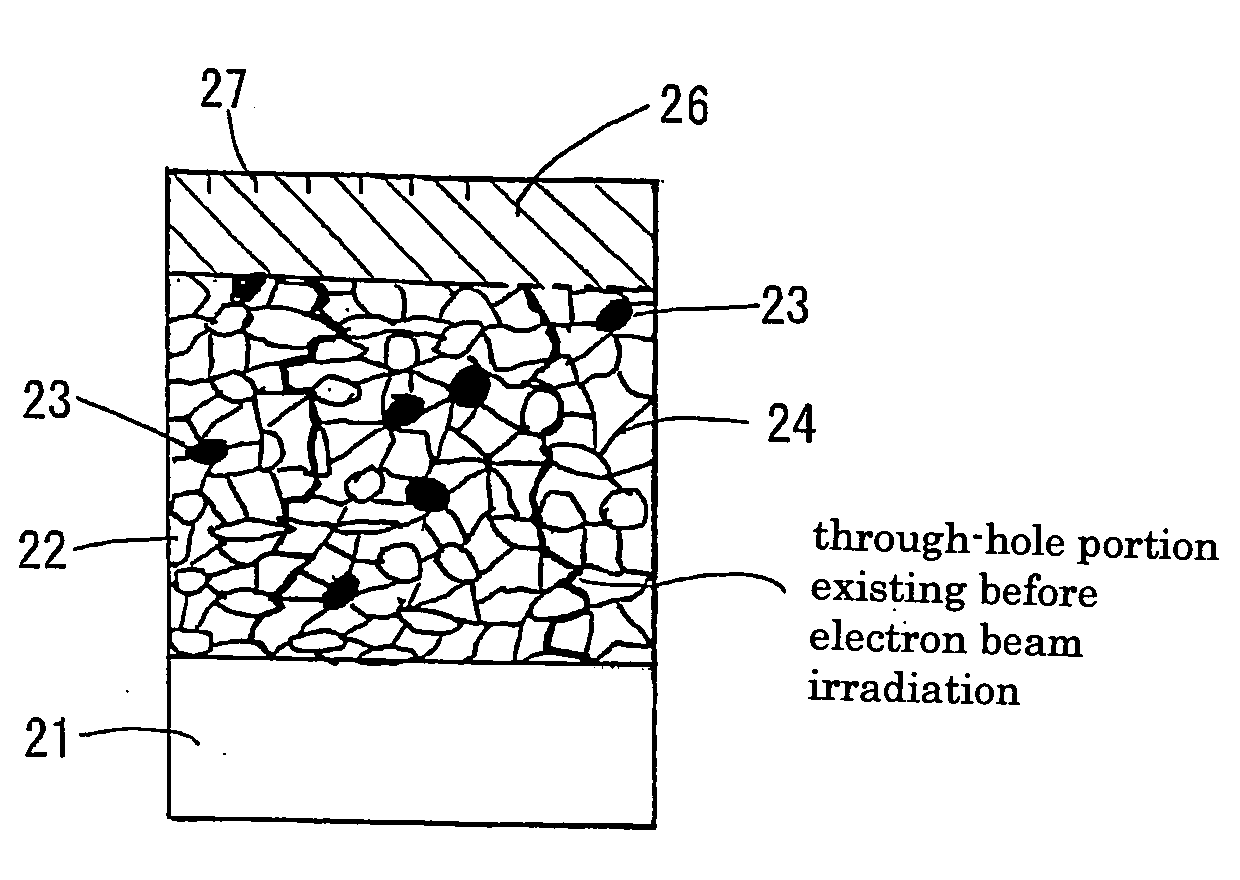

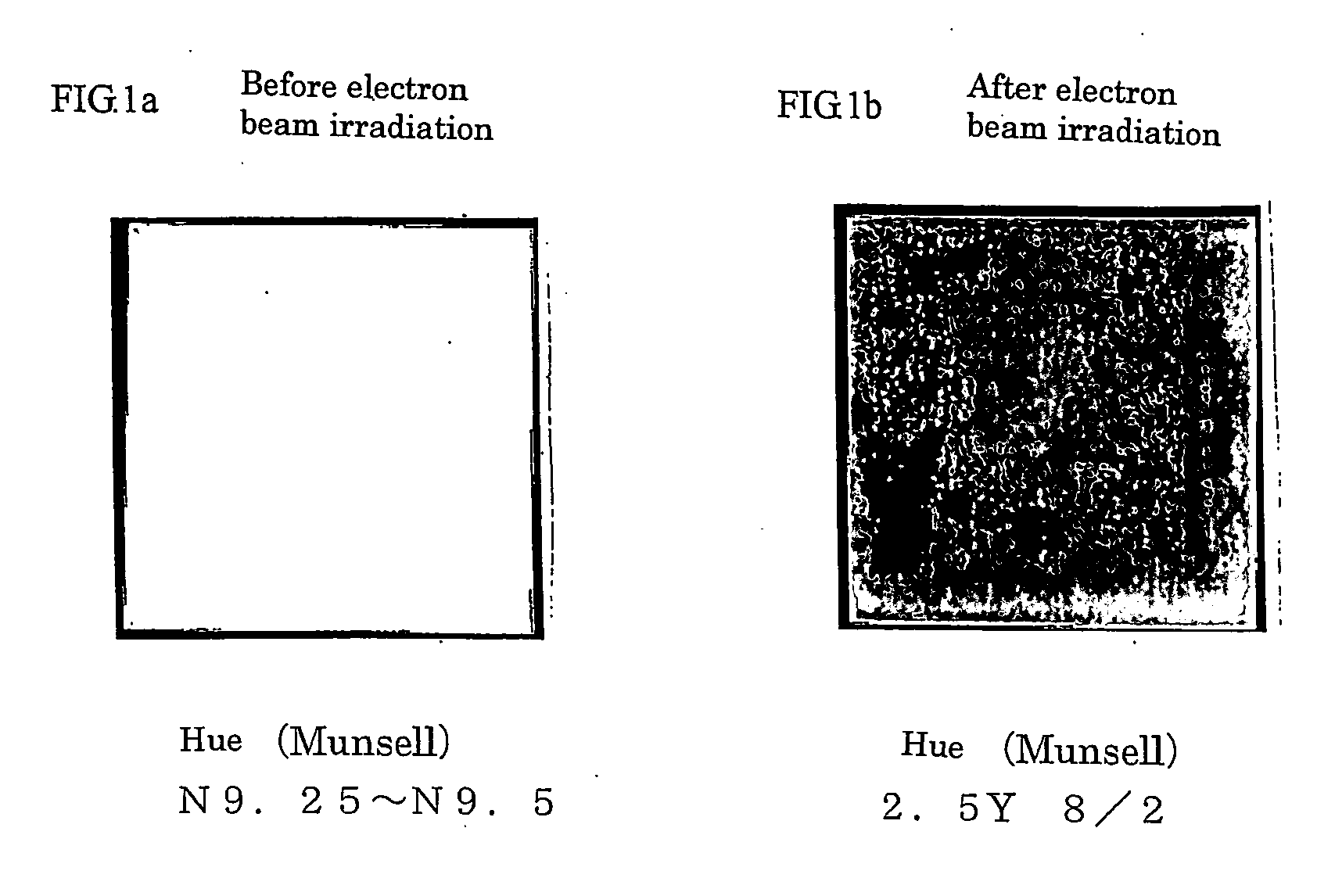

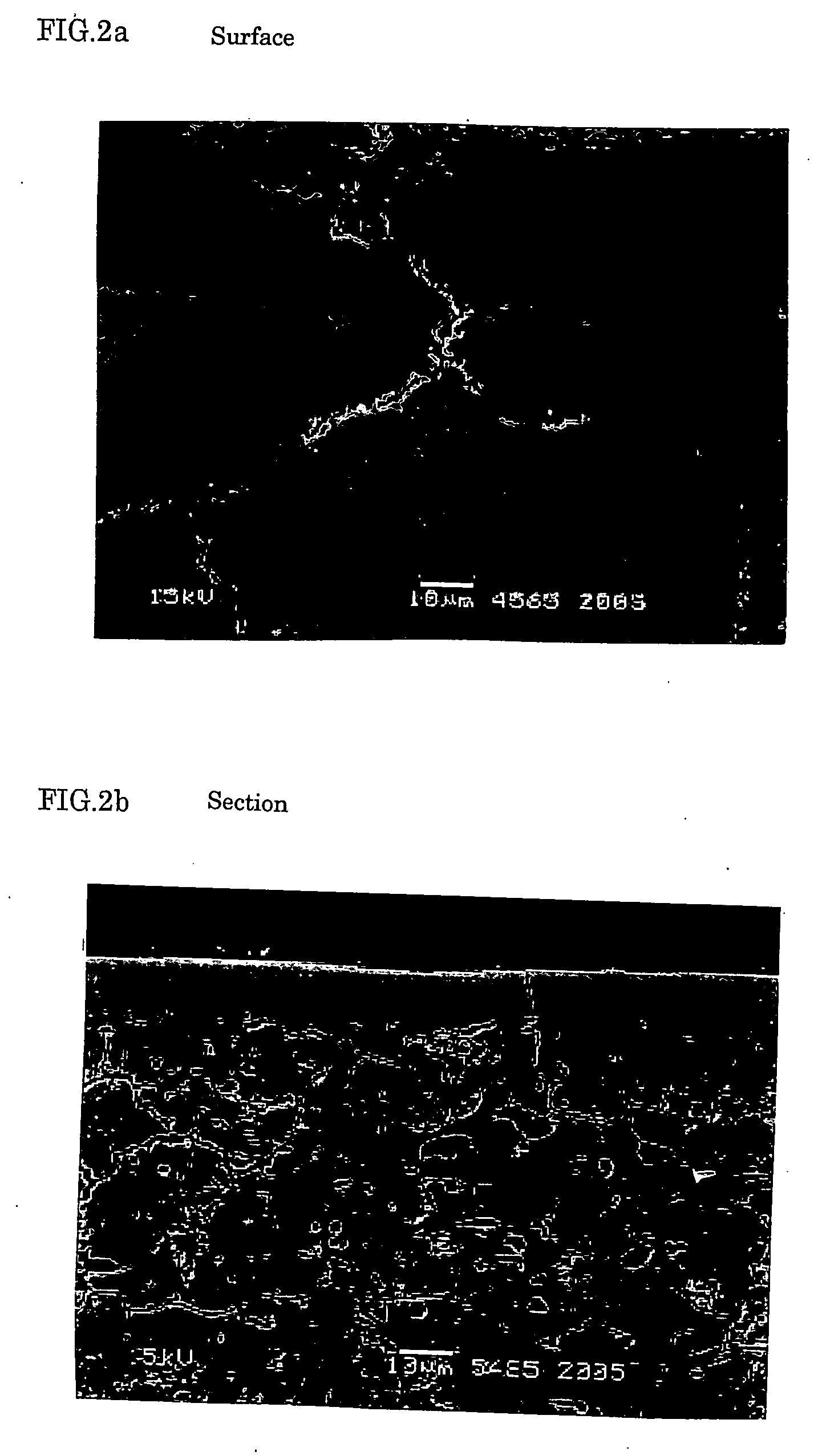

Spray coating member having excellent injury resistance and so on and method for producing the same

InactiveUS20090120358A1Excellent injury resistanceExcellent in various propertyMolten spray coatingElectric discharge heatingCorrosionSpray coating

For the purpose of solving problems inherent to a white Al2O3 spray coating, i.e. drawbacks that the injury resistance, corrosion resistance, heat resistance, abrasion resistance and the like are poor and the light reflectance is high because the coating is porous and weak in the bonding force among particles, there are proposed a spray coating member having excellent injury resistance and the like in which a surface of a substrate is covered with a colored Al2O3 spray coating of a luminosity lower than grayish white, achromatic or chromatic color.

Owner:TOCALO CO LTD

Method and system for dosing a pharmaceutical sample in a packaging machine

InactiveUS7536843B2Securing of qualityImprove accuracyLiquid fillingSolid materialBiomedical engineeringDosing units

The present invention relates to a method and system for dosing a pharmaceutical product in a packaging machine having at least one volumetric dosing unit with a dosing chamber. The system check-weighs the volumetrically dosed product with appropriate speed and is integrated into a filling or packaging machine. In accordance with the invention, a volume of a first pharmaceutical component is metered and weighed before being introduced into a package. The procedure is repeated with a second pharmaceutical component. The package containing the components is then weighed. Advantageously, accuracy and precision of the amount of the weighed components can be monitored with the present invention to secure the quality of the pharmaceutical product.

