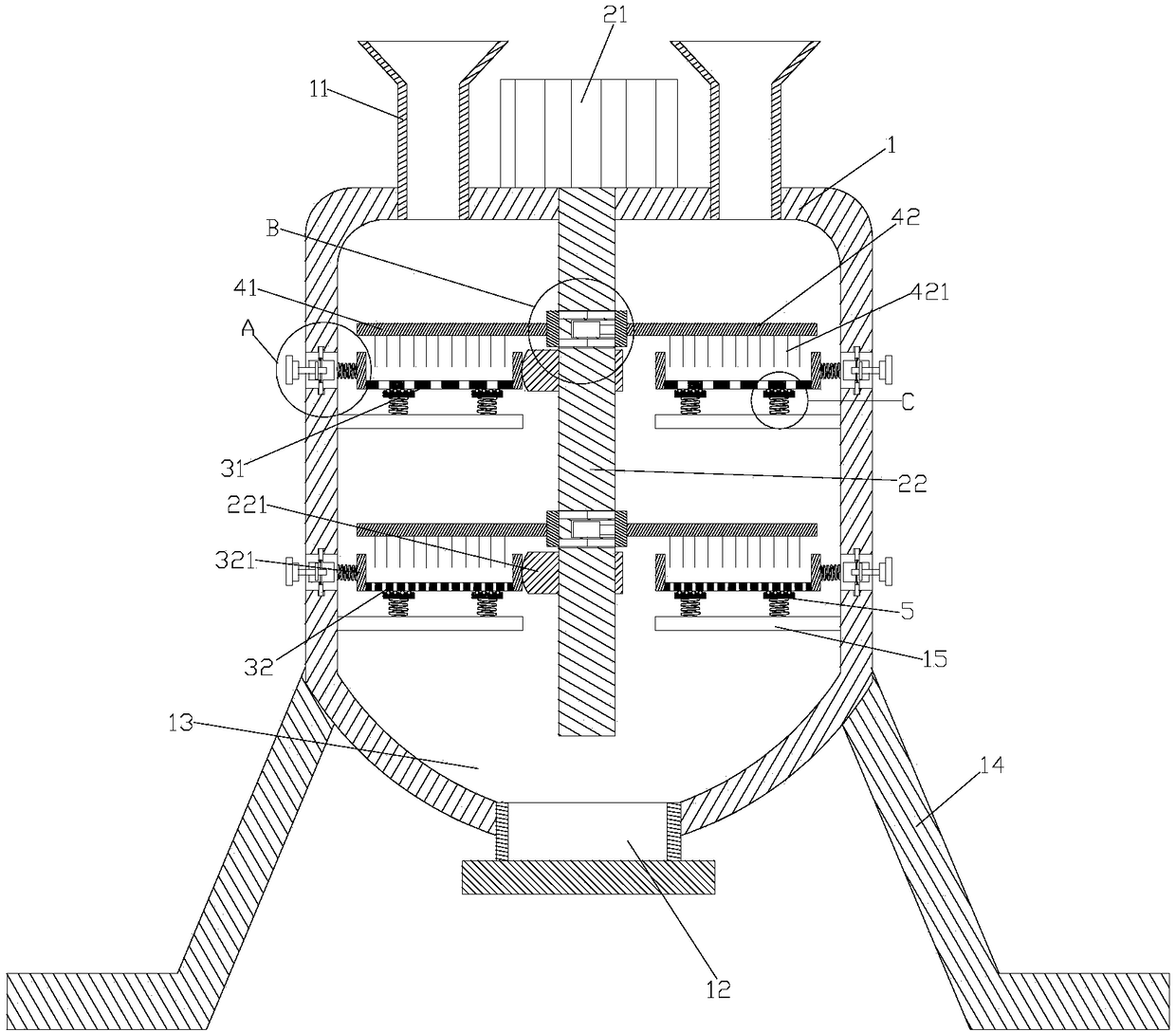

Plastic particle screening device

A screening equipment and technology of plastic particles, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of difficult cleaning of materials, low service life of sieve plates, and easy blocking of sieve holes by plastics, so as to facilitate cleaning and collection, prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

