Automatic fruit screening and casing device

An automatic screening and fruit technology, applied in sorting and other directions, can solve problems such as low fruit prices, weak fruit market competitiveness, and small export volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

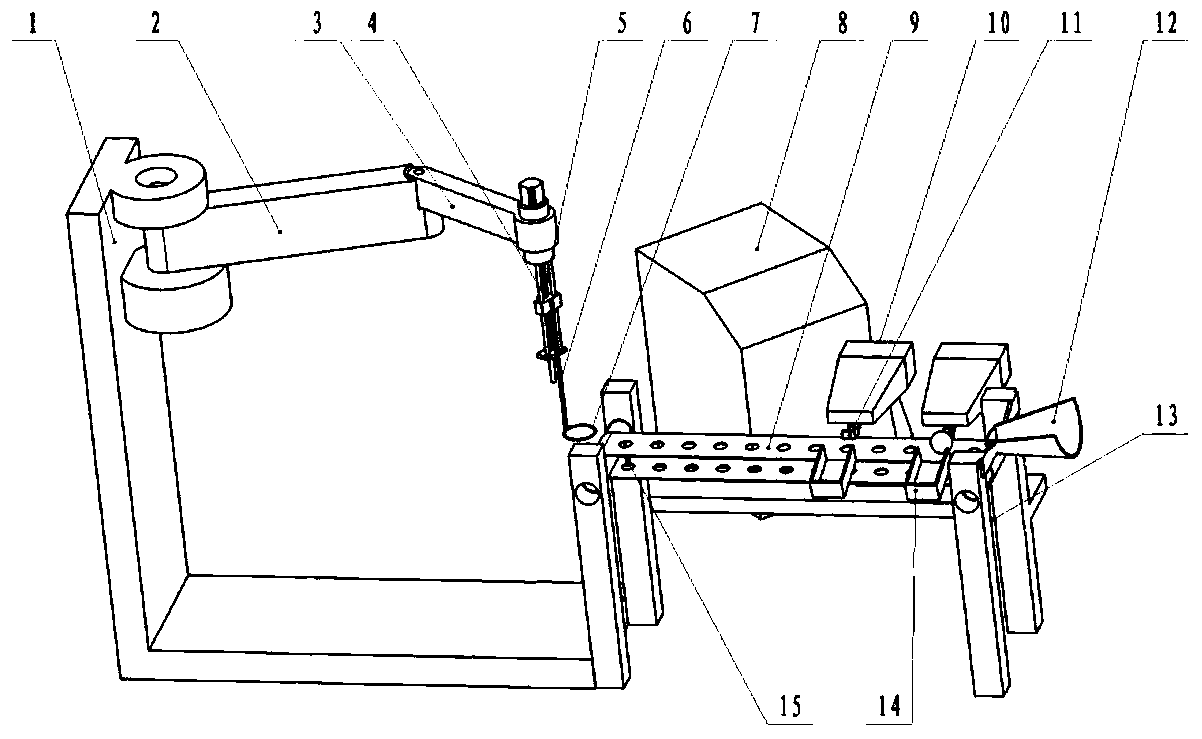

[0008] The present invention is realized by the following technologies: an automatic fruit screening and boxing device, which consists of a bottom plate 1, a moving arm 2, an adjusting arm 3, a guide rail 4, a lead screw 5, a connecting frame 6, an air bag expansion hand 7, and a control cabinet 8 , a conveyor belt 9, an infrared device 10, a push rod 11, a fruit tray 12, a platform 13, a receiving tray 14, and a photoelectric sensor 15; it is characterized in that: the movement arm 2 is installed above the bottom plate 1, and the adjustment arm 3 is connected to the movement arm 2 Together, the guide rail 4 is fixed under the adjustment arm 3, the lead screw 5 is fixed in the end hole of the adjustment arm 3 by the bearing, one end of the connecting frame 6 is set on the two guide rails 4, and the other end is connected to the air bag expansion hand 7, and the control cabinet 8 is located in the whole At the rear of the device, the conveyor belt 9 is set on the platform 13, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com