Owner:ASTRAZENECA AB

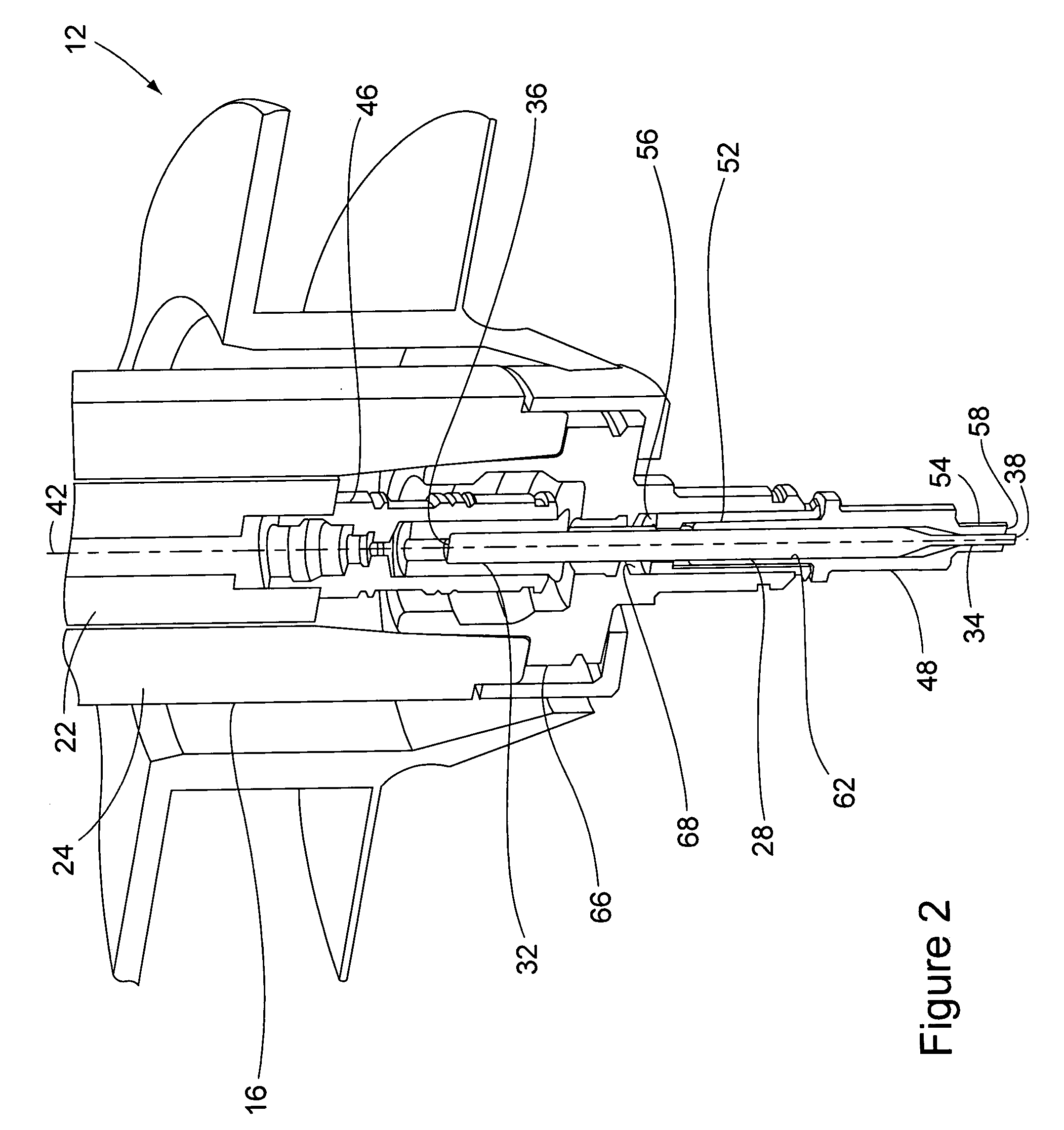

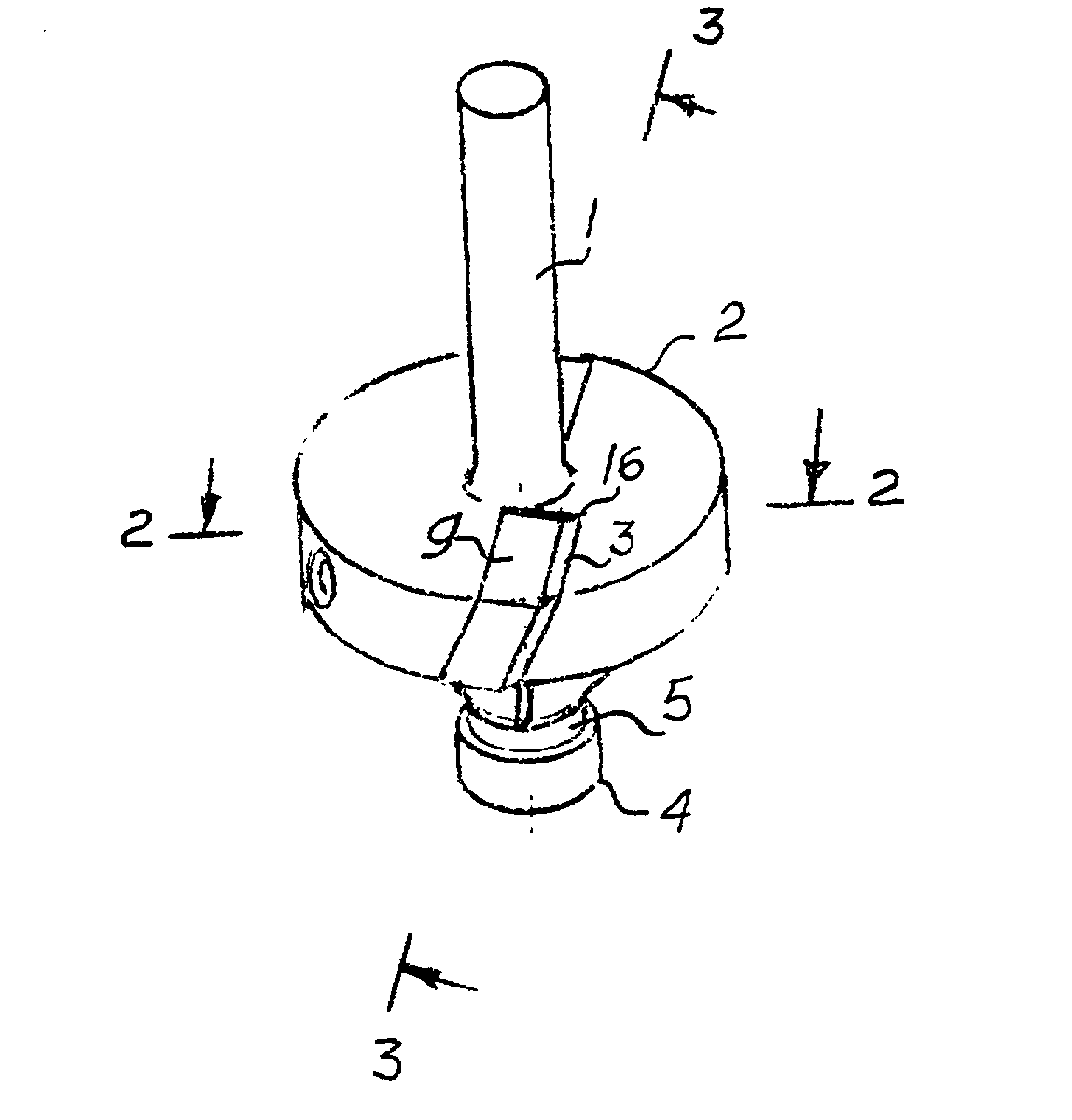

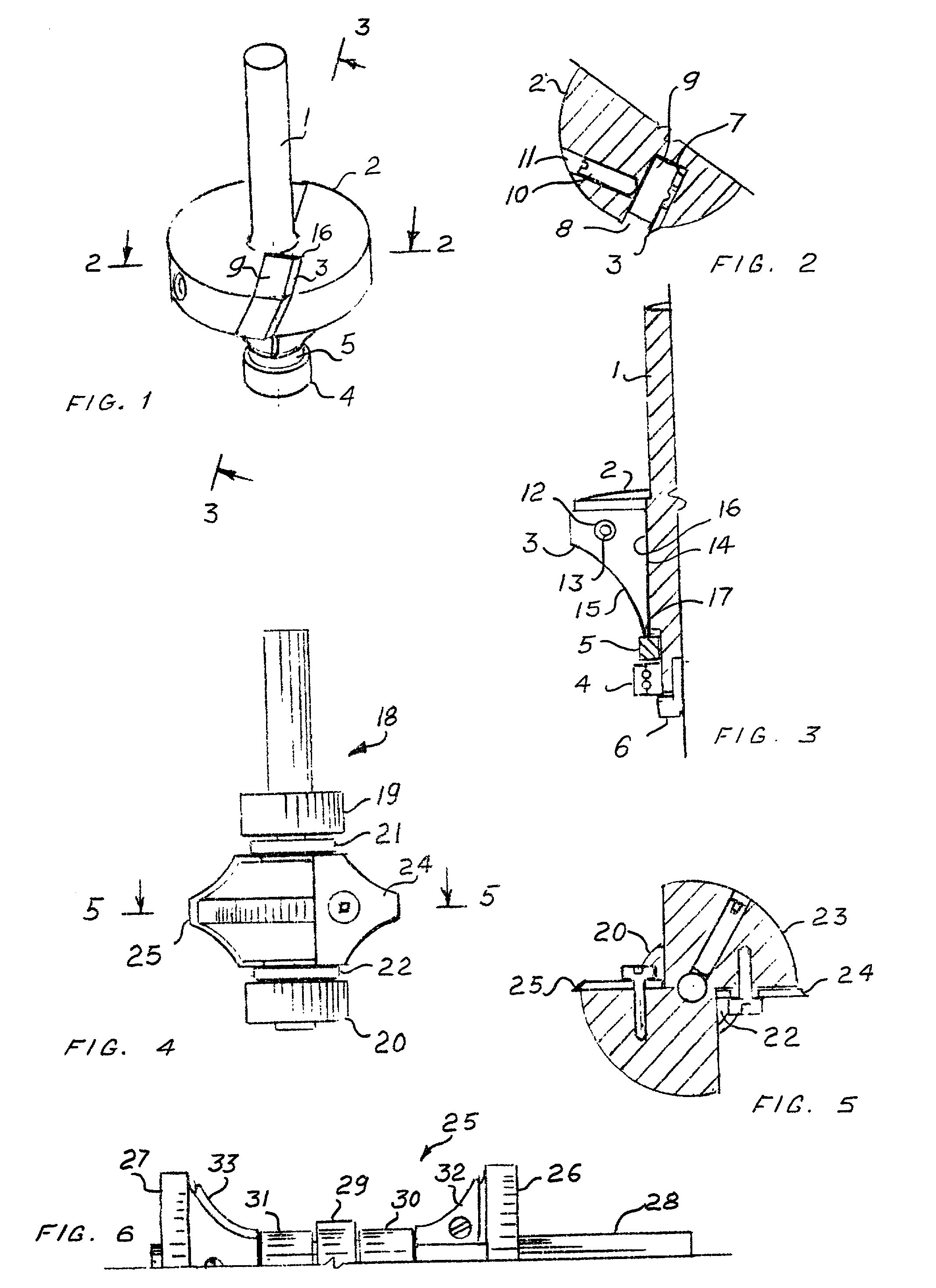

Friction stir welding apparatus

ActiveUS20060163316A1Facilitates installation and removalIncreases available production timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFriction stir welding

A friction stir welding apparatus has a novel tool-in-tool construction where a friction stir welding pin tool extends through a center bore of a friction stir welding shoulder tool and is moveable axially and rotationally relative to the shoulder tool. The pin tool and shoulder tool both have their own dedicated tool holders and spindles that enable the tools to rotate and move axially relative to each other and enable easy replacement of each of the tools.

Owner:THE BOEING CO

Fluid Delivery and Treatment Device and Method of Use

ActiveUS20160228681A1Promote formationPromote disseminationStentsBalloon catheterFluid infusionMedicine

A medical device system is provided herein which has an elongated, flexible hollow member with an expandable infusion segment attached at the most distal end of the device. The device has a plurality of fluid infusion ports on the expandable infusion segment for delivering an intended fluid to a target site in a body lumen. Additionally, a method is provided herein for infusing an intended fluid to a target site within a body lumen.

