Automatic chip feeder and control thereof

A fully automatic, control box technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as mechanical multi-task scheduling, and achieve the effects of overcoming interface design difficulties, convenient management and construction, and rapid packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the implementation of the present invention is not limited thereto.

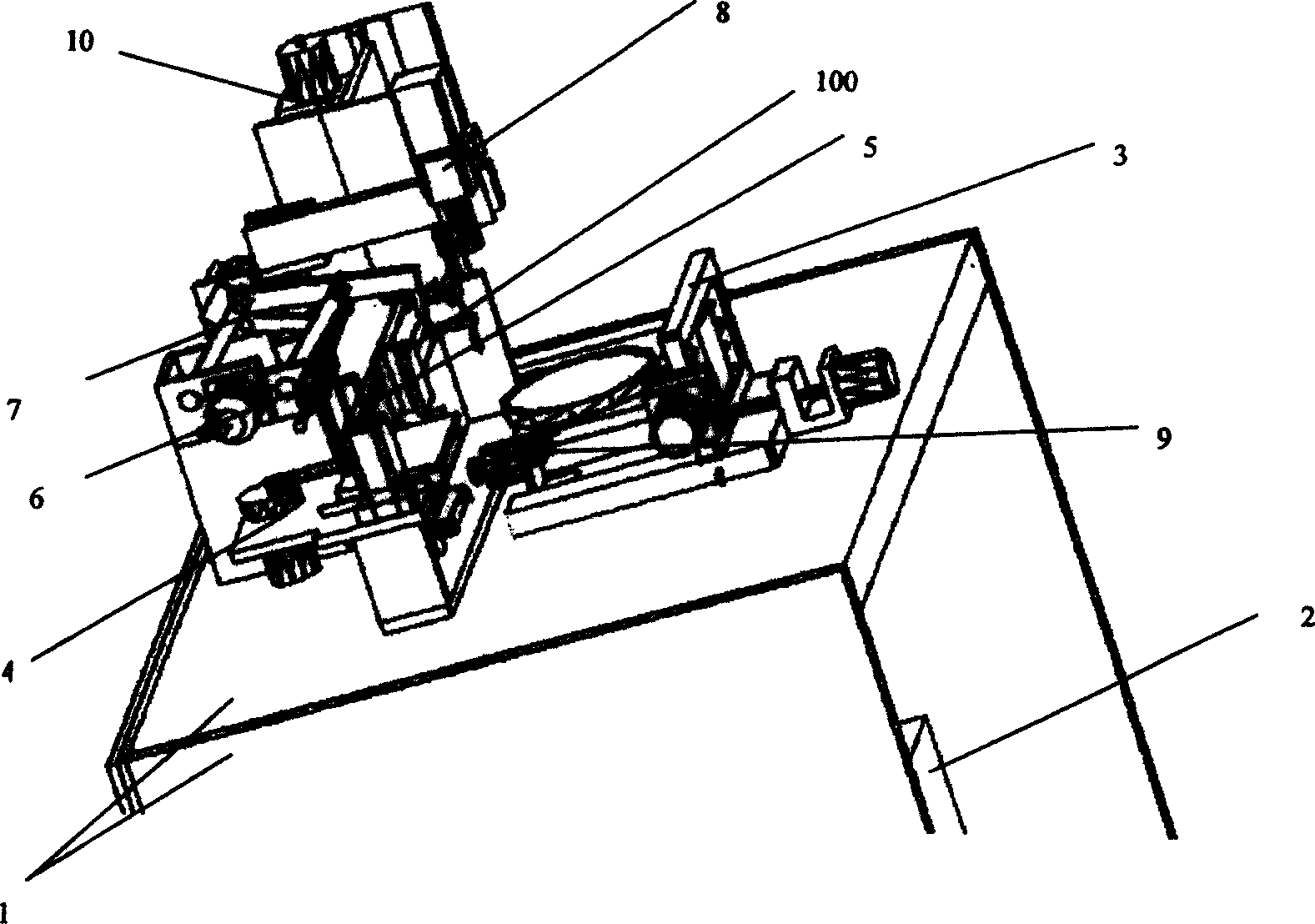

