Rapidly packaged double-sided soft lithium-air battery and preparation method thereof

A lithium-air battery, fast technology, applied in the direction of battery electrodes, battery pack parts, battery box/coating, etc., can solve the problem of reducing the gas exchange rate between oxygen and air positive electrodes, the regional capacity cannot be effectively utilized, and the positive electrode reaction is uneven To avoid the use of heat sealing process, prevent volatilization and penetration of external water vapor, and reduce the exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

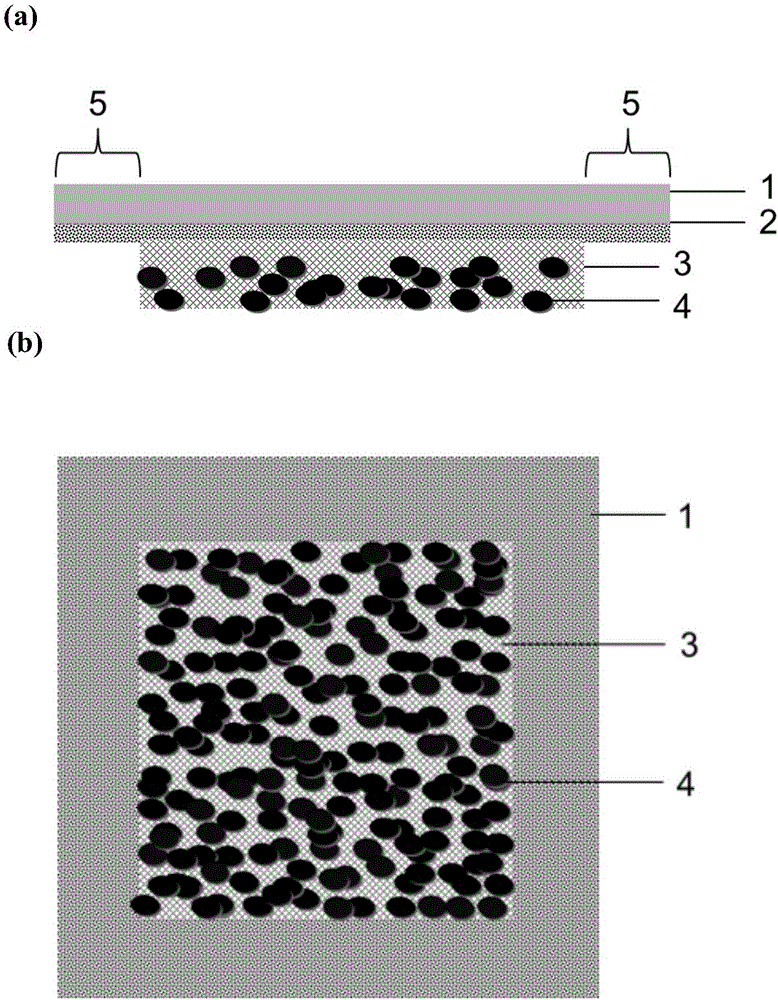

[0035] (1) The surface of one side of the breathable membrane is evenly coated with a pressure-sensitive adhesive layer: Coat the polytetrafluoroethylene emulsion on the glass fiber cloth, after drying and sintering, activate the one side, and apply a coating on the activated surface. The cloth machine is coated with a silicone pressure-sensitive adhesive layer, and the thickness of the silicone pressure-sensitive adhesive layer is 10 μm;

[0036] (2) Positive electrode current collector loaded positive electrode material: configure Super P: PTFE slurry with a mass ratio of 8:2, spray the slurry on the surface of one side of the 55 μm thick aluminum mesh by spraying, and control the carbon load to 10 mg / cm 2 , put it into the muffle furnace after rolling, and keep it warm at 350°C for 30min;

[0037] (3) The air-permeable film and the positive electrode current collector are bonded through the pressure-sensitive adhesive layer: the sides of the upper and lower air-permeable fi...

Embodiment 2

[0042] (1) The surface of one side of the breathable membrane is uniformly coated with a pressure-sensitive adhesive layer: select a 100 μm thick polytetrafluoroethylene single-stretched film, activate one side, and coat the activated surface with a coating machine. Silicone pressure-sensitive adhesive layer, the thickness of the silicone pressure-sensitive adhesive layer is 15 μm;

[0043] (2) Positive electrode current collector loaded positive electrode material: configure carbon nanotubes: PTFE slurry with a mass ratio of 9:1, use the coating method to spray the slurry on one side of the 90 μm thick carbon paper, and control the carbon load to 5mg / cm 2 , after being hot-pressed at 200°C 10Mpa, put it into the muffle furnace, and keep it at 350°C for 30min;

[0044] (3) The air-permeable film and the positive electrode current collector are bonded through the pressure-sensitive adhesive layer: the sides of the upper and lower air-permeable film coated with the pressure-se...

Embodiment 3

[0049] (1) Evenly coat the pressure-sensitive adhesive layer on one side of the gas-permeable membrane: first, activate the 150 μm polyvinylidene fluoride membrane on one side, and apply a butyl acrylate pressure-sensitive adhesive layer on the activated surface with a coating machine , the thickness of the adhesive layer is 30 μm;

[0050] (2) Current collector loaded positive electrode material: configure graphene: PTFE slurry with a mass ratio of 9:1, use the coating method to evenly coat the slurry on one side of the 90 μm thick carbon paper, and control the carbon load to 3mg / cm 2 , put it into the muffle furnace after being hot-pressed at 200°C 10Mpa, and keep it warm at 350°C for 30 minutes, then put the pole piece into the condensation sputtering apparatus, load gold nanoparticles by sputtering deposition method, and the current size is controlled at 10mA, deposition time is 80s;

[0051] (3) The air-permeable film and the positive electrode current collector are bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com