Owner:ANGIODYNAMICS INC

Extension of Truncated CT Images For Use With Emission Tomography In Multimodality Medical Images

InactiveUS20120155736A1Reduce areaReduce computing timeReconstruction from projectionMaterial analysis using wave/particle radiationComputed tomographyTomography

An apparatus and method for expanding the FOV of a truncated computed tomography (CT) scan. An iterative calculation is performed on the original CT image to produce an estimate of the image. The calculated estimate of the reconstructed image includes the original image center and a estimate of the truncated portion outside the image center. The calculation uses an image mask with the image center as one boundary.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Extension of truncated CT images for use with emission tomography in multimodality medical images

ActiveUS8155415B2Reduce areaReduce computing timeReconstruction from projectionCharacter and pattern recognitionDiagnostic Radiology ModalityComputed tomography

An apparatus and method for expanding the FOV of a truncated computed tomography (CT) scan. An iterative calculation is performed on the original CT image to produce an estimate of the image. The calculated estimate of the reconstructed image includes the original image center and a estimate of the truncated portion outside the image center. The calculation uses an image mask with the image center as one boundary.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

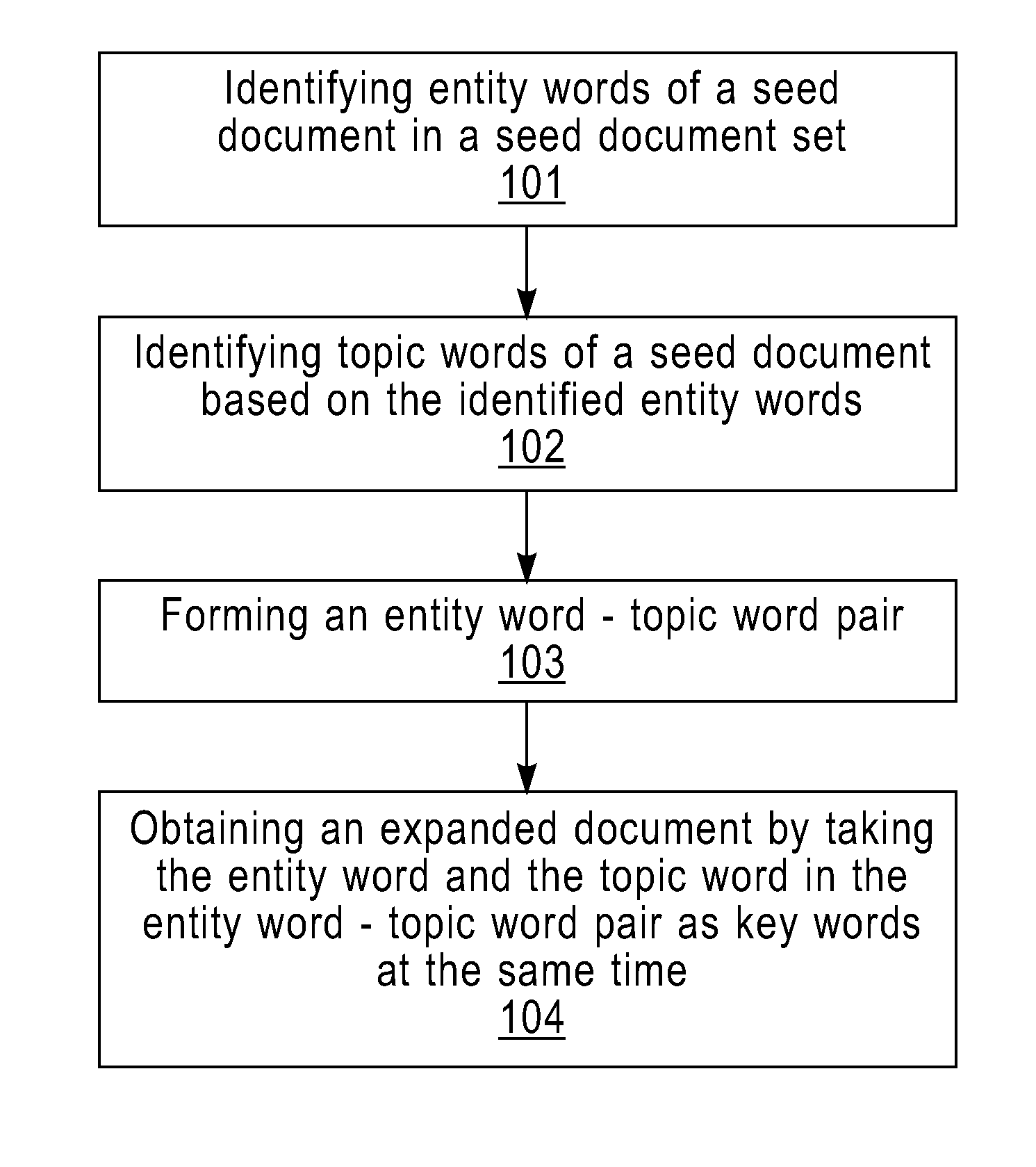

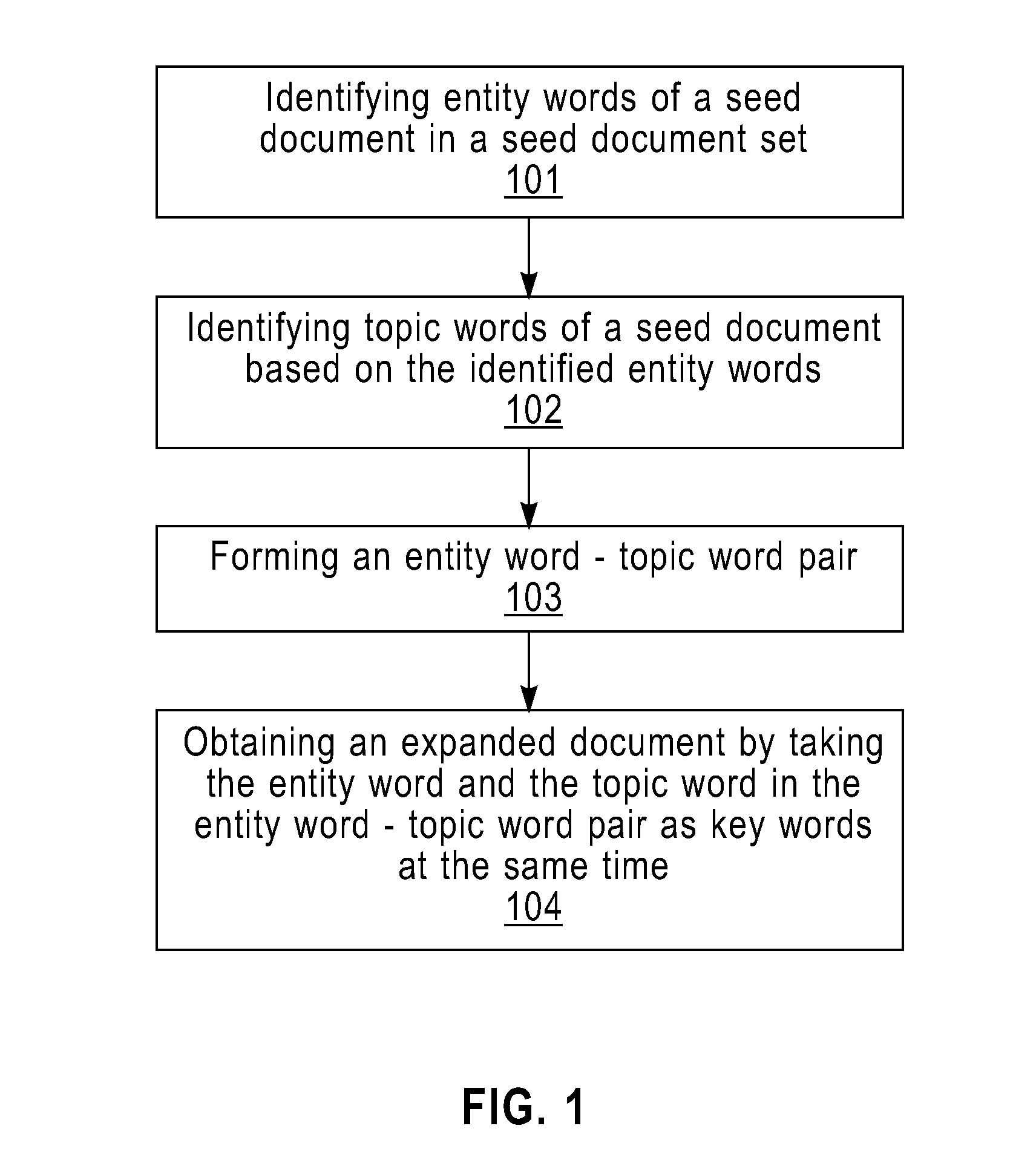

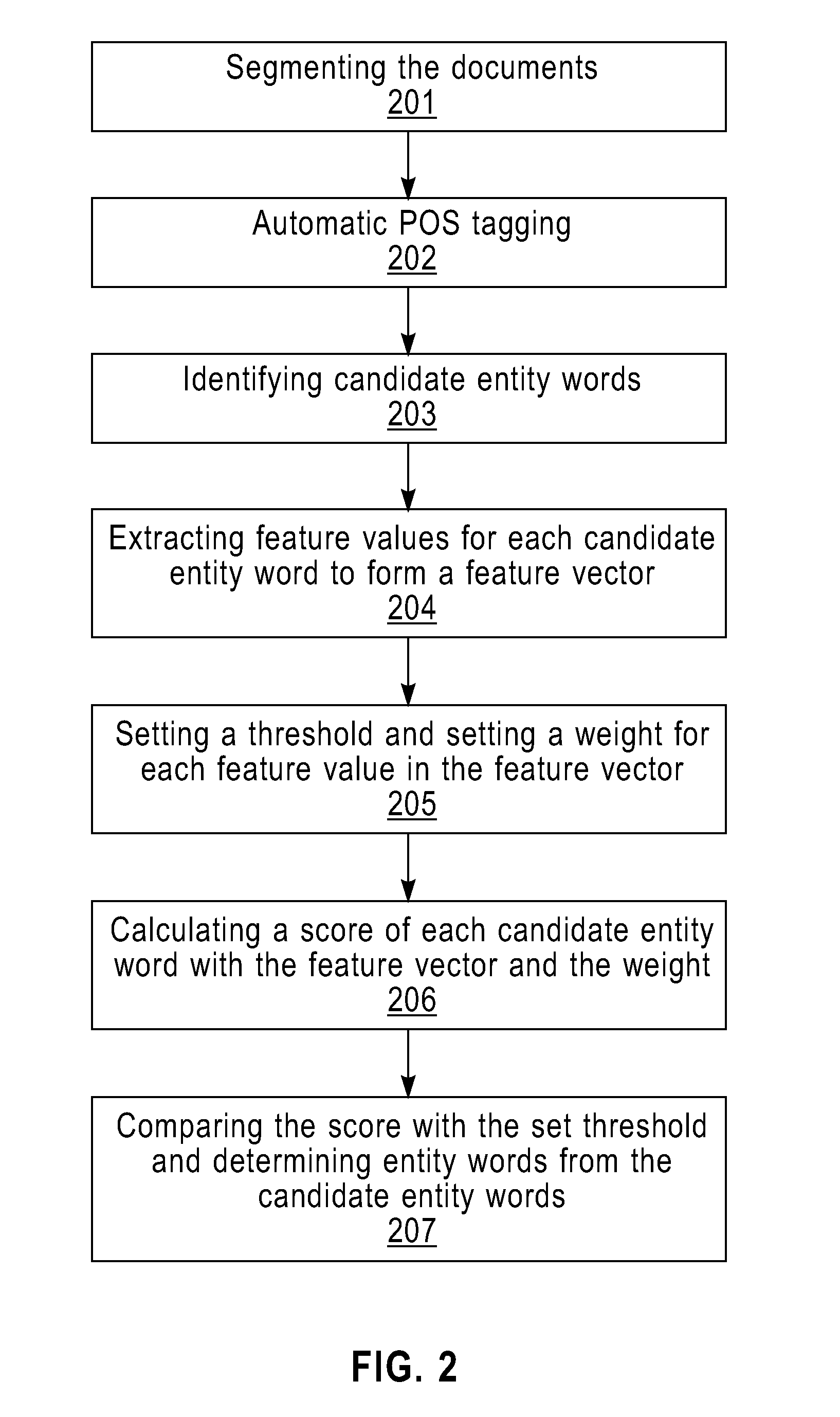

Document processing method and system

InactiveUS20100306248A1Correction accuracyPrecise maintenanceDigital data processing detailsSpecial data processing applicationsDocument preparationDocument processing

A method and system for expanding a document set as a search data source in the field of business related search. The present invention provides a method of expanding a seed document in a seed document set. The method includes identifying one or more entity words of the seed document; identifying one or more topic words identifying one or more topic words related to the based entity word in the seed document where the entity word is located; forming an entity word-topic word pair from each identified topic word and the entity word on the basis of which each topic word is identified; and obtaining one or more expanded documents through web by taking the entity word and topic word in the each entity word-topic word pair as key words at the same time. A system for executing the above method is also provided.

