Online detecting and removing system and method for blasting bead cigarette

A technology of popping beads and cigarette holders, which is applied in the field of online detection and removal system of popping beads, can solve the problems of lowering product quality, leaking popping beads from cigarette holders, poor product consistency, etc., and achieves the effect of guaranteeing experience, improving consistency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

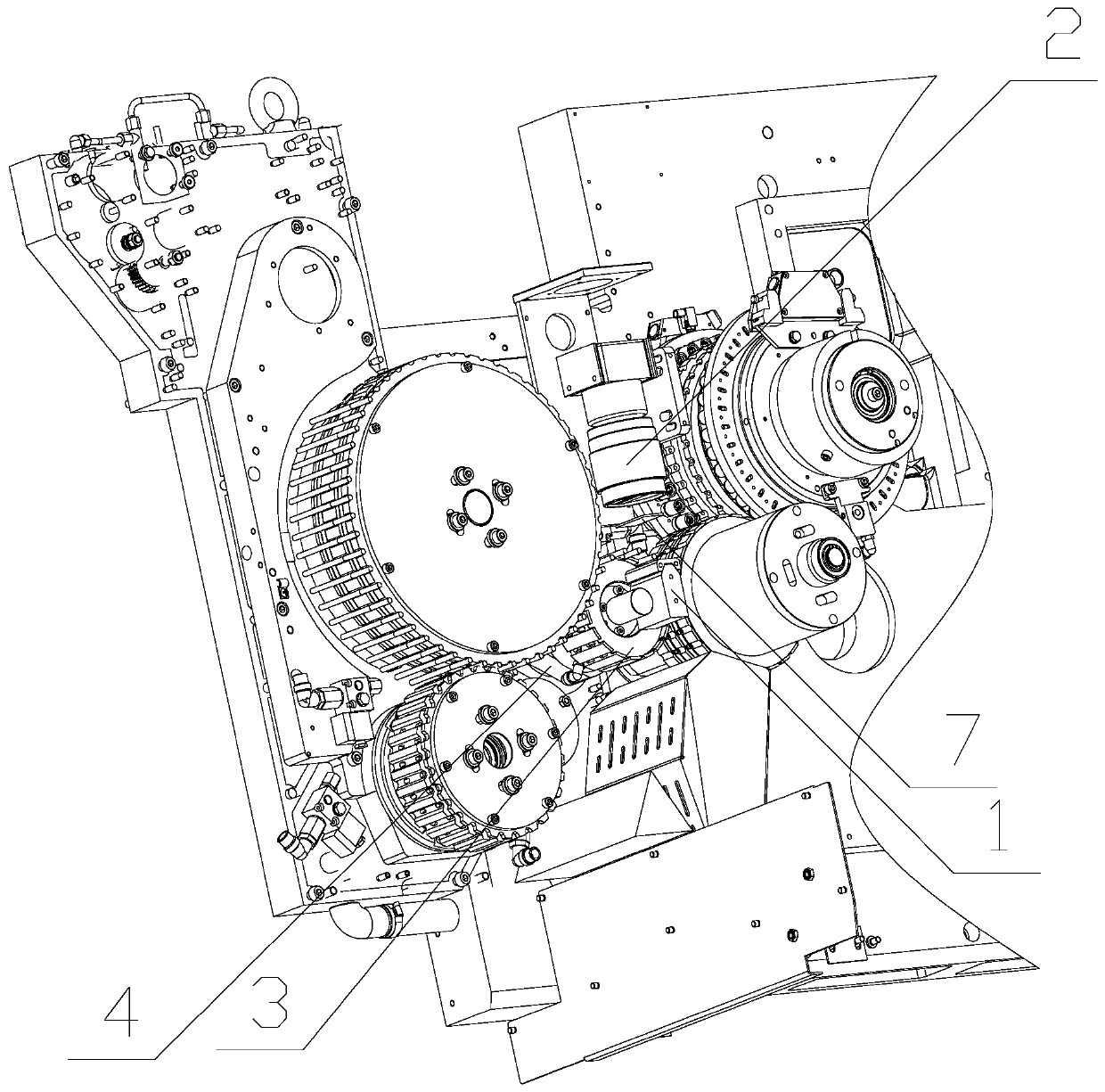

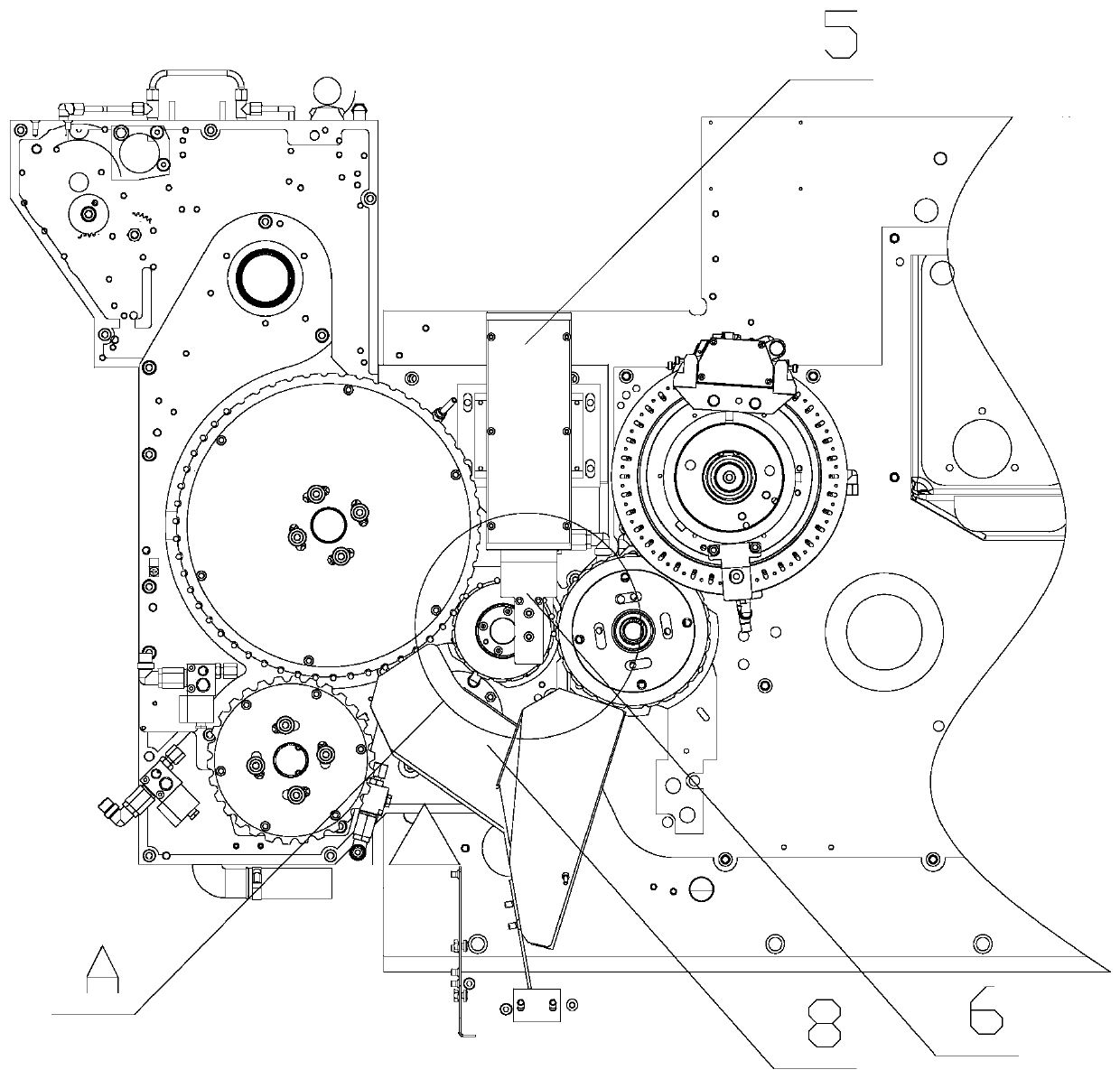

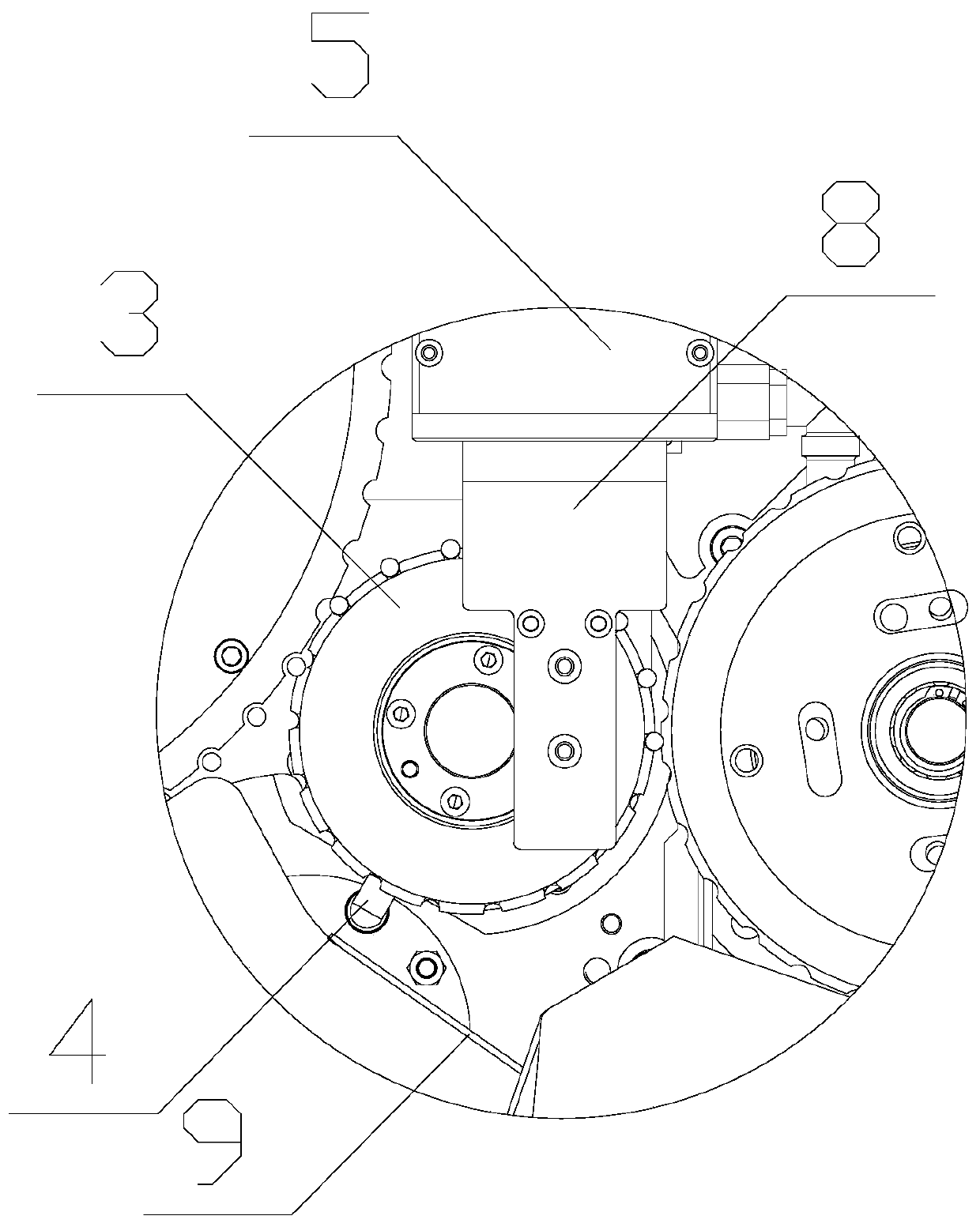

[0041] Such as Figure 1 to Figure 3 As shown, a system for on-line detection and removal of puffed bead smoke includes a light source assembly 1, a CCD imaging assembly 2, a background processing terminal, and a pneumatic removal assembly 4. The radial relative intervals of the smoke wheel 3 are arranged on the outer side of the smoke-distributing wheel 3, and a plurality of smoke grooves for placing explosive beads are evenly spaced on the outer peripheral side wall of the smoke-distributing wheel 3, and the explosive beads One end of the bead stick filter tip of the cigarette protrudes from the smoke groove to the side close to the smoke distribution wheel 3, and when the smoke distribution wheel 3 rotates, the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com