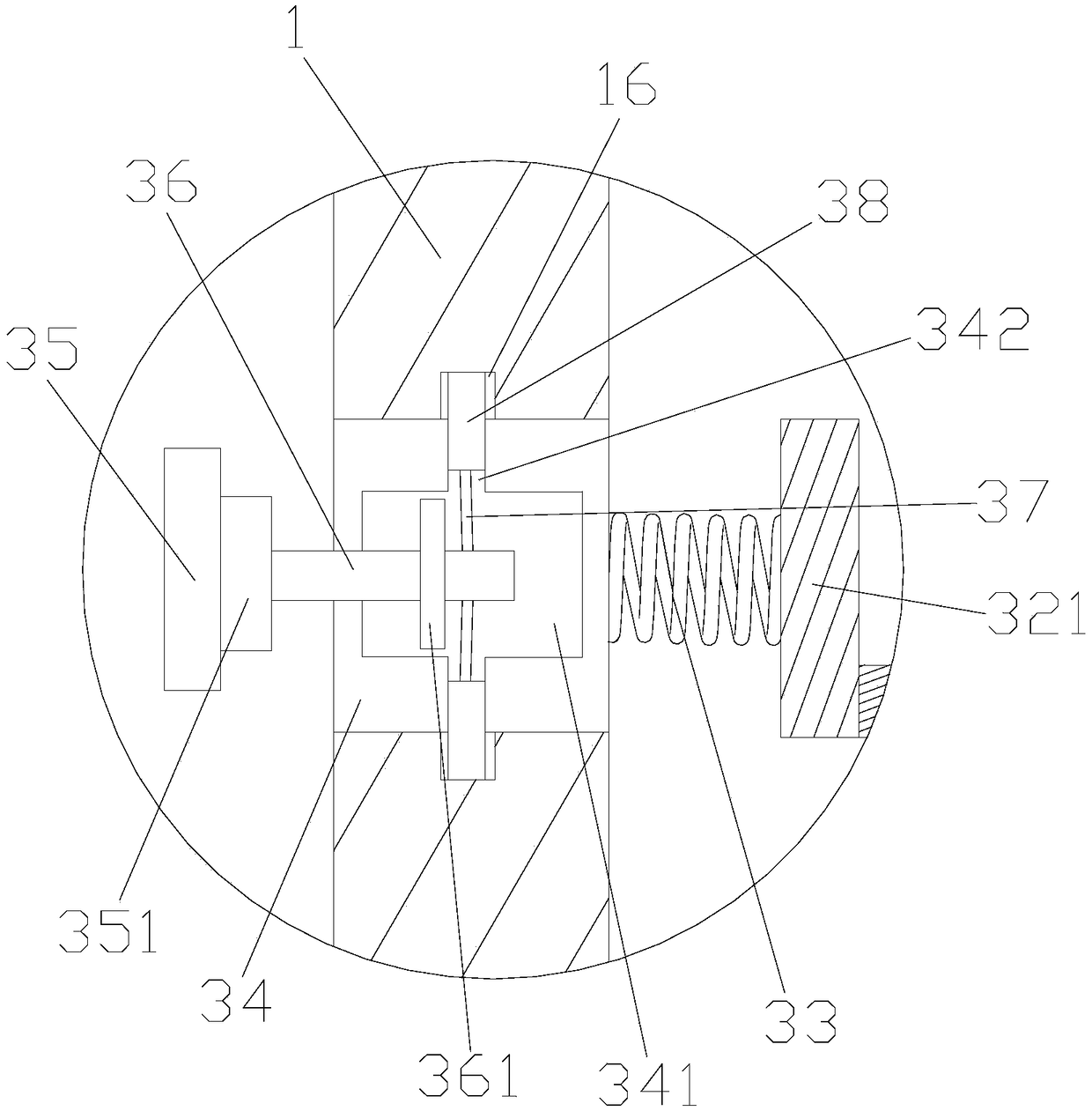

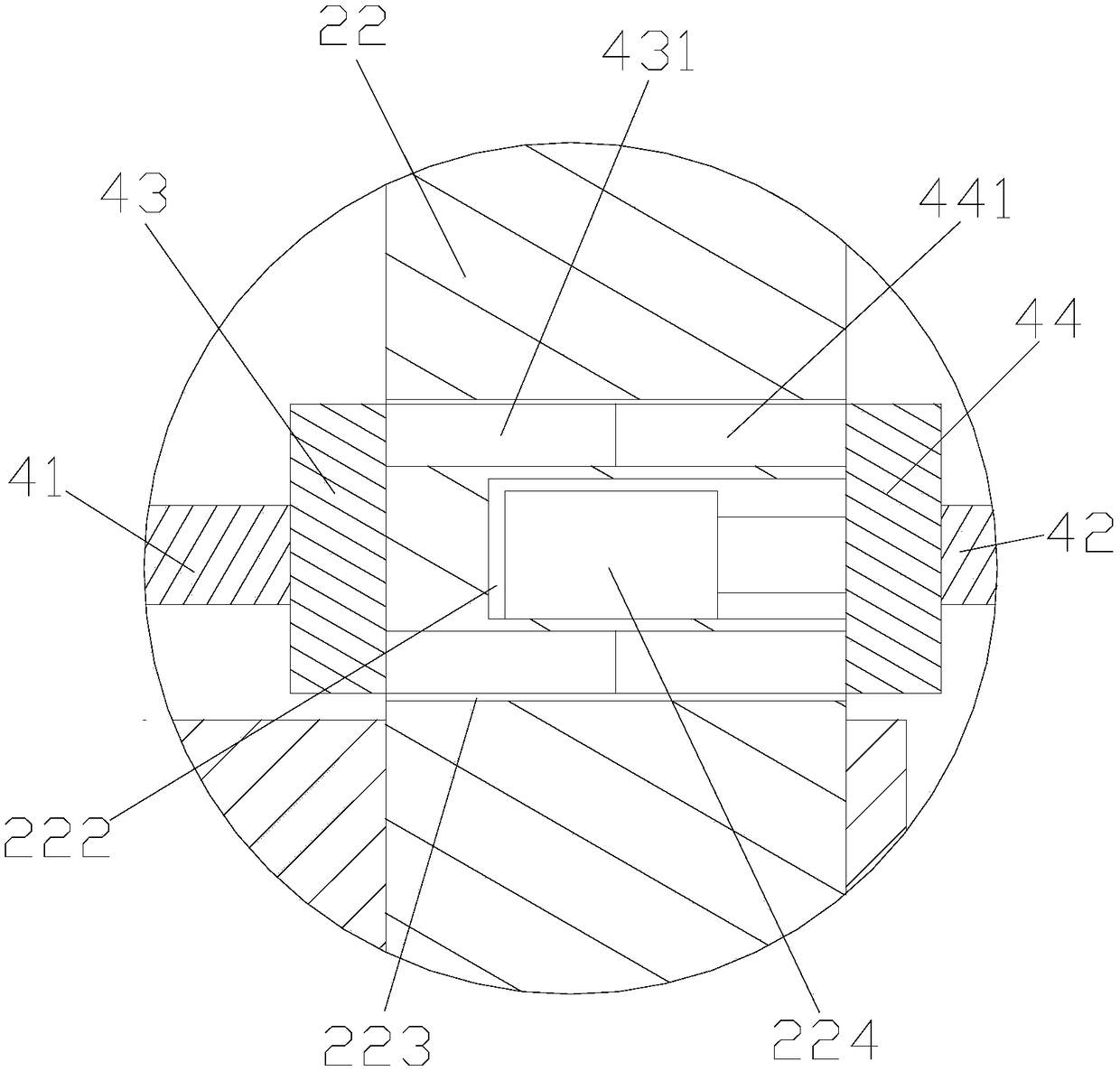

Method used

Image

Examples

Embodiment 2

[0044] Such as Figure 9-12 As shown, the difference between this embodiment and Embodiment 1 is that: the two sides of the box body 1 are provided with a hot air blower 17, and the air outlet 171 of the hot air blower 17 is installed in the box body 1, and the box body 1 is also provided with a sealing device that matches the feed port 11; the hot air blower 17 is fixed on the outer wall of the box body 1; the cleaned and broken plastic enters the box body 1 through the feed port 11, when When the plastic enters the box body 1 from the feed port 11, the sealing device is opened, so that the feed port 11 is in an open state, which is convenient for the plastic to fall to the filter layer through the feed port 11 to screen the plastic; when the plastic enters the After entering the box body 1, the hot air blower 17 starts to work, pushes hot air into the box body 1 through the air outlet 171, keeps a certain temperature in the box body 1, and performs drying treatment on the pl...

Embodiment 3

[0051] Such as Figure 13-15 As shown, the difference between this embodiment and Embodiment 1 is that: the bracket seat 14 includes an upper bracket 142 and a lower bracket 143, a shock absorbing device is arranged between the upper bracket 142 and the lower bracket 143, and the upper bracket 142 The bracket 142 is connected to the box body 1 through a third connecting block 141; the vibration generated by the shaking device is absorbed by the shock