Owner:IBM CORP

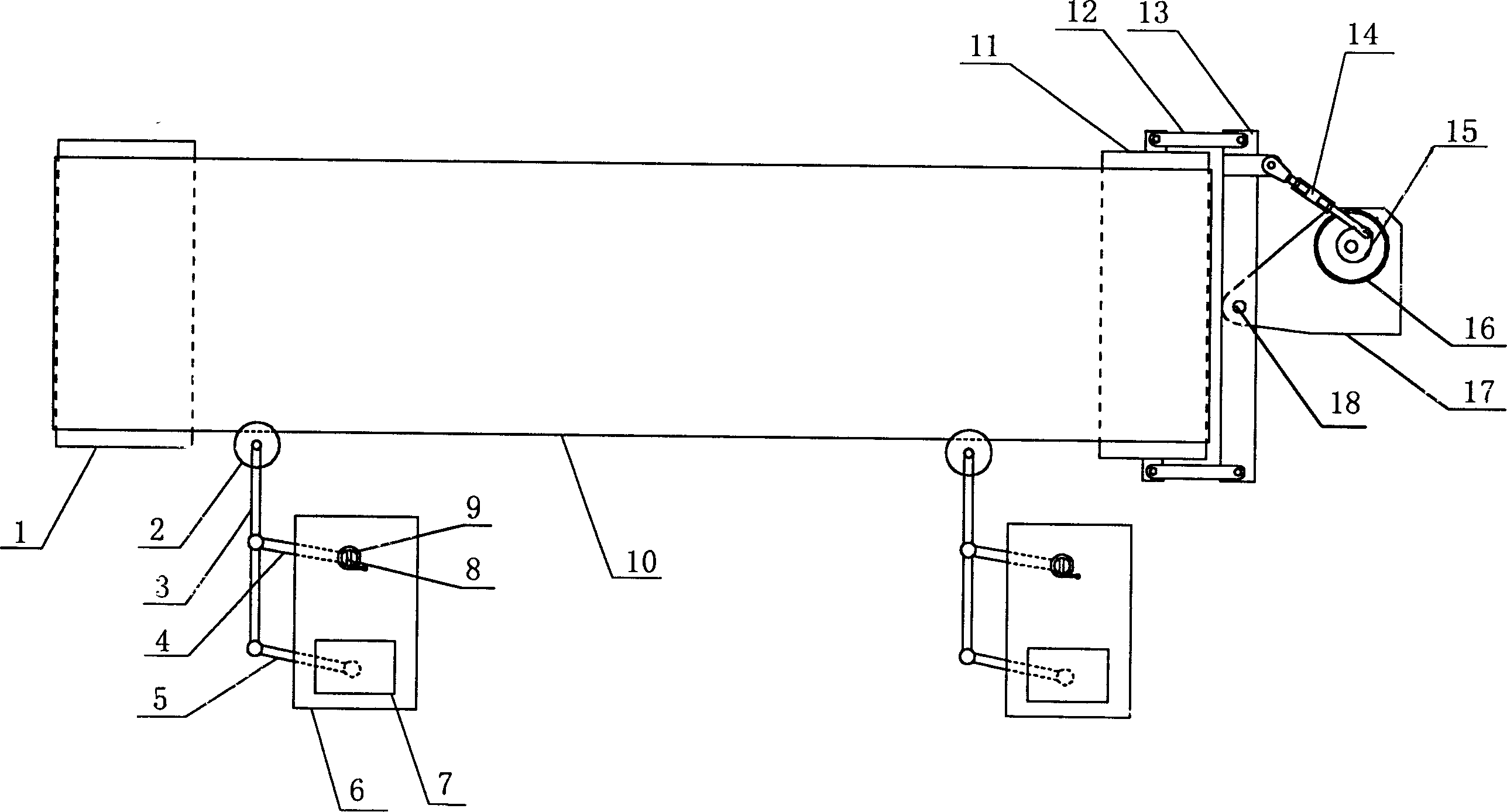

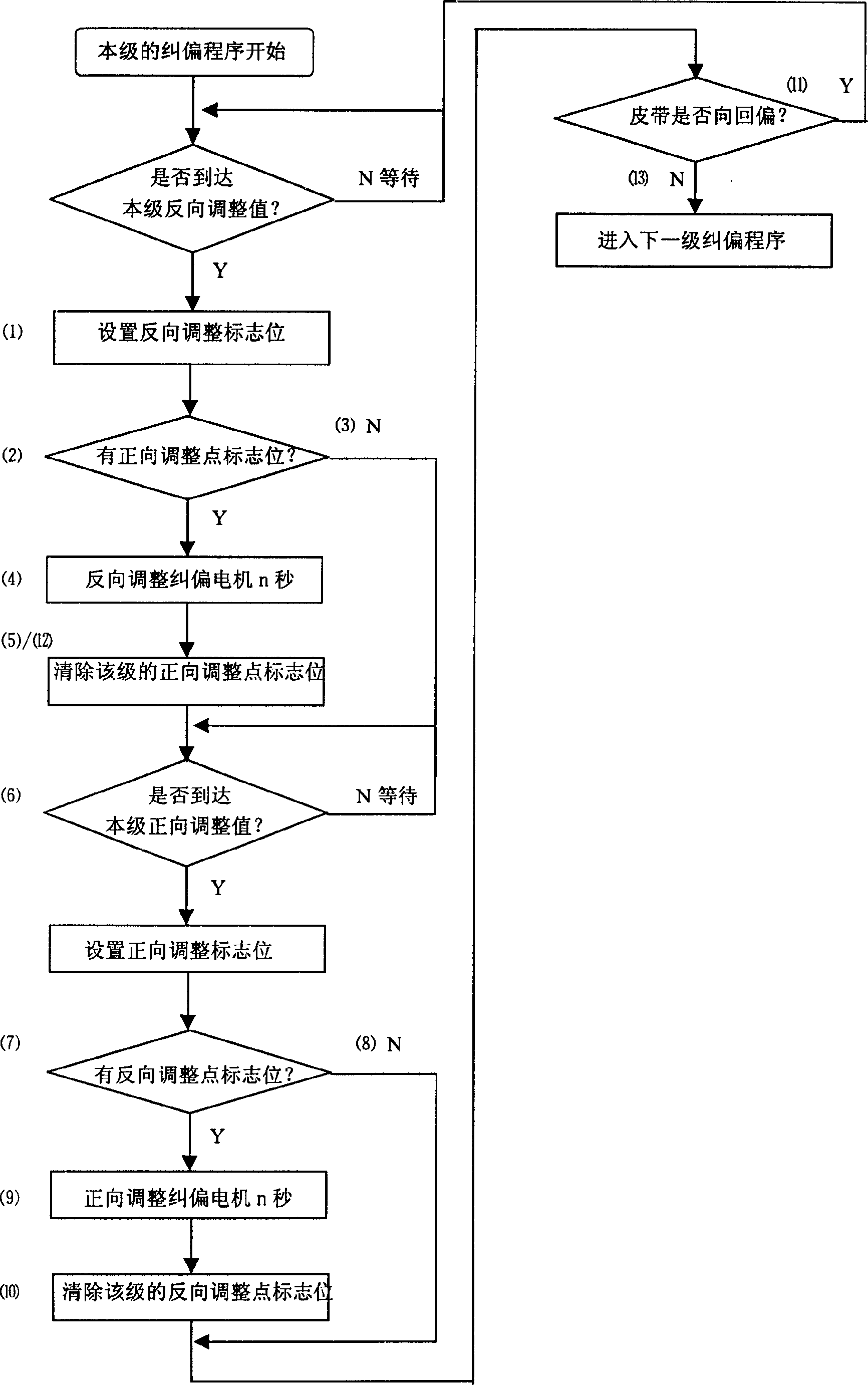

Automatic error correcting system of short leather belt and its method

InactiveCN1597469ACorrection method is reasonable and feasibleCorrection accuracyConveyorsControl devices for conveyorsSystem structureLeather belt

This invention relates to a system and a method for calibrating short belt against a correct position. A system consists of a four-bar-linkage, a motor a cam, which is hinged with a push rod, and a position monitor. The four-bar-linkage is used as an actuator. The motor drives the cam to actuate the four-bar-linkage via the push rod hinged with the cam. The push rod is respectively hinged with the cam and a movable rod of the four-bar-linkage as its both ends. The position monitor is equipped with a detecting lever. A roller is elastically pressed to contact with an edge of the belt. The method is carried out by: feeding the detected position signals into computer system, outputting a calibrating signal to the motor and to change the tension forces on both edges of the conveying belt via the cam mechanism and actuator. It is simple and reliable.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

