Method of packing liquid filling into spouted pouch and sealing the pouch and apparatus therefor

A content, spouted bag technology, applied in packaging, liquid materials, packaging protection, etc., can solve the problems of deterioration of deoxidation rate, overflow, easy generation of bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

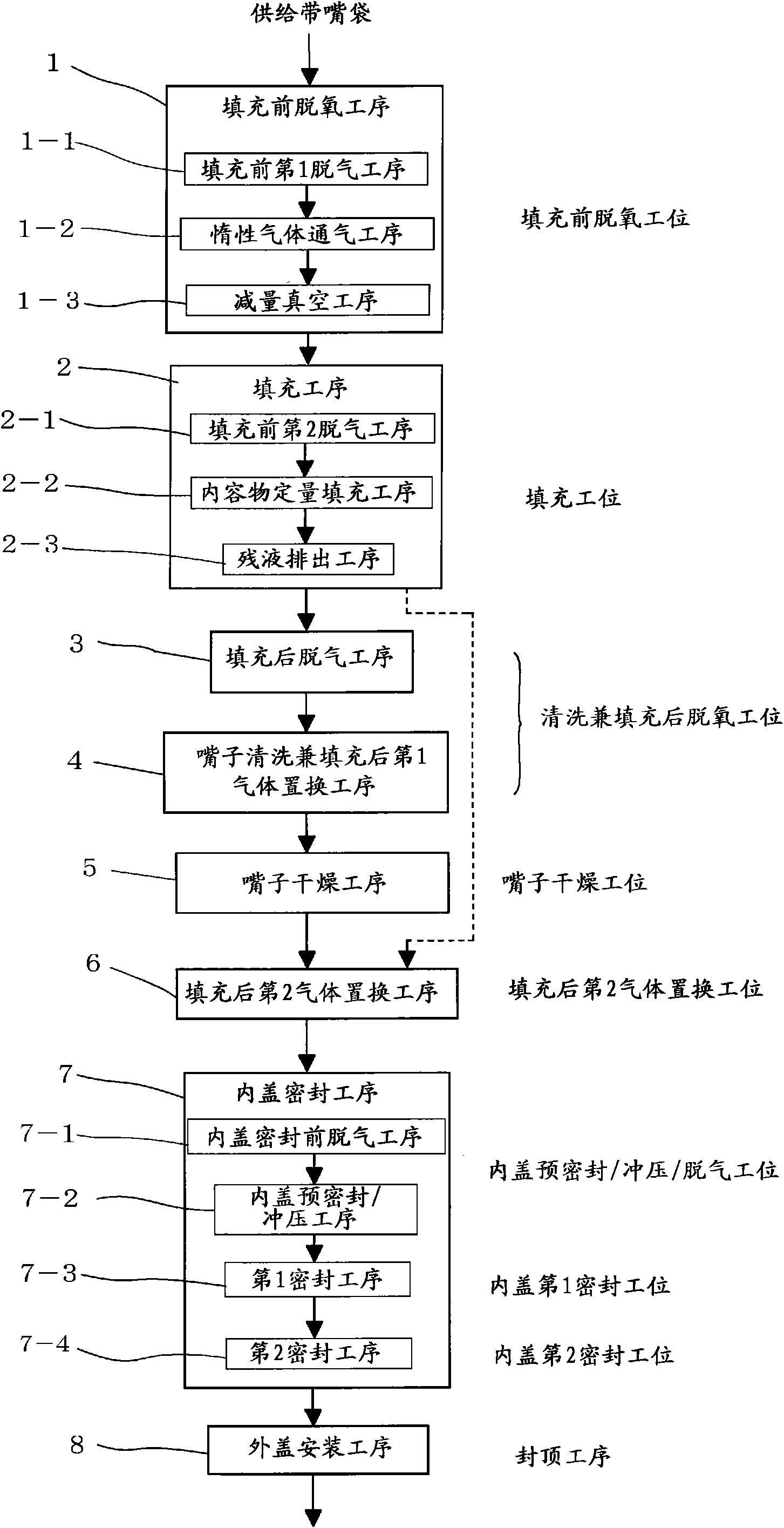

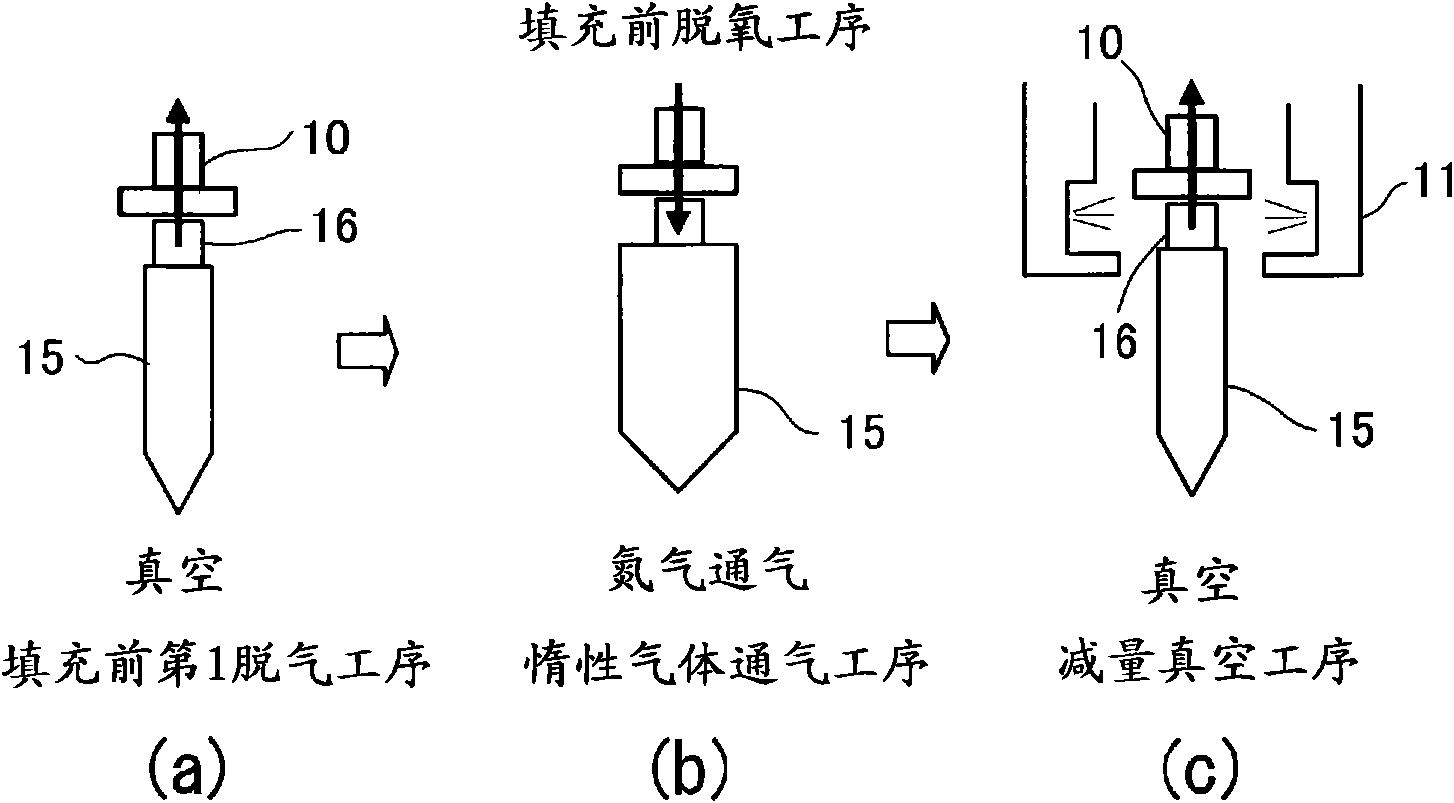

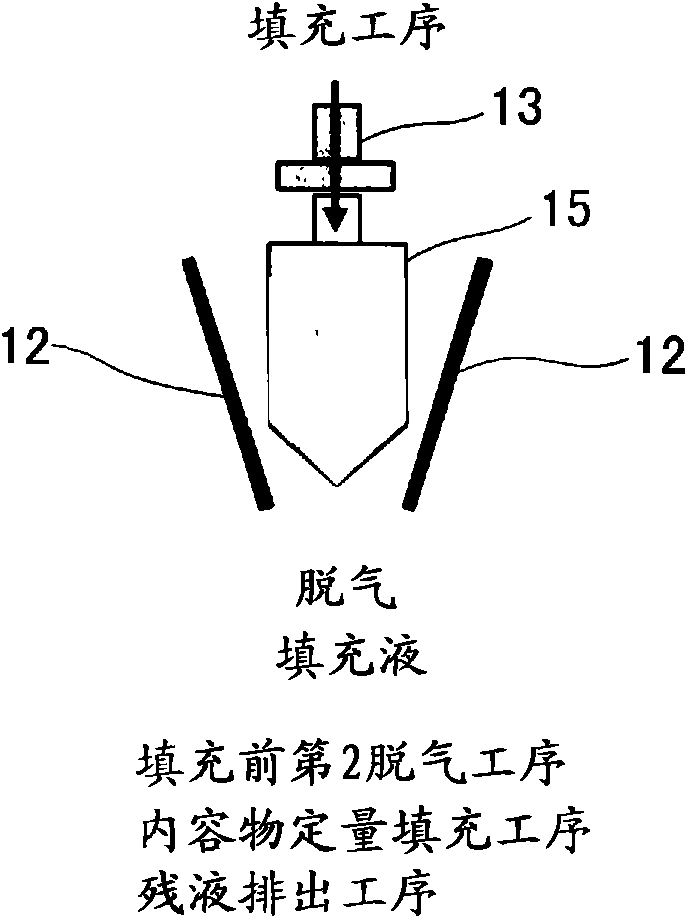

Method used

Image

Examples

Embodiment

[0052] In order to confirm the deoxidation effect brought about by installing the deoxidation process before filling, the following experiment was carried out.

[0053] The experiment is shown in Table 1. Among the first degassing process, inert gas ventilation process, and degassing process in the pre-filling deoxygenation process, only the first degassing process and the inert gas ventilation process were performed without the degassing process. Experiment (No.1, No.2), experiment without degassing process in nitrogen atmosphere (No.3), experiment with degassing process in nitrogen atmosphere (No.4), measure the gas content after sealing, Oxygen concentration, oxygen amount, find the replacement rate. All samples were degassed for 0.5 seconds, nitrogen aeration was only performed for 0.03 seconds for No.1, and 0.14 seconds for the others. The results are shown in Table 1. In addition, the data in Table 1 are measured values obtained by directly sealing the pouch without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com