absorbing device, so as to prevent the box body 1 from being affected by the violent shaking of the box body 1 and shorten the service life of the box body 1; Through the separate setting of the upper and lower brackets, when the shaking device causes the box body 1 to vibrate to a certain extent, the lower bracket 143 can stably contact the ground, providing a good supporting effect for the box body 1, and avoiding the bracket seat when the box body 1 vibrates. 14 The subsequent vibration causes the tank 1 to fall; through the mu...

Embodiment 4

[0057] Such as Figure 16-17 As shown, a plastic processing system includes plastic cleaning and drying equipment, plastic crushing equipment 8, and plastic particle screening equipment. The plastic particle screening equipment has the same structure as the plastic screening equipment in Example 1, and will not Repeat; the plastic crushing equipment 8 includes a base 7 located at the bottom of the plastic crushing equipment 8, a loading box 88 located on the base 7, and a rolling hammer located above the loading box 88 821; the base 7 supports the plastic crushing equipment 8, so that the plastic crushing equipment 8 can be stably fixed on the base 7 to crush the plastic; the length of the base 7 is greater than the length of the plastic crushing equipment 8, and the two sides of the base 7 Extend the plastic crushing equipment to form an extended platform, the length of which is equal to the length of the loading box 88; The plastic in the loading box 88 is crushed in the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com