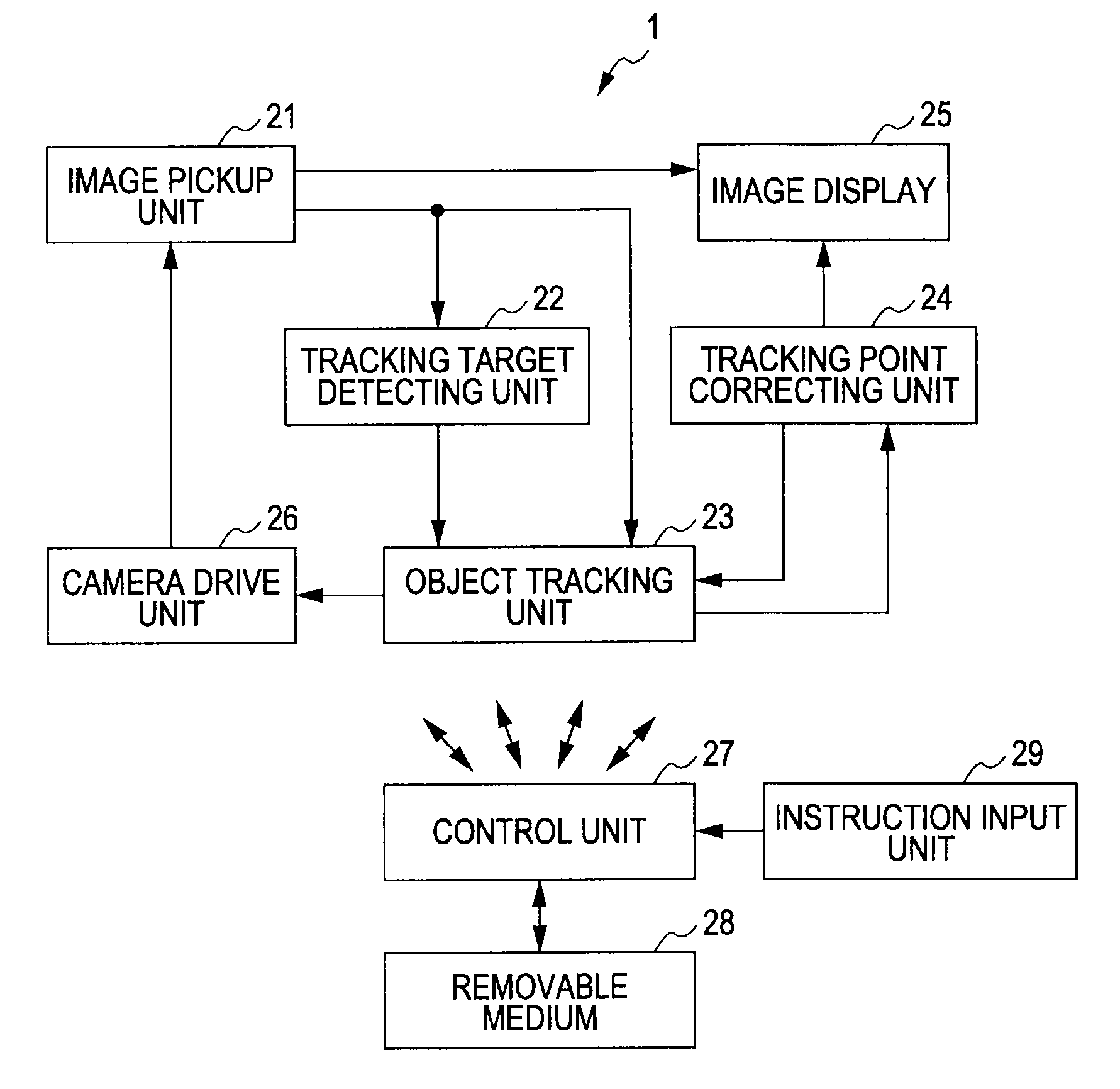

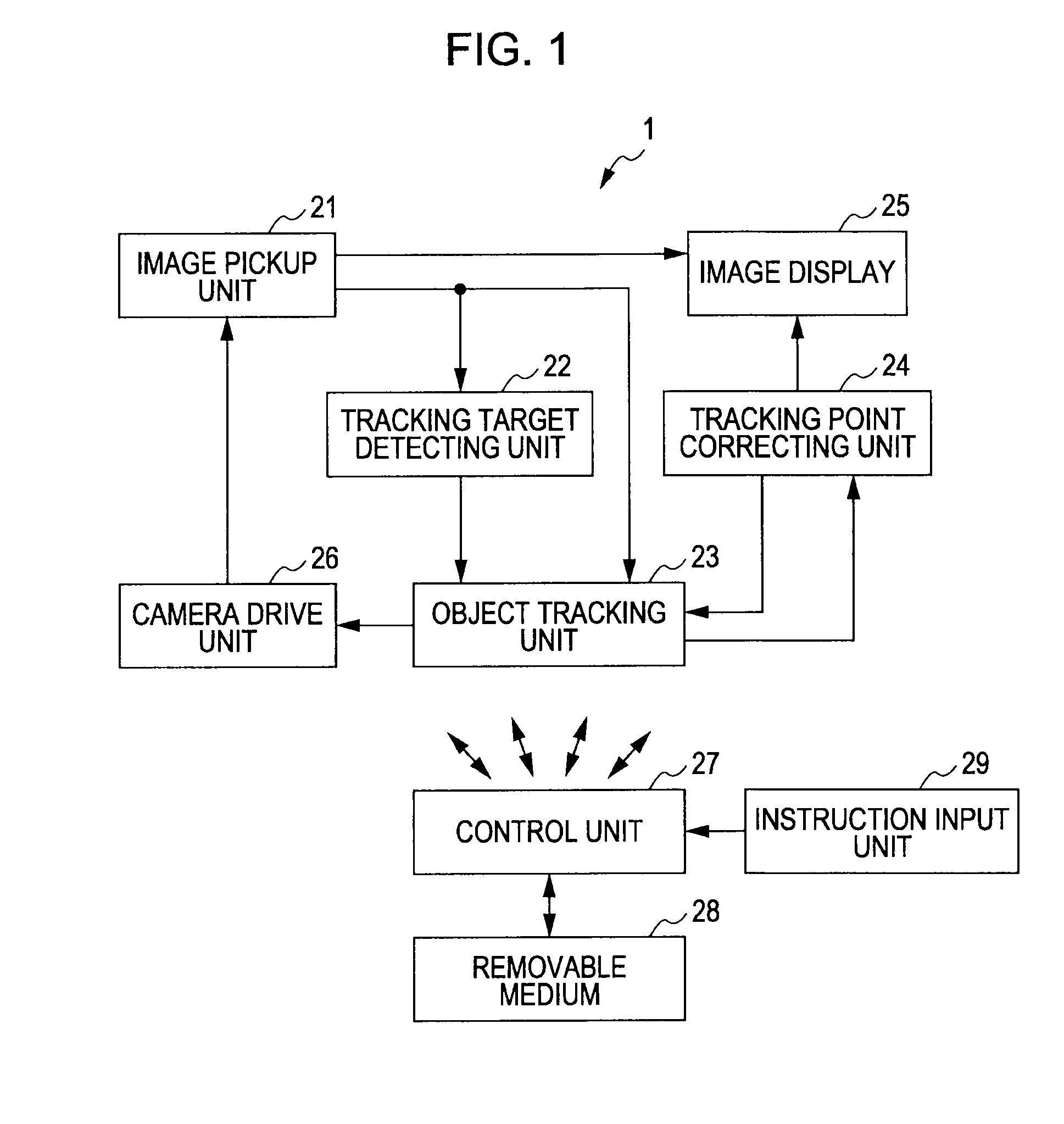

Image signal processing apparatus, image signal processing method, and program

InactiveUS20090252374A1Accuracy of motion can be accuratelyHigh precision trackingImage enhancementTelevision system detailsPattern recognitionMotion vector

An image signal processing apparatus includes a detecting unit configured to detect a motion vector of a tracking point provided in an object in a moving image, a computing unit configured to compute a reliability parameter representing the reliability of the detected motion vector, a determining unit configured to determine whether the detected motion vector is adopted by comparing the computed reliability parameter with a boundary, an accumulating unit configured to accumulate the reliability parameter, and a changing unit configured to change the boundary on the basis of the accumulated reliability parameters.

Owner:SONY CORP

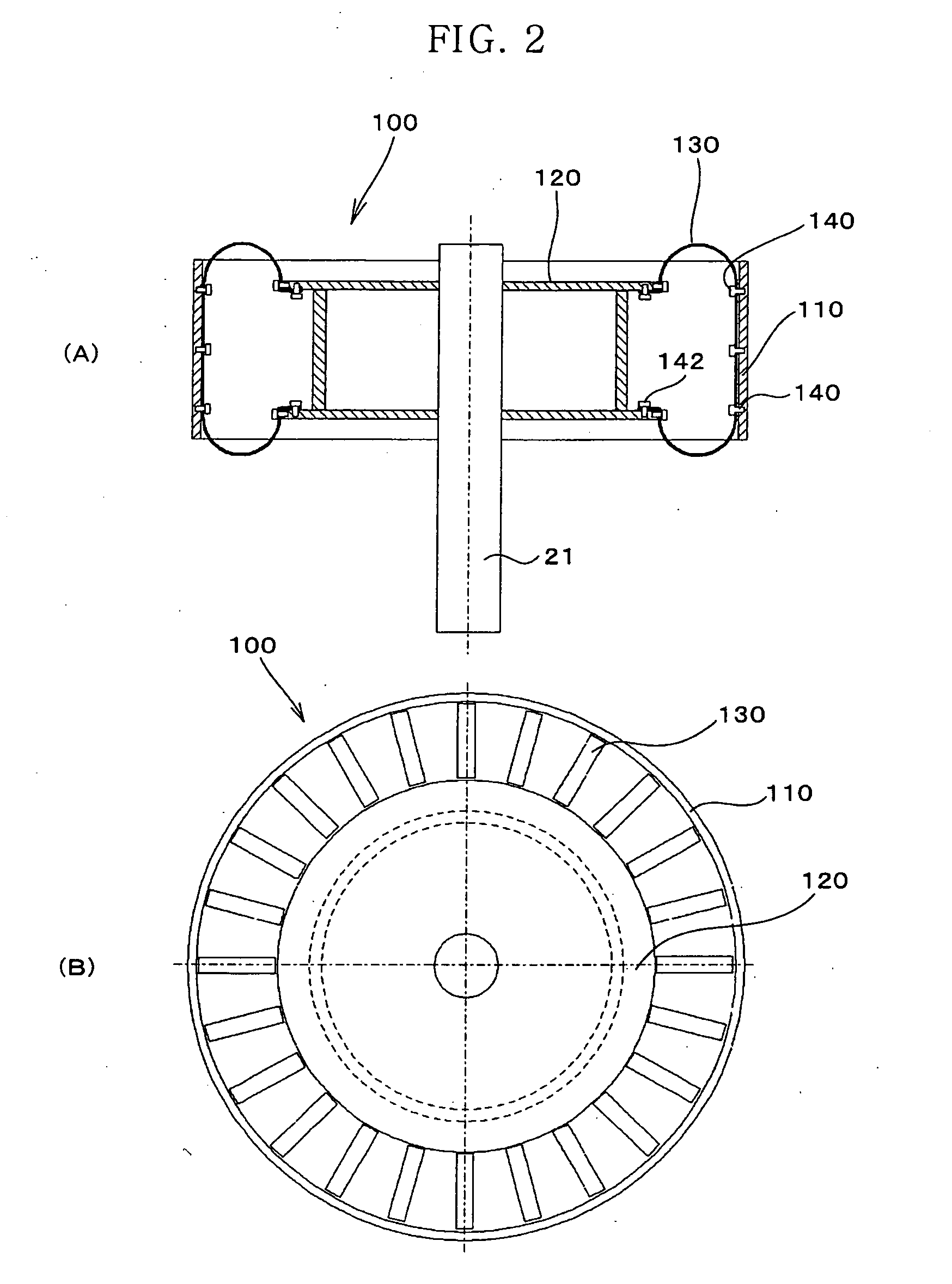

Master tire and method of inspecting tire uniformity tester using the master tire

ActiveUS20110113875A1Generated stablyCorrection accuracyInflated body pressure measurementStatic/dynamic balance measurementTire uniformityMetallic materials

The present invention provides a master tire for inspecting the accuracy of a tire tester easily and securely. A master tire 100 according to the present invention is equipped with an upper-lower rim member 120, a cylindrical member 110 equivalent to the tread portion of a tire, and leaf spring 130 secured to the cylindrical member 110 and the rim member 120 with bolts 140 and bolts 142. A spindle 21 is secured to the rim member 120 so that the center axis thereof is not displaced. The rim member 120 is vertical to or slightly inclined with respect to the spindle 21. The cylindrical member 110 is made of a metallic material, such as iron or aluminum, or a hard plastic having stable characteristics.

Owner:KOBE STEEL LTD

Knife-positioning washer for piloted router bit

InactiveUS20030039517A1Shorten the timeCorrection accuracyMilling cuttersMilling machinesDrill bitGasket

