Continuous dust removal device for communication base station

A technology for communication base stations and dust removal devices, which is used in transportation and packaging, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as large operational uncertainty, high manual operation work intensity, and inability to guarantee the quality of dust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

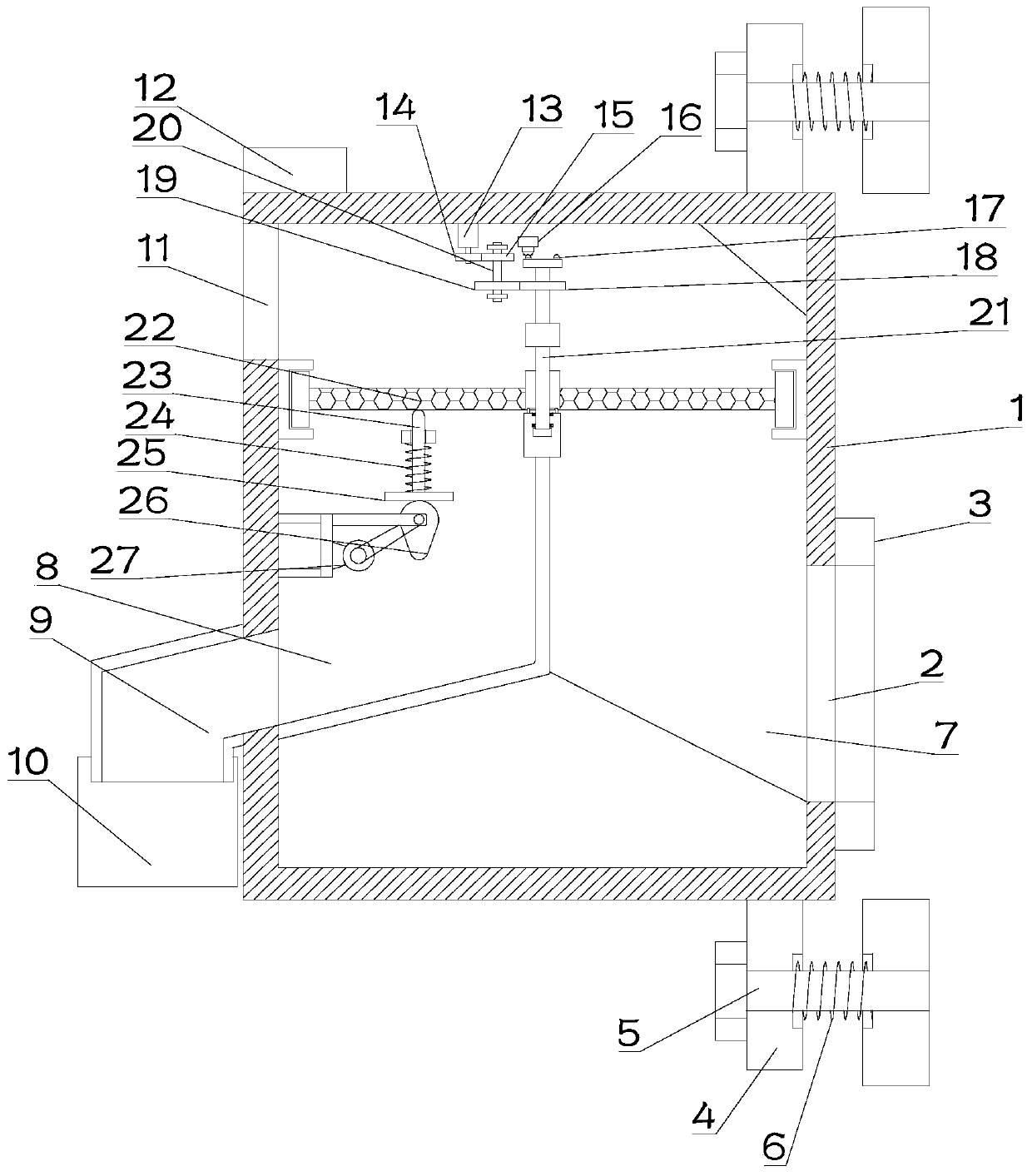

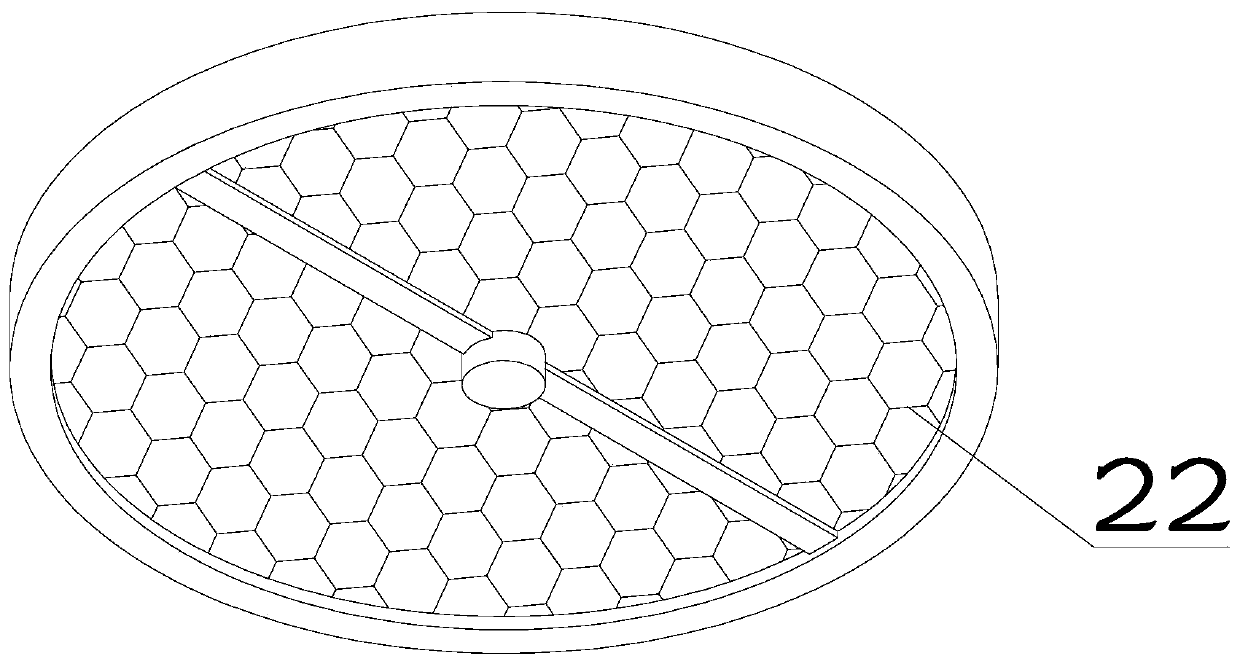

[0023] see Figure 1~3 , in Embodiment 1 of the present invention, a continuous dust removal device for a communication base station includes a dust removal main body 1, and a cavity is arranged inside the dust removal main body 1, and the cavity is divided into a filter chamber 7 and a cleaning chamber 8 by a partition , the filter cavity 7 is used to filter the air, and the cleaning cavity 8 is used to clean the dust on the filter screen; one side of the filter cavity 7 is provided with an air inlet 2, and the filter cavity 7 and the upper end of the cleaning cavity 8 are A filter screen 22 is rotated at the communication port, and an exhaust port 11 is also provided on the dust removal main body 1. The air inlet 2 and the exhaust port 11 are respectively arranged on the upper and lower parts of the filter screen 22. The filter screen 22 It is a circular structure, and is evenly divided into two parts; the inside of the cleaning chamber 8 is provided with a vibrating mechani...

Embodiment 2

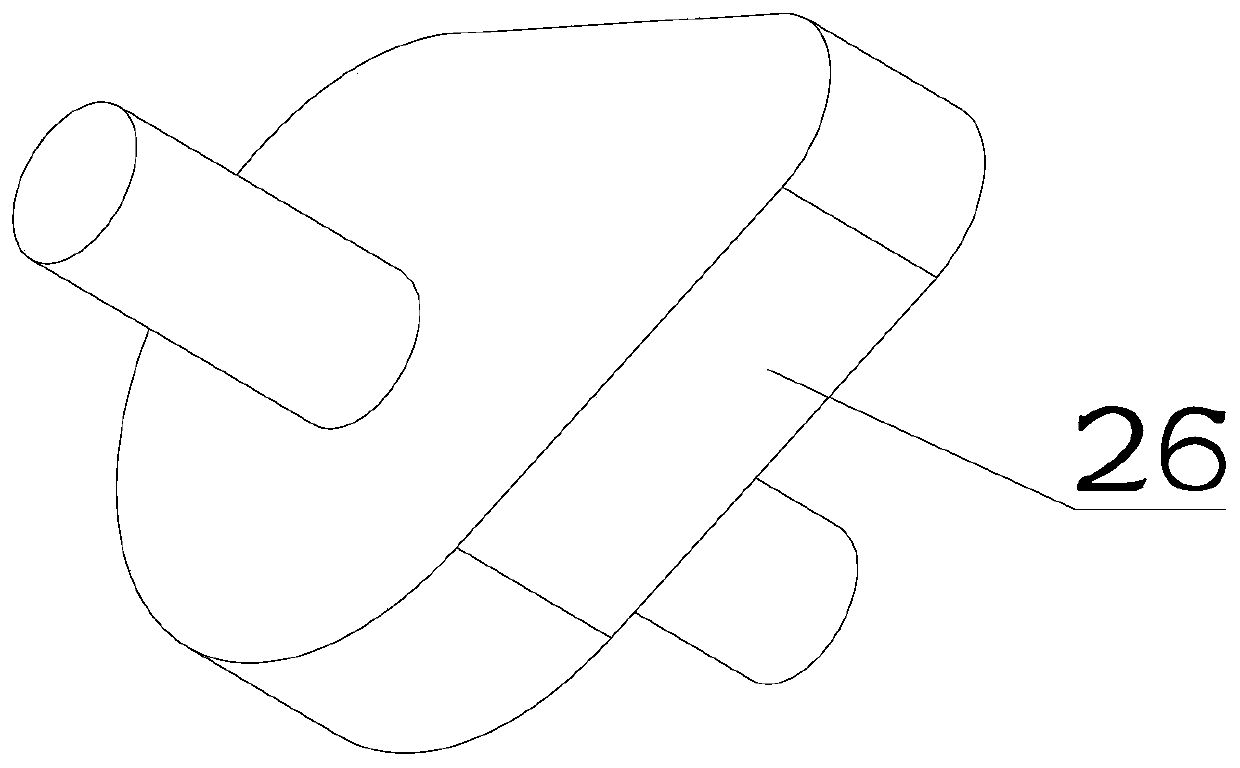

[0025] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the vibrating mechanism includes a vibrating rod 23, the upper end of the vibrating rod 23 is in contact with the bottom of the filter screen 22, and the vibrating rod 23 is set through the through hole on the support block, And the driving block 25 is installed on the bottom of the vibrating rod 23, the outer side of the vibrating rod 23 is sleeved with a B elastic member 24, and the upper and lower ends of the B elastic member 24 are fixedly installed on the supporting block and the driving block 25 respectively, and the supporting block Fixedly installed inside the cleaning chamber 8, the bottom of the drive block 25 is in contact with a cam 26 that drives the drive block 25 to reciprocate up and down, and the cam 26 is fixed inside the cleaning chamber 8 through a bracket, and the cam 26 drives the drive block 25 to drive the vibration The rod 23 reciprocates up and down, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com