System used for automatically detecting and sorting work pieces

An automatic detection and workpiece technology, applied in sorting and other directions, can solve the problems of time-consuming and labor-consuming, high re-inspection rate, affecting the sales and use of workpieces, and achieve the effect of saving manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

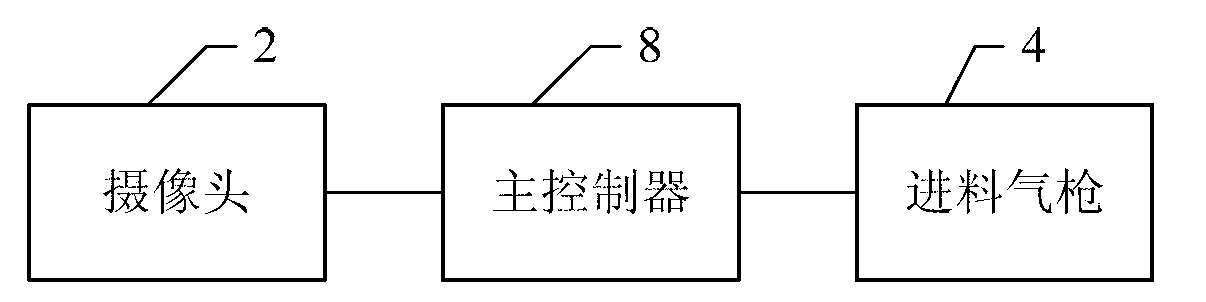

[0026] figure 1 with 2 An embodiment of the system for automatically detecting and sorting workpieces is shown, the system includes: a conveying device 1, an image device (not shown), a feed air gun 4, a qualified product collection box 61, and a defective product recovery box 62 , a recovery box 63 for the product to be tested, a packaging machine 7 , a processor 8 and a feeding device 9 . The specific structure of these components and the connection relationship between them are as follows:

[0027] The conveying device 1 is connected with the feeding device 9 , so that the workpieces 5 are sequentially output from the outlet of the feeding device 9 to the top surface of the conveying device 1 . Wherein, a scraper 91 is provided above the discharge port of the feeding device 9 to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com