Owner:GOLDING THOMAS H III

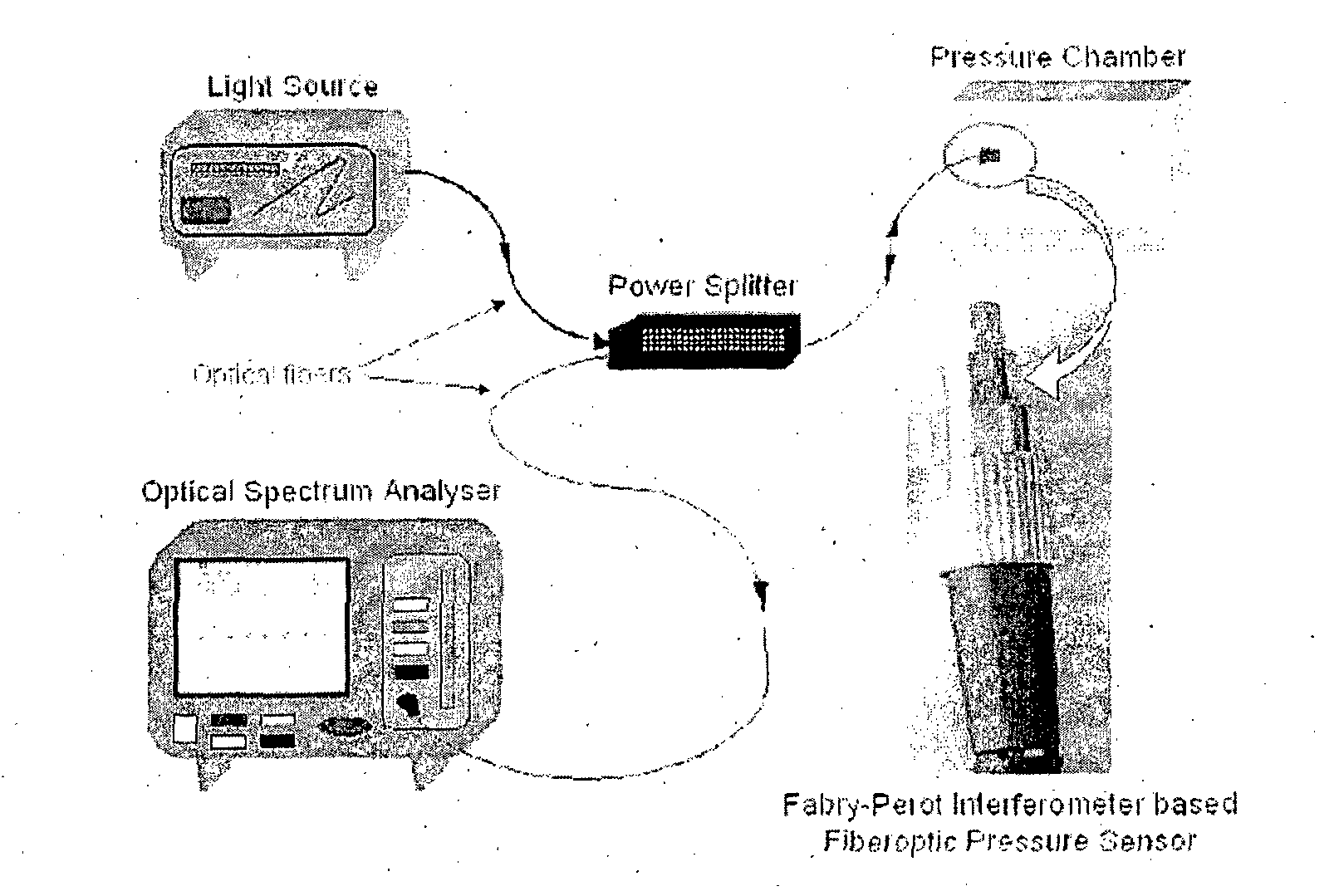

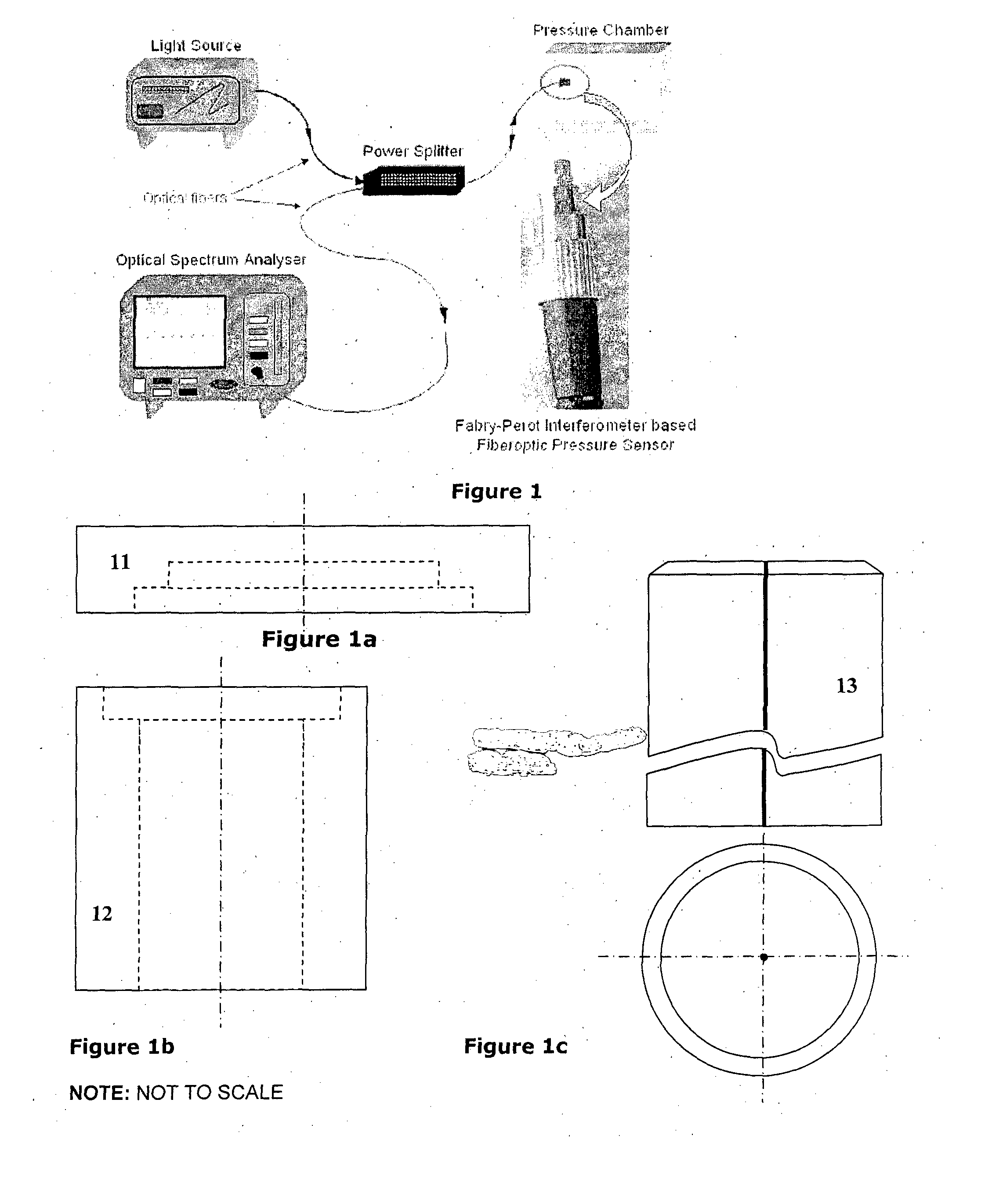

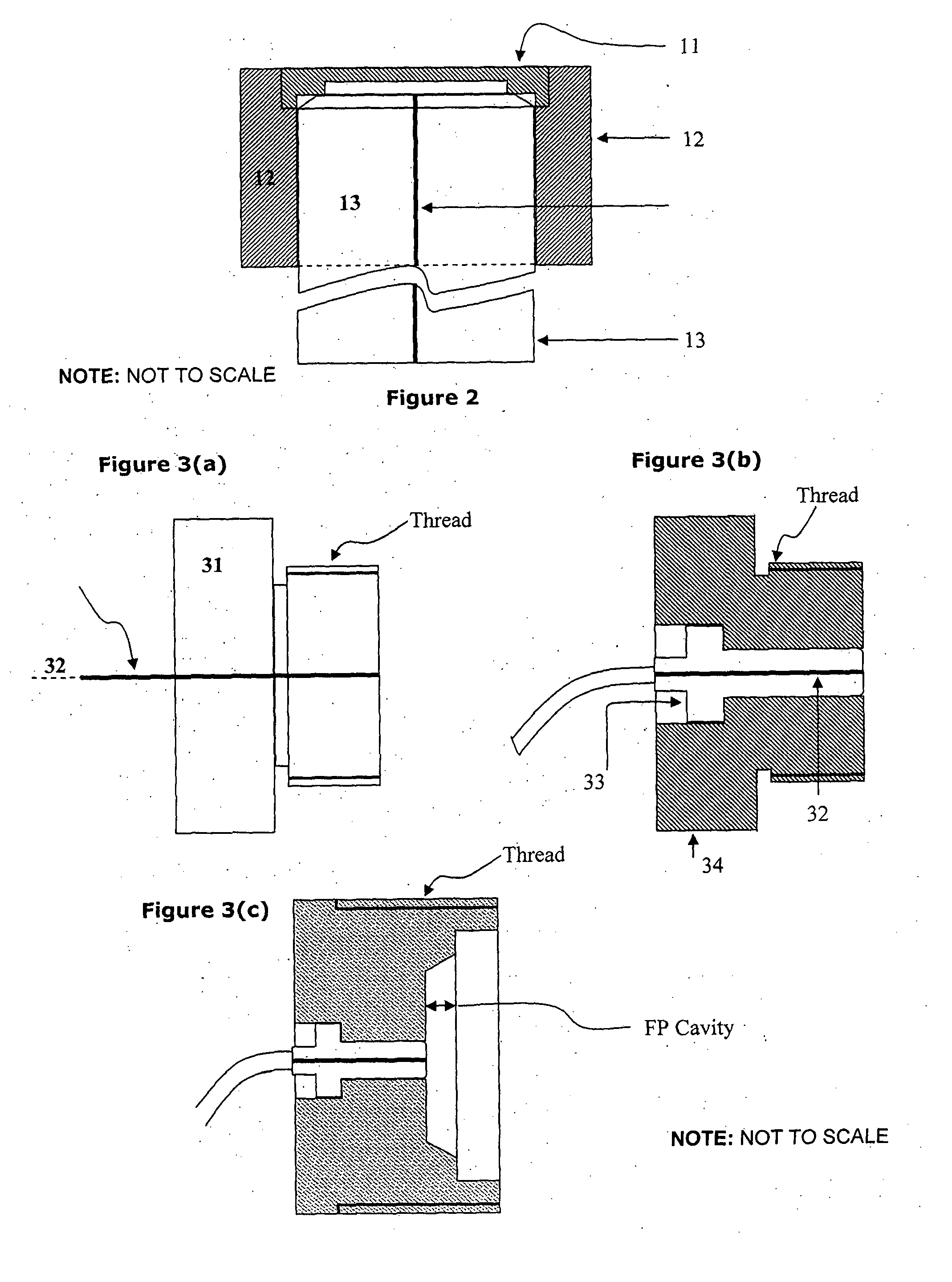

Micromachined metal diaphragm based fabry-perot fiberoptic sensor system and data processing involving the same

InactiveUS20140168659A1Correction accuracyAccurate qualityThermometers using material expansion/contactionFluid pressure measurement by electric/magnetic elementsMiniaturizationCompound (substance)

The present invention relates to micro machined metal diaphragm for Fabry-Perot interferometer sensor and Fabry Perot Fiber optic Sensor system using said metal diaphragm and method of fabrication thereof. Fabry Perot sensor with micro machined metallic diaphragms at the fiber optic end is developed ensuring accuracy, controllability by deterministic process. Advantageously, the system involves the metal diaphragm with high reflectivity inside surface facing the fiber end as a basic functional element. Importantly, the micro machined metal diaphragm is miniaturized to suit various critical applications including bio medical sensing devices for measuring various physiological parameters with desired accuracy. The metallic diaphragm based Fabry-Perot fiber optic sensor is directed to favour wide scale applications such as for measuring various parameters in nuclear industry, Chemical and Electrically harsh industry, biomedical applications with desired precision and favorable performance largely unaffected by radiation, high temperature or highly corrosive environment at work / application.