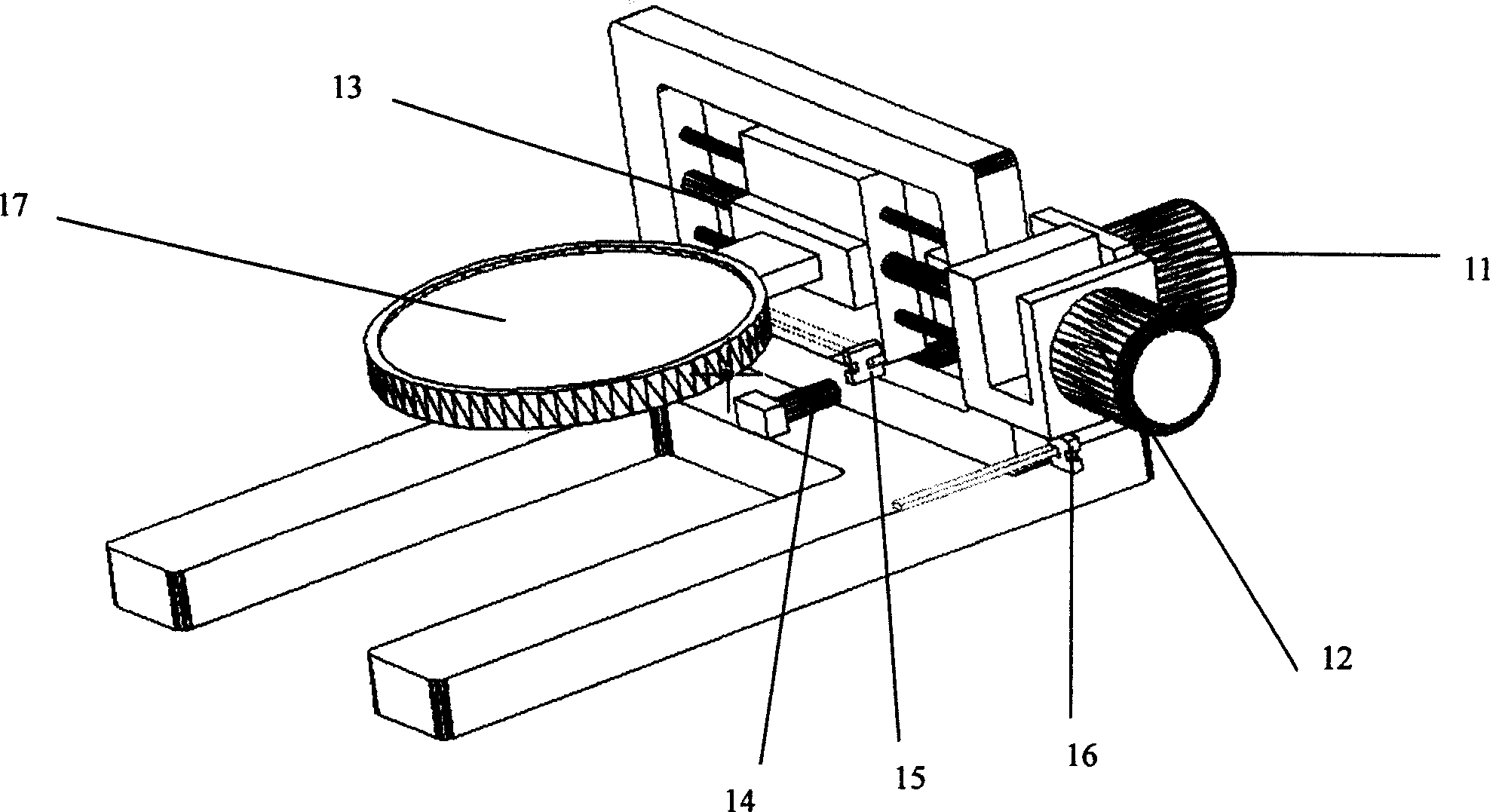

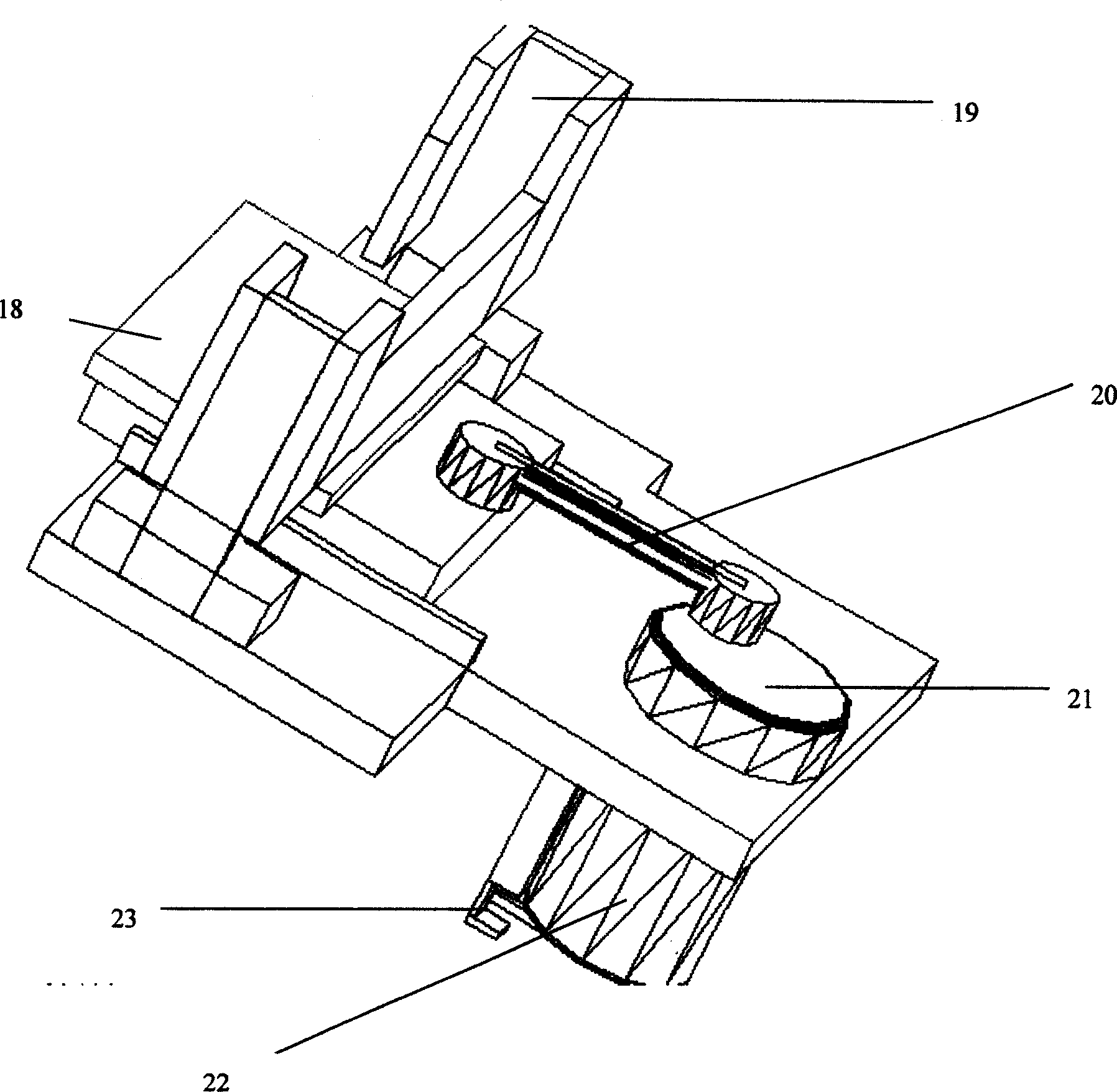

[0038] Such as figure 1As shown, the fully automatic core loading machine described in this embodiment includes a frame 1, a control box 2 is fixed at the lower end of the frame 1, a wafer table 3 and a feeding chute 5 are installed on the top, and the wafer table 3 is connected with a thimble 9, and the feeding chute 5 The two ends are respectively connected with a feeder 4 and a feeder 10, and are connected with a claw 6 and a welding arm 7, an image acquisition device 8 is installed above it, a heater 100 is installed below it, and the image acquisition device 8 is connected with the control box. connected to the control circuit. Among them, the frame 1 provides a stable operation platform for the whole machine, and at the same time protects the control box 2; the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com