High-pressure hub casting mold and casting method thereof

A technology for casting molds and hubs, which is applied to the high-pressure wheel hub casting mold and its casting field, can solve the problems of reduced effective utilization rate of molten metal, easy generation of pinholes, air holes, and large machining allowances for wheel hub castings, so as to reduce reserved machining. The effect of reducing the amount of deformation of the casting and the high utilization rate of the molten metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

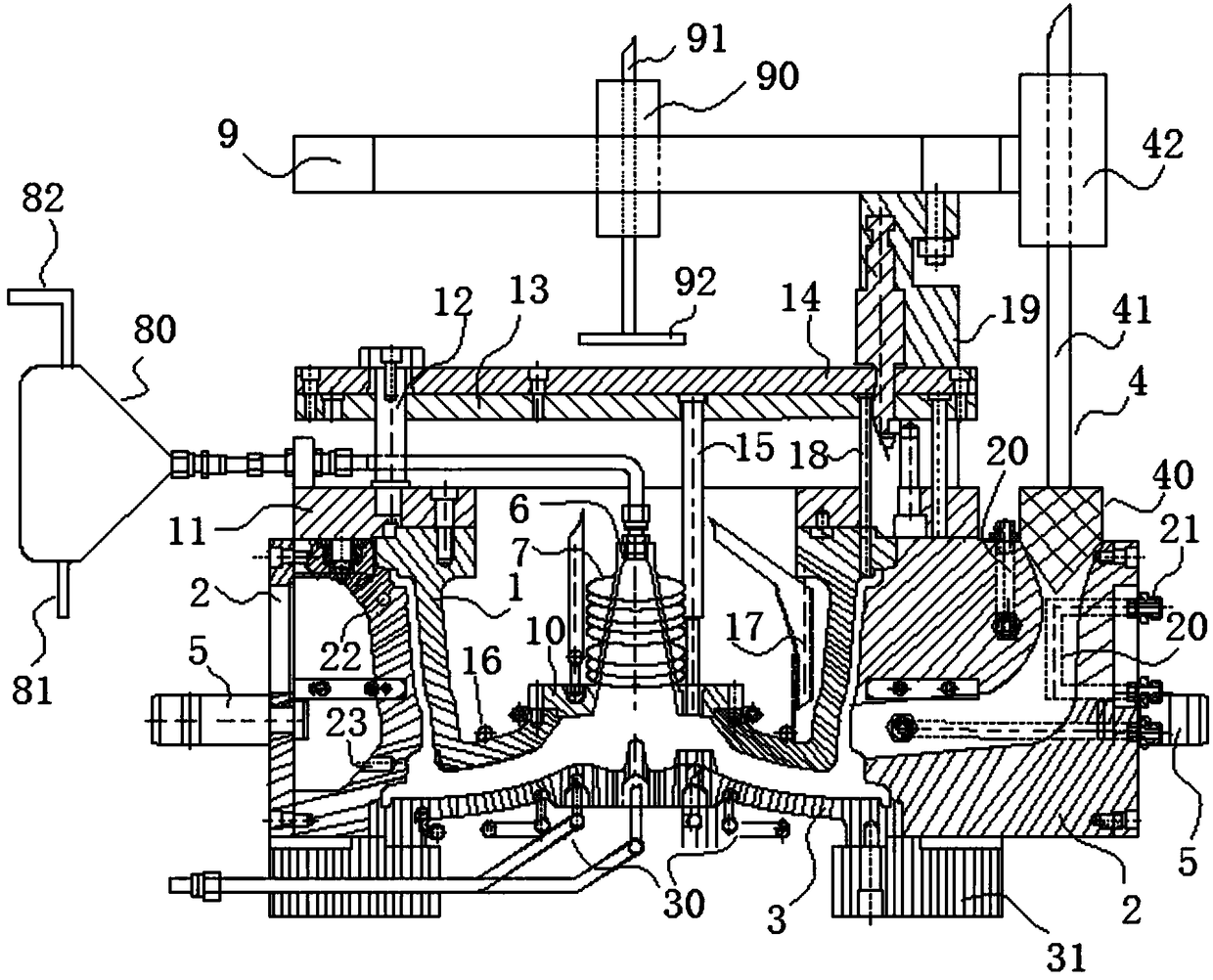

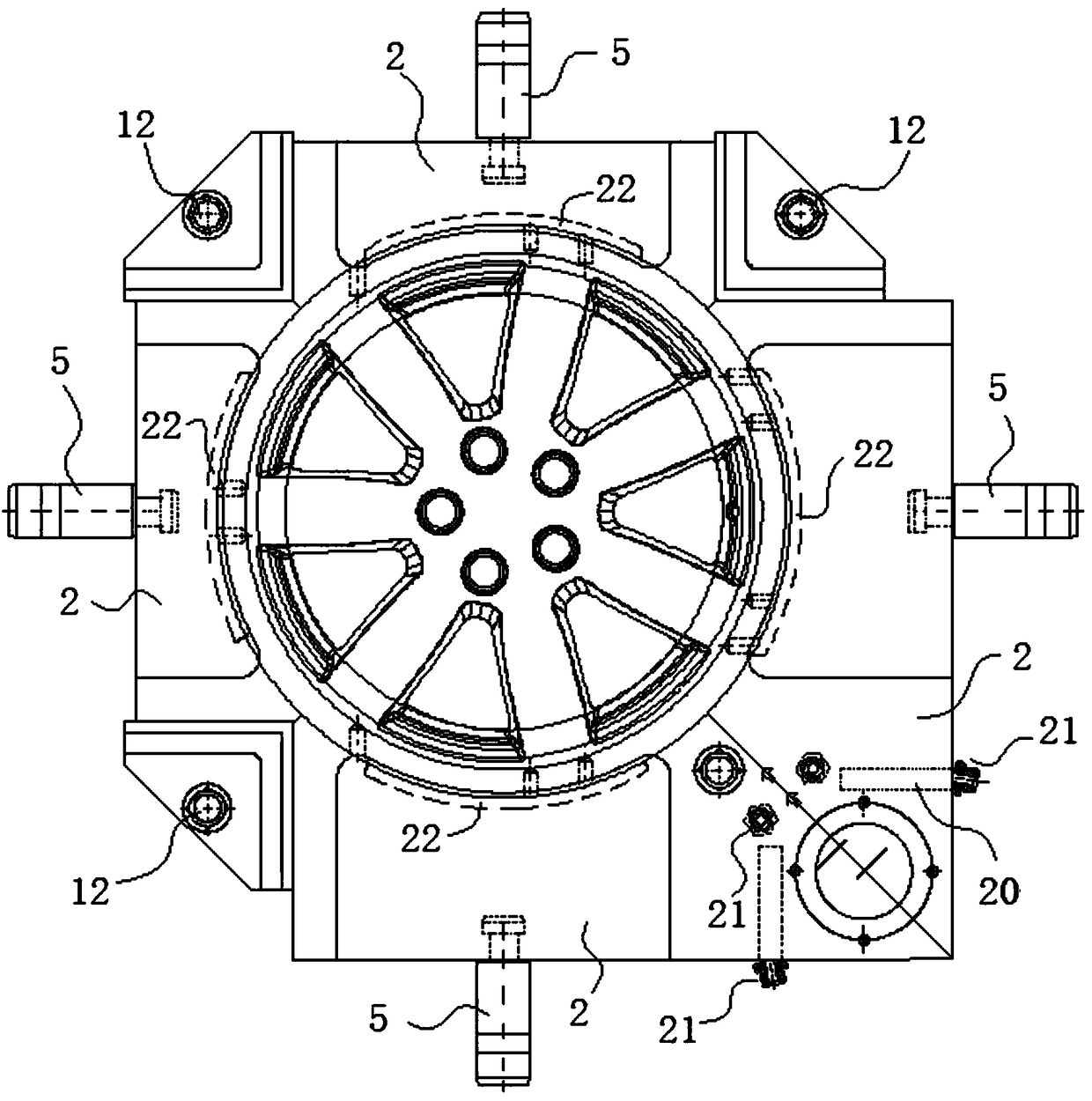

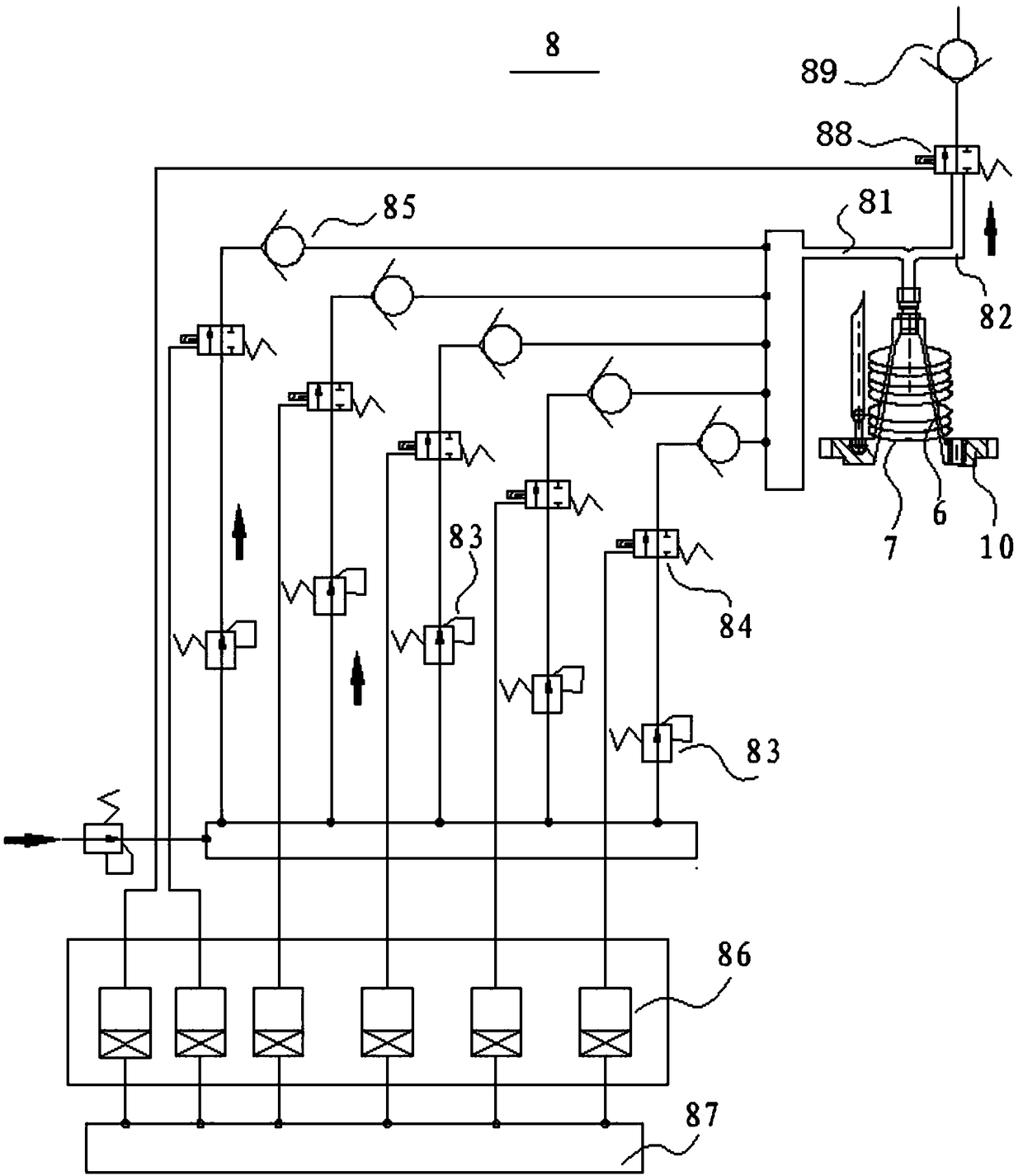

[0060] Such as figure 1 , figure 2 As shown, the high-pressure wheel hub casting mold provided by the present invention is used to be installed on a casting machine to cast a wheel hub, especially for casting a wheel hub of 18 inches and above, including: an upper mold 1, and the upper mold 1 is connected with the connecting parts The top plate of the casting machine is connected; the side mold 2, the side mold 2 is connected with the side mold driving device of the casting machine; the bottom mold 3, the bottom mold 3 is installed on the upper side of the casting machine table; the side mold of the casting machine The driving device drives the side mold 2 to close the mold horizontally, and the upper mold driving device of the casting machine drives the upper mold 1 to close the mold downward. After the upper mold 1, the side mold 2 and the bottom mold 3 are closed, the casting cavity of the wheel hub to be cast is formed. ; The center of the upper mold 1 is connected with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com