Owner:SEC DEPT OF ATOMIC ENERGY

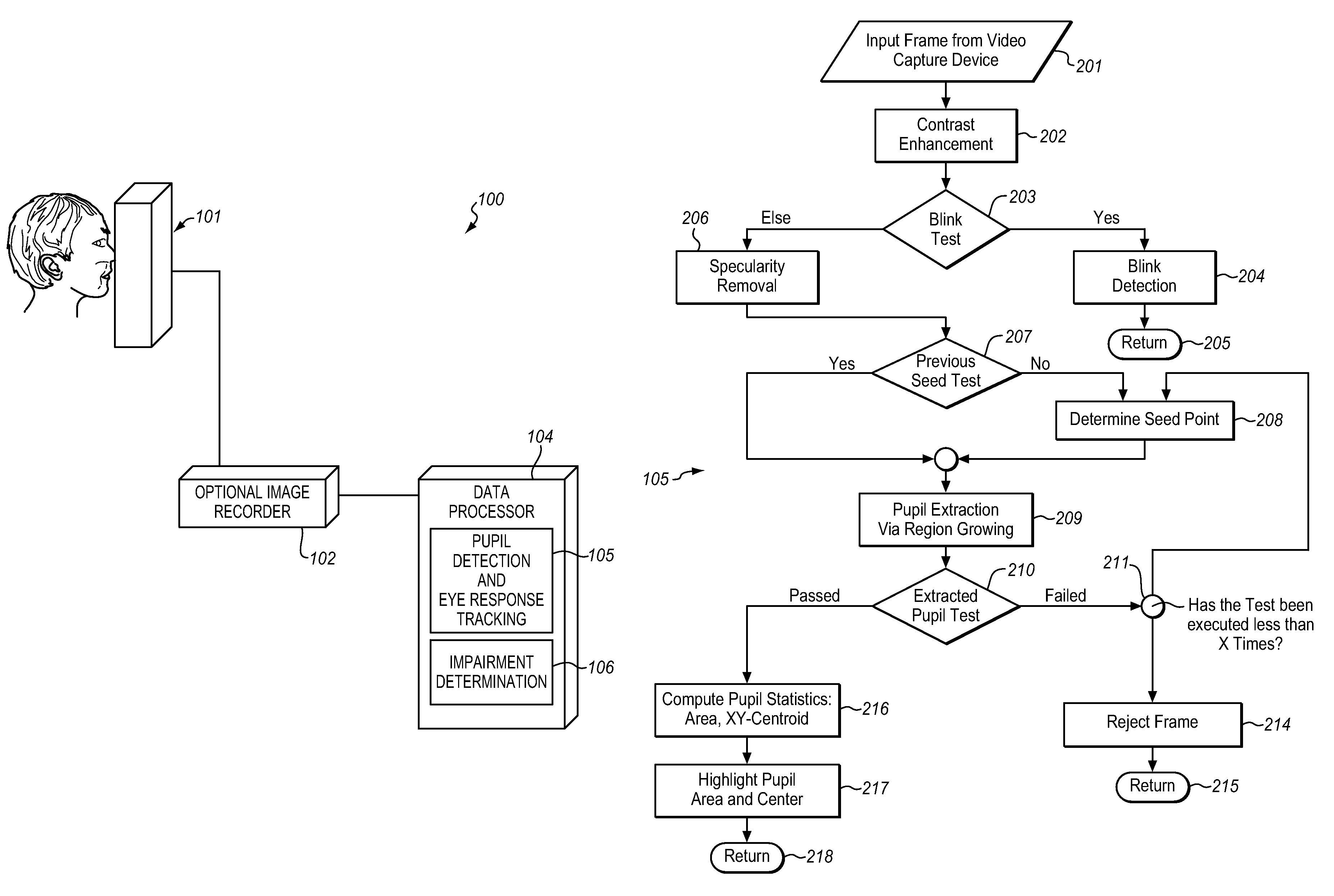

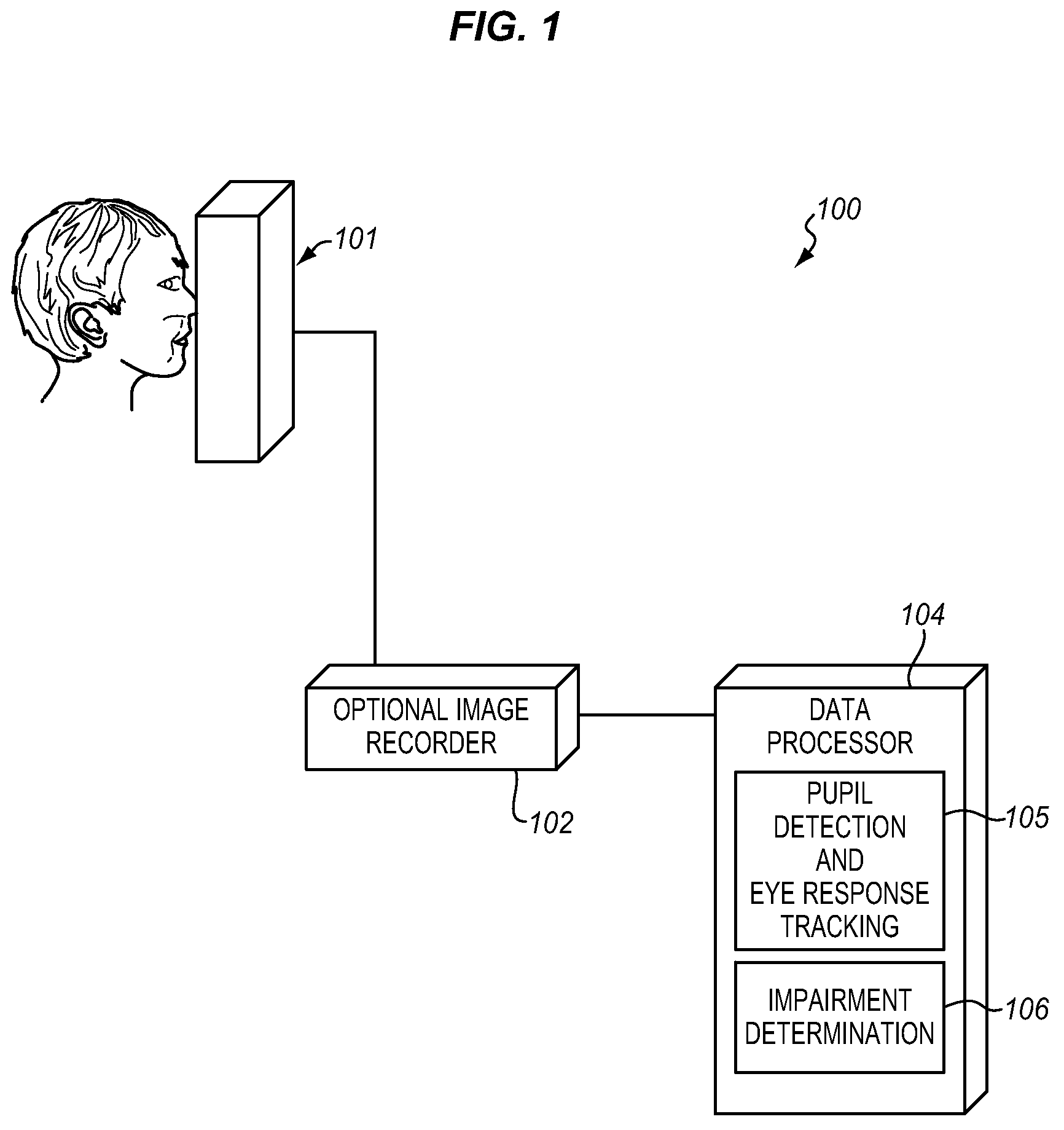

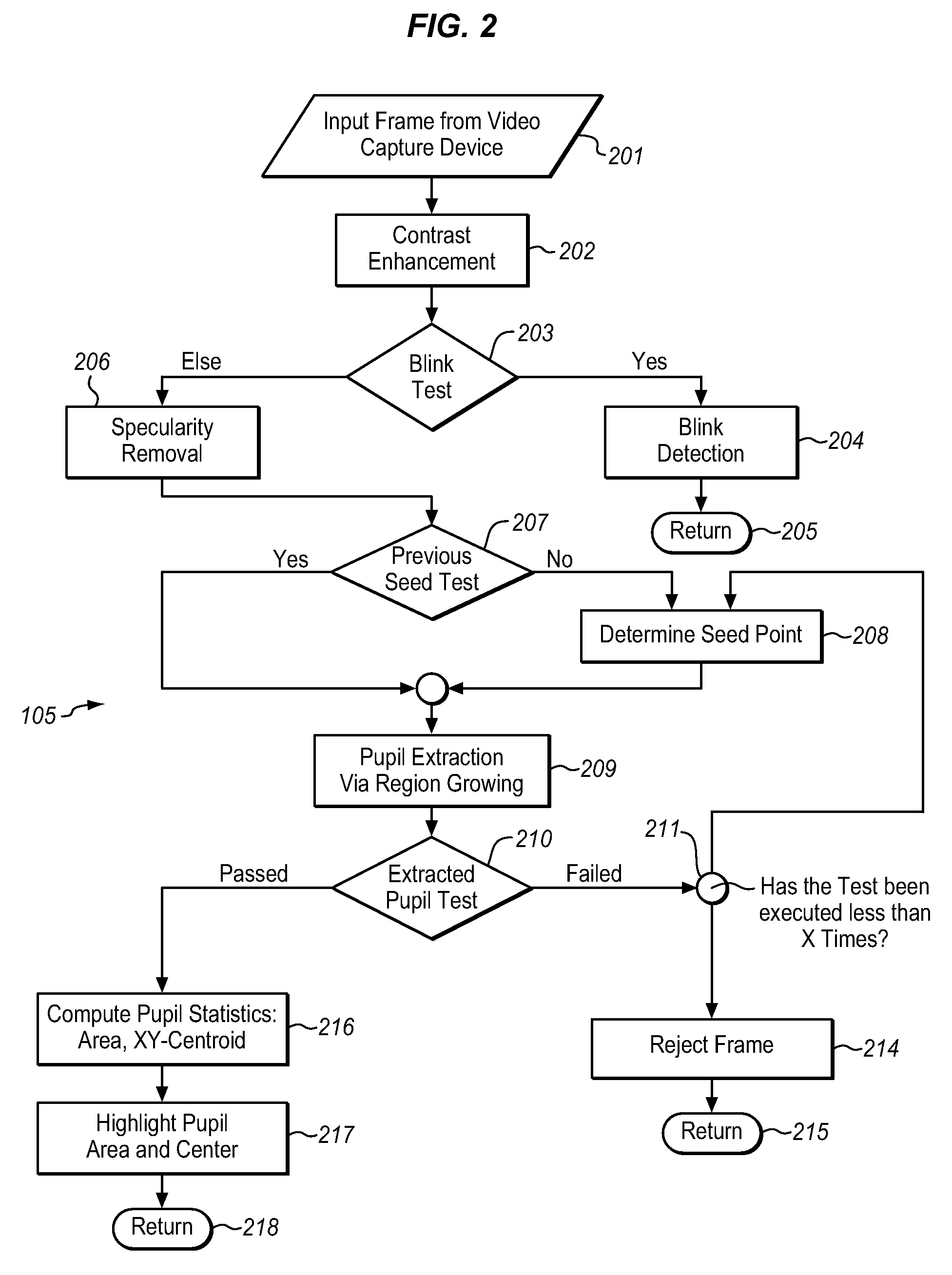

System for analyzing eye responses to automatically track size, location, and movement of the pupil

ActiveUS7798643B2Accurate and fast positioningAccurate shapeAcquiring/recognising eyesDiagnostic recording/measuringDigital imageBilateral eyes

The present system for analyzing eye responses accurately and automatically tracks the size, location, and movement of a subject's pupil(s) in response to a predetermined test protocol. These eye responses include both ocularmotor and pupillary responses to illumination and target tracking for either eye or both eyes simultaneously. The series of digital image frames of a subject's eyes, taken during the execution of a predetermined stimulus protocol, are automatically processed to determine pupil location, size, and responsiveness to changes in illumination.

Owner:VISIONETX

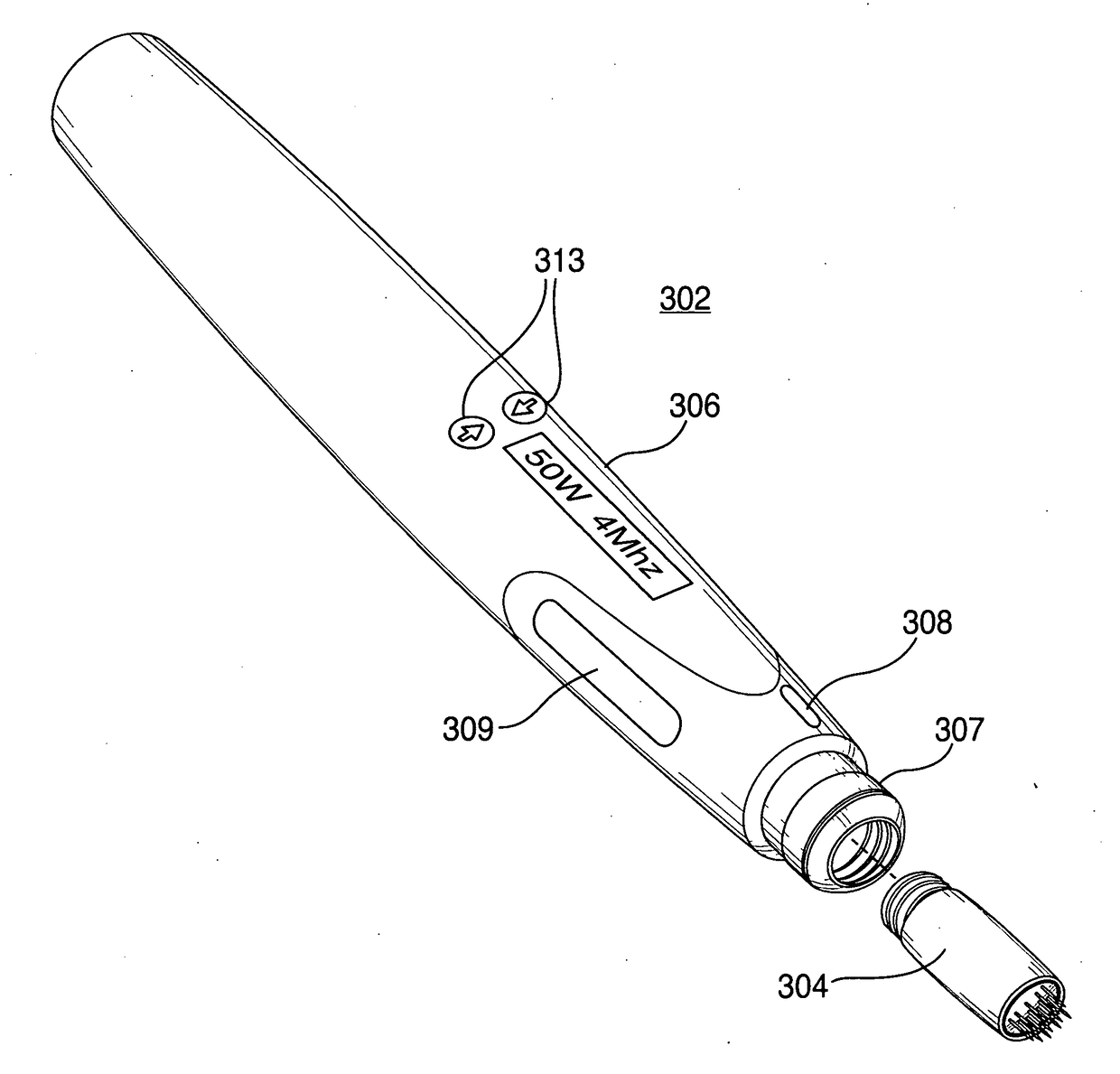

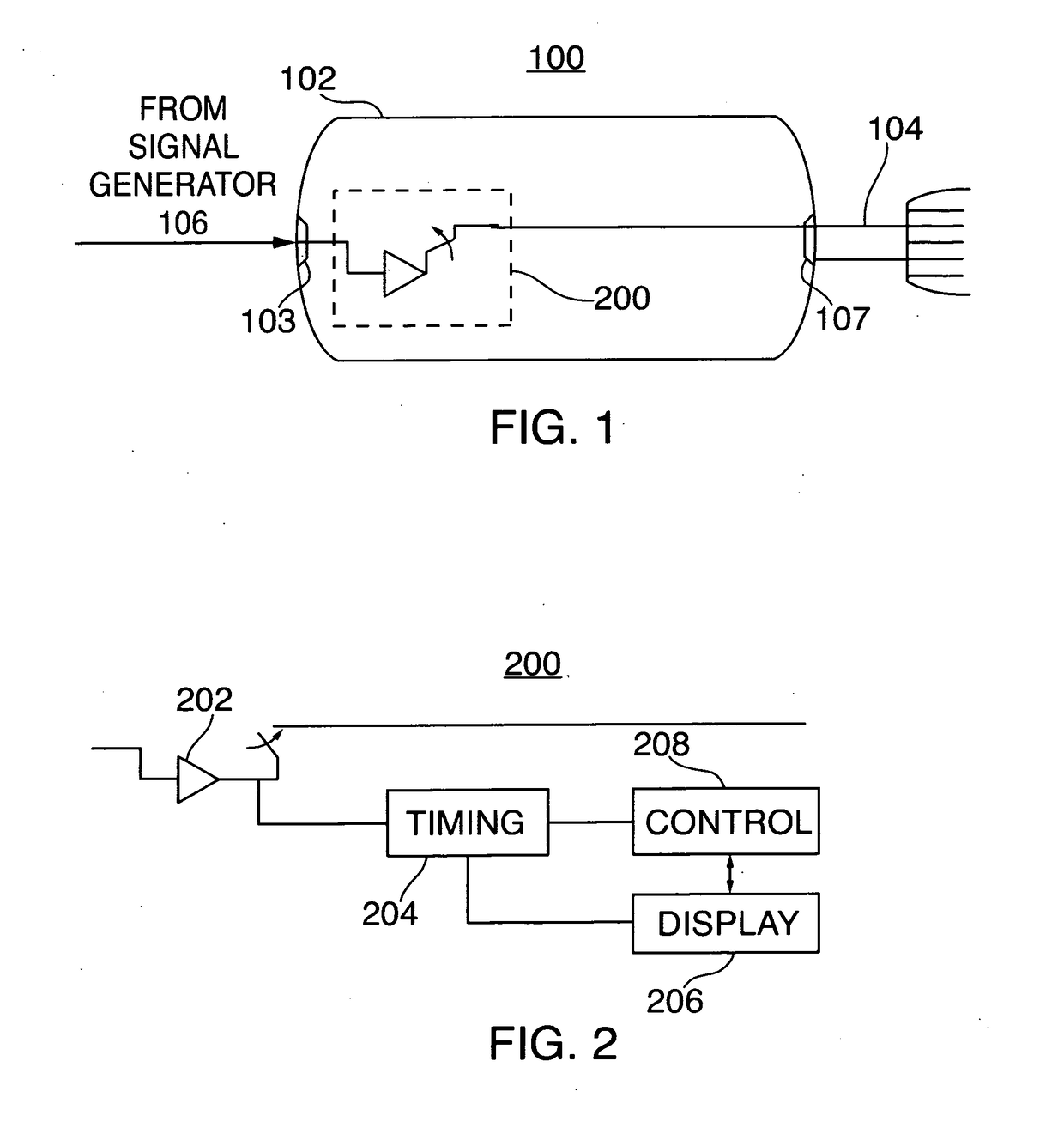

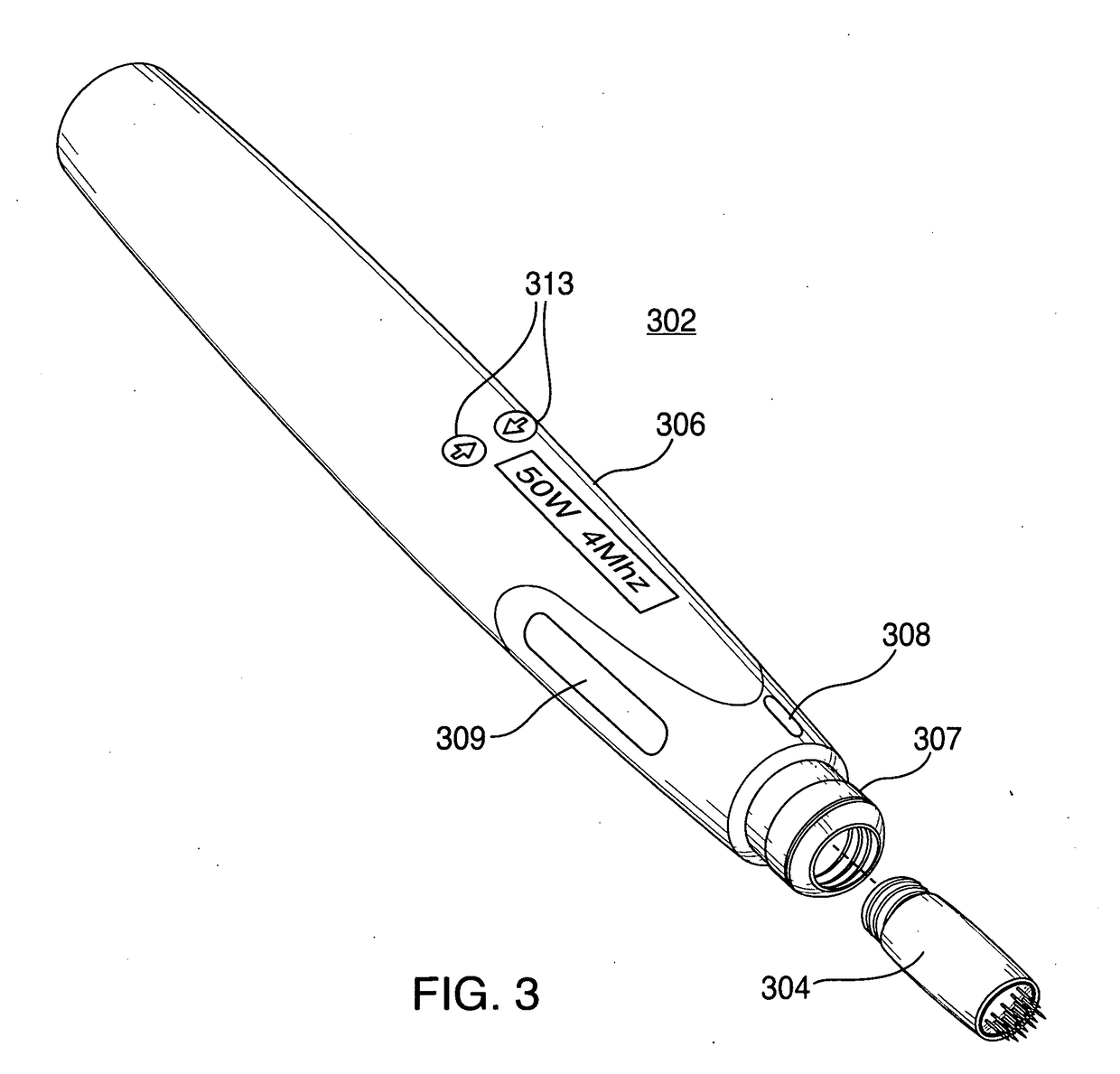

Radio frequency handpiece for medical treatments

InactiveUS20170112568A1Facilitate providing an optimal and comfortable therapyImprove efficiencySurgical needlesSurgical instruments for heatingMedical departmentSignal generator

Aspect of the inventions may include a universal handpiece that can be coupled to pre-existing legacy RF signal generator systems to provide certain precision controlled radiofrequency therapies and treatments for skin. Further, another embodiment of the present invention may include an interchangeable electrode (tip section) with an array of distally insulated microneedles, conductive pads or smooth surface configurations which couple to the handpiece for allowing for heating of dermis without damage to the superficial epidermis. This allows the handpiece to be used for various different treatment types by changing the tip or electrode section to meet the requirements of a desired therapy, rather than requiring another dedicated handpiece.

Owner:EPSTEIN WENDY

System for manufacturing an inlay panel using a laser

InactiveUS20090014118A1Straightening imperfect linesSimple designLamination ancillary operationsDecorative surface effectsGraphicsLaser fabrication

A method of manufacturing an inlayed panel uses the steps of providing an art master rendering as a decorative design for the inlaid panel; entering into a control computer graphical data corresponding to a plurality of laser cutting paths, first laser cutting a panel in accordance with the graphical data; second laser cutting a panel in accordance with the graphical data to produce a plurality of panel portions; and attaching the plurality of panel portions to a substrate to form the decorative panel. One of the plurality of panel portion then is finished. The step of entering graphical data corresponding to the plurality of cutting paths can be performed on a CAD system to produce machine code for controlling the laser beam. The graphical data can be entered, in some embodiments by scanning electronically the art master to form an art master data file.

Owner:RATCLIFFE BLAKE EDWARD

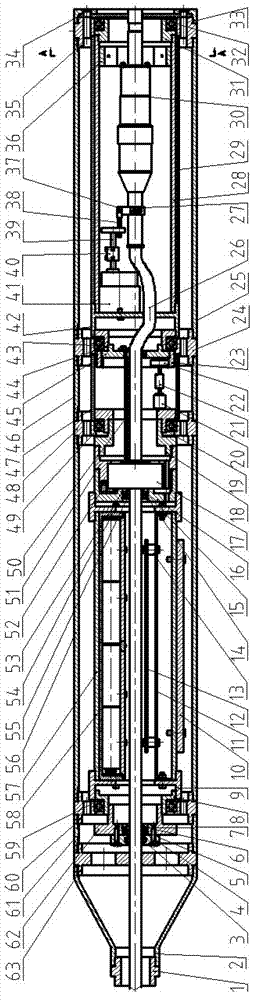

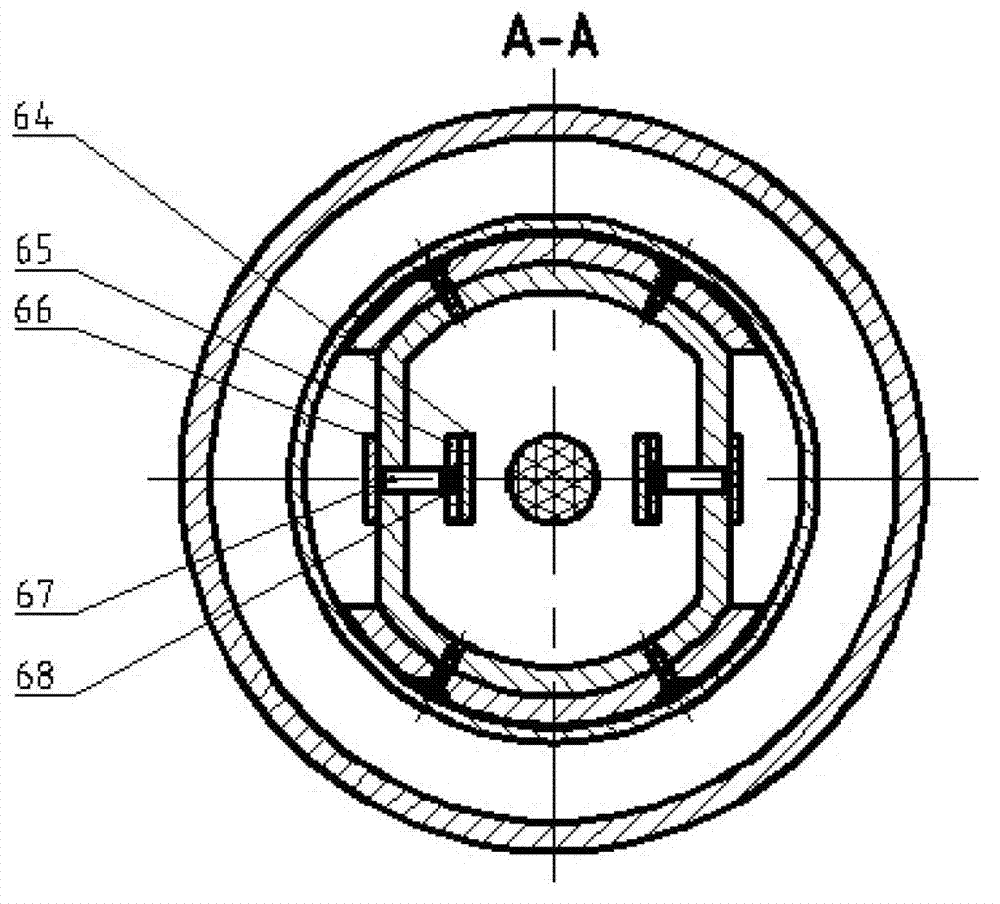

Laser directional drilling tool for coal-bed-methane level development hole and drilling method using same

ActiveCN102808580AReduce consumptionImprove drilling efficiencySurveyDirectional drillingData acquisitionHigh energy laser beam

The invention relates to a laser directional drilling tool for a coal-bed-methane level development hole and a drilling method using the same. The drilling method includes: using high-energy laser beams to rapidly heat local coal rock to enable the coal rock to break due to excessively high internal stress, and allowing high-speed auxiliary air to bring away debris of the coal rock. The drilling tool comprises a laser emitter, and a deflection control part and a deflection actuating part thereof. The deflection control part of the laser emitter is composed of a battery box, a circuit board and the like. The deflection actuating part of the laser emitter comprises a cam and a gear. The cam controls deflection of the laser emitter. The gear controls overall rotation of the laser emitter. In the drilling method, the drilling tool is lowered into a drill hole to be drilled, drilling is started according to the principle of laser rock crushing, data acquisition, storage and processing are performed simultaneously, and a stepping motor is adjusted to control deflection of the laser emitter so as to automatically and directionally correct the deflection in drilling. The drilling tool and the drilling method are applied to directional drilling for the coal-bed-methane level development hole and are higher in drilling efficiency, better in directional control performance and lower in bit consumption.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com