Remanufactured blank cleaning device and application method thereof

A cleaning device and remanufacturing technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. Efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

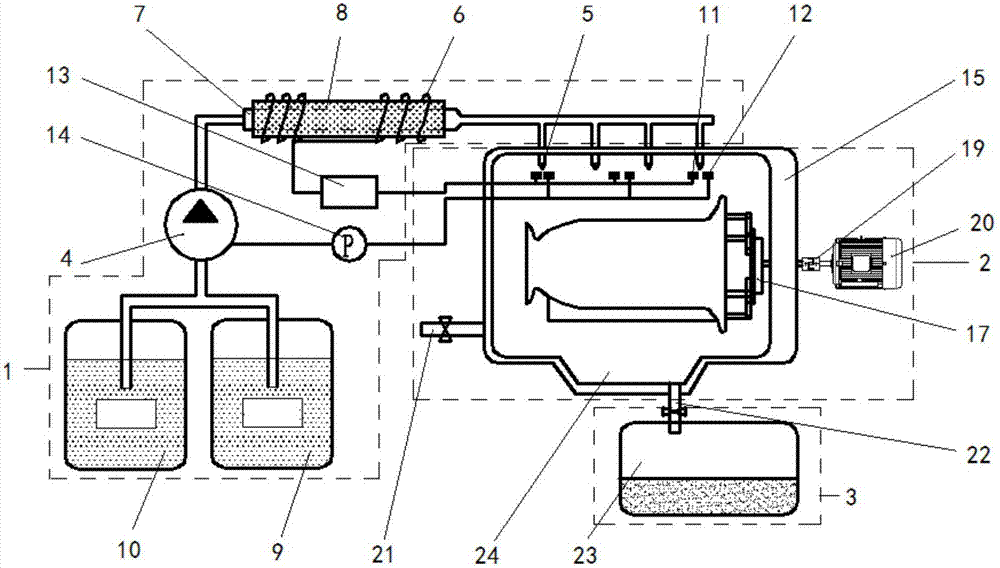

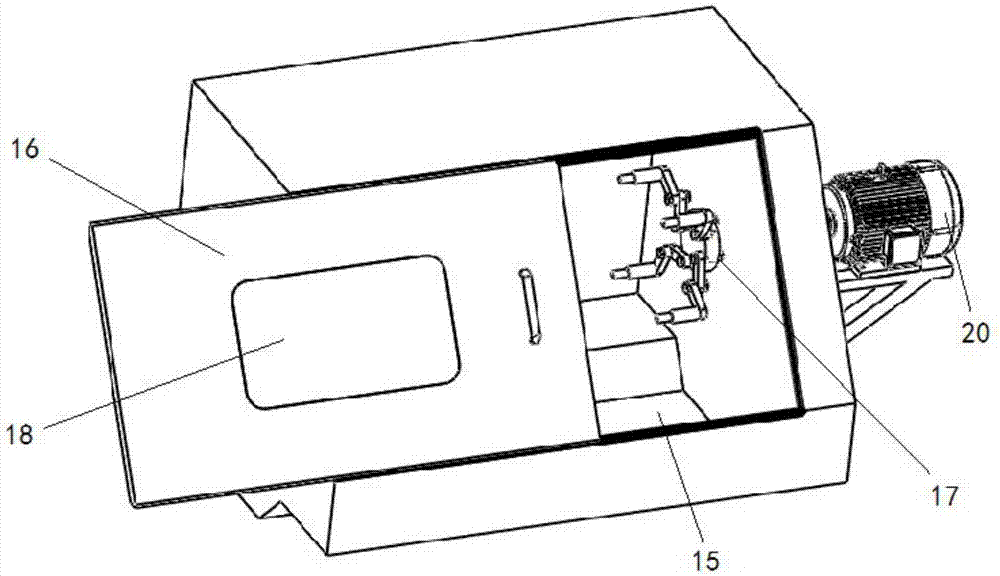

[0035] Embodiment 1: When using the device to clean the engine and remanufacture the blank:

[0036] Step 1: Preferably deionized water with a mass fraction of 60% and n-butanol with a mass fraction of 40% are mixed, then the critical temperature of the water-alcohol two-phase mixed fluid is 320°C, the critical pressure is 12MPa, and the flow rate is 14- The variable pump 4 of 56ml / r is that the deionized water of 60% and the n-butanol of 40% are respectively drawn out from the first liquid collector 9 and the second liquid collector 10 with the mass fraction, pressurized, and Pumped into the electromagnetic heating tube 7, heated to above 320°C by the electromagnetic coil 6 with a power of 10-60kw, and at the same time, the pressure of the water-alcohol mixed fluid at the outlet of the electromagnetic heating tube 7 reaches above 12MPa, forming supercritical water- Alcohol mixed fluid;

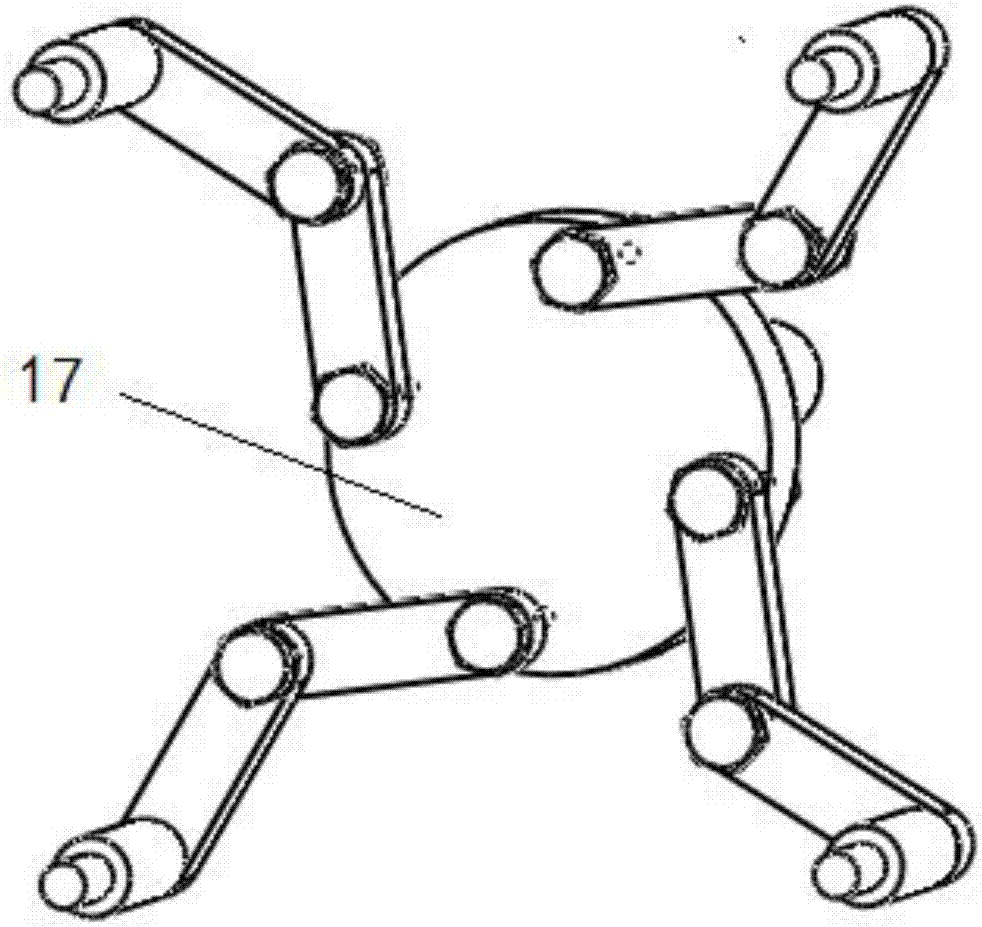

[0037] Step 2: The motor-reducer integrated machine 20 drives the holding mechanism 17 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com