Automatic test packing machine for electronic component

A technology for electronic components and automatic testing devices, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of low degree of automation, restricted productivity, shortened production cycle, etc., and achieves compact and orderly working process and high degree of automation. , the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

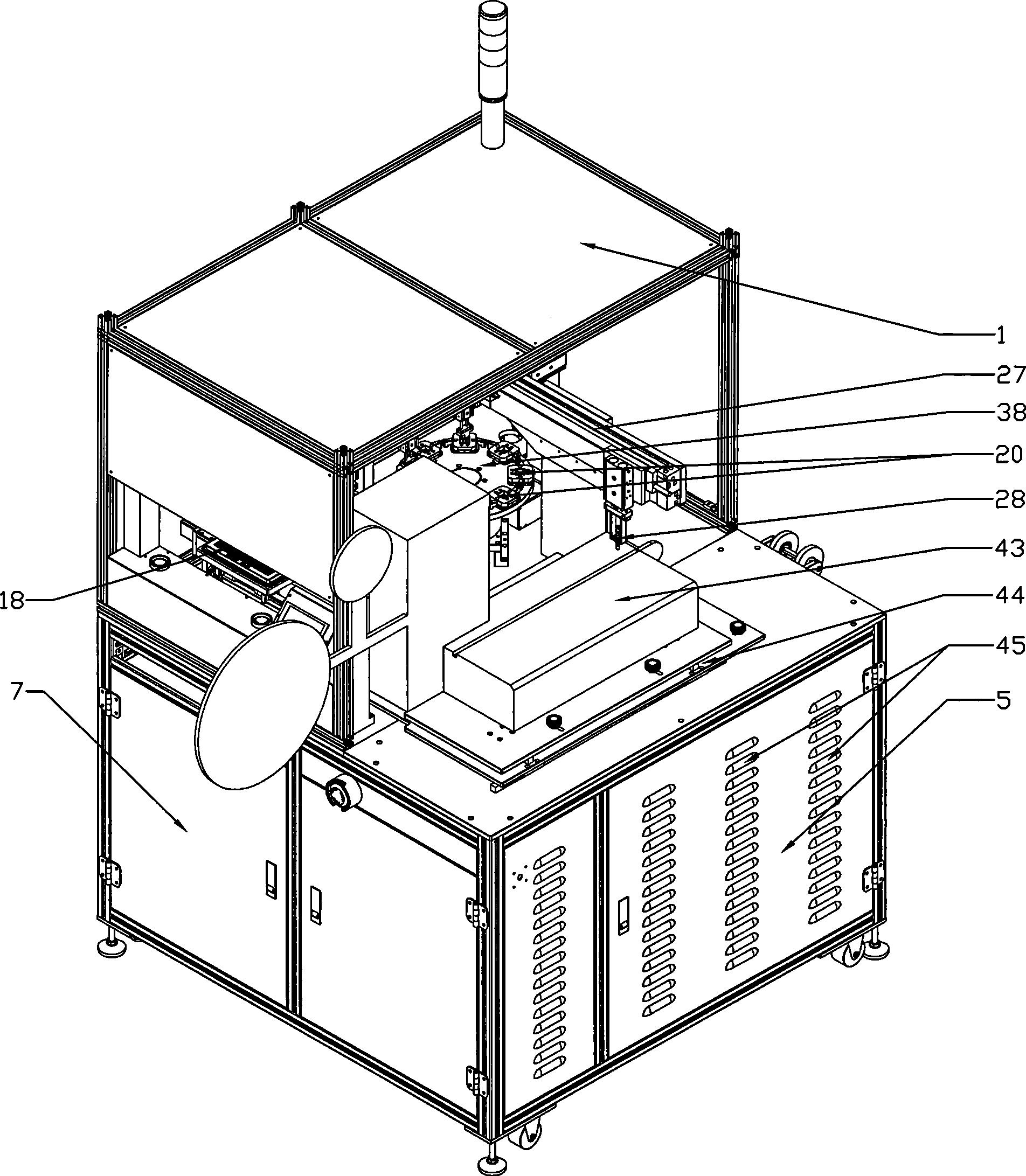

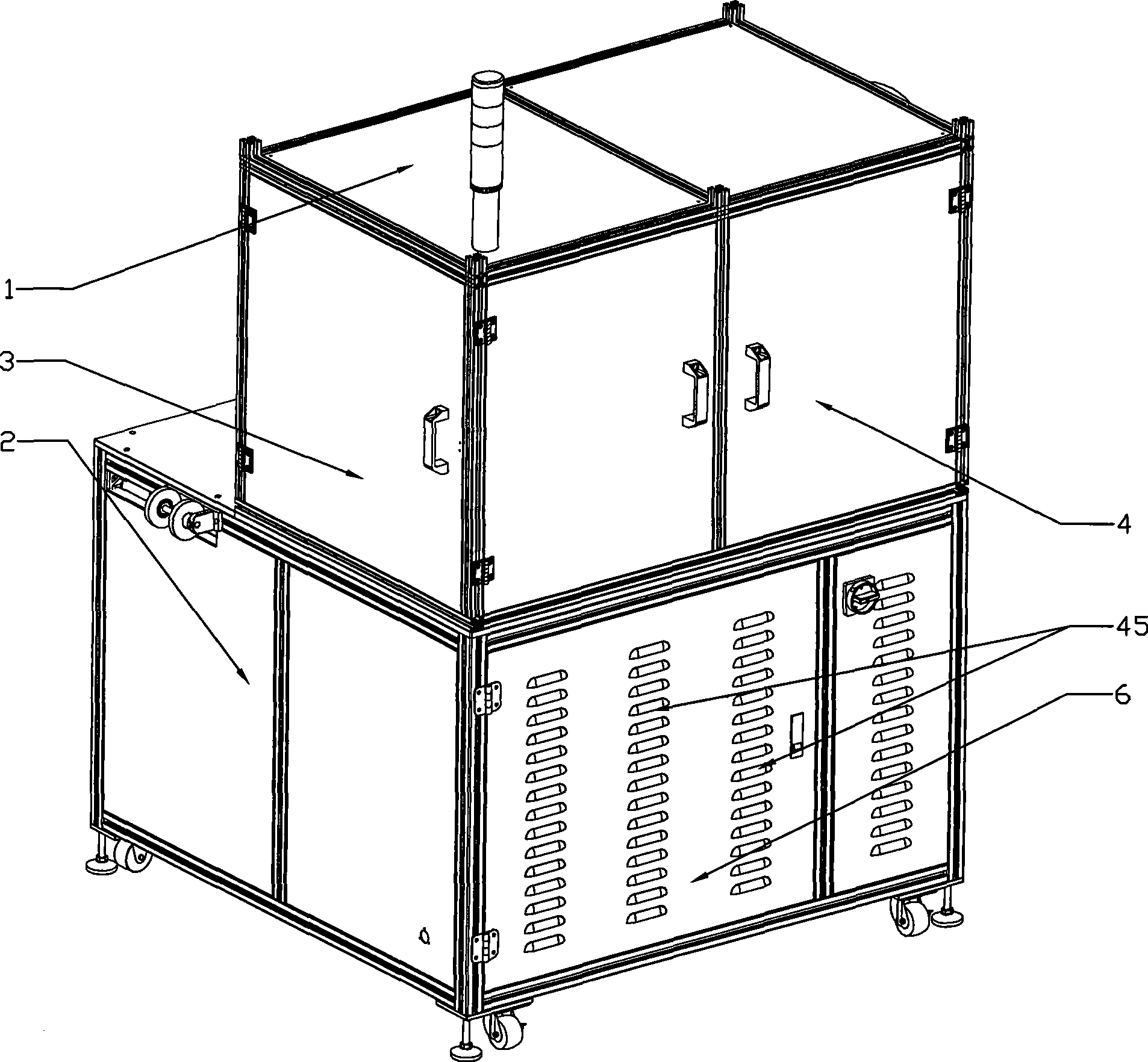

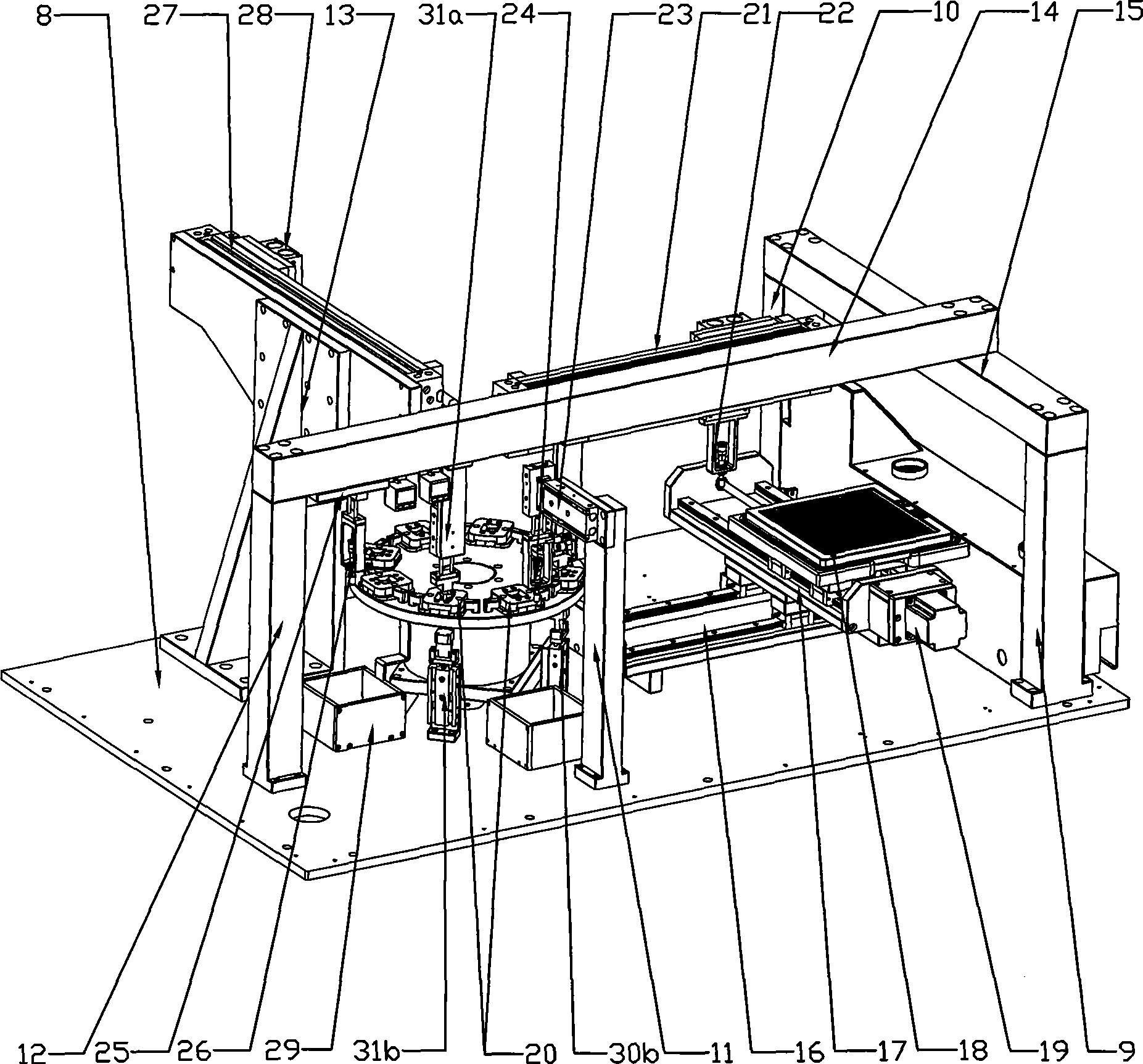

[0017] Such as Figure 1-7 As shown, the present invention includes a protective cabinet 1, an electrical cabinet 2, the protective cabinet 1 is provided with a side cabinet door 3, a rear cabinet door 4, and the electrical cabinet 2 is provided with a front cabinet door 5, a rear cabinet door 6, a side cabinet Door 7, the front cabinet door 5 and the rear cabinet door 6 are provided with ventilation holes 45, the upper end surface of the electrical cabinet 2 is provided with an automatic testing device and a finished product packaging device, and the automatic testing device is in the protective cabinet 1 , the finished product packaging device is outside the protective cabinet 1; the protective cabinet 1 plays a protective role for the automatic testing device, and the side cabinet door 3 and the rear cabinet door 4 can facilitate observation of the testing device And it is convenient to carry out maintenance and repair work, the front cabinet door 5, the rear